- Home

- content hub

- Your Guide to Foam Board Printing for Impactful Signage

Your Guide to Foam Board Printing for Impactful Signage

Emma Davis

Content Writer

Jan 18, 2026120 views

Jan 18, 2026120 views

Foam board printing is a fantastic way to get high-quality images and text onto a board that’s both lightweight and surprisingly rigid. It’s a go-to choice for everything from sleek business presentations to eye-catching event signage, mainly because it delivers a professional, high-impact look without the hefty price tag.

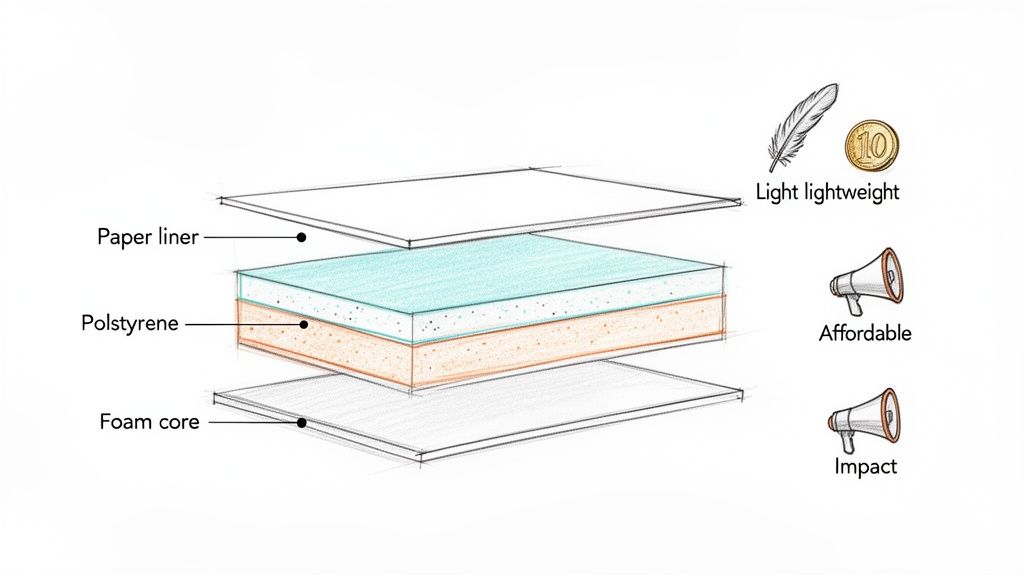

A Visual Megaphone for Your Message

Think of a foam board sign as a visual megaphone. It's built to grab attention and broadcast your message, whether you're in a crowded trade show hall or a quiet office lobby. But what is it, really? The magic lies in its simple but clever construction: a core of dense polystyrene foam sandwiched between two smooth paper liners.

This layered design is the secret sauce. The inner foam gives it structure and rigidity without the weight, while the paper on the outside provides the perfect canvas for crisp, vibrant printing. It's this combination that makes foam board printing such a versatile tool.

Why Choose Foam Board?

The real power of foam board is how it perfectly balances quality, cost, and convenience. It fills that sweet spot between a flimsy poster and expensive, heavy-duty signage, giving you a professional solution that’s easy on the budget.

Here’s why so many people love it:

- Professional Finish: The smooth surfaces, whether matte or semi-gloss, offer a high-end look that fits right into corporate settings, presentations, and retail displays.

- Lightweight and Portable: It’s so light you can carry it with one hand. This makes it a breeze to transport, set up, and move around—perfect for events and temporary installations.

- Cost-Effective Impact: You get huge, attention-grabbing visuals for a fraction of what you’d pay for materials like acrylic or metal. Your marketing budget will thank you.

- Versatility in Application: From detailed photo displays to bold, simple directional signs, foam board can be easily cut and customized for almost any idea you can dream up.

The Growing Demand for Quality Signage

The proof is in the numbers. The global foam boards market, valued at USD 70.3 billion, is on track to hit USD 110.6 billion by 2035. The specific type used for high-quality printing—polystyrene foam boards—is leading the charge with a massive 47.7% market share because of its smooth finish, sturdiness, and great price.

