- Home

- content hub

- What is Aqueous Coating? Eco-Friendly Print Finish Explained

What is Aqueous Coating? Eco-Friendly Print Finish Explained

Emma Davis

Content Writer

Aug 28, 20251132 views

Aug 28, 20251132 views

Let's get right into it. Aqueous coating is a clear, water-based finish that gets applied to paper right on the printing press. Think of it as an invisible shield for your printed materials. It's the secret sauce that keeps ink from smudging, guards against fingerprints, and prevents scuffs, all while giving the paper a fantastic look and feel—whether you're going for a high-gloss shine or a subtle matte.

Understanding the Essentials of Aqueous Coating

You'll often hear people in the printing world refer to aqueous coating as "AQ." It's one of the most common and practical finishes out there, and for good reason. Unlike older varnishes or UV coatings, which can be oil-based or need special light to cure, aqueous coating's main ingredient is water. This makes it a much more environmentally friendly choice right off the bat.

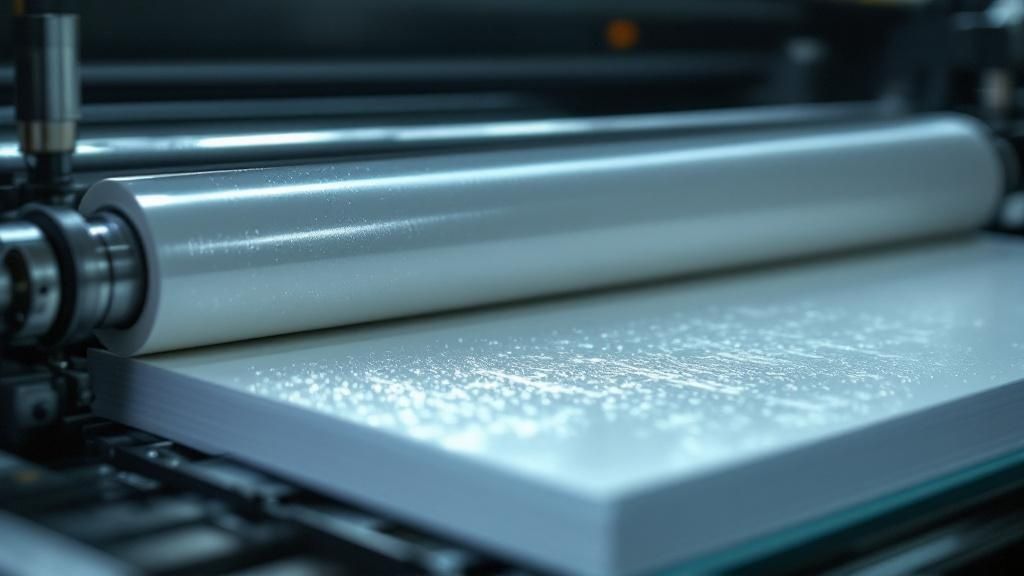

The magic happens inline, directly on the printing press. The liquid coating is applied over the wet ink and then zapped with high-intensity heat and air. This process forces the water to evaporate almost instantly, leaving behind a tough, clear polymer film that seals the ink and protects the paper. It’s an incredibly efficient method, especially for high-volume jobs like brochures, catalogs, and packaging where you need both durability and speed.

Core Attributes and Benefits

So, why is aqueous coating so popular? It really comes down to a perfect blend of performance, price, and eco-friendliness. It offers a solid layer of protection without the higher price tag or environmental drawbacks you might get with other finishes.

Here’s a quick rundown of what makes it so great:

- Scuff and Smudge Resistance: It forms a tough barrier that stands up to fingerprints, dirt, and general wear and tear during shipping and handling.

- Eco-Friendly Nature: Since it's water-based, it has extremely low levels of Volatile Organic Compounds (VOCs) and is easy to recycle.

