- Home

- content hub

- A Business Owner's Guide to the Types of Printing

A Business Owner's Guide to the Types of Printing

Emma Davis

Content Writer

Jan 20, 202692 views

Jan 20, 202692 views

In a world saturated with digital noise, the simple, tangible act of handing someone a beautifully printed piece can make your brand unforgettable. But with so many ways to get ink on paper, choosing the right printing method can feel like you're trying to solve a complex puzzle. This guide is here to clear things up, framing each printing method as a specific tool for a specific job.

Choosing the Right Printing Method for Your Brand

Think of it like a chef picking the right knife. A small paring knife is perfect for intricate, detailed work, but you'd grab a heavy-duty cleaver for the big jobs. In the printing world, digital printing is your nimble tool for quick, small-batch projects, while offset printing is the powerhouse you bring out for large, high-quality runs. Grasping this core difference is the first step toward making smarter, more cost-effective decisions for your brand.

The choice you make directly hits your budget, your timeline, and—most importantly—the impression your materials leave on your customers. Get it right, and every dollar you invest in print will work as hard as it possibly can.

Why Print Still Matters

Even with everything moving online, physical media has a powerful, tactile advantage that screens just can't replicate. A well-designed brochure or a premium business card creates a memorable, hands-on experience.

The numbers back this up. The global commercial printing market is valued at a massive USD 838.26 billion and is expected to grow to USD 1,190.47 billion by 2035. This isn't a dying industry; it’s a resilient one, proving that print is far from obsolete. You can dig into these trends over at IBISWorld.

The right printing method doesn't just put ink on paper. It translates your brand's quality, attention to detail, and core message into a physical object your audience can hold and remember.

Matching the Method to the Mission

Before we dive into the nitty-gritty of each method, your project's goals will point you in the right direction. Just ask yourself a few key questions:

- Quantity: Are you printing 50 invitations for a small gathering or 50,000 catalogs for a nationwide campaign? Volume is almost always the biggest factor in determining what's cost-effective.

- Turnaround Time: Do you need your prints tomorrow, or can you wait two weeks? Digital printing is built for speed, while offset requires a bit more setup time.

- Quality and Color: Do you need a perfect Pantone color match to keep your branding consistent, or is standard color accuracy good enough? Offset printing offers unparalleled precision for color-critical work.

- Material: Are you printing on standard paper, thick cardstock, vinyl, or even fabric? Some methods are much better suited for specific materials than others.

Answering these questions first will instantly narrow down your options. This guide will walk you through the different types of printing, making sure your next batch of marketing materials is a certified success.

1. Digital Printing: Fast, Flexible, and Made for Today

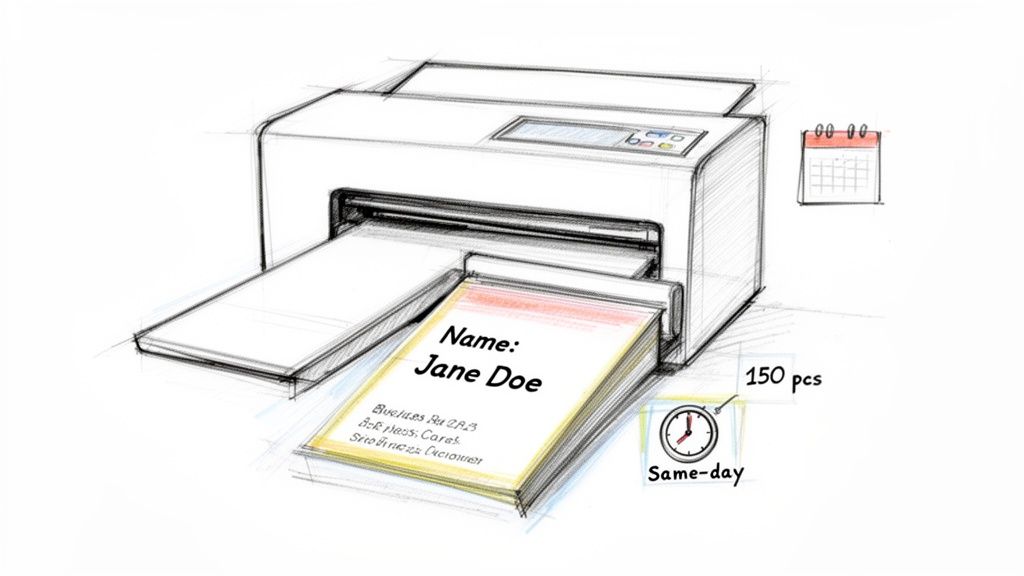

Picture this: you have a networking event tomorrow and just realized you're down to your last few business cards. You need a batch of 150 new ones, and you need them now. This exact scenario is where digital printing saves the day.

