- Home

- content hub

- What Is Letterpress Printing A Modern Guide

What Is Letterpress Printing A Modern Guide

Emma Davis

Content Writer

Sep 29, 2025480 views

Sep 29, 2025480 views

Letterpress printing is one of those timeless techniques where the process is just as beautiful as the final product. At its heart, it’s a form of relief printing. Imagine a very sophisticated, artistic stamp: a raised surface is inked up and then physically pressed into a thick, soft sheet of paper.

This physical impression is what sets letterpress apart. It creates a distinct, tangible indentation that you can see and feel—a quality known as debossing. This tactile result is the unmistakable signature of true letterpress craftsmanship.

A Legacy Pressed Into Paper

Modern digital printing simply lays a flat layer of ink onto a surface. Letterpress, on the other hand, gives every single piece texture, depth, and character. It turns paper from a simple carrier of information into a sensory experience. This method has a rich history stretching all the way back to Johannes Gutenberg in the 15th century, and its hands-on, artistic nature is still celebrated today.

Because of the meticulous attention to detail required—from hand-mixing the perfect ink color to carefully calibrating the press—this timeless craft is treasured for creating premium products that leave a lasting mark.

Key Characteristics Of Letterpress

The magic of letterpress really comes down to a few unique and recognizable qualities. Once you know what to look for, you'll understand why it’s the go-to choice for projects where making an incredible first impression is non-negotiable.

- Tactile Impression: This is the star of the show. The design is physically pushed into the paper, creating subtle shadows and a texture that just begs to be touched.

- Crisp Ink Application: Ink is transferred directly from the plate to the paper. The result? Exceptionally crisp lines and vibrant, saturated color that sits beautifully within the debossed area.

- Luxurious Paper: Letterpress shines on thick, soft papers, often made from 100% cotton. This kind of stock is plush and resilient, allowing it to take that deep impression without tearing or cracking.

At its core, letterpress is about creating a connection. It’s a physical process that produces a physical result, standing out in a world saturated with fleeting digital content.

This method is so much more than just putting ink on paper; it's a deliberate choice to communicate quality, care, and thoughtfulness. Its distinct feel makes it a top contender in the world of specialty printing, especially for things like wedding invitations, fine art prints, and business cards designed to make a serious statement. Each piece is a small work of art, a testament to the skill and patience poured into its creation.

Tracing the Roots of Letterpress Printing

To really get what letterpress printing is, you have to look back at its incredible history. This isn't just another printing method; it's a legacy that completely changed how the world communicates. The story starts way back in the 15th century when books were priceless, handwritten treasures only the wealthiest and most powerful could afford.

Everything changed with one brilliant invention. The journey of mass communication as we know it kicked off with Johannes Gutenberg and his modern movable type, invented around 1440 in Germany. His system was a clever combination of reusable metal type, a specially formulated ink, and a wooden screw press he adapted from local winemakers.

This setup was a game-changer. It allowed a small team to produce 180 copies of the massive, 1,282-page Gutenberg Bible in just a few years—a feat that would have been impossible for scribes. The floodgates of information were officially open.

Suddenly, knowledge could be shared faster and more widely than ever before. This innovation didn't just print books; it fueled the Renaissance and laid the groundwork for widespread literacy.

The Industrial Evolution of Printing

For centuries, the heart of letterpress remained the same, but the machinery around it evolved in dramatic ways. The Industrial Revolution in the 19th century was a massive turning point, introducing steam-powered presses that turned a manual craft into a high-speed engine for industry.

- Lightning Speed: Machines like the cylinder press could churn out thousands of sheets an hour, a far cry from the few hundred a day that came before.

- Sharper Results: Sturdy iron presses replaced the old wooden ones, delivering more consistent pressure and crisper impressions.

- Information for Everyone: Newspapers, books, and pamphlets became commonplace, making information a part of daily life for the average person.