- Fast Production: The coating dries in a flash, which means printers can move on to cutting, folding, and finishing much sooner. This really speeds up turnaround times.

- Prevents Yellowing: Forget about your printed pieces looking old and faded. Unlike some varnishes from back in the day, AQ coating resists yellowing, keeping your designs vibrant for years to come.

Aqueous coating hits that sweet spot: it’s cost-effective enough for massive print runs, protective enough for pieces that get handled a lot, and green enough to meet today's sustainability standards.

To make it even clearer, I've put together a table that breaks down the key characteristics of aqueous coating. Think of this as your quick-reference guide.

Aqueous Coating Key Characteristics at a Glance

| Attribute | Description |

|---|---|

| Composition | A clear, water-based liquid with acrylic polymers and resins. |

| Application | Applied inline on a printing press and dried quickly with heat and air. |

| Protection Level | Offers good resistance to scuffs, fingerprints, and minor abrasions. |

| Environmental Impact | Low in VOCs (Volatile Organic Compounds) and fully recyclable. |

| Drying Speed | Dries almost instantly, speeding up the overall production timeline. |

| Finish Options | Available in gloss, satin, matte, and specialty soft-touch finishes. |

| Cost-Effectiveness | Generally more affordable than UV coating and some specialty varnishes. |

This table really sums up why aqueous coating has become a go-to choice for so many different print projects. It’s a versatile, reliable, and responsible option.

How Aqueous Coating Actually Works

To really get a feel for how aqueous coating works, don't think of it as a separate, extra step. It’s better to picture it as the final act of the printing process itself. The magic happens "inline," which is just a fancy way of saying the coating is applied on the very same press that just laid down the ink. This seamless integration is why it’s a go-to for big print runs.

At its heart, the coating is a water-based liquid. We're talking about a mixture that's typically 70% to 80% water, blended with acrylic polymers and resins. This simple, water-heavy recipe is what gives the coating its eco-friendly credentials.

The Application and Drying Process

The action starts the second a sheet of paper is done with the ink stations on a press. Before the fresh ink can even think about smudging, the sheet is whisked away to a dedicated coating unit right on the machine. Here, a thin, perfectly even layer of the aqueous solution is spread over the entire surface.

Think of it like a tiny, high-speed squeegee pulling a clear, protective film over your design. Once coated, the sheet zips under a gauntlet of high-intensity heaters and powerful air jets. This is where the real transformation happens.

The combination of intense heat and airflow forces the water in the coating to evaporate in a flash. What’s left behind is a solid, clear layer of polymer that has bonded with the paper fibers, sealing the ink underneath. This creates that durable, protective shield aqueous coating is famous for.

It's a lot like how water-based paint dries on a wall, but supercharged—it all happens in seconds, not hours. This incredible speed is a massive win in the world of commercial printing. It means the printed sheets can be handled, cut, and folded almost immediately without smearing or scuffing the final product.

Why This Method Excels in Modern Printing

This inline approach makes aqueous coating a perfect match for high-volume jobs, solidifying its place as a workhorse in modern offset printing. Since everything from inking to coating and drying happens in one fluid, continuous pass, production time gets slashed and the risk of handling errors plummets.

- Speed and Efficiency: Sheets come off the press ready for the next stage, whether that's binding, folding, or shipping.

- Consistent Quality: The automated inline process guarantees every single piece gets a uniform, flawless finish.

- Cost-Effectiveness: By folding the coating step into the main printing run, there's no need for a separate offline machine, which saves a ton of time and money.

In the end, this smooth, integrated workflow is what makes aqueous coating such a smart and reliable choice. It takes a standard printed sheet and turns it into a tough, professional-looking product without slowing down the relentless pace of commercial production.

The Real Benefits of Choosing Aqueous Coating

The buzz around aqueous coating isn't just hype. It’s a smart move for anyone who cares about quality, durability, and responsibility. Choosing this finish brings some serious, real-world advantages to the table, protecting everything from your printed materials to the planet.