In short, foam board printing is a smart, strategic choice for durable, temporary signs that look polished and professional. It’s the go-to when you need your visuals to pop, without the logistical headache or cost of heavier materials.

This guide will walk you through everything you need to know to make foam board work for you. Whether you’re just exploring options for mounted prints or planning a major event, you’re about to learn how to get stunning results.

Choosing the Right Foam Board for Your Project

Picking the right material for your foam board printing project is a lot like choosing the right tires for a car. At a glance, they might all seem similar, but the right choice guarantees the best performance, durability, and a final product that’s perfectly suited for its job. Your decision here affects everything from visual punch to how long your sign will last, so let's walk through the options.

The two main things you’ll be deciding between are the material type and its thickness. Each combo is built for a specific purpose, whether it’s a lightweight board for an internal meeting or a heavy-duty, weather-resistant sign for a bustling trade show. Nailing this choice is the first step toward a perfect print.

Understanding Core Material Types

Not all foam boards are created equal. The stuff on the inside (the core) and the paper on the outside can be surprisingly different, giving each type its own unique strengths. Getting to know the main players will help you match your project's needs with the best material.

Here are the primary types you'll run into:

- Standard Foam Board: This is the classic you probably picture—a polystyrene foam core sandwiched between two sheets of smooth, clay-coated paper. It’s light, easy on the wallet, and gives you a fantastic surface for crisp, vibrant printing.

- PVC Foam Board (Sintra/Komatex): When your project needs a little more muscle, PVC foam board is the answer. It's made from a solid, moderately expanded closed-cell polyvinyl chloride (PVC). This makes it way more durable, rigid, and resistant to moisture and dings than standard foam board.

- Acid-Free or Archival Foam Board: If you’re mounting priceless photos or fine art, this is the professional standard. It's made with materials that won't yellow or degrade over time, keeping your prints safe and sound for years to come.

In the world of advertising and signage, PVC foam boards are a clear favorite because they print beautifully and can take a beating. In fact, the market for PVC foam board was valued at USD 2.1 billion and is expected to hit USD 3.6 billion by 2032. That kind of growth shows just how essential it has become for creating tough, long-lasting displays. You can find more details on this trend over at Verified Market Research.

How Thickness Impacts Your Sign

Thickness is all about rigidity and presence. A thicker board doesn't just resist bending and warping; it also feels more substantial and high-end. The right thickness really comes down to the sign's size and where it’s going to live.

Let's look at the most common options:

- 3/16" (5mm): This is the go-to, all-around favorite thickness. It strikes the perfect balance between being sturdy and lightweight, making it ideal for most indoor uses like point-of-sale displays, conference signs, and presentation boards.

- 1/2" (13mm): When you need something that’s built like a tank and makes a statement, 1/2" thickness is your best bet. It’s perfect for big signs that absolutely have to stay flat, high-end trade show displays, or any sign that needs to stand on its own without a hint of bowing.

Key Takeaway: For most indoor signs under 24" x 36", the 3/16" foam board is the perfect workhorse. For larger, more permanent, or freestanding displays, upgrading to 1/2" thickness or PVC foam board is a smart investment in durability.

To make things even easier, we've put together a quick comparison table to help you visualize the best fit for your project.

Foam Board Material and Thickness Guide

This guide breaks down common foam board types and thicknesses to help you choose the best option for your specific application, from indoor presentations to durable outdoor signage.

| Material Type | Common Thickness | Best For | Durability | Price Point |

|---|---|---|---|---|

| Standard Foam Board | 3/16" | Indoor presentations, short-term retail signs | Low | $ |

| Standard Foam Board | 1/2" | Larger indoor signs, easel displays | Medium | $$ |

| PVC Foam Board | 3/16" | Short-term outdoor use, trade shows, durable displays | High | $$$ |

Now that you have a handle on the fundamentals, you can confidently choose the perfect material for whatever you're creating next.

Ready to get started? Explore our full foamcore collection to see all these options and find the ideal match for your creative vision.

