- Home

- content hub

- Explore Different Types of Print for Your Projects

Explore Different Types of Print for Your Projects

Emma Davis

Content Writer

Oct 7, 2025236 views

Oct 7, 2025236 views

When you're ready to get something printed, the two biggest names you'll hear are digital and offset. They're the workhorses of the printing world, but they're built for completely different jobs. Think of digital printing as your go-to for quick, smaller projects, while offset is the undisputed champ for massive print runs where quality is king.

Knowing which one to choose is the first step in making sure your project turns out exactly how you envisioned it.

A Roadmap to the World of Printing

Before we get into the nitty-gritty, let’s keep it simple. Picking a printing method is like choosing the right tool from a toolbox. You wouldn’t use a sledgehammer to hang a picture, right? The same logic applies here. The right process is everything, whether you're printing a stack of business cards, a run of glossy brochures, or even some custom t-shirts.

This one decision ripples through your entire project, affecting everything from your budget to the final look and feel. A small batch of flyers for a local bake sale has completely different needs than a million-copy run of a national magazine. One demands speed and affordability for a small quantity, while the other requires flawless quality and the lowest possible price-per-piece at a massive scale.

Why Choosing the Right Print Type Matters

Get this choice right, and your project will look amazing without breaking the bank. Get it wrong, and you could be looking at budget overruns or a final product that just doesn't hit the mark.

For example, if you chose offset printing for just 50 posters, you'd be paying a ton for setup costs that don't make sense for such a small job. On the flip side, using digital printing for 50,000 catalogs would mean missing out on the huge cost savings that offset offers when you print in bulk.

This guide is your roadmap. We'll break down the essentials behind the major printing methods so you can feel confident in your choices. We’re going to cover:

- Core printing technologies and how they work (in plain English!).

- The strengths and weaknesses of each method.

- Real-world examples so you know exactly when to use each one.

- Key factors like quantity, quality, and turnaround time that will guide your decision.

By the time you're done here, you'll be able to stop guessing. You'll have the practical know-how to pick the best printing method for any project, ensuring your vision comes to life just as you imagined. This is the foundational knowledge you need to talk to printers like a pro and get top-tier results every single time.

Digital Printing for Speed and Flexibility

Think of digital printing as a supercharged version of the printer sitting in your office. It takes a digital file—like a PDF or JPG—and prints it directly onto paper, much like an inkjet or laser printer does at home.

Unlike traditional methods that rely on custom metal plates to transfer ink, digital printing skips that whole step. This one difference is what makes it so incredibly fast and flexible, earning it a top spot among modern types of print.

Because there are no plates to create, the setup time is virtually zero. The first print is ready almost instantly, which makes it remarkably efficient and budget-friendly for small to medium-sized jobs. We're talking about everything from a handful of business cards to a few hundred event flyers.

The Power of Print-on-Demand

This direct-to-print technology is the engine that drives the entire Print-on-Demand (POD) industry. POD allows artists, creators, and small businesses to sell custom-printed products like t-shirts, mugs, and posters without ever touching inventory.

Here’s how it works: an order comes in online, the item is printed, and it ships directly to the customer. It's a game-changer that minimizes financial risk and practically eliminates waste.

The global POD market was valued at $8.16 billion and is expected to skyrocket to nearly $19.8 billion as people continue to seek out unique, personalized items. In fact, 48% of shoppers are willing to wait longer for custom-made goods, showing that personalization is now a mainstream expectation.

Key Takeaway: Digital printing is all about speed, flexibility, and personalization. It’s the go-to choice for jobs that need a quick turnaround, variable data (like names on invitations), or cost-effective small batches.

When to Choose Digital Printing

So, is digital the right fit for your project? The answer really comes down to what you need. It shines in situations where old-school printing would be too slow, too expensive, or just plain overkill.

For a closer look at all the things you can create, check out our guide on professional digital printing services.

Here are the perfect scenarios for going digital:

- Small Print Runs: Ideal for quantities under 1,000 units. Think startup business cards, flyers for a local gig, or a small batch of marketing brochures.

- Fast Turnarounds: Need materials for a trade show tomorrow? Digital is your best friend. Many projects can be printed and ready the same day.

- Personalized Content: Perfect for direct mail campaigns where every postcard has a different name and address, or for custom wedding invitations where each one is unique.

- Proofing and Prototypes: Want to see exactly how your booklet or catalog will look before committing to a massive order? Digital printing gives you an accurate, affordable proof.