One of the biggest wins is its incredible scuff and fingerprint resistance. Picture a catalog getting tossed in the mail or a brochure being passed from hand to hand at a trade show. Aqueous coating acts like an invisible suit of armor, keeping your materials looking sharp and clean long after they leave the press.

This simple protective layer prevents the kind of wear and tear that can make a brand look cheap. The result? Fewer damaged pieces and a consistently professional image that builds trust.

Speed Up Production, Not Down on Quality

In the printing world, time is everything. Aqueous coating dries almost instantly right on the press, which is a game-changer for speeding up production schedules. There's no waiting around for the finish to cure, so cutting, folding, and binding can happen right away.

This quick turnaround is a massive advantage, especially when you're up against a tight deadline. Plus, unlike some old-school varnishes, aqueous coating is highly resistant to yellowing. Your prints will keep their true colors for years, protecting your brand’s visual identity.

The dual benefit of speed and longevity makes aqueous coating a practical workhorse. It helps you get products to market faster while ensuring they continue to look great long after they've been delivered.

A Greener Way to Print

Beyond the practical perks, using aqueous coating says something positive about your company's values. Since it's water-based, it contains very low levels of Volatile Organic Compounds (VOCs)—the nasty pollutants common in solvent-based finishes. This makes the whole process safer for print workers and better for the air we breathe.

That commitment to sustainability matters more than ever to customers. By choosing a finish that's easy to recycle and has a small environmental footprint, you're aligning your brand with a greener future. To see more ways to make sustainable choices, check out our guide to green printing options.

This industry-wide shift is clear. The global market for aqueous coating systems, valued at roughly $3.2 billion in 2024, is expected to jump to $5.6 billion by 2034 as more printers move away from harsh solvent-based alternatives. You can find more details on this growth over at Reports and Data.

Aqueous Coating vs Other Print Finishes

When it's time to choose a finish for your print project, the options can feel overwhelming. You've got a few different paths you can take, and picking the right one comes down to your budget, deadline, and what you want the final piece to look like.

Let's break down how aqueous coating stacks up against its two main competitors: UV coating and traditional varnish. Think of them as different tools in a toolbox—each is perfect for a specific job.

Aqueous Coating vs UV Coating

The main rival to aqueous coating is undoubtedly UV coating. This finish gets its name from the ultraviolet light used to cure it, which creates an exceptionally hard, durable, and super high-gloss surface. If you need maximum shine and protection against scuffs and scratches, UV is your go-to. It’s a popular choice for things like high-end book covers and luxury packaging.

But that top-tier performance comes with a few trade-offs. UV coating is typically more expensive than aqueous, and the chemicals and energy needed for the curing process give it a larger environmental footprint. While its protection is second to none, it can sometimes crack along folds if the paper isn't scored properly beforehand. If you're interested in using this glossy effect to highlight specific parts of a design, you can learn more about our spot UV printed products.

Aqueous Coating vs Varnish

Then we have varnish, the old-school original print finish. Varnishes come in both oil-based and water-based formulas and can be applied across the entire sheet (a "flood" varnish) or just to certain areas (a "spot" varnish). This flexibility is its biggest strength, opening the door for creative textural effects that are harder to achieve with other coatings.

The downside? Varnish takes longer to dry, which can slow down production. It's also known to yellow over time, especially the oil-based versions, which can eventually change how the colors in your design look. Aqueous coating, on the other hand, dries almost instantly and stays crystal clear for the life of the piece, keeping your colors vibrant and true.

To make the choice clearer, let's put these three finishes side-by-side.