How Your Designs Come to Life

Ever wonder how a digital file on your screen becomes a crisp, vibrant foam board sign? It’s not just a matter of hitting “print.” Getting your design from pixel to physical product involves some pretty impressive technology, all aimed at making sure your colors pop and your message gets noticed. Let's pull back the curtain on the two main ways we make that happen.

The go-to method these days is direct-to-surface UV printing. Picture a highly advanced inkjet printer, but instead of paper, it’s built to print directly onto rigid materials like foam board. As this machine lays down specialized inks, a powerful ultraviolet (UV) light follows right behind, instantly curing—or hardening—the ink directly onto the board.

This instant-cure process is a real game-changer. It stops the ink from bleeding or soaking into the surface, which means you get incredibly sharp details and colors that look like they're about to jump off the board. Because the ink is hardened right away, it’s also tough against fading, scratches, and even a bit of moisture, making it a durable choice for professional signs.

An Alternative Method: Mounting Graphics

There’s another way to get the job done: mounting. This is more like applying a perfectly fitted, high-end sticker to your foam board. We start by printing your design onto a sheet of premium adhesive vinyl. Then, using specialized equipment, we carefully apply that printed graphic to the face of the foam board, ensuring a smooth, bubble-free finish.

This technique is especially handy when you’re after a specific look that direct printing can’t quite achieve. For instance, if you want an ultra-glossy finish or a unique texture, mounting a custom-printed vinyl is the perfect way to get that effect. Thinking about different surface treatments? Exploring various laminating options for your prints can add another layer of protection and really make your final product shine.