This era cemented letterpress as the undisputed king of printing for over 500 years. If you want to dive deeper into the mechanics of these incredible machines, A Collector's Guide to the Antique Printing Press is a fantastic resource.

While newer technologies eventually offered faster alternatives, the decline of commercial letterpress in the mid-20th century actually sparked its rebirth. It found new life as an artisanal craft, celebrated for its unique tactile beauty rather than its speed.

Letterpress and Its Artisanal Relatives

The core idea behind letterpress—making a physical impression on paper—is shared by other traditional printing methods. Understanding these helps put letterpress into the broader context of relief and intaglio printing.

A similar technique that also uses pressure to create a distinct, raised effect is engraving. Both methods offer a premium, textured finish that modern digital printing just can't replicate. You can see how these classic techniques stack up by checking out our guide on https://www.4over4.com/printing/category/engraving.

The enduring appeal of letterpress comes directly from this rich history. Every print carries an echo of centuries of craftsmanship, connecting a modern wedding invitation or business card right back to Gutenberg’s revolutionary press. It’s a tangible link to the past, reminding us of the timeless power and artistry of the printed word.

How the Letterpress Printing Process Works

The unique charm of a letterpress print doesn't just happen. It’s the result of a hands-on, multi-step process that beautifully merges modern design with old-school mechanics. Think of it as a craft where patience and precision are just as crucial as the artwork itself, turning a digital file into a tangible piece of art.

Unlike the instant gratification of modern printing, letterpress is slow and deliberate. It’s a craft. Before a single drop of ink hits the paper, the digital design has to be turned into a physical printing plate. Most often, this is a photopolymer plate created in a process similar to developing old camera film. UV light hardens the design onto a light-sensitive material, leaving a raised, mirror-image of your final artwork.