Aqueous vs UV Coating vs Varnish: A Head-to-Head Comparison

This table breaks down the essential differences between the three most common print finishes, helping you see at a glance which one might be the best fit for your next project.

| Feature | Aqueous Coating | UV Coating | Varnish |

|---|---|---|---|

| Finish Options | Satin, gloss, matte, soft-touch | High gloss is standard; matte available | Gloss, satin, matte |

| Durability | Good scuff and rub resistance | Excellent; very hard and durable | Fair to good, depending on the type |

| Drying Speed | Very fast (inline with press) | Instant (cured with UV light) | Slowest of the three |

| Cost | Cost-effective; often the cheapest | Most expensive option | Mid-range price point |

| Yellowing | Non-yellowing | Non-yellowing | Prone to yellowing (especially oil-based) |

| Environmental | Eco-friendly; water-based, low VOCs | Higher energy use and chemicals | Oil-based has high VOCs; water-based is better |

Ultimately, each coating has its place. Varnish offers creative flexibility, and UV provides unmatched protection and shine. But for a huge range of everyday print jobs, aqueous coating hits the sweet spot.

Aqueous coating often represents the ideal middle ground. It provides excellent scuff resistance, dries quickly, resists yellowing, and is environmentally friendly—all at a cost-effective price point that makes it suitable for a wide range of applications.

