- Home

- content hub

- What Is Thermal Printing? The Ultimate Guide

What Is Thermal Printing? The Ultimate Guide

Emma Davis

Content Writer

Aug 25, 2025346 views

Aug 25, 2025346 views

Ever seen a receipt fade over time? Or wondered how shipping labels get printed so quickly without smudging? The secret is thermal printing, a clever process that uses heat instead of ink to create an image.

At its core, thermal printing is exactly what it sounds like: printing with heat. It works by using a special printhead to apply heat to a specific type of paper or ribbon. This targeted heat causes a chemical reaction that produces the text and images you see. No messy ink cartridges, no expensive toner.

It’s a refreshingly simple and effective idea.

Your Introduction to Inkless Printing

Unlike your home office inkjet printer that sprays tiny droplets of ink, a thermal printer relies on a direct connection between its heated printhead and the media. This direct-contact method is incredibly precise and fast.

This elegant simplicity is also its biggest strength. With far fewer moving parts—no nozzles to clog or toner drums to replace—thermal printers are built like tanks. They’re known for their reliability and minimal maintenance, which makes them absolute workhorses in busy commercial settings where every second of uptime counts.

Key Benefits at a Glance

So, why has this technology become so essential in industries like retail, logistics, and healthcare? It really comes down to a few powerful advantages.

- High-Speed Output: Thermal printers are incredibly fast. They can churn out receipts and labels at a speed that inkjet or laser printers just can't match, making them perfect for high-volume jobs like printing a mountain of shipping labels or keeping a checkout line moving.

- Lower Operating Costs: This is a huge one. When you remove ink and toner from the equation, your only recurring consumable is the paper itself (and a ribbon, for some types). Over the long run, this leads to some serious savings.

- Reliability and Durability: A simpler design means fewer things can break. This translates to a longer operational life and dependable performance, even in tough environments like a bustling warehouse or a busy kitchen.

This killer combination of speed, savings, and sturdiness is precisely why thermal printing is the go-to solution for any operation that needs to be efficient and accurate.

To give you a quick snapshot, here’s a breakdown of the core features and what they mean in the real world.

Thermal Printing at a Glance

This table sums up the key characteristics that make thermal printing such a popular choice for business applications.

| Feature | Description | Primary Benefit |

|---|---|---|

| Printing Method | Uses a heated printhead to create an image on special media. | No ink or toner needed, resulting in less mess and maintenance. |

| Speed | Significantly faster than traditional inkjet or laser printers. | Increased productivity in high-volume environments. |

| Maintenance | Fewer moving parts and no ink cartridges to replace. | Reduced downtime and lower total cost of ownership. |

Ultimately, it’s a technology designed for consistency and efficiency, stripping away unnecessary complexities to deliver a reliable result every time.

How Thermal Printers Create Images with Heat

Forget everything you know about ink cartridges and messy toner. Thermal printers operate on a completely different principle: they write with heat.

Think of it as a high-tech, lightning-fast stamp. Instead of ink, it uses a precisely controlled burst of heat to trigger a chemical reaction, instantly creating a crisp, durable image. The whole process is a beautifully simple dance between a few key parts.

The star of the show is the thermal printhead. This isn't one big heating block; it's a long strip packed with hundreds, sometimes thousands, of tiny heating elements. Each little element corresponds to a single dot (or pixel) in the image you're printing.

As your special paper or label stock feeds through, it's pressed against the printhead by a rubber roller called a platen. The platen’s job is crucial: it ensures firm, even contact. Without it, you’d get spotty, unreadable prints.

The Printing Process in Action

So, how do these parts come together to create that shipping label in a split second? It's a marvel of engineering that turns your digital file into a physical print before you can blink.

- Receiving the Job: The printer gets the digital data for the text or barcode you need.

- Quick Thinking: A small internal processor instantly figures out which specific heating elements on the printhead need to fire up to form the image.

- Heating Up: Those designated elements heat to the perfect temperature in a flash.

- Making the Mark: As the media slides past, the heat transfers and either activates the special paper or melts the ink from a ribbon onto the label.

This direct, no-fuss method is what makes thermal printing so incredibly fast. It’s why you see them churning out receipts, shipping labels, and product tags in busy retail and warehouse environments. If your business relies on high-volume barcoding and labeling solutions, this is the technology that keeps things moving.