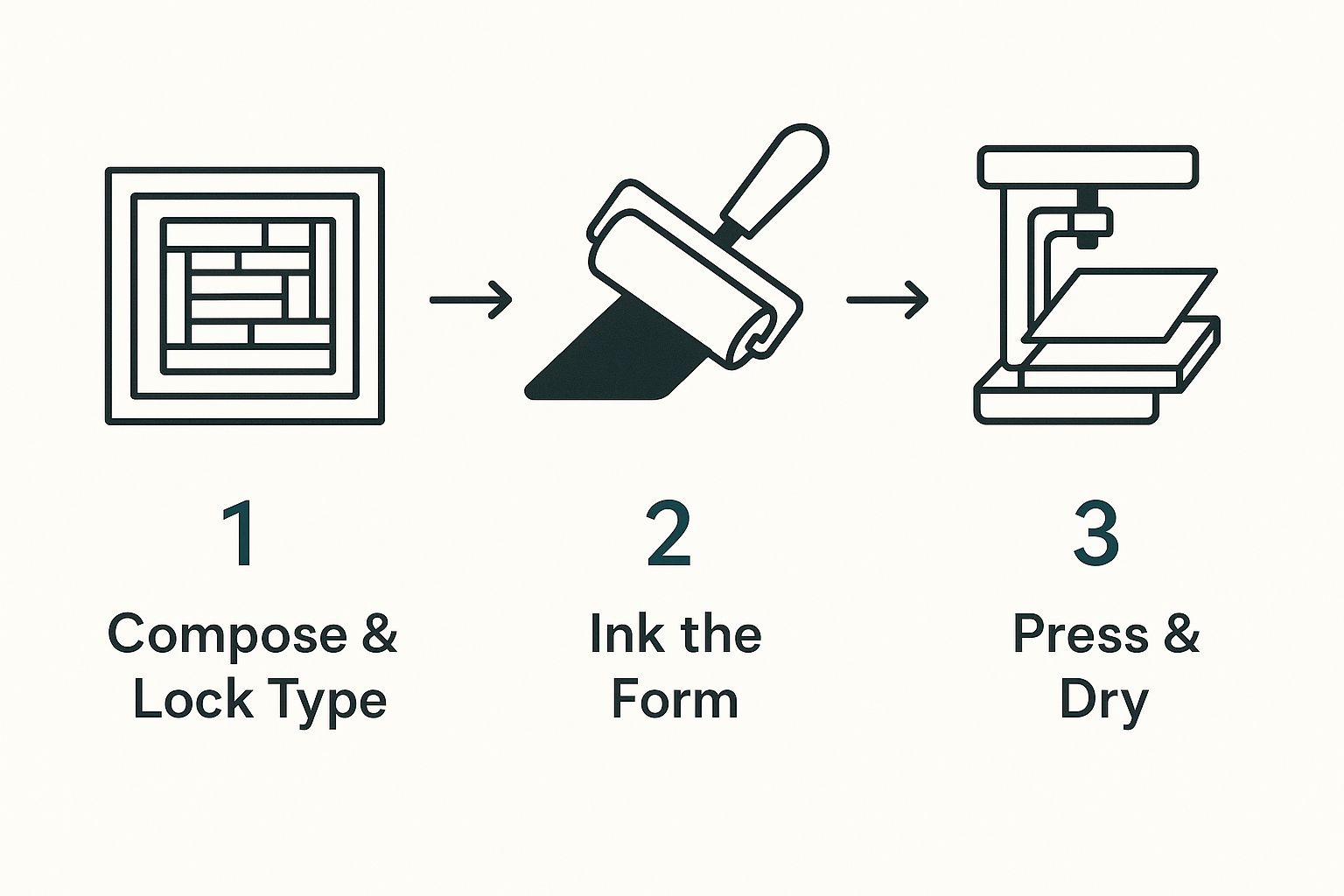

This entire workflow is a carefully choreographed dance of composition, inking, and pressing, as you can see below.

What the infographic really drives home is that letterpress is a sequential, methodical craft. Each stage builds directly on the one before it to create that final, stunning impression.

Preparing the Press

With the plate made, the real artistry can begin: setting up the press. This isn’t like clicking "Print" on a computer. It's a meticulous calibration that can take a good chunk of time. The printer first locks the plate securely into the press bed—a frame known as a "chase"—making sure it's perfectly level and positioned.

Then comes the ink. Letterpress inks are often mixed by hand to nail the exact Pantone color your design calls for. A skilled printer uses a sharp eye and precise measurements to blend pigments, creating a custom hue that brings your vision to life.

The setup phase, known as "makeready," is where the printer's expertise truly shines. They adjust the press packing, roller height, and plate position to achieve the ideal impression depth—deep enough to be felt, but not so deep it punches through the paper.

The Printing Run

Once the press is calibrated and the ink is just right, the printing can finally get underway. Each sheet of thick, soft paper is fed into the press one at a time. This deliberate, sheet-fed method is a true hallmark of letterpress and is the secret behind its artisanal quality.

As the press cycles, a set of rollers glides over the plate, applying a thin, even coat of ink. The paper is then pressed firmly against the inked plate, transferring the design and creating that signature deep impression everyone loves. This action is repeated for every single piece.

A critical detail? Each color needs its own plate and a separate run through the press.

- Single-Color Jobs: The process is run once for every single card or invitation.

- Multi-Color Jobs: For a two-color design, the paper is printed, set aside to dry, and then run through the press a second time with a new plate and the second ink color. This effectively doubles the setup and run time, which is a major factor in the final cost.

Finishing Touches

The journey isn't over just because the ink is dry. After printing, the pieces are often left to cure for 24 hours or more. This ensures the ink is fully set and won't smudge.

Finally, the finishing touches are added to wrap up the project. This can include:

- Trimming: Printed sheets are cut down to their final size with absolute precision.

- Edge Painting: A pop of color is applied to the edges of the thick card stock, adding a beautiful, custom detail.

- Scoring and Folding: For items like greeting cards, each piece is scored to create a clean, crisp fold.

This entire sequence is worlds away from automated printing. For anyone used to the speed of modern machines, learning about the intricacies of digital printing offers a fascinating comparison. Ultimately, the letterpress process is a tribute to true craftsmanship, where every step is carefully managed to create something truly exceptional.