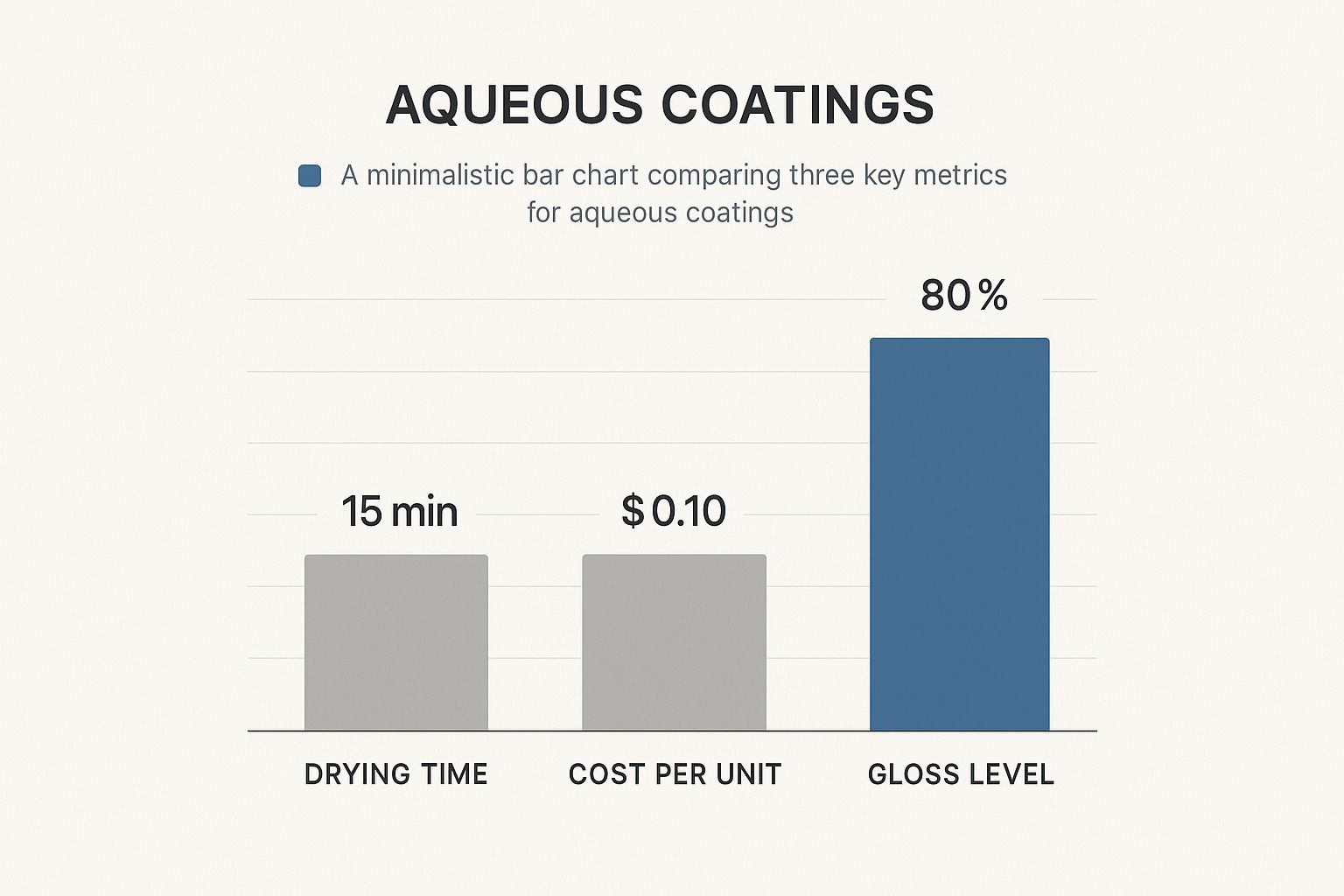

This visual helps illustrate where aqueous coating shines, balancing speed, cost, and the quality of the finish.

As you can see, it delivers a great-looking gloss at a low per-unit cost, all without slowing down the printing process.

This balance is why water-based solutions are becoming so popular. The entire industrial coatings market, valued globally at USD 149.72 billion in 2023, is seeing a shift toward coatings with a lower environmental impact. The reduced volatile organic compound (VOC) emissions of waterborne coatings like aqueous are a major reason for their growing popularity. For most everyday printing needs, aqueous coating offers a reliable, balanced, and smart solution.

Where You'll Find Aqueous Coating in Action

You’ve probably handled a dozen items with an aqueous coating on them today without even noticing. It’s a true workhorse in the printing world—a quiet, invisible layer that shows up on everything from your junk mail to the latest bestseller at the bookstore.

Its most common stomping ground is in marketing and promotional materials. That sleek, professional feel of a high-quality brochure? That's often aqueous coating at work. It's the same finish that keeps presentation folders and catalogs from looking beat up, ensuring a brand’s message arrives crisp and clean, free of smudges and fingerprints. To see how a professional finish elevates marketing materials, explore our high-quality brochures printing options.

Basically, if a printed piece has to survive a tough journey, aqueous coating is usually involved.

Protecting Goods from Production to Customer

Direct mail is a perfect example. A postcard needs to endure the rough and tumble of the postal system—all that sorting machinery and handling. An aqueous finish gives it the resilience to show up in a mailbox looking sharp, not scuffed and worn out. It acts as a shield against dirt and moisture, protecting the ink underneath.

Publishing is another industry that relies on it heavily. That pleasant, smooth feel of a new book cover or magazine? That's the coating. More importantly, it protects them from the wear and tear of being picked up, thumbed through, and put back on the shelf by countless potential readers. Beyond just protection, the right finish is a key part of crafting an effective book cover—it’s the first handshake a story has with its reader.

Product packaging is another huge arena. Think about boxes for electronics, cosmetics, or food products. That coating is what keeps them looking great on the shelf after a long trip from the factory.

By preventing scuffs and abrasions during shipping and stocking, aqueous coating helps products look their best at the critical moment a customer sees them for the first time.

This isn't just a niche product; it's a massive, growing market. The global demand for water-based solutions is surging. In fact, the waterborne coatings market was valued at USD 57.67 billion in 2022 and is expected to grow at a compound annual growth rate of 5.6% through 2030. This growth is largely fueled by the worldwide push for more sustainable, low-emission products. You can read the full research on this growing market to see just how big this trend has become.

How to Choose the Right Aqueous Finish

Picking the right finish for your print job is a bigger deal than you might think. It’s not just a protective layer; it’s a crucial design choice that shapes how people perceive your brand. Every aqueous coating has its own personality, and the trick is to find the one that matches the message you want to send.