Offset Printing for Quality at Scale

While digital printing is the champion of speed and flexibility, offset printing—also called lithography—is the undisputed king for large-scale projects where quality is absolutely non-negotiable. It's a traditional, powerhouse method among the different types of print, trusted for decades by major publishers and businesses for a reason.

Think of it like a highly advanced rubber stamping process. Your design is first etched onto a metal plate. That plate is inked, and the image is transferred (or "offset") onto a rubber blanket. Finally, that rubber blanket presses the image onto the paper. The result? An exceptionally crisp, clear, and consistent print.

This indirect transfer method is clever because it protects the delicate metal plates from the wear and tear of direct contact with paper. This allows for millions of identical impressions without a single drop in quality, making it the only real choice for high-volume jobs where every single copy has to be perfect.

The Trade-Off Between Cost and Volume

The defining feature of offset printing is its setup. Creating the custom plates for a job requires an initial investment of time and money, which makes it a tough sell for small, one-off runs. However, once that press starts rolling, the cost per piece plummets. Fast.

This is where the economics of offset truly shine. While the upfront investment is higher, the per-unit cost on large orders is dramatically lower than digital printing. That makes offset incredibly cost-effective for projects like:

- Magazines and Newspapers: Churning out thousands or even millions of copies with rock-solid consistency.

- Books and Catalogs: Ensuring every single page is sharp and colors are uniform from the first copy to the last.

- Large-Scale Marketing Materials: Printing thousands of brochures, posters, or direct mailers for a big campaign.

Key Insight: Offset printing is an investment in scale. The more you print, the cheaper each individual item becomes, delivering professional quality at a price that digital methods can’t touch for massive quantities.

Unbeatable Quality and Color Precision

Beyond the cost savings at scale, offset printing simply delivers superior image quality. The process allows for finer detail and much richer color depth than most digital methods. But its real superpower is the ability to use Pantone Matching System (PMS) inks.

Unlike the standard CMYK (Cyan, Magenta, Yellow, Black) color mixing used in digital printing, Pantone inks are pre-mixed to exact color formulas. This is a game-changer for brands. It guarantees that a company's signature blue or a specific product's red will be perfectly consistent across every single printed item, every single time. To see what this method is capable of, you can explore professional offset printing solutions that really show off its full potential.

The bottom line is simple. For large projects that demand flawless execution, vibrant colors, and maximum cost-efficiency per piece, offset printing is the industry standard. It’s the proven workhorse that delivers premium results when you need to make a massive impact.

Choosing the Right Print Method for Your Project

Knowing the difference between big-name printing methods like digital and offset is a great start, but the real trick is knowing how to apply that knowledge to your actual projects. Making the right call from the get-go isn't just about avoiding headaches; it's about saving real money and making sure the final product looks exactly like you imagined.

The choice really boils down to a handful of key factors. Before you even pick up the phone to call a printer, running through these simple questions will point you in the right direction and make the whole process a lot smoother.