The magic of thermal printing lies in its directness. By eliminating the middleman—ink or toner—it achieves a level of speed and reliability that traditional printers often struggle to match, making it a powerful tool for commercial applications.

The Role of Specialized Media

Of course, none of this would work without the right material to print on. You can't just feed regular copy paper into a thermal printer.

It requires either a special heat-sensitive paper, often called thermochromic paper, or a combination of a thermal ribbon and standard label material. Thermochromic paper is coated with a chemical that simply turns black when heated. On the other hand, a thermal ribbon holds a wax or resin-based ink that melts onto the label when the printhead applies heat, creating a far more permanent and resilient image.

Which one you use is the fundamental difference between the two main types of thermal printing.

Direct Thermal vs. Thermal Transfer Printing

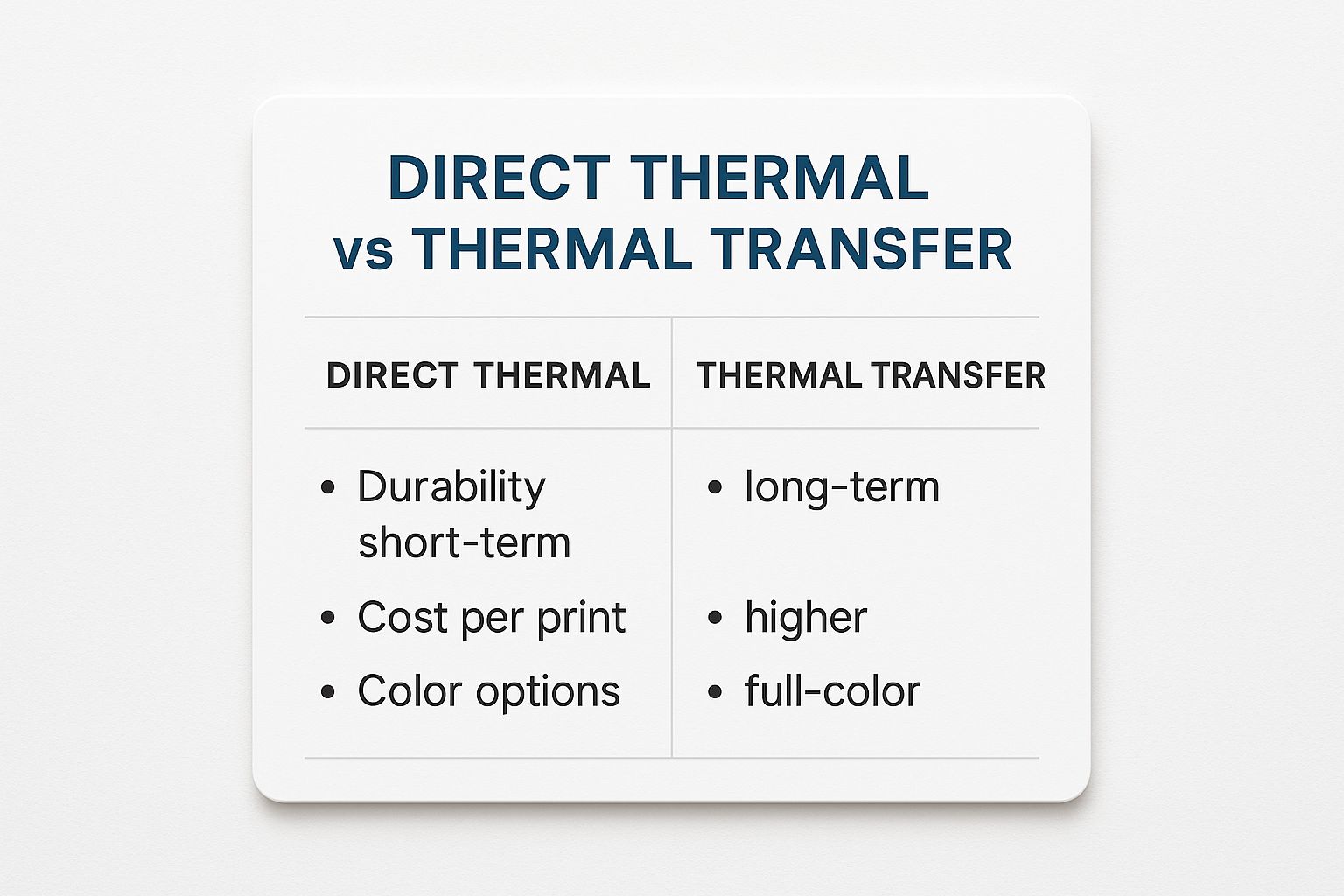

When you start looking into thermal printing, you'll quickly discover it’s not just one technology. It really branches into two main methods: direct thermal and thermal transfer. They both rely on a heated printhead to work their magic, but how they create the image couldn't be more different.