Think of digital printing as your office printer's bigger, faster, and much more capable sibling. It takes a digital file—like a PDF of your business card design—and prints it directly onto paper. The key difference from older methods is that it doesn't need printing plates, which are custom-made metal plates used to transfer an image in traditional printing.

This plate-free process is the secret sauce behind its incredible speed. There’s no clunky, time-consuming setup, making it the undisputed champion for projects that need a lightning-fast turnaround.

Perfect for Short Runs and On-Demand Needs

Because there are almost no setup costs, digital printing is the king of short-run projects. Need just 100 flyers for a weekend sale? Or maybe 50 custom invitations? Digital makes it happen without breaking the bank.

This is a game-changer for small businesses and marketers. Instead of committing to a massive order of 5,000 brochures that might be outdated in six months, you can print a few hundred at a time. This “print-on-demand” model cuts down on waste, saves you money, and ensures your marketing materials are always current.

Make It Personal with Variable Data Printing

Here’s where digital printing really flexes its muscles: Variable Data Printing (VDP). This is like a mail merge on steroids. VDP lets you change specific elements—like names, addresses, or images—on each individual piece as it’s being printed, all without slowing down the process.

So, what can you do with this? Imagine sending out 500 postcards where each one greets the recipient by name, references a product they recently viewed, or includes a unique QR code just for them. It transforms a generic marketing blast into a personal conversation.

The impact is huge. The global digital printing market was valued at US$33.5 billion in 2024 and is expected to hit US$57.08 billion by 2033. A big driver of that growth is VDP, which can increase direct mail response rates by 20-30% and slash material waste by 30-50%.

The Tech Behind the Magic

Two main technologies power the world of digital printing, each with its own specialty:

- Laser Printing: This method uses a fine powder called toner and heat to create the image. It’s brilliant for producing razor-sharp text and clean lines, making it the go-to for professional documents, reports, and flyers.

- Inkjet Printing: Using tiny nozzles to spray liquid ink, inkjet is the master of color. It can reproduce photos with incredible vibrancy and smooth gradients, perfect for art prints, photo books, and eye-catching visuals.

Here’s the bottom line: If your project is all about crisp text and professional graphics, laser is your workhorse. If you need rich, stunning, photographic-quality color, inkjet is the artist.

When Is Digital Printing the Right Choice?

As versatile as it is, digital isn't the perfect fit for every job. Its main drawback is a higher cost per piece on massive orders. Once you get into the thousands or tens of thousands, the old-school muscle of offset printing becomes much more cost-effective.

But if your project ticks any of these boxes, digital is almost certainly your best move:

- You need it fast (think same-day or within 24-48 hours).

- You’re printing a low to medium quantity (usually anything under 1,000 pieces).

- Every print needs to be personalized with unique info.

- You want to print on-demand to avoid holding onto huge inventories.

For these situations, the speed and flexibility of our digital printing services are simply unbeatable.