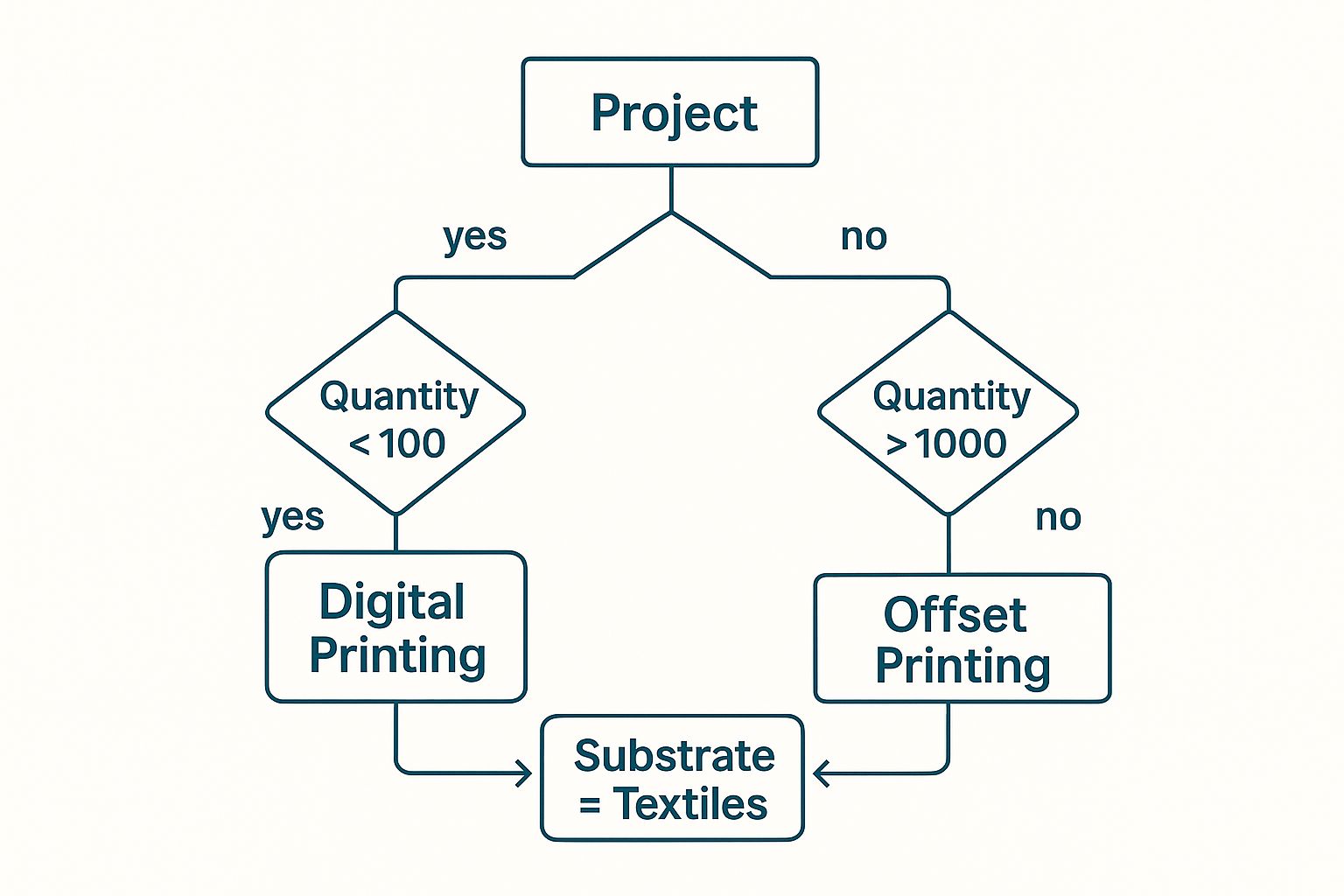

This decision tree gives you a quick visual on how to start thinking about your project's core needs.

As you can see, two of the biggest questions—how many you need and what you're printing on—can instantly narrow your options and lead you to the most practical, budget-friendly solution.

Key Factors for Your Decision

To feel confident in your choice, just weigh your project against these four critical points. Each one plays a huge role in figuring out which printing technique is the perfect match for your budget and goals.

Project Quantity: Let's talk numbers. How many pieces are you printing? For smaller jobs, typically anything under 1,000 units, digital printing is almost always the more affordable route because it has zero setup costs. But once you get into large runs, offset printing’s per-unit price drops dramatically, offering some serious savings.

Required Quality and Color: How picky do you need to be with your colors? If you need a perfect, spot-on color match using the Pantone system, offset is your best friend. It’s crucial that your printed materials align with your company's visual identity, which often means developing effective brand guidelines to keep everything consistent.

Turnaround Time: How fast do you need it? Digital printing was practically built for speed, with some jobs being turned around in just a few hours. Offset printing, on the other hand, is more of a marathon than a sprint. It involves a longer setup with plate creation and ink drying time, making it a better fit for projects that aren't on a tight deadline.

Material and Finishing: What’s the canvas for your masterpiece? Both methods are great with standard paper, but if you're venturing into specialty materials or unique finishes, one process might be a better fit than the other. Adding a protective layer is often a great final touch, and you can explore options like custom laminating services to boost both durability and visual pop.

By carefully weighing these four factors—quantity, quality, speed, and material—you can strategically select the most appropriate printing method. This structured approach guarantees a result that aligns perfectly with your budget, timeline, and creative vision every time.

Digital vs Offset Printing A Quick Comparison

Sometimes, seeing things side-by-side makes the decision crystal clear. This table breaks down the core differences between digital and offset printing to help you quickly figure out which one is the right fit for your job.

| Factor | Digital Printing | Offset Printing |

|---|---|---|

| Best for Quantity | Small to medium runs (under 1,000) | Large runs (over 1,000) |

| Cost | Low setup cost, higher per-unit cost | High setup cost, lower per-unit cost |

| Speed | Fast turnaround, often same-day | Slower turnaround due to setup |

| Color Quality | Good color accuracy (CMYK) | Superior color accuracy (Pantone) |

| Customization | Excellent for variable data printing | Not suitable for variable data |

| Material Options | Good range of standard materials | Widest range, including specialty stocks |

Ultimately, there's no single "best" method—just the best method for your project. Use this table as a quick reference, and you'll be well on your way to making a smart, cost-effective choice that brings your vision to life.