Think of it like picking out a new shirt. Are you going for a sharp, shiny look for a night out, or something more muted and sophisticated for a business meeting? The finish on your print project works the same way, setting the tone before a single word is read.

Decoding the Different Finishes

Let's walk through the most common aqueous finishes you'll encounter. Each one brings something unique to the table, both in how it looks and how it feels, so knowing the difference is key to getting the result you want.

Gloss Finish: If you want your colors to pop and grab immediate attention, gloss is your go-to. It creates a shiny, reflective surface that makes images look vibrant and dynamic. This is why it’s a classic choice for things like sales flyers, brochures, and catalog covers—anything that needs to stand out in a crowd.

Matte Finish: For a more understated, modern vibe, you can't go wrong with a matte finish. It has a smooth, non-reflective surface that cuts down on glare, giving your project an air of sophistication. It feels premium to the touch, making it a perfect fit for high-end lookbooks, art prints, or business cards that aim for quiet confidence.

Satin Finish: Can't decide between shiny and subtle? Satin is the happy medium. It offers a gentle, low-level sheen that’s elegant without being flashy. It still provides good scuff protection and keeps colors looking sharp, but with a softer look than full gloss. It's a fantastic, versatile choice for almost anything, from book covers to annual reports.

The most impactful finishes often appeal to more than just sight. A unique texture can make a simple print piece unforgettable, transforming it from a disposable item into a memorable brand experience.

If you’re aiming for a piece that people simply can't put down, there’s one more finish you need to know about. A soft-touch coating adds a velvety, almost rose-petal-like texture that’s incredibly satisfying to hold. This tactile quality creates a powerful sensory connection, making it an amazing choice for luxury packaging or high-end invitations.

You can explore these kinds of unique and interactive options in our specialty printing collection.

Frequently Asked Questions About Aqueous Coating

You've got the basics down, but a few practical questions always pop up when it's time to actually choose a finish. Let's tackle the common ones so you can feel totally confident in your decision.

Here are the details that really matter when you're finalizing your next print job.

Can You Write on Aqueous Coating?

Yes, you absolutely can—but the finish you choose makes all the difference. A matte or satin aqueous coating has just enough tooth for a ballpoint pen or permanent marker to grab onto, so writing is no problem.

The trouble starts with a high-gloss finish. Its slick, non-porous surface makes ink bead up and smudge instead of drying properly. If you know people will need to write on the final piece, like on a response card or a sign-up sheet, stick with a matte finish. Another great trick is to simply ask your printer to leave a specific box or area uncoated.

Is Aqueous Coating Fully Waterproof?

Aqueous coating is water-resistant, but it's not truly waterproof. It does a fantastic job protecting your prints from everyday hazards like fingerprints, humidity, and minor drips or spills. That resistance is what keeps the ink from smearing and the paper from getting wavy after a small splash.

Think of it like a good raincoat, not a submarine. It'll keep you dry in a drizzle, but it's not meant for a deep-sea dive.

If your project needs to withstand serious moisture—like an outdoor sign or a restaurant menu—lamination is the way to go for truly waterproof protection.

Does This Coating Affect Print Colors?

Since it's a clear coating, its effect on color is pretty minimal and really just depends on the finish you select.

- Gloss finishes make colors look a bit deeper and more vibrant. The shiny surface bounces more light back at you, making everything pop.

- Matte finishes tend to soften colors, creating a more muted, sophisticated look because they scatter light instead of reflecting it directly.

When exact color matching is critical for your brand, your best move is always to ask for a printed proof. This lets you see firsthand how the coating and your color palette play together before you commit to the full run.

At 4OVER4, we specialize in high-quality printing with a huge range of finishes to bring your ideas to life. Explore our printing services and find the perfect finish for your next project today!

More from what is aqueous coating

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

64

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

106

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

105

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

332

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026