This difference is everything. It dictates the print's durability, the ongoing costs, and what you can realistically use it for. Think of it like choosing between a Post-it note and an engraved plaque—both have their place, but you wouldn't use one for the other's job.

The Quick and Simple: Direct Thermal

Direct thermal printing is the sprinter of the two—fast and straightforward. If you've ever gotten a receipt from a cash register, you've seen it in action. It works by using a special, chemically treated paper that turns black when heated.

That’s it. There’s no ink, no toner, and no ribbon. The printhead applies heat right onto this thermochromic paper, and your text or image appears instantly. This simplicity makes it exceptionally fast and cheap to operate since your only consumable is the paper itself.

But there’s a catch. That same heat sensitivity makes the paper vulnerable to sunlight and friction. Over time, the print will fade away, which is why it's best for things that don't need to last forever.

You'll typically see direct thermal printing used for:

- Shipping Labels: Perfect for getting a package from A to B within a few weeks.

- Retail Receipts: They just need to last long enough for a potential return.

- Event Tickets & Visitor Badges: Designed for one-time, short-term use.

The Tough and Lasting: Thermal Transfer

On the other side, you have thermal transfer printing. This method is all about endurance. Instead of heating the paper directly, the printhead heats up a wax or resin-based ribbon.

This heated ribbon then melts onto the label, essentially fusing the ink to the surface. The result is a crisp, high-definition print that’s built to last. It can stand up to sunlight, moisture, heat, and even chemicals without smudging or fading. This process does require two supplies—the labels and the ribbon.

While the cost per print is a bit higher because of the ribbon, the trade-off is immense durability. For any label that needs to stay readable for months, years, or in a tough environment, thermal transfer is the go-to. It’s a must for things like professional product labeling—for instance, if you're producing high-quality packaging labels printing, this is the method that ensures your branding and information stay put.

Direct Thermal vs. Thermal Transfer: A Head-to-Head Comparison

So, how do you choose? It really comes down to what you need the label to do. Are you printing something for the short-term, or do you need it to last through thick and thin?

This table breaks down the core differences to make the decision a little easier.

| Feature | Direct Thermal | Thermal Transfer |

|---|---|---|

| Supplies Needed | Just the heat-sensitive labels. | Labels and a thermal ribbon. |

| Print Durability | Short-term. Fades with exposure to heat, light, and friction. | Long-term. Resists fading, smudging, and chemicals. |

| Cost Per Print | Lower, since you only buy labels. | Higher, due to the added cost of ribbons. |

| Best For | Shipping labels, receipts, event tickets, visitor passes. | Product ID, asset tracking, inventory, compliance labels. |

In the end, it’s a classic case of sprinter vs. marathon runner. Direct thermal gets the job done fast and cheap for short-term needs. Thermal transfer is your reliable workhorse, built for endurance and quality that lasts. Understanding this fundamental choice is the key to getting the most out of thermal printing for your business.

Why Businesses Choose Thermal Printers

Knowing how thermal printing works is one thing, but the real story is why so many businesses depend on it. This isn't just about picking a piece of tech; it's about gaining an edge through speed, smarter spending, and rock-solid reliability.

At its core, thermal printing is so popular because it solves some of the most common, nagging problems in business operations. Think about it: no more clogged ink nozzles, no more scrambling for expensive toner cartridges, and no more slow print jobs that create a bottleneck.

This technology was built from the ground up for speed and endurance, making it a serious workhorse in any environment where things need to move fast.

Unmatched Speed and Efficiency

In business, time really is money, and thermal printers are designed to save you time. They can spit out labels and receipts much, much faster than any inkjet or laser printer you've seen.