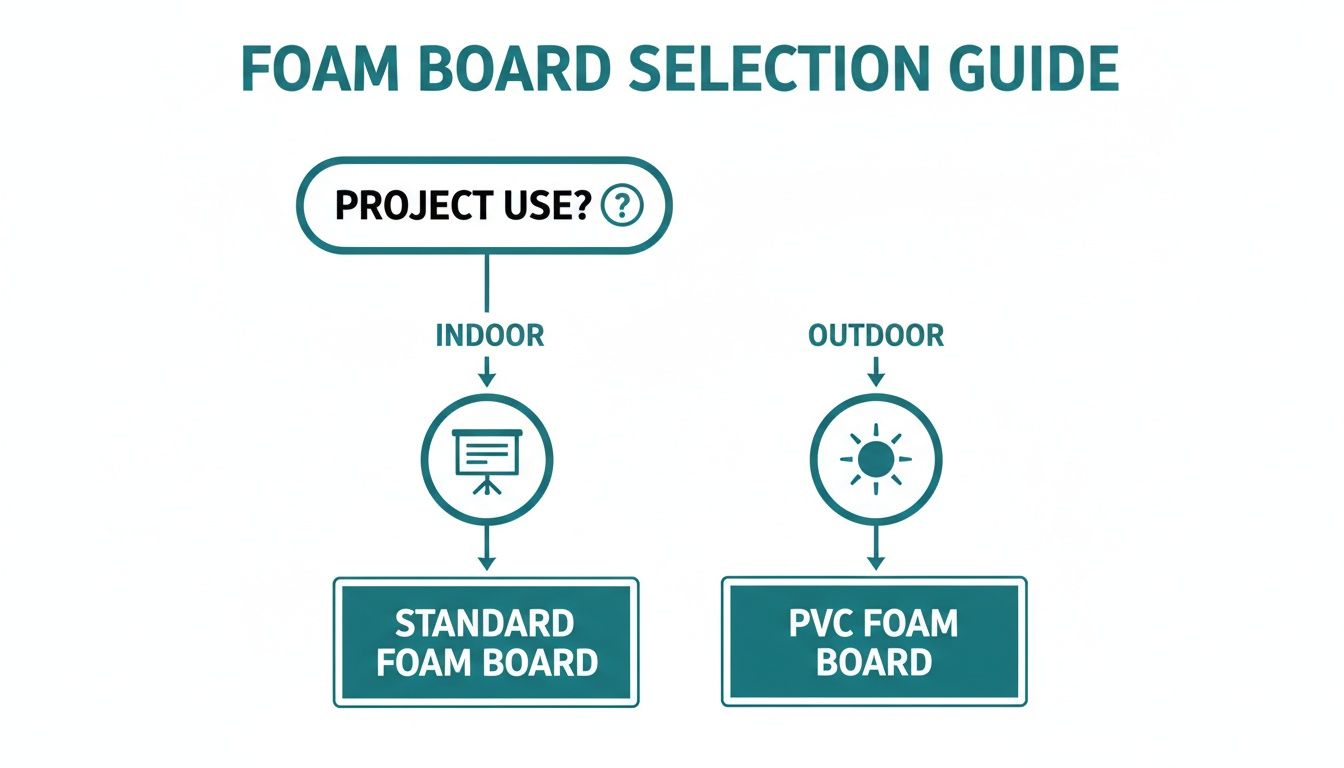

To help you figure out which board is best for your project, check out this quick guide. It breaks down the choice between our standard and PVC foam boards based on where you plan to use them.

As you can see, for indoor jobs like trade show displays or presentations, a standard board is perfect. But if your sign is heading outdoors or into a high-traffic area, you’ll want the extra muscle of a PVC board.

The Secret Ingredient: Professional Color Calibration

No matter which printing method we use, getting the color right is non-negotiable. Your brand's specific shade of blue isn’t just a color—it’s your identity. That’s where professional color calibration comes in.

Professional printers use advanced color management systems to ensure the colors on your screen are faithfully reproduced on the final printed board. This involves calibrating printers, monitors, and software to a universal color standard, guaranteeing consistency across every single print run.

Our top-of-the-line equipment is meticulously calibrated to translate digital color profiles (like CMYK) into physical ink with stunning accuracy. This obsession with detail is what keeps your branding consistent and professional, building trust with your audience. Understanding the principles of graphic design for branding helps create visuals that connect, and it’s our job to make sure they print perfectly. In the end, it’s this marriage of technology and color science that guarantees your foam board project looks exactly how you pictured it.

Preparing Your Files for a Perfect Print

Sending your design file to print can feel a little like launching a rocket. You’ve put in all the work, and now you have to trust that everything is set up correctly for a successful mission. This section is your pre-flight checklist, designed to make sure your digital file translates perfectly into a stunning physical sign, without any frustrating (and costly) mistakes.

Getting these details right from the start is the secret to a smooth process. It saves you time, prevents reprints, and guarantees your final foam board looks every bit as professional as you imagined. We'll walk through the three most critical parts of file prep: resolution, color mode, and bleed. Once you get these down, you'll be submitting files like a seasoned pro.

Decoding Resolution for Crisp Images

Have you ever seen a printed sign that looked blurry, blocky, or just fuzzy around the edges? That’s almost always a resolution problem. Think of your digital image as a mosaic made of thousands of tiny colored squares called pixels. Resolution, measured in DPI (dots per inch), tells the printer how many of those tiny pixels to squeeze into each square inch of the foam board.

For high-quality foam board printing, the magic number is 300 DPI. A file with this resolution has enough pixel data packed in to produce sharp lines, crisp text, and clear photos that look fantastic even up close. Trying to print a file with a lower resolution, like the 72 DPI standard for web images, is like stretching a small rubber band too far—it gets thin, distorted, and eventually breaks. The image just falls apart.

Pro Tip: Always set your design file to 300 DPI from the very beginning. This one step is the single biggest factor in achieving a sharp, professional-looking print and avoiding that dreaded pixelated look.

Choosing the Right Color Mode

Here’s something many people don’t realize: digital screens and physical printers speak two completely different color languages. Your computer monitor, tablet, and phone create colors by mixing Red, Green, and Blue light. This is the RGB color model, and it’s called an "additive" process because when you add all the colors together, you get pure white light. Perfect for glowing screens, but totally wrong for ink on paper (or foam board).

Printers work by subtracting light. They start with a white surface and add ink in Cyan, Magenta, Yellow, and Black (CMYK) to absorb light and create colors. If you send an RGB file to a printer, its software has to make its best guess at how to translate those light-based colors into ink-based ones. This conversion often leads to disappointing surprises, like your vibrant electric blue turning into a dull, muted navy.

