- Home

- content hub

- what is silk screen printing: A quick guide to bold, lasting designs

what is silk screen printing: A quick guide to bold, lasting designs

Emma Davis

Content Writer

Dec 8, 2025188 views

Dec 8, 2025188 views

Imagine using a detailed stencil to press a thick, vibrant layer of ink onto a t-shirt. That’s the core idea behind silk screen printing—a time-tested method for creating bold, durable designs that truly last. For professional-quality graphics with incredible color and resilience, it’s still the gold standard.

What Is Silk Screen Printing Explained

Also known as serigraphy, silk screen printing is a classic technique where ink is transferred onto a surface through a mesh screen. A squeegee pushes the ink through the openings of a stencil that has been chemically bonded to the screen, laying down a thick, opaque layer of color. This results in a design that is not only bright but also incredibly tough.

Unlike digital printing, which sprays tiny dots of ink, screen printing applies solid layers of color one at a time. This method is what gives the final product its signature look and feel: a slightly raised, tactile design that sits right on top of the material.

For a quick overview of what this method offers, take a look at the table below. It breaks down the essential features that make screen printing a go-to choice for so many businesses.

Silk Screen Printing At a Glance

| Attribute | Key Feature |

|---|---|

| Durability | Excellent; ink bonds with the material, resisting fading and wear. |

| Color Vibrancy | Superior; opaque inks create bright, solid colors, even on dark surfaces. |

| Best For | Medium to large volume orders (e.g., 50+ items). |

| Cost | High initial setup cost, but low per-item cost on large runs. |

| Materials | Versatile; works well on fabric, paper, plastic, metal, and wood. |

| Design Detail | Good for bold graphics, but less ideal for photographic or highly intricate designs. |

This table highlights why screen printing remains so popular. It’s a workhorse method built for quality and volume.

The Stencil and Squeegee Method

Think of it as painting with a highly precise stencil. Every color in your design needs its own unique screen. So, for a three-color logo, you’d need three separate screens prepared. The printer then meticulously aligns each one, applying its color in the exact right spot to build the final image, layer by layer.

This method is celebrated for its ability to produce consistent, high-quality results across large quantities. Once the screens are set up, the process of printing hundreds or even thousands of items is remarkably efficient and cost-effective.

This scalability is exactly why businesses and brands keep coming back to screen printing for all sorts of projects. The benefits are hard to ignore:

- Exceptional Durability: The ink chemically bonds with the fabric or material during a heat-curing process. This makes the print incredibly resistant to fading, cracking, and washing.

- Vibrant Colors: Screen printing inks are much thicker and more opaque than digital inks. This allows for stunningly bright and vivid colors, even when printing on dark-colored materials.

- Cost-Effectiveness at Scale: While there are initial setup costs, the price per item drops dramatically as the order quantity goes up, making it perfect for bulk projects.

From custom t-shirts and tote bags to posters and signage, this technique can turn a simple digital design into a tangible product that makes a real impact. To see just how versatile it is, check out these examples of custom promotional products.

The Step-by-Step Silk Screen Printing Process

Ever wondered how a digital design gets onto dozens of t-shirts, looking sharp and feeling like it’s part of the fabric? It’s not magic—it's a meticulous, hands-on process that has been perfected over centuries. Getting a handle on this journey from a simple computer file to a finished product will help you understand production timelines and see why some designs are just made for this method.

At its heart, silk screen printing is all about creating a very specific stencil for each individual color in your design. This isn't your grade-school paper cut-out. It’s a precise, photo-chemical process that ensures every last detail is captured perfectly before a single drop of ink touches the material.

Preparing the Screen Stencil

The whole thing kicks off with a fine mesh screen, usually made of polyester, stretched super-tight over a frame. This screen gets coated with a light-sensitive liquid called emulsion. After it dries in a dark room, the screen is basically a blank canvas, ready to be turned into a custom stencil.

Next, we take a transparent film—think of it as a high-contrast black-and-white printout of one color from your design—and place it on the coated screen. The screen is then hit with a powerful UV light. The light instantly hardens the emulsion everywhere except where the black design blocks it. That unhardened part just washes away with water, leaving a perfect stencil of your artwork right in the mesh.