The Defining Qualities of a Letterpress Print

What is it about a letterpress piece that makes someone stop, look closer, and run their fingers over it? It’s not just one thing—it’s a combination of sensory details that digital printing simply can't mimic. These qualities turn a simple piece of paper into a memorable, tactile experience that’s a feast for the eyes and the hands.

The most iconic trait is that deep, crisp impression you can both see and feel. We also call this debossing. The design isn’t just sitting on the paper; it’s physically pressed into it. This creates subtle shadows and a three-dimensional quality that just begs to be touched.

This physical bite into the paper adds a tangible layer of sophistication and craft. The unique aesthetic and tactile feel of letterpress is deeply connected to the art of mastering book design and layout, creating a truly memorable experience for the reader.

The Vibrancy of the Ink

Another signature feature is the incredible saturation of the ink. Letterpress relies on thick, opaque inks that are pressed directly onto the paper, which results in color that is exceptionally pure and vibrant. Unlike digital printing where ink often soaks in and looks flat, letterpress ink sits beautifully right inside the debossed areas.

This method delivers a richness that's tough to match. Colors look solid and true, with clean, sharp edges that make typography and illustrations really pop off the page. It's a visual punch that has become a hallmark of high-quality letterpress work. While the effect is stunning, it's different from techniques that create a raised surface. To explore a related but opposite effect, you can learn more about the process of embossing.

The beauty of letterpress lies in its imperfections. Slight variations in ink coverage and impression depth from one piece to the next are not flaws but evidence of a handcrafted process, making each print truly unique.

The Perfect Paper Canvas

The final element that brings it all together is the paper itself. The ideal canvas for this kind of work is a thick, soft paper stock, often made from 100% cotton. This type of paper has long, plush fibers that are perfect for catching a deep, beautiful impression without cracking or tearing.

- Weight and Feel: Letterpress papers are noticeably heavier and more substantial—think 110lb or even 220lb cover stock. This gives the final product a luxurious, premium feel in your hands.

- Texture: The soft, slightly textured surface of cotton paper works perfectly with the tactile nature of the impression, enhancing the whole sensory experience.

- Durability: These high-quality papers are archival and built to last, making them perfect for keepsakes like wedding invitations and art prints.

Together, these three things—the tangible impression, the vibrant ink, and the luxurious paper—are what make letterpress printing so special. They create a powerful connection with the recipient that communicates care, quality, and a deep appreciation for timeless craftsmanship. It’s a printing method designed to be not just seen, but felt.

Modern Uses for a Timeless Printing Craft

You might think of letterpress as a historical artifact, something locked away in a museum. But it's actually a vibrant, thriving craft that designers and brands turn to when they need to make a powerful statement. In a world saturated with fleeting digital ads, the tangible weight and texture of a letterpress piece create a memorable connection that truly stands out.

This timeless method is the go-to choice for projects where quality and sensory experience are everything. It’s about more than just ink on paper; it’s about conveying a message of care, luxury, and permanence from the very first touch.

Where Letterpress Shines Today

The applications for letterpress are diverse, but they all share one common goal: to leave a lasting impression. Some of the most popular modern uses showcase its unique ability to elevate everyday items into treasured objects.

- Wedding Invitations: For many couples, letterpress is the only choice. The deep impression and luxurious feel set a sophisticated, personal tone for their most important day, creating a keepsake for guests.

- Business Cards and Stationery: A letterpress business card does more than share contact info—it communicates confidence and an uncompromising commitment to quality. It tells potential clients you value craftsmanship and sweat the details.

- High-End Product Packaging: Brands use letterpress for hang tags, coasters, and packaging to create an unforgettable unboxing experience. This tactile detail makes a product feel more special and justifies a premium price point.

These aren't just printing jobs; they're strategic branding decisions. The physical quality of letterpress reinforces a message of excellence.