Step away from the everyday digital and offset printers, and you’ll discover a whole world of specialized techniques. These are the masters of their craft, each designed to tackle very specific challenges.

Think of these methods as the special ops of the printing world. They handle everything from the flexible packaging on your favorite snacks to the bold graphics on a concert t-shirt. Getting to know them expands your creative toolkit and shows you just what's possible for those truly unique projects.

One of the most common, yet often invisible, methods is Flexography. At its core, it’s like a super-sophisticated, high-speed version of a potato stamp. A flexible photopolymer plate gets wrapped around a rotating cylinder, picks up ink, and rapidly stamps the design onto the material. It’s brilliant for printing on non-porous surfaces like plastic, foil, and cellophane.

This makes flexography the undisputed king of packaging, labels, and anything else that comes on a roll. The next time you open a bag of chips or peel the label off a soda bottle, you're almost certainly holding the handiwork of a flexo press. For sheer speed and durability on a massive scale, nothing else comes close for these applications.

Screen Printing for Bold and Durable Designs

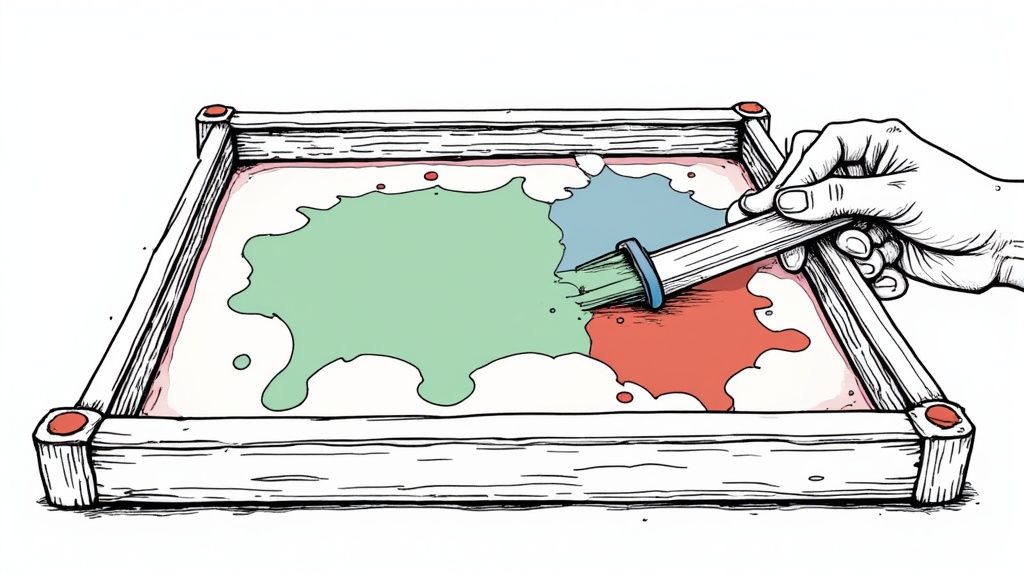

Another incredibly popular technique is Screen Printing, which you might also know as silkscreening. The process is straightforward but effective: ink is pushed through a mesh screen onto a surface. A stencil blocks out parts of the screen, letting the ink pass through only in the shape of your design.

The result is a thick, vibrant, and incredibly durable layer of ink that sits right on top of the material instead of soaking in. This is exactly why screen printing is the champion for apparel—like t-shirts and hoodies—as well as posters and promo items where you need bold, opaque colors that last. These prints can handle countless washes and years of wear without fading.

Did You Know? Screen printing opens the door to some really cool effects that other methods struggle with. Using specialty inks, you can create unique textures like puff prints, shimmering metallic shines, and even glow-in-the-dark designs. It’s a great way to add a tactile and visual flair that makes your project stand out.

High-Volume and Large-Scale Solutions

When a project demands either extreme volume or massive scale, two other heavyweights enter the ring.

Gravure (Rotogravure): This is the absolute powerhouse for ultra-high-volume jobs. The image is actually engraved into a metal cylinder, which is then flooded with ink and pressed directly onto paper. It’s famous for its exceptional detail and consistency, making it perfect for long-run magazines, catalogs, and high-end packaging where quality can't dip, even over millions of copies.

Large-Format Printing: Just like the name suggests, this method is all about going big. Using specialized inkjet printers, it’s responsible for producing everything from giant event banners and trade show backdrops to building wraps and the graphics on city buses. If your message needs to be seen from a block away, large-format is how you do it.