People in the industry often call this the "burning" process, and it's easily the most critical step. The final quality of the print—its sharpness and clarity—is completely dependent on how well this stencil is made. It turns a simple screen into a precision tool.

This technique has some seriously deep roots. Silk screen printing, also known as serigraphy, actually got its start in China during the Song dynasty (960-1279 AD). Back then, stencils were made from mesh woven from human hair, which was later swapped out for silk—giving the process its name.

Applying Ink and Curing the Print

With a separate screen prepped and ready for each color, the real printing can begin. The item getting printed, let's say a t-shirt, is laid flat on a board called a platen. The first screen is lowered down on top of it, positioned perfectly.

A line of thick, specially formulated ink is poured across the top of the screen. Using a tool called a squeegee, the printer pulls the ink across the stencil with firm, even pressure. This pushes the ink through the open mesh and directly onto the garment below, transferring the first layer of the design.

This workflow—design, print, product—is beautifully simple, which is exactly why it’s so efficient for large batches.

This process is repeated for every single color, using a new screen for each one. The printer has to nail the registration, which is the precise alignment of each color layer, to create a final image that looks seamless. If you're curious to see it in action, this guide on how to screen print t-shirts at home gives a great hands-on perspective.

Finally, the printed item is sent through a large conveyor dryer. The heat cures the ink, making it bond chemically with the fibers of the fabric. This last step is what gives screen prints their famous durability and ensures the design won't crack, peel, or wash away. It's the reason this method is a go-to choice for so many items in our fabric collection.

Key Materials And Equipment In Screen Printing

The quality of a screen print really comes down to the tools of the trade. From the screen that holds your design to the ink that brings it to life, every single piece plays a part. Getting a feel for these core components will help you have smarter conversations with your printer and make better choices for your project.

The whole process is built around the mesh screen, which is a fine polyester mesh pulled super tight over a wood or aluminum frame. These screens are the canvas for the stencil and come in different "mesh counts"—a term that just means the number of threads per square inch.

A lower mesh count, say around 110, has bigger openings in the grid, letting more ink flow through. This is perfect for big, bold graphics on dark shirts. On the flip side, a higher mesh count like 230 or more has tiny, fine openings, which is exactly what you need to capture sharp details and get a softer print on lighter fabrics.

The Squeegee And Its Role

The squeegee is where the magic really happens. It’s a pretty simple tool—just a rubber blade attached to a handle—but it’s absolutely critical. Its one job is to push ink across the screen with perfectly even pressure.

The hardness of that rubber blade, measured in durometers, changes the print. A softer blade lays down a thicker coat of ink, while a harder blade gives you a thinner, more precise layer. A pro printer knows exactly which squeegee to grab to make sure the final design is crisp and clean, with no smudges or bleeding ink.

Think of the screen as the blueprint and the squeegee as the builder. The precision of the squeegee's pass determines whether the blueprint is executed flawlessly, directly impacting the sharpness and vibrancy of the final product.

Getting the right combination of mesh count and squeegee is fundamental to understanding what is silk screen printing on a technical level.

A Look At Specialized Inks

The ink itself is what defines the final look, feel, and toughness of your design. The two most common types you’ll run into in commercial printing give you very different results.

- Plastisol Ink: This is the industry go-to for apparel. It’s an oil-based ink that cures and sits on top of the fabric, creating a bright, opaque print that you can feel. It's incredibly durable and makes colors pop, especially on dark garments.

- Water-Based Ink: This type of ink actually soaks into the fabric fibers instead of sitting on top. The result is a much softer, more breathable print that you can barely feel with your hand. It’s a popular choice for achieving that vintage or "soft-hand" feel, especially on lighter-colored shirts.

Knowing the difference here is key. If you need a bold, long-lasting logo for staff uniforms, plastisol is your best bet. But for a softer, more fashionable design on a retail t-shirt, water-based ink delivers a premium finish.

So, you understand the nuts and bolts of silk screen printing. That's a great start. But the real question is, when should you actually use it? It's a fantastic tool, but like any specialized tool, it excels at certain jobs and isn't the best fit for others.