Picture a busy warehouse during the holiday rush. Your team needs to print hundreds of shipping and mailing labels printing every single hour. A standard office printer would grind the whole operation to a halt.

Thermal printers completely eliminate that delay. Each label is printed in a split second, keeping packages flowing smoothly down the line and out the door.

Significant Long-Term Cost Savings

Yes, the upfront cost of a thermal printer can be higher than a basic desktop printer, but the total cost of ownership tells a completely different story. It’s almost always lower, and the reason is simple: you completely eliminate the biggest recurring expense in printing—ink and toner.

The savings become crystal clear with direct thermal models, where your only real ongoing cost is the paper itself. With thermal transfer, you have to buy ribbons, but even then, both methods let you sidestep the sky-high prices of proprietary ink cartridges.

When you remove ink and toner from your operational budget, you suddenly free up cash for other parts of your business. That makes a thermal printer more than just a tool; it's a smart financial move that pays for itself over time.

Superior Reliability and Low Maintenance

Here's a simple truth: fewer moving parts mean fewer things that can break. A typical inkjet printer is a complex machine with pumps and nozzles that can easily clog or malfunction. Thermal printers, with their beautifully simple mechanics, are just plain tougher.

This built-in durability makes them perfect for demanding places like factory floors, busy commercial kitchens, or chaotic logistics hubs. They need very little maintenance, which means they're always up and running when you need them most. That kind of reliability means less downtime, less frustration for your team, and a more consistent operation overall.

Where You See Thermal Printing in Action

Chances are, you've run into thermal printing dozens of times today and didn't even notice. This isn't some niche tech tucked away in a factory; it's the invisible engine behind the speed and precision of countless industries you interact with every single day. From the receipt at the grocery store to the wristband at a hospital, its fingerprints are everywhere.

Why is it so common? Simple: it just works. It delivers clear, reliable results, fast, right when they're needed most. That no-fuss efficiency has made thermal printing a cornerstone technology, a fact you can see in its market growth. The global market, valued at USD 49.3 billion, is expected to hit USD 66.4 billion by 2030, largely thanks to the boom in e-commerce and retail.

Let's look at a few places where this tech goes from an abstract idea to an absolute must-have.

Retail and Hospitality Hubs

Step into any modern store, and you're surrounded by thermal printing. The most obvious example is the receipt that spits out of the register—that's direct thermal printing at work, perfect for something you only need for a short time.

But its job doesn't stop there.

- Price Tags and Shelf Labels: Imagine having to update prices for a massive weekend sale. Thermal printers churn out thousands of crisp, easy-to-read labels that can be applied in minutes, not hours.

- Barcode Labels: Barcodes are the language of modern inventory. Thermal printers create those sharp, high-contrast lines that scan perfectly every time, cutting down on errors and keeping checkout lines moving.

- Event Tickets and Wristbands: For concerts, festivals, or theme parks, you need something that lasts. Thermal printers produce durable tickets and wristbands that won't smudge or tear, making sure thousands of people get in without a hitch.

Logistics and Shipping Operations

In the world of logistics, there's no room for "oops." A smudged label means a lost package and an unhappy customer. That's why thermal printing has become the undisputed industry standard for shipping and tracking.

This is where thermal transfer printers really shine. They create those tough, long-lasting shipping labels that can survive the chaos of sorting facilities and cross-country travel. These labels hold up against friction, moisture, and temperature swings, ensuring the barcode is just as scannable when it reaches the customer's door as when it left the warehouse. This is also where getting high-quality online labels is critical for looking professional and ensuring deliverability.

Critical Healthcare Environments

In healthcare, accuracy isn't just a goal—it's non-negotiable. Thermal printing brings the kind of precision and reliability needed to ensure patient safety and keep track of critical samples.

Think about it: in a hospital, the right information has to be in the right place at the right time, period. Thermal printing is trusted because it makes clear, durable labels that don't smudge. An ink smudge on a lab sample or prescription could lead to a serious medical error.

You’ll find it used for:

- Patient Wristbands: These are printed with barcodes holding a patient's vital information. They're built to last, resisting water, hand sanitizer, and daily wear.

- Lab and Specimen Labels: Thermal transfer labels are essential for tracking blood vials, tissue samples, and other specimens, making sure nothing ever gets mixed up.

