- Home

- content hub

- Print Production Management: Proven Strategies That Work

Print Production Management: Proven Strategies That Work

Emma Davis

Content Writer

Jun 2, 20252051 views

Jun 2, 20252051 views

Building Your Print Production Management Foundation

Successfully managing print production can be complex. It requires a strong foundational approach, understanding the key elements that make a print operation successful, and integrating them into a cohesive strategy. Let's explore the core principles that drive success in modern print production management.

Essential Principles For Print Production Success

High-performing print shops consistently focus on several key areas. These principles, when combined effectively, form the foundation of a successful print production management strategy. It's not just about what to do, but how to implement these principles in daily operations.

-

Efficiency: Streamlining workflows is essential. Reducing waste and optimizing resources are crucial for profitability. This might involve adopting lean manufacturing principles or investing in automation technologies.

-

Quality: Maintaining high quality standards ensures customer satisfaction and reduces costly rework. Consistent quality control checks and thorough training programs are vital for this.

-

Profitability: Balancing cost efficiency with quality and meeting client needs is the ultimate objective. Successful print managers continually analyze operations to maintain profitability.

The Evolving Landscape of Print

Consider the role of print in our digital age. Despite predictions of its demise, the printing industry remains resilient. The global printing market is expected to reach $960 billion in 2025, growing at about 2.5% annually.

This growth is driven by increasing demand in sectors like packaging, textiles, and promotional materials. The adoption of digital printing technology also contributes significantly. For more detailed statistics, check out this resource: Printing Industry Outlook

Data-Driven Decision Making in Print Production

Data-driven decision making is increasingly vital in modern print production management. Successful print managers use data analytics to gain valuable operational insights.

This data informs decisions about resource allocation, workflow optimization, and even predicting market trends. This approach allows print businesses to adapt and compete. They can anticipate demand shifts and adjust production strategies accordingly, maximizing efficiency and profitability. This strong foundation enables print businesses not just to survive, but to thrive.

Technology Solutions That Transform Print Production

Print production management has evolved. It's no longer simply about managing presses and paper. Instead, it's about integrating technology to optimize every step, from the initial order to the final delivery. This involves using solutions that not only automate tasks but also provide insightful data to improve decision-making.

AI-Powered Systems: The Future of Print Production Management

The emergence of Artificial Intelligence (AI) is a major advancement. AI is changing print production by enabling predictive maintenance, which forecasts equipment malfunctions before they happen. This minimizes downtime and helps maintain production schedules.

AI-powered inventory management systems also optimize stock levels, minimizing waste and storage expenses. For instance, AI can analyze past data to predict future paper needs, ensuring sufficient stock without excess inventory.

Furthermore, AI enhances marketing campaigns through hyper-personalization. This enables print businesses to target specific customer groups with tailored offers, boosting marketing effectiveness. Over 60% of print service providers are investing more in AI for these reasons, changing how companies improve productivity and profitability. For more statistics, see: Printing Industry Outlook

Automated Quality Control: Ensuring Consistent Excellence

Quality control is essential in print production. Automated quality control systems are now vital for maintaining consistent output quality. These systems use advanced sensors and image recognition to identify even small defects during production.

This results in fewer errors, reduced waste, and greater customer satisfaction.

Cloud-Based Management Platforms: Streamlining Operations

Cloud-based management platforms are centralizing print production management. These platforms connect all operational aspects, from order processing and job scheduling to inventory management and customer communication.

This creates a single, reliable data source, improving collaboration and streamlining workflows. The enhanced visibility enables managers to monitor progress, identify bottlenecks, and make data-driven changes in real-time.

Integrating New Systems Without Disruption

Adopting new technologies doesn't have to be disruptive. Print businesses can avoid costly downtime and maintain productivity by selecting systems that integrate smoothly with existing workflows. A phased implementation approach helps teams adapt gradually and minimizes the learning curve. Learn more: How to master offset printing.

These advancements enhance efficiency, lower costs, and improve quality throughout the print production lifecycle. By using these tools, print businesses can gain a competitive advantage.