Making the right call usually boils down to three things: quantity, color pop, and durability. Screen printing really comes into its own when you need a whole bunch of the same thing. Yes, there's an upfront cost to create the screens for each color, but once they're made, the price per item drops dramatically the more you print.

Ideal Projects for Screen Printing

Think about any project where you need consistency and a bold, lasting impression. For apparel, like creating a run of custom classic t-shirts, this method delivers vibrant colors that really stand up to wear and washing. The ink sits on top of the fabric in a thick, solid layer, giving it a professional finish that’s tough to replicate.

Screen printing is the go-to choice for:

- Bulk Apparel Orders: We're talking team uniforms, merchandise for an event, or t-shirts for your whole staff. If you need 50 or more pieces, this is almost always the most cost-effective route.

- Promotional Products: Think tote bags, bandanas, posters, and other giveaways. The ink is incredibly durable, so your brand’s message won't fade away after a few uses.

- Bold, Graphic Designs: Got a design with solid colors and clean lines? Screen printing was practically made for it. It’s perfect for creating that powerful, punchy visual.

This method really took off commercially in the 20th century, especially after the invention of a multi-color rotatable screen printing machine around 1960. It was a complete game-changer for the garment industry and kicked off the printed t-shirt boom we still see today.

When to Consider Other Methods

On the flip side, screen printing isn't a one-size-fits-all solution. Because of the setup involved, it's not practical for small, one-off jobs. If you only need a single shirt, the cost to create the screens would be way too high.

You’ll want to look at other printing methods if your project involves:

- Photorealistic Images: Trying to capture the subtle color gradients of a photograph is tough with screen printing. A technique like Direct-to-Garment (DTG) printing is much better suited for that level of detail.

- Very Small Orders: For a prototype or an order of less than 10-15 items, the setup costs just don't make sense financially.

- Designs with a Ton of Colors: Every single color in your design needs its own screen. A design with ten or more colors can get complicated and expensive very quickly.

The core takeaway is simple: Screen printing is a volume game. It rewards planning and scale with unparalleled durability and vibrancy, making it a strategic choice for businesses looking to make a lasting impression across a large run of products.

For businesses outfitting their teams or creating awesome event swag, this classic method is still king. If you're planning a larger run of custom apparel, take a look at the different options for high-quality t-shirt printing to see how it can elevate your brand.

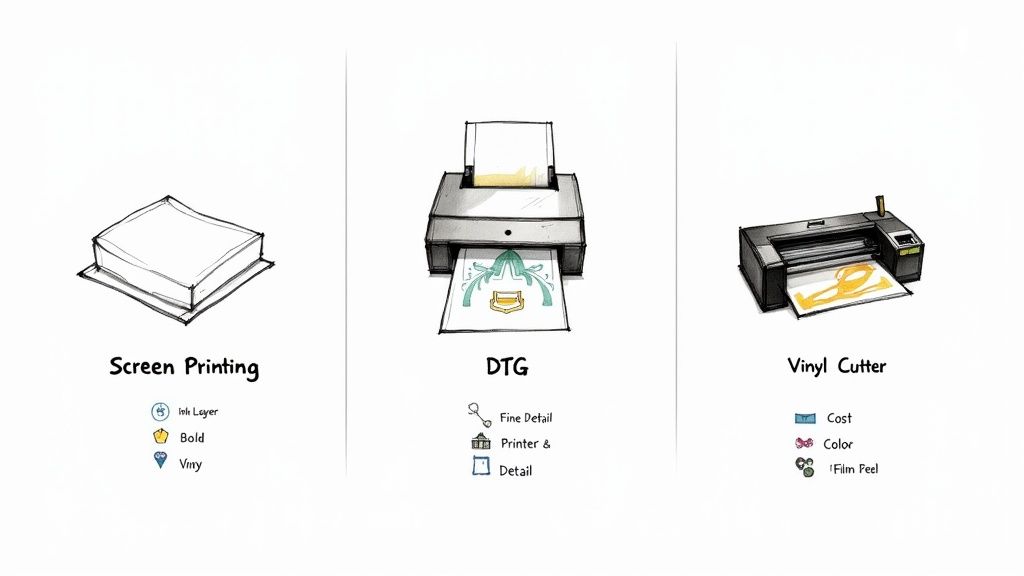

Comparing Screen Printing To Other Methods

To really get a feel for what screen printing brings to the table, it helps to put it side-by-side with the other big names in custom printing. The "best" method isn't one-size-fits-all; it always comes down to the specifics of your project—how many you need, how complex the design is, and what your budget looks like.