- RGB (Red, Green, Blue): This is for anything that will live on a screen—websites, social media graphics, digital ads.

- CMYK (Cyan, Magenta, Yellow, Black): This is the only color mode you should use for projects destined for print, including your foam board signs.

By designing in CMYK from the start, what you see on your calibrated screen is a much more accurate preview of the final printed product. You stay in control, ensuring your brand’s signature red doesn't accidentally become a muddy maroon.

Why Bleed Is Your Safety Margin

Imagine you’re painting a room and want a perfectly clean line where the wall meets the ceiling. You’d use painter's tape, right? You paint slightly over the tape to make sure there are no gaps. In printing, bleed is your painter's tape—a small safety margin for your design.

When we print your sign, it's often on a larger sheet of foam board that gets trimmed down to its final size. Even with hyper-precise cutting machines, there can be microscopic shifts of a millimeter or two during the trimming process. If your background color or image stops exactly at the edge of your design, a tiny shift could leave an ugly, unprofessional-looking white sliver on one side.

To prevent this, you simply extend your background 1/8th of an inch (0.125") past the final trim line on all four sides. This extra area is the "bleed." Now, if the cutter shifts slightly, it slices through this extra printed area, guaranteeing the color goes edge-to-edge flawlessly. It’s a simple trick that makes a world of difference for a clean, polished finish.

Inspiring Ways to Use Foam Board Signs

While the tech specs are good to know, the real magic of foam board printing happens when you see it out in the wild. Its usefulness goes way beyond just hanging a poster. For businesses, it's a powerful tool to grab attention, point customers in the right direction, and project a sharp, professional image. Let’s walk through a few real-world examples where foam board signs really shine.

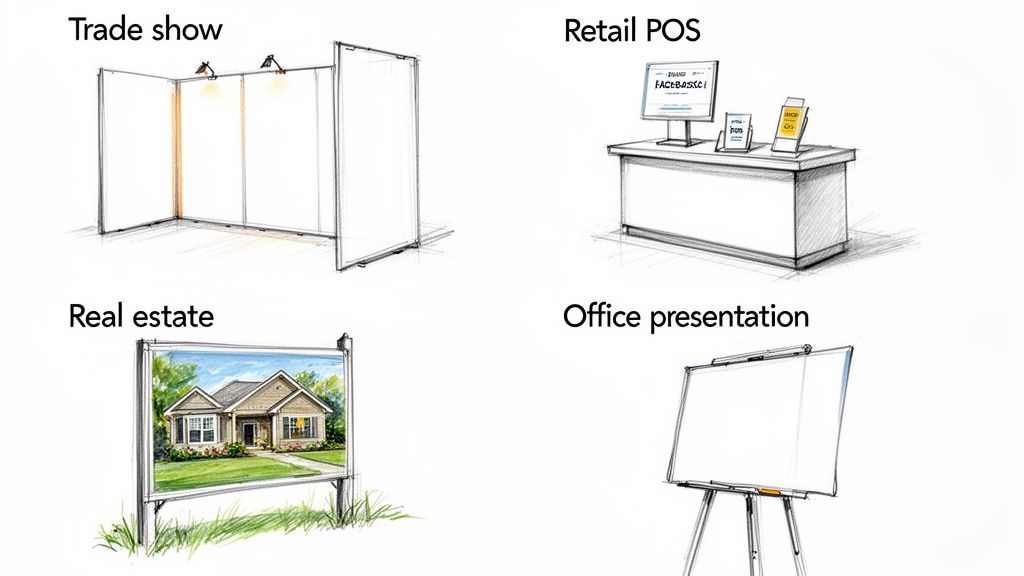

Picture a startup getting ready for its first big trade show. The budget is tight, but their booth needs to look polished and pull people in. This is exactly where large-format foam board printing saves the day. They can create a stunning, full-color backdrop with their logo and main selling points, instantly making their space look legitimate and inviting.