Workflow Optimization That Actually Works

Print production management depends heavily on optimized workflows. This means going beyond the theoretical and implementing practical strategies that deliver real results. Let's delve into how successful print businesses organize their operations, from the initial job request to the final product delivery.

Eliminating Bottlenecks and Standardizing Processes

A crucial element of efficient print production management is identifying and removing bottlenecks. These holdups disrupt the smooth flow of work, leading to increased production time and higher costs. A thorough analysis of each stage of your workflow—pre-press, printing, post-press, and delivery—can help locate these bottlenecks.

Standardizing processes also contributes significantly to increased efficiency. Creating clear, documented procedures for each task promotes consistency and minimizes errors. However, standardization shouldn't come at the expense of flexibility. Adaptable workflows are essential to accommodate the diverse requirements of different print jobs.

Lean Manufacturing for Print Environments

Lean manufacturing principles, while initially developed for other sectors, can be effectively applied to print production. This method emphasizes minimizing waste in all its forms – time, materials, and labor. For instance, streamlining setup times between print jobs through standardized procedures can dramatically improve overall efficiency.

Minimizing material waste is another core principle of lean manufacturing. This involves minimizing paper waste by making accurate estimations and using efficient cutting methods. It also includes minimizing ink and other consumable usage. You might find this interesting: How to master digital printing.

Adaptable Workflows for Varying Job Requirements

Print jobs rarely fit a single mold. Different projects have unique needs, from specific paper stock and ink colors to specialized finishing techniques and varying quantities. Developing adaptable workflows ensures efficient handling of these diverse requirements without compromising quality.

This adaptability hinges on a flexible approach to resource scheduling. Assigning skilled personnel and the correct equipment to each job optimizes production flow and minimizes downtime.

Resource Scheduling, Project Management, and Quality Checkpoints

Effective print production management relies on well-planned resource scheduling. This involves strategically allocating staff, equipment, and materials to meet deadlines without overtaxing resources or creating bottlenecks. Project management software can greatly assist in this process.

Implementing quality checkpoints throughout the workflow is critical. These checkpoints help identify potential problems early on, preventing costly mistakes and maintaining consistent quality. This proactive approach minimizes the need for rework and improves customer satisfaction.

To illustrate the workflow optimization process and its benefits, let's look at a comparison table:

Introduction to the Table: The following table compares traditional print production workflows with optimized workflows. It highlights the key differences in each process stage and quantifies the efficiency gains achieved through optimization.

| Process Stage | Traditional Approach | Optimized Approach | Efficiency Gain |

|---|---|---|---|

| Job Intake | Manual entry, potential for errors | Automated data entry, reduced errors | 20% reduction in processing time |

| Pre-Press | Multiple manual checks, potential for delays | Automated preflight checks, streamlined approvals | 15% reduction in pre-press time |

| Printing | Manual press adjustments, longer setup times | Pre-set press configurations, faster setup | 10% reduction in printing time |

| Post-Press | Manual finishing, potential for inconsistencies | Automated cutting and finishing, improved consistency | 25% reduction in post-press time |

| Delivery | Manual scheduling, potential for delays | Automated scheduling and tracking, optimized delivery routes | 12% reduction in delivery time |

Conclusion of the Table: As shown in the table, optimizing each stage of the print production workflow results in significant efficiency gains, leading to faster turnaround times, reduced costs, and improved quality.