The main alternatives you'll run into are Direct-to-Garment (DTG) and Heat Transfer Vinyl (HTV). Each has its own battlefield where it shines. Screen printing is the undisputed king of large-volume orders, delivering knockout color vibrancy and durability for a low price per shirt. DTG is like a specialized inkjet printer for t-shirts, perfect for one-off photorealistic prints. And HTV is the go-to for simple, bold graphics like the names and numbers on a sports jersey.

Screen Printing vs Direct To Garment (DTG)

Think of DTG as the digital sibling to screen printing's analog process. A DTG machine sprays ink directly onto the fabric, much like your office printer puts ink on paper. This means it can handle an unlimited number of colors and reproduce incredibly detailed, full-color photos without any per-color setup fees. It's the perfect choice for printing a single prototype of a complex t-shirt design.

But there are trade-offs. DTG ink is thinner and soaks into the fabric fibers. This means the colors don't have the same bold, opaque punch as screen printing inks, especially on dark-colored garments. More importantly, the cost per shirt stays pretty much the same whether you order 1 or 100, making it a pricey option for bulk orders.

The core difference comes down to scale and vibrancy. Screen printing provides unbeatable color pop and cost efficiency for large runs, while DTG offers detailed, full-color capability for small, custom orders.

Screen Printing vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl takes a completely different path. With HTV, your design is precision-cut from a sheet of colored vinyl and then permanently bonded to the garment using a heat press. This technique is fantastic for clean, simple, and bold graphics—think company logos, single-color text, or personalizing sports jerseys with names and numbers.

HTV makes it easy to add unique details to each item in an order, like adding a different name to each shirt. It also works on a huge range of fabrics, including finicky synthetics where other methods might struggle.

The downside? You can feel the vinyl as a distinct layer on top of the fabric. It can sometimes feel a bit stiff on the shirt and may crack or peel after many, many washes. It’s also not built for intricate, multi-color designs, as every single color has to be cut and layered by hand, which gets complicated fast.

Choosing The Right Tool For The Job

Deciding between these methods really boils down to your project's specific needs. To make it easier, here’s a quick-glance comparison of the three most popular apparel decoration methods.

Screen Printing vs DTG vs Heat Transfer

| Feature | Screen Printing | DTG (Direct-to-Garment) | Heat Transfer (HTV) |

|---|---|---|---|

| Best For | Bulk orders (25+ items) with limited colors | Small runs (1-10 items), full-color photos, complex designs | Simple graphics, text, numbers, individual personalization |

| Durability | Excellent. Very long-lasting, withstands many washes. | Good. Can fade slightly over time, especially without proper care. | Good. Can crack or peel with age and repeated washing. |

| Color Vibrancy | Highest. Opaque inks create bright, bold colors on any fabric. | Good. Less vibrant than screen printing, especially on darks. | Excellent. Vinyl colors are solid and pop on any garment color. |

| Feel on Fabric | Soft. Ink becomes part of the fabric, minimal texture. | Very Soft. Ink soaks into the fibers, almost no feel. | Noticeable. A distinct layer on top of the fabric, can feel stiff. |

| Cost | Low per-item cost on large runs; high initial setup fees. | High per-item cost, but no setup fees. Cost-effective for single items. | Moderate per-item cost. Good for small batches and personalization. |

| Design Complexity | Best for simpler designs with a limited color palette. | Unlimited colors. Perfect for photos and intricate, gradient-filled art. | Best for simple shapes, text, and single-color logos. |

Each method has its place. Screen printing is the workhorse for merchandise and uniforms, DTG is the artist's choice for detailed one-offs, and HTV is the specialist for bold, simple personalization.