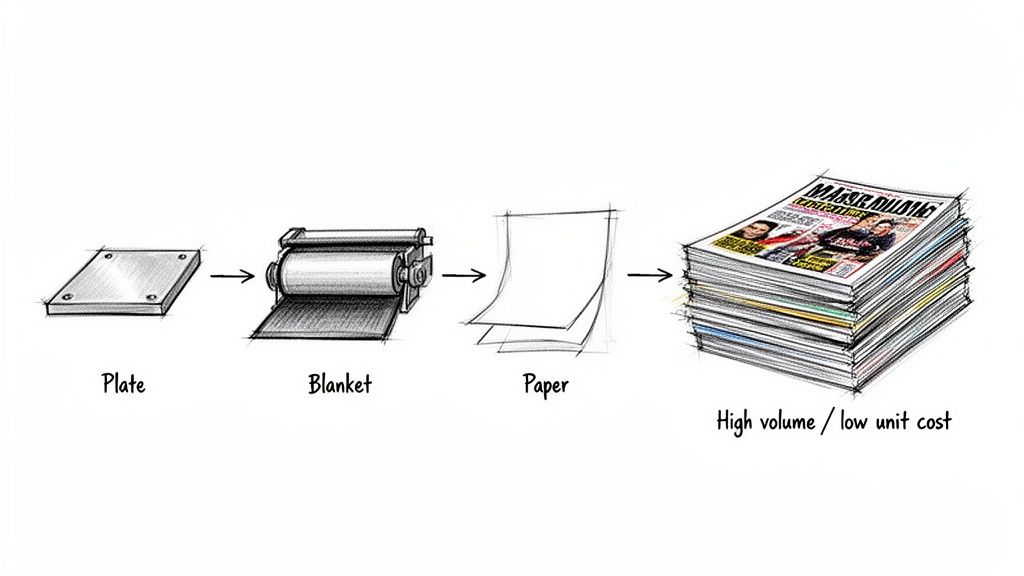

Offset Printing for Unmatched Quality and Volume

When your project demands flawless quality and you're printing in serious numbers, offset lithography is the undisputed champion. This method is the gold standard for projects where brand consistency and image clarity are absolutely non-negotiable, like high-end product catalogs, magazines, and corporate brochures.

So, how does it work? Think of it like a high-tech rubber stamp. Instead of printing directly onto paper, we first etch your design onto a metal plate. That plate transfers the ink to a rubber blanket, which then presses the final, perfect image onto the paper.

This indirect transfer is the secret sauce behind offset’s success. It produces rich, consistent, and razor-sharp results that define premium print. The flexible rubber blanket conforms perfectly to the paper’s surface, ensuring a smooth and even ink application every single time, from the first copy to the 50,000th.

The Power of Economies of Scale

Here’s where offset printing really shines: its incredible cost-efficiency at high volumes. Sure, there’s an initial investment in creating the custom plates, but that setup cost is spread out over the entire print run. This means the more you print, the less each individual piece costs.

Think of it like baking cookies. Making just one cookie is a huge hassle because you still have to mix all the dough. But once that dough is ready, churning out 100 more cookies is fast and cheap. Offset printing works the same way; after the initial setup, the press can run thousands of copies at a very low per-unit price.

This economic advantage is why offset remains a cornerstone of the commercial printing world. Even with the rise of digital, the global printing market—valued at a massive $868 billion—is projected to hit $969.7 billion by 2030. That kind of stability is built on large-scale workhorses like offset, proving it’s not going anywhere.

Unbeatable Color Accuracy and Consistency

When your brand's specific shade of red needs to be perfect on every single brochure, offset printing is the only way to guarantee it. This method absolutely excels at color matching, especially when using the Pantone Matching System (PMS).

Offset printing gives you total control over color. By using specific Pantone inks instead of mixing CMYK on the fly, you can achieve an exact color match that digital printing often struggles to replicate. This ensures your brand identity stays strong and consistent across the board.

This level of precision is critical for any business that relies on a recognizable brand color. Just think of the iconic blue of Tiffany & Co. or the distinct red of Coca-Cola. Offset ensures that color is identical across all your marketing materials, from business cards to annual reports.

Here’s a quick rundown of when offset is the clear winner over digital:

| Feature | Offset Printing | Digital Printing |

|---|---|---|

| Best Quantity | 1,000+ pieces | Under 1,000 pieces |

| Cost-Effectiveness | Low per-unit cost on large runs | Best for short runs |

| Color Accuracy | Superior, especially with Pantone | Good, but can have slight variations |

| Turnaround Time | Slower (requires plate setup) | Faster (no plates needed) |

| Material Options | Wide range, including textured paper | More limited on certain stocks |

Is Offset the Right Choice for Your Project?

So, how do you know when to make the leap from digital to offset? The tipping point is almost always about quantity. While the exact number can vary, if your order is over 1,000 pieces, offset usually becomes the more economical choice.

Consider these common scenarios where offset printing is the ideal solution:

- Book and Magazine Publishing: When printing thousands of copies, the quality and cost-per-page simply can't be beat.

- Product Catalogs: For large runs that demand perfect product photo reproduction to drive sales.

- Corporate Branding Materials: When color consistency across thousands of brochures, letterheads, and folders is critical.

- Large-Scale Direct Mail: For campaigns reaching tens of thousands of households with identical flyers or postcards.