By choosing letterpress, you are investing in a sensory experience. The recipient doesn't just see the design; they feel its quality, making the message more impactful and memorable.

Artistry and Modern Applications

Beyond its commercial uses, letterpress remains a beloved medium for artists and creators. You'll often see it used for limited-edition art prints, greeting cards, and book covers, where its rich ink saturation and crisp lines are perfect for fine art.

Many modern designs also combine letterpress with other specialty techniques to create even more stunning effects. For example, pairing the deep impression of letterpress with the bright shine of metallics can produce a truly remarkable finish. To see how these elements can work together, you can explore the beautiful options available with foil stamping. This blend of old-world craft and modern aesthetics is exactly what keeps letterpress so relevant and exciting.

Your Letterpress Printing Questions, Answered

As you start to imagine what letterpress could do for your project, a few practical questions always pop up. It's a classic technique, and that means it plays by a different set of rules than modern digital printing. Let's walk through some of the most common queries to help you get a handle on the costs, design choices, and technical side of things.

Getting these details right from the start is the key to making sure your project is a perfect match for the craft. When that happens, the final result is always something special.

Why Is Letterpress More Expensive?

The higher cost of letterpress comes down to two things: a very hands-on process and top-shelf materials. This isn't an automated, push-a-button kind of printing. It's a true craft, performed by a skilled operator who handles every single piece individually. That time and expertise is a big part of what you're paying for.

Here’s a quick breakdown of what drives the cost:

- Custom Plates: Every color in your design needs its own physical printing plate. This is a one-time cost for each project, but it's a necessary first step.

- Manual Labor: An expert printer has to manually set up the press, mix the inks by hand to get your exact color, and then feed each sheet of paper through the machine. One at a time.

- Premium Paper: Letterpress truly shines on thick, luxurious cotton paper. This kind of stock costs a good bit more than the paper used for standard printing, but the tactile result is worth it.

Ultimately, the price reflects a bespoke, handcrafted product—not just a simple print run. You're investing in the artistry and the undeniable quality that makes a letterpress piece feel so memorable.

What Designs Work Best for Letterpress?

Letterpress is at its absolute best with designs that lean into clean lines, distinct shapes, and a smart use of negative space. It makes typography and vector-style illustrations look incredibly crisp and clear. Think bold and defined, not soft and blended.

Because every color requires a separate plate and another pass through the press, designs that use just one to three colors are the most popular and cost-effective. While fine, delicate lines can look stunning, you’ll want to be careful with very large, solid areas of color. They can sometimes look a little uneven or "salty" simply because of how the ink transfers from the plate to the paper.

The Bottom Line: Letterpress isn't the right tool for reproducing photos, gradients, or complex, multi-colored artwork. Its superpower is bringing simple, elegant designs to life with a texture and depth you just can't get any other way.

Can You Print on Both Sides?

Yep, you can absolutely print on both sides of the paper! It just takes some careful planning to get it right. The deep impression on one side of the sheet can sometimes create a faint "bruise" or show-through on the other side, which can spoil the clean finish.

Printers have a few clever tricks to get around this:

- A Lighter Impression: Your printer can use a much lighter "kiss" impression. This inks the paper perfectly but doesn't create that deep deboss, minimizing any effect on the reverse side.

- Thicker Paper: Using a much heavier paper stock, like a 220lb sheet, gives the paper enough heft to absorb the impression on both sides without one interfering with the other.

- Duplexing Sheets: This is the premium solution. The printer prints on two separate sheets and then expertly glues them together, back-to-back. Duplexing guarantees a deep, beautiful impression on both sides and gives you a final piece that feels incredibly substantial and luxurious.

At 4OVER4, we specialize in bringing the timeless beauty of letterpress to life for your brand. Whether you need unforgettable business cards or premium invitations, we have the expertise to create something truly special. Explore our custom printing solutions at https://4over4.com today.

More from what is letterpress printing

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

64

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

106

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

105

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

332

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026