They can also scatter smaller signs around the booth to call out product features, show off pricing, or provide QR codes that link to their site. And because the material is so light, setting up and packing away is a breeze—a huge time-saver when every minute counts.

Transforming Retail and Event Spaces

In the blink-and-you'll-miss-it world of retail, catching a customer’s eye is everything. Foam board is the perfect material for creating can’t-miss point-of-sale (POS) displays that shout about a new sale, promote a seasonal special, or introduce a new product line. A thoughtfully placed sign on an easel by the door or a custom-cut display on the counter can be the nudge that turns a browser into a buyer.

Now, think about a real estate agent holding an open house. Instead of relying on small, forgettable photos, they can print huge, gorgeous images of the property on foam board. Placed on easels in key rooms, these signs can highlight the home's best assets—like a sun-drenched garden or a sleek new kitchen—creating an immersive experience that sticks with potential buyers.

The sheer versatility of foam board is a huge part of its appeal across so many industries. From buttoned-up corporate presentations to beautiful wedding welcome signs, its ability to deliver high-quality visuals in a lightweight, budget-friendly package makes it an absolute marketing staple.

The broader foam market is seeing massive growth, which is great news for the printing and display world. Valued at USD 119.02 billion, the global foam market is expected to hit USD 186.16 billion by 2033. This surge underscores just how vital this material is for brand communication and advertising in countless business sectors.

Professional Presentations and Office Branding

Step into the corporate world, and you'll see foam board signs adding a dose of professionalism to presentations and meetings. A speaker can use a series of boards to walk through key data points, charts, and infographics, creating a visual aid that’s far more engaging and tangible than another PowerPoint slide. They're also fantastic for internal communications, like displaying company values in the lobby or providing clear directional signage in a sprawling office.

Of course, to make sure your foam board signs truly pop, it all starts with a solid foundation in effective logo and brand design. When you pair a great design with the perfect material, you create visual assets that do the heavy lifting for you. Ready to bring your own ideas to life? Explore the endless possibilities with these and other custom rigid signs for all your business needs.

Finishing and Mounting for a Professional Look

The final touches on your foam board printing project are what transform a great print into an unforgettable display. Think of it like framing a piece of art; the print itself is stunning, but the right finish and mounting method elevate it, protect it, and prepare it for its moment in the spotlight.

These last steps are absolutely crucial. They ensure your sign not only looks professional but also has the durability to stand up to its environment, wherever that may be. A simple print is good, but a finished print is so much better.

Choosing Your Protective Finish

Finishing options, like lamination, act as a protective shield for your design. This thin layer of plastic film guards against scratches, fingerprints, and UV rays that cause colors to fade over time. It’s a simple addition that can significantly extend the life of your sign.

The type of lamination you choose has a huge impact on the final look and feel. Each one offers a distinct aesthetic, so the best choice really depends on your design and where the sign will be displayed.

Here’s a quick breakdown of the most popular choices:

- Gloss Lamination: This finish creates a shiny, reflective surface that makes colors appear richer and more vibrant. It's an excellent choice for photographic prints or designs with bold, saturated colors that you really want to pop.

- Matte Lamination: For a more subtle, sophisticated look, matte is the way to go. It produces a smooth, non-reflective surface that minimizes glare, making it perfect for signs viewed under bright lights or from various angles.

Key Insight: Choose gloss to make your colors sing and grab immediate attention. Opt for matte when you need a high-end, glare-free finish for professional settings like corporate presentations or art displays.

Smart Mounting for Maximum Impact

Once your sign is printed and finished, the next question is: how will you display it? The right mounting hardware does more than just hold your sign up. It contributes to the entire presentation, whether you need a simple tabletop display or a sleek, modern wall installation.

Exploring different mounting hardware solutions can open up a world of creative possibilities for showcasing your prints.

Here are a few common mounting options to consider:

- Easels: The classic, go-to solution for temporary displays. An easel is a simple yet effective way to present your foam board sign at trade shows, conferences, or retail entrances without having to alter any walls.

- Grommets: These are small metal rings punched into the corners or edges of your sign. Grommets are perfect for hanging your foam board from ceilings or walls using rope, wire, or hooks. It’s a secure and straightforward method.