If your project demands premium quality at scale, exploring professional offset printing is a smart business move. It’s an investment in quality that pays off with a polished, professional result that truly represents your brand.

Exploring Specialty and Large Format Printing

Ready to create something people can not only see but also feel? Let's move beyond standard ink on paper and dive into the exciting world of specialty printing. This is where brands truly come to life, using texture, dimension, and sheer scale to create unforgettable experiences.

These techniques are the creative tools that turn a simple printed item into a premium piece of marketing. From a vibrant t-shirt that builds a walking fan base to a luxurious invitation that demands to be touched, specialty methods are all about making a powerful statement.

Screen Printing: Bold and Vibrant Designs

Think of your favorite band t-shirt or that striking concert poster with thick, opaque colors. That’s the magic of screen printing. This technique works by pushing ink through a stenciled mesh screen onto a surface—a method that has been refined for centuries but remains incredibly effective.

Because it lays down such a thick layer of ink, screen printing is famous for producing exceptionally vivid and durable colors. This makes it the go-to choice for printing on materials that go way beyond paper, like:

- Apparel: T-shirts, hoodies, and tote bags.

- Posters: Creating art prints with rich, solid colors.

- Promotional Items: Printing logos on items like water bottles and pens.

The process is best suited for designs with a handful of solid colors, as each color requires its own separate screen. While the initial setup is a bit more involved than digital, the results are bold, long-lasting, and have a distinct, high-quality feel you just can't fake.

Flexography: The Engine of Modern Packaging

Ever wonder how the intricate designs on a potato chip bag or a soda can label get printed at a massive scale? The answer is flexography, or "flexo" for short. Just imagine a modernized, high-speed version of a rubber stamp, but on a massive rotating cylinder.

Flexo uses flexible photopolymer printing plates wrapped around these cylinders to transfer ink. It's incredibly fast and efficient, which makes it the undisputed workhorse for printing on the non-porous materials used in just about all modern packaging.

Flexography is probably the most common type of printing you’ve never heard of. It's responsible for the print on almost everything you find in a grocery store, from food labels and plastic bags to milk cartons and candy wrappers.

Its ability to print on such a wide variety of surfaces—including plastic, foil, and cellophane—makes it indispensable for the packaging industry. While creating the initial plates makes it a poor fit for short runs, it's completely unbeatable for high-volume, consistent production.

Foil Stamping and Embossing for a Touch of Luxury

When you want your print to practically scream elegance and quality, you add texture. Foil stamping and embossing are two finishing techniques that add a tactile dimension, encouraging people to physically engage with your materials.

- Foil Stamping: This process uses heat and pressure to apply a thin metallic foil to paper. It creates a shimmering, eye-catching effect that’s perfect for logos, special text, or decorative accents on business cards, invitations, and high-end packaging.

- Embossing & Debossing: Embossing creates a raised 3D impression on the paper, while debossing creates a recessed one. Both add physical depth and a sophisticated feel, transforming a simple design into a memorable sensory experience.

These methods are all about elevating your brand's perceived value. In fact, studies on consumer behavior have found that high-quality, tactile finishes on packaging can significantly influence purchasing decisions, making items feel more premium and desirable.

We've touched on some of the most popular specialty techniques that add flair and texture to printed materials. The table below breaks down these methods, showing you the unique visual effect each one creates and where it shines best. This should help you pinpoint the perfect technique to make your next project truly stand out.

Specialty Printing Techniques at a Glance

| Technique | Visual Effect | Best For Products | Key Benefit |

|---|---|---|---|

| Screen Printing | Bold, opaque, and vibrant colors with a tactile feel. | T-shirts, hoodies, posters, promotional items. | Unmatched color vibrancy and durability on various materials. |

| Flexography | Fast, consistent printing on flexible and non-porous surfaces. | Labels, food packaging, plastic bags, gift wrap. | High-speed efficiency for massive print runs. |

| Foil Stamping | Metallic, shimmering finish in various colors (gold, silver, etc.). | Business cards, invitations, book covers, luxury packaging. | Adds an immediate sense of luxury and premium quality. |

| Embossing | Raised, 3D texture on the paper's surface. | Stationery, certificates, packaging, formal invitations. | Creates a sophisticated, tactile experience that implies importance. |

| Debossing | Recessed, indented impression into the paper. | Leather goods, journals, coasters, high-end business cards. | Offers a subtle, elegant texture that feels handcrafted. |

| UV Printing | Sharp, vibrant, and durable ink cured instantly with UV light. | Signage, phone cases, acrylic prints, promotional goods. | Adheres to a huge range of materials, including non-porous ones. |

| Dye-Sublimation | Ink becomes part of the fabric for a permanent, soft feel. | Apparel, banners, mouse pads, photo panels. | Produces photo-quality, fade-resistant images on fabrics. |

Each of these techniques opens up a whole new realm of creative possibilities. By understanding what makes each one special, you can make more strategic design choices that not only look good but also connect with your audience on a deeper, more physical level.