These specialized techniques really show the incredible diversity of the printing industry. From the subtle elegance of foil stamping that adds a touch of luxury—a process you can explore with custom foil stamping services—to the industrial might of gravure, there’s a perfect printing solution for nearly any idea you can dream up.

What's Next for the Printing Industry?

Don't believe the rumors—print is far from a dying medium. In fact, it's constantly evolving to meet brand-new demands. The explosion of e-commerce has turned packaging into a critical branding moment, while hyper-targeted direct mail and personalized products are driving serious growth. This constant reinvention is exactly why understanding different types of print is more important than ever.

The global printing industry is on track to hit a market value of roughly $960 billion, and digital printing is leading the pack. This boom is fueled by a huge demand for short-run, customized products, from one-of-a-kind packaging to personalized marketing materials that really connect. If you're curious, you can dig into these printing industry statistics to see the full scope of this expanding market.

Innovations Shaping Tomorrow's Print

Technology isn't just improving old processes; it's pushing the boundaries of what print can even do, creating entirely new possibilities for businesses and creatives. Two areas, in particular, are paving the way forward:

- AI and Automation: Modern printing presses are getting a lot smarter. AI-powered printers can now automatically fine-tune color calibration, slash waste, and even predict their own maintenance needs. The result? A massive boost in efficiency and much lower operating costs.

- 3D Printing (Additive Manufacturing): This isn't just a novelty anymore. 3D printing is fundamentally changing how we approach manufacturing and prototyping. It allows for the rapid creation of incredibly complex, three-dimensional objects straight from a digital file, speeding up product development and making on-demand parts a reality.

These advancements all point to a clear trend: sustainability and efficiency are becoming the heart of the industry. As technology makes printing cleaner and more resource-friendly, the options for environmentally conscious projects just keep growing.

As the industry charges ahead, sustainable practices are moving from a "nice-to-have" to a "must-have." For anyone looking to minimize their environmental footprint, a great next step is learning more about the options for eco-friendly green printing.

At the end of the day, print’s remarkable ability to adapt is what guarantees its place in the future. It remains a powerful, tangible, and deeply relevant medium, no matter the era.

Common Questions About Printing Methods

Jumping into the world of professional printing can feel a bit overwhelming, but it doesn't have to be. Let's clear the air and tackle some of the most common questions people have when picking the right print method for their projects.

What Is the Most Cost-Effective Printing for Small Businesses?

For small businesses needing shorter runs, digital printing is almost always the way to go. It’s incredibly cost-effective because there are no custom plates to create or lengthy setup processes. This makes it perfect for printing smaller batches of flyers, business cards, or brochures without breaking the bank.

But what happens when you need more? Once your order size climbs past 500-1,000 pieces of the same design, offset printing often becomes the more economical choice. The cost per item drops dramatically with higher volumes, making it the clear winner for large-scale marketing campaigns.

How Do I Choose Between CMYK and Pantone Colors?

This decision really boils down to how precise you need your colors to be. Each system has its place.

Here’s a quick breakdown:

- CMYK (Cyan, Magenta, Yellow, Black): Think of this as the color system your desktop printer uses, but on a professional scale. It mixes four ink colors to create a huge spectrum of hues. It’s the standard for digital printing and is perfect for projects with photographs or designs that feature a lot of different colors.

- Pantone (PMS): This is all about precision. The Pantone Matching System uses pre-mixed inks based on specific formulas to create an exact color, every single time. If your brand has a signature color—that specific shade of blue or red—that absolutely must be consistent across all your materials, Pantone is your only guarantee. It's typically used with offset printing.

Choosing the right color model is one of the most important decisions for maintaining brand consistency. CMYK offers fantastic versatility for full-color designs, while Pantone is the undisputed champ for hitting a perfect, repeatable color match.

What Type of Printing Is Best for T-Shirts?

When it comes to printing on apparel, you've got a couple of fantastic options, and the best one depends on your design and order size.

Screen printing is the classic choice for a reason. This method pushes thick, durable inks through a stencil onto the fabric, creating bold, vibrant designs that really pop and hold up incredibly well in the wash. It's especially cost-effective for large orders with just a few colors in the design.

Another great option is Direct-to-Garment (DTG) printing. This is basically a high-tech inkjet printer made for fabric. Because it's a digital process, it excels at reproducing intricate, multi-color designs, like photographs. It’s the perfect solution for small orders or even one-off custom shirts.

Ready to bring your vision to life with the perfect print method? At 4OVER4, we offer a vast range of high-quality printing solutions tailored to your needs. Explore our services and start your project today!

More from types of print

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

64

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

106

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

105

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

332

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026