While screen printing dominates large-scale apparel, the vinyl technology used in HTV is also a powerhouse in other industries. For instance, creating tough, weather-resistant signs and banners often relies on similar vinyl materials. You can explore a range of options for printing vinyl banners to see just how versatile this technology is for large-format advertising.

How to Prepare Your Business for a Screen Printing Order

Placing a big screen printing order can feel a little intimidating the first time around, but a bit of prep work makes all the difference. When you get your assets and information lined up beforehand, you don’t just speed things up—you guarantee the final product is exactly what you envisioned. The whole point is to remove any and all guesswork for both you and your printer.

The single most critical piece of the puzzle is your artwork. For screen printing, your designs absolutely must be in a vector format. That means files like .AI (Adobe Illustrator), .EPS, or a vector-based .PDF are what you need. Why? Because they can be scaled up or down to any size without a single drop in quality. This is a non-negotiable, as using a standard image file like a JPEG or PNG will only lead to blurry, pixelated stencils and a disappointing print.

Finalizing Your Artwork and Colors

Beyond just the file type, getting the color right is everything for brand consistency. Don't just tell your printer you want "blue." You need to be specific by using the Pantone Matching System (PMS). Handing over a PMS code, like "Pantone 286 C," gives the printer the exact ink formula to mix. It ensures your brand’s signature blue looks identical on every single item.

Think of a Pantone code as a universal recipe for a color. It removes all subjectivity and guarantees that the royal blue on your digital proof is the exact royal blue that appears on your finished apparel, regardless of who prints it.

Checklist for a Smooth Order

Once your art is ready to go, there are just a few more details your printer will need to give you an accurate quote and timeline. Getting this sorted out now prevents annoying delays and surprise costs later on.

To make sure everything goes off without a hitch, have this info ready:

- Garment Selection: Know the exact style, material (like 100% cotton or a 50/50 blend), and color of the items you’re printing on. Different fabrics can change how the ink looks and feels.

- Quantity and Sizes: Have a clear breakdown of how many you need in each size. Screen printing prices are based on volume, so the more you order, the less you'll pay per piece.

- Print Placement: Be crystal clear about where the design goes—full front, left chest, upper back, you name it. It also helps to include the desired print dimensions in inches.

After you send these details over, you'll get a digital proof back. Check it obsessively. Look for spelling errors, confirm the colors, and double-check the placement before you give the green light. Taking these steps is the key to a successful project, whether you’re ordering staff t-shirts or branded promotional items like custom tote bags printing for your next big event.

Got More Questions? Here Are Some Common Ones We Hear

Even after getting the basics down, it’s smart to have a few specific questions answered before you sign off on a big print order. Here are the clear, straightforward answers to the questions that pop up most often.

Can You Actually Print on Dark Shirts?

Yes, and honestly, this is where silk screen printing really shines. The inks used in this process, especially plastisol inks, are thick and opaque. This means they lay down a solid, vibrant layer of color that looks fantastic on dark fabrics like black, navy, or deep green.

Unlike some other methods where the design can look a bit washed out on a dark background, screen printing delivers a bright, bold print that really pops.

What's the Smallest Order I Can Place?

Most print shops will have a minimum order, which usually falls somewhere between 25 and 50 pieces. Why the minimum? It all comes down to the setup.

Creating the screens—one for each color in your design—is the most time-consuming part of the whole job. That initial setup cost has to be spread out over a decent number of items to make it affordable.

Once the screens are ready to go, printing more is quick and efficient. But for a tiny handful of items, the setup cost just doesn't make sense, which is why methods like DTG are better suited for very small batches.

How Long Will the Print Actually Last?

A professionally done screen print is built to last. We’re talking about a print that can easily outlive the garment itself. When the ink is cured correctly with heat, it forms a permanent bond with the fabric fibers.

This creates a design that’s incredibly resistant to all the usual wear and tear—cracking, peeling, and fading—even after you've run it through the wash dozens of times. That durability is exactly why it’s the go-to choice for things like company uniforms and brand merchandise that need to look good for a long, long time.

Ready to bring your bold designs to life with professional quality that lasts? 4OVER4 offers premium silk screen printing solutions perfect for your business apparel and promotional products.

More from silk screen printing

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

64

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

106

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

105

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

332

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026