Large Format Printing: Making a Big Impact

Sometimes, your message just needs to be big. Large format printing is the umbrella term for a range of techniques designed to produce massive visuals, from towering banners to detailed architectural plans. This is how you grab attention from a distance.

This category isn't a single method but includes several, each suited for different jobs. For instance, UV printing uses ultraviolet light to instantly cure ink on almost any surface, including wood, metal, and acrylic. This makes it perfect for durable outdoor signage. For vibrant fabric displays, dye-sublimation infuses ink directly into the material for a permanent, soft, and fade-resistant finish.

Whether you need a trade show backdrop, a vinyl banner for a grand opening, or a fleet of vehicle wraps, exploring professional online large format print services is the first step toward making a huge visual impact.

These specialty and large-scale types of printing open up a world of creative possibilities, allowing you to design materials that captivate your audience and leave a truly lasting mark.

How to Select the Perfect Printing Type

Navigating the world of printing can feel like a lot, but picking the right method really just boils down to answering a few key questions. This is where we move from theory to action. By looking at what your project actually needs, you can confidently choose the option that gives you the best results without blowing your budget or your deadline.

Think of it as a simple checklist. Every question you answer helps narrow down the options, pointing you toward the most logical and efficient solution. There's no single "best" way to print—just the one that's a perfect match for what you're trying to accomplish right now.

Start with These Four Core Questions

To cut through the confusion, start by defining the most important parts of your project. Your answers will almost immediately tell you whether you need a digital, offset, or specialty solution.

What Is Your Quantity? This is the big one. Are you printing 200 flyers for a local bake sale or 20,000 catalogs for a nationwide launch? For smaller runs (usually under 1,000 pieces), digital printing is almost always the winner because there are no hefty setup costs. For massive volumes, offset printing’s tiny per-unit cost delivers unbeatable value.

How Soon Do You Need It? Your timeline dictates the technology. If you need something in your hands within 24-48 hours, digital is really your only horse in the race. Offset and many specialty methods need more time to get going—creating plates, mixing custom inks, and setting up the machinery often takes several days.

What Material Are You Printing On? Are you using standard paper, thick cardstock, vinyl, plastic, or even fabric? Digital and offset are the champs for most paper products, but methods like screen printing really shine on t-shirts, and UV printing is built for putting ink on rigid materials like acrylic or wood.

How Critical Is Color Accuracy? Does your brand live and die by a very specific shade of Tiffany Blue? If you need a perfect Pantone (PMS) color match, offset printing is the way to go, hands down. Digital printing uses a CMYK mix to create colors, which looks fantastic but can have tiny variations from one print run to the next.

Just answering these four questions will instantly cross a bunch of unsuitable options off your list and bring some much-needed clarity to your decision.

Applying the Framework to Real-World Scenarios

Let's put this into practice and see how it works with a couple of common projects.

Scenario 1: A New Café Needs Loyalty Cards

- Quantity: 500 cards to get started.

- Deadline: ASAP—they need them before the grand opening next week.

- Material: Heavy cardstock.

- Color: Standard CMYK is perfectly fine.

- Verdict: Digital printing is the perfect fit. The low quantity makes it affordable, the turnaround is lightning-fast, and it handles thick cardstock with ease.

Scenario 2: A National Retailer Is Launching a Holiday Catalog

- Quantity: 50,000 copies.

- Deadline: Four weeks.

- Material: Glossy paper to make the product photos pop.

- Color: Must perfectly match the brand’s signature Pantone red.

- Verdict: Offset printing is the only real choice here. The massive volume brings the per-unit cost way down, and it delivers the exact color precision a major brand needs for a big campaign.