- Prescription Labels: Pharmacies rely on thermal printers to create clear, readable instructions and warnings on medication bottles, which is a huge factor in patient safety.

How to Choose the Right Thermal Printer

Picking out the right thermal printer is about more than just finding a model that fits your budget. It’s really about matching the technology to your day-to-day workflow. If you get it wrong, you’re looking at frustrating bottlenecks and wasted money. But the right one? It becomes a silent, indispensable partner in your operations.

To find that perfect fit, you need to dig a little deeper than the price tag. It boils down to three key things: how much you print, how you connect, and how sharp those prints need to be.

Assess Your Print Volume and Environment

First thing's first: how much work will this printer actually be doing? The answer to this question splits the options into a few clear categories, each built for a different level of demand.

- Desktop Printers: These are your go-to for low-to-medium volume jobs. Think a small retail shop printing receipts or a home-based Etsy seller getting out a few dozen orders. They’re compact, affordable, and happily churn out a few hundred labels a week.

- Industrial Printers: Built like tanks, these are the heavy-hitters for high-volume, round-the-clock printing. They’re the workhorses you’ll find in warehouses, on manufacturing floors, and in logistics hubs, easily handling thousands of prints every single day.

Where your printer lives is just as important as how much it prints. An industrial printer is designed to shrug off dust and temperature swings on a factory floor, while a sleek desktop model belongs on a clean office desk or retail counter.

Determine Connectivity and Resolution Needs

Next, think about how your printer will talk to your computer and other devices. A standard USB connection is the simplest, most reliable option for a single workstation.

If you need more freedom, Wi-Fi or Bluetooth models let you print from anywhere in the room, which is a game-changer in a busy warehouse or retail space. For a shared office environment, Ethernet gives you a rock-solid, wired network connection that everyone can rely on.

Finally, let's talk quality, which is measured in Dots Per Inch (DPI). For most everyday tasks like shipping labels or receipts, 203 DPI is more than enough. But if you're printing tiny barcodes, detailed logos, or fine print, bumping up to 300 DPI ensures everything is perfectly crisp and scannable.

Of course, the printer is only half the equation. Choosing the right labels is just as crucial. Whether you need temporary shipping stickers or long-lasting product tags, exploring options for custom labels printing will help you find the perfect material to complement your new hardware.

Got Questions About Thermal Printing? We've Got Answers.

Let's clear up some of the most common questions people have about thermal printers. Think of this as the final piece of the puzzle, giving you the practical info you need to feel like an expert.

Do Thermal Printers Run Out of Ink?

Nope. This is probably their most celebrated feature. Thermal printers don't use ink or toner cartridges in the way you're used to. No clogs, no smudges, no last-minute trips to the office supply store.

Direct thermal printers use heat to activate a special coating on the paper itself, which darkens to form your text or image. Thermal transfer models use a heated ribbon to melt a layer of wax or resin onto the label. Either way, you'll never buy a traditional ink cartridge again.

How Long Do Thermal Prints Last?

This one really comes down to which type of thermal technology you're using. The difference in durability is huge.

- Direct Thermal: Think about a standard store receipt. Those are direct thermal prints. They’re sensitive to heat and light and will usually stay readable for about 6-12 months before they start to fade. This makes them ideal for things with a short lifespan, like shipping labels or event tickets.

- Thermal Transfer: Now these are built to last. Because the "ink" is a resin or wax that's literally bonded to the label's surface, these prints are tough. They can handle smudging, chemicals, and sunlight for years, making them perfect for permanent inventory labels or outdoor signage.

Are Thermal Printers Expensive?

It's a classic "pay now or pay later" situation. The initial price tag on a thermal printer might be a bit higher than your basic office inkjet. But the real story is in the total cost of ownership, which is almost always lower.

The big win comes from completely eliminating the ongoing cost of ink or toner. For any business printing labels day in and day out, the money saved on those consumables adds up fast. It doesn't take long for the printer to pay for itself.

This makes them a savvy financial move for any operation that depends on high-volume, consistent printing.

Ready to put this technology to work for your business? 4OVER4 offers professional printing solutions to create the perfect high-quality, durable custom labels for your needs. Check out all the options available.

More from what is thermal printing

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

61

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

104

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

104

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

326

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026