- Standoffs: For a truly modern and elegant look, standoffs are unbeatable. These metal hardware pieces mount your sign slightly away from the wall, creating a sophisticated "floating" effect with subtle shadows. This method is ideal for permanent displays in lobbies, offices, or galleries where you want to make a lasting impression.

By carefully considering both the finish and the mounting, you ensure your foam board printing project achieves that polished, professional look that’s perfectly suited for its purpose.

Answering Your Foam Board Printing Questions

So, you’re just about ready to order your foam board signs, but a few last-minute questions are probably bubbling up. It's totally normal. Getting these final details sorted is the key to feeling great about your purchase, and that's exactly what this section is for.

Think of this as your quick-reference guide. We’re tackling the most common questions we get, covering everything from durability to delivery times, so you have complete confidence before you hit that "order" button.

How Durable Is Foam Board Printing for Outdoor Use?

This is a big one. Standard foam board is really designed for indoor life. Its paper surface looks amazing, but it doesn't play well with moisture or humidity. It's the go-to choice for things like conference presentations, indoor retail displays, and trade show booths where it's safe from the weather.

Now, if you do need something for short-term outdoor use, you'll want to pivot to PVC foam board. This stuff is a durable plastic, making it naturally waterproof and way more resilient. For any sign that's going to see the sun, we always recommend adding a UV-protective laminate. It's a small add-on that keeps your vibrant colors from fading.

What Is the Best Way to Care for My Foam Board Sign?

Good news: keeping your foam board sign looking crisp and professional is incredibly simple. A little bit of care goes a long way.

- Dusting: Just grab a soft, dry microfiber cloth and give it a gentle wipe. Easy.

- Cleaning Smudges: If you get a minor smudge, a lightly dampened cloth will usually do the trick.

- Avoid Chemicals: This is important—stay away from harsh chemical cleaners, anything abrasive, or solvents. They can easily ruin the printed surface and the board itself.

When you're not using them, store your signs flat in a cool, dry place out of direct sunlight. This keeps them from warping and protects the print. And a pro tip: always handle them by the edges to avoid fingerprints on your design.

Can Foam Board Signs Be Cut into Custom Shapes?

Absolutely! This is where foam board printing gets really fun. We're not just limited to squares and rectangles. Using precision die-cutting, we can create signs in just about any custom shape you can dream up.

This opens up a massive world of creative possibilities. We can cut your company logo to its exact shape, create life-size standees of people or products, or design totally unique displays that stop people in their tracks. It's the perfect way to make your brand unforgettable at events, in your store, or at a trade show.

The ability to create custom shapes is a game-changer for marketers. It lets a sign be more than just an information panel—it becomes an interactive and memorable piece of your brand's story.

What Are the Typical Turnaround Times for Foam Board Printing?

We know that deadlines are everything. Getting your signs when you need them is our priority. The exact turnaround time depends on a few things, like how complex your order is, the quantity, and any special finishes like custom cuts or lamination.

That said, many of our standard foam board orders can be produced very quickly. Here at 4OVER4, we even offer same-day printing options for those super urgent, last-minute projects. As you build your order on our product page, you’ll see a real-time estimate for both production and shipping, so you know exactly when to expect your delivery.

Feeling confident and ready to create a sign that captures attention? At 4OVER4, we make it easy to bring your vision to life with high-quality foam board printing and a wide range of customization options. Start your order today and see the difference professional printing makes.

More from foam board printing

23

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

38

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

119

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

166

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

95

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026

91

In a world saturated with digital noise, the simple, tangible act of handing someone a beautifully printed piece can make your brand unforgett

Emma Davis

Emma Davis

Jan 20, 2026

93

A pop up banner is a portable, free-standing display sign that’s an absolute workhorse for visual marketing. Think of it as your brand's

Emma Davis

Emma Davis

Jan 19, 2026

102

Custom product label printing is all about creating unique, branded labels that turn your products from generic items into something instantly

Emma Davis

Emma Davis

Jan 17, 2026