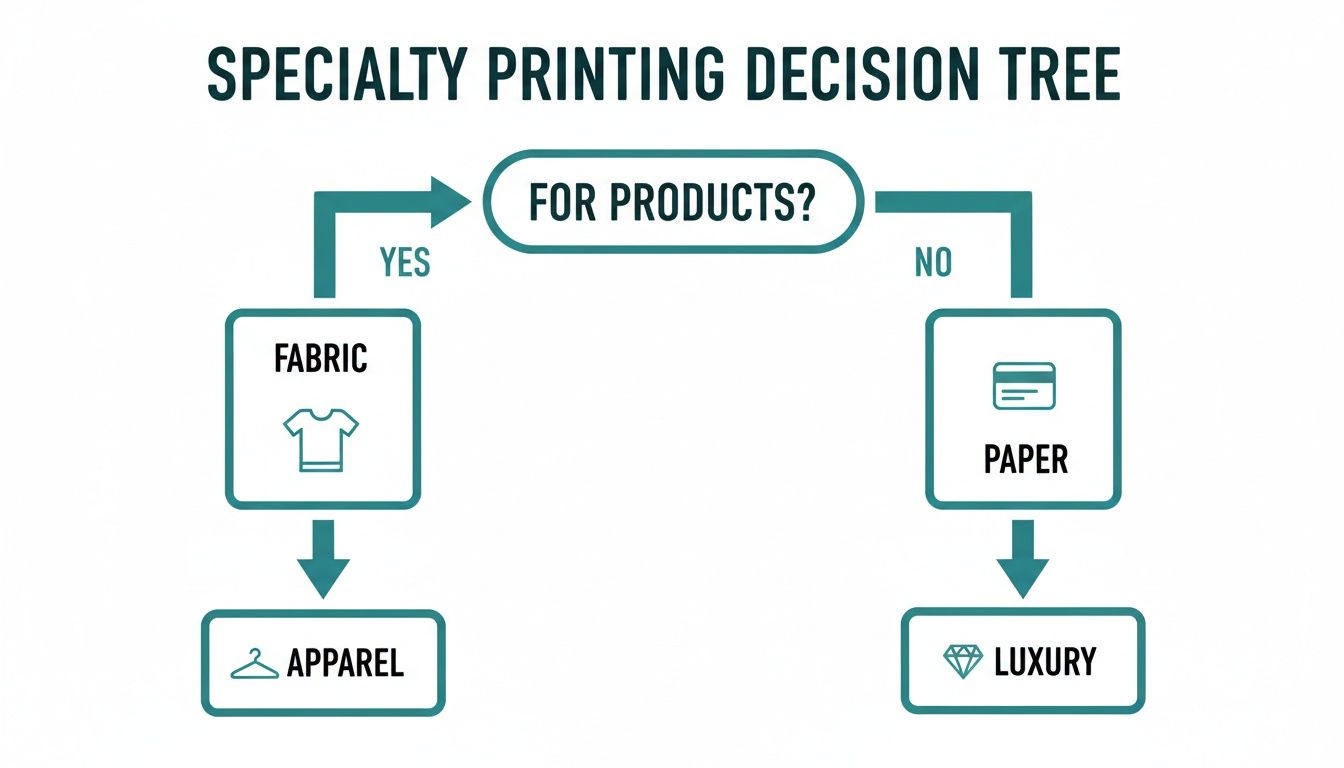

This simple decision tree helps visualize how different project needs lead to specific specialty printing methods.

As the chart shows, even a basic starting point—like choosing between fabric or paper—can send you down a completely different path toward the right specialty process.

Don't Forget the Finishing Touches

Once you've landed on the core printing method, it’s worth thinking about whether your project could use a little extra something to really stand out. These final flourishes can take a standard print job and turn it into something truly memorable.

Finishes aren't just an afterthought; they're a strategic part of the design. A soft-touch laminate on a business card or a spot gloss on a brochure cover can completely change how someone experiences your brand through touch and feel.

Adding a unique finish makes your materials more engaging and much harder to forget. You can explore a huge variety of fantastic finishes to see what might work for your design, from shiny metallic foils to elegant, textured embossing.

At 4OVER4, we have a massive library of templates ready to go, helping you see exactly how different finishes will look on your products before you commit. This takes the guesswork out of the creative process and empowers you to make design choices with confidence.

By following this straightforward approach—nailing down your quantity, speed, material, and color needs, and then layering on the right finish—you’re no longer just ordering prints. You’re making smart, strategic decisions that save you money and make your brand look its absolute best.

Got Questions About Printing? We've Got Answers.

Even after diving into the world of printing methods, a few questions might still be swirling around. That's perfectly normal. We've put together this section to tackle the most common things people ask, giving you clear, straight-to-the-point answers so you can nail down your project details with confidence.

Think of this as the final pre-flight check. We'll clear up some key industry terms and offer practical advice to make sure your vision comes to life exactly as you imagined, from your screen to the final printed piece. Our goal is to pull back the curtain on the process, empowering you to make smart decisions every time.

What Is the Difference Between CMYK and Pantone Colors?

Getting a handle on these two color models is absolutely essential for keeping your brand looking consistent. At their core, they are two completely different ways of producing color.

Picture yourself as a painter. CMYK (which stands for Cyan, Magenta, Yellow, and Black) is like having a limited palette of primary colors that you mix together to create all the other shades in your masterpiece. It's an incredibly versatile process, which is why it's perfect for printing things with full-color photographs, like magazines or complex brochures.

Pantone (PMS), on the other hand, is like walking into a paint store and buying a can of a very specific, pre-mixed color—let's say "Tiffany Blue." You aren't mixing it yourself; you're using an exact, globally recognized formula. This is how you guarantee that your brand's specific shade of blue looks identical on a business card, a trade show banner, and a company t-shirt, no matter where or when they're printed.

Use CMYK for projects loaded with photos and complex gradients. Stick with Pantone when your logo's exact color is non-negotiable and needs to be perfect across every single thing you print.

When Does Offset Printing Become Cheaper Than Digital?

This is one of the biggest budget questions we get, and it's a great one. While there isn't a single magic number that applies to every project out there, a pretty solid rule of thumb exists.

The tipping point where offset printing starts to make more financial sense than digital is usually somewhere between 500 and 1,000 pieces of the same exact design. For any print run smaller than that, the high upfront setup cost of creating custom metal plates for an offset press makes digital the clear winner for your wallet.

But once you cross that threshold, the per-item cost of offset printing drops like a rock. The press is already set up and running, so each extra copy adds very little to the total cost. This makes it the undisputed champion for any large-volume order.

What File Format Is Best for Printing?

Without a moment's hesitation: a high-resolution PDF. It’s the undisputed gold standard for professional printing. A well-made PDF acts like a locked container for your entire design, embedding all your fonts, images, and graphics so that what you see on your screen is exactly what gets printed.

For the absolute best results, always stick to these two rules:

- Resolution: Make sure your file is set to 300 DPI (dots per inch). This is the minimum resolution needed to produce sharp, clear images that don't look blurry or pixelated.

- Bleed: Always include a "bleed" area in your design files. This is just a small extra margin of your background color or image that extends past the final trim lines. It’s a simple but crucial step that prevents any ugly white slivers from showing up after your product is cut to its final size.

How Can I Ensure My Brand Colors Look Consistent?

Keeping your brand colors consistent across different materials, printers, and projects is the cornerstone of brand recognition. For ironclad consistency, your best bet is always the Pantone Matching System (PMS).

Giving your printer your brand's specific Pantone codes is the most surefire way to guarantee color accuracy, especially when you're using offset printing. If you have to print using CMYK, make sure the four-color values (C, M, Y, and K) are identical across all of your design files. For any project where the color is absolutely mission-critical, do yourself a favor and invest in a hard-copy proof. This lets you see and approve the final color in your hands before you commit to the full print run.

Ready to turn your ideas into high-quality printed reality? At 4OVER4, we offer a huge range of printing services, from quick-turnaround digital runs to massive offset projects and unforgettable specialty finishes. Explore our printing options and find the perfect solution for your brand.

More from types of printing

23

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

38

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

119

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

166

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

95

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026

93

A pop up banner is a portable, free-standing display sign that’s an absolute workhorse for visual marketing. Think of it as your brand's

Emma Davis

Emma Davis

Jan 19, 2026

120

Foam board printing is a fantastic way to get high-quality images and text onto a board that’s both lightweight and surprisingly rigid. It�

Emma Davis

Emma Davis

Jan 18, 2026

102

Custom product label printing is all about creating unique, branded labels that turn your products from generic items into something instantly

Emma Davis

Emma Davis

Jan 17, 2026