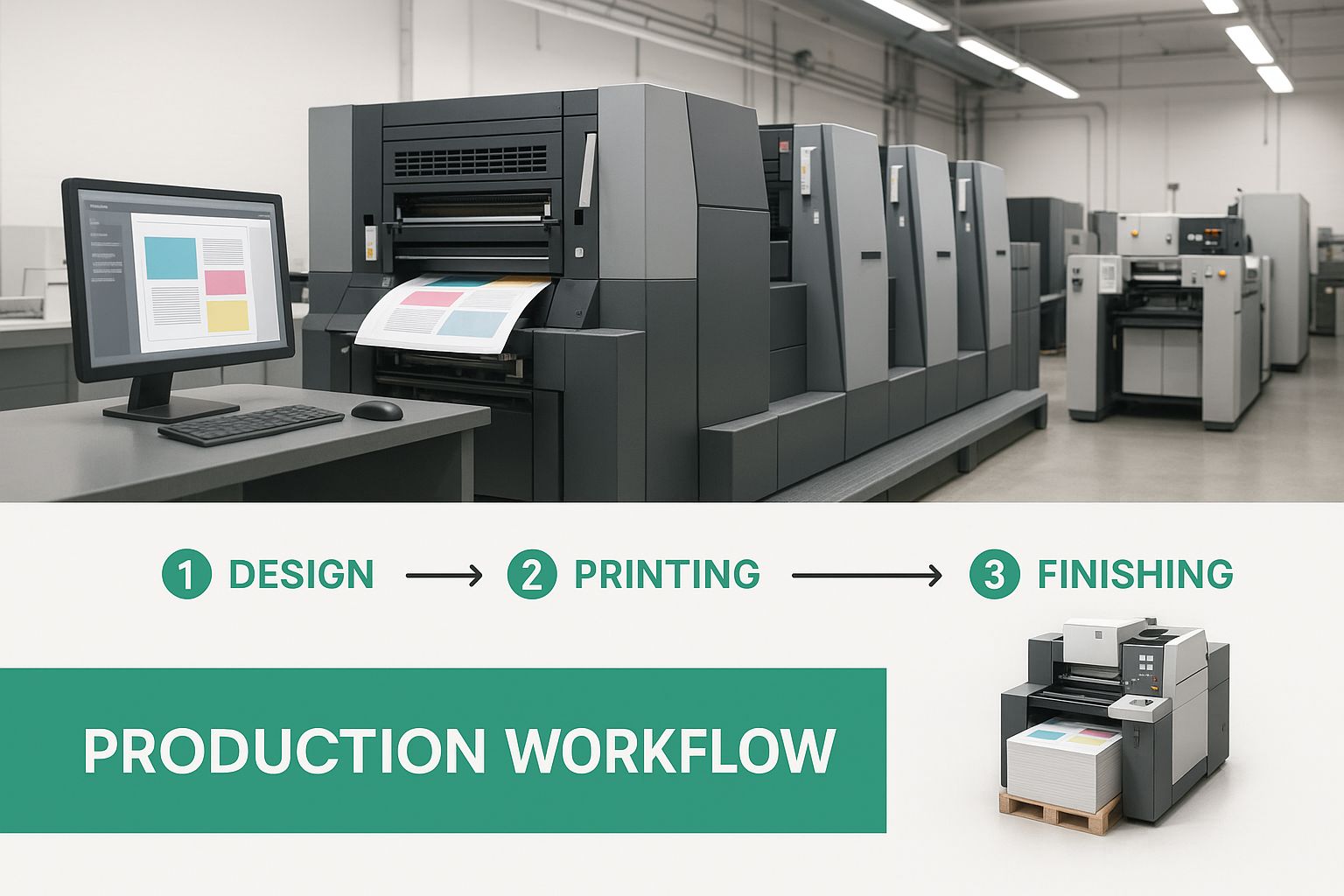

This infographic depicts a modern print production floor, visualizing the flow of a typical production workflow from job intake to final delivery. The key takeaway is the seamless integration of the different stages within the print production process, showcasing how optimization can streamline operations and improve efficiency. These strategies enable print businesses to improve efficiency, reduce waste, and enhance quality, ultimately boosting profitability and competitiveness.

Identifying High-Growth Market Opportunities

Print production management is a dynamic field, requiring businesses to adapt to the ever-shifting landscape of market demands. While some print sectors may be facing headwinds, others are flourishing, creating exciting opportunities for print businesses that can identify and capitalize on these high-growth areas.

Lucrative Niches in Print

Astute print managers are increasingly focusing on specialized print areas like custom packaging and promotional materials. These niches often command higher prices and offer better profit margins. For instance, the increasing consumer demand for personalized and environmentally friendly packaging is a trend driven by both consumer values and brand differentiation. Packaging Products offers a deeper dive into these trends.

Promotional materials are also undergoing a transformation. They’re moving beyond basic flyers and brochures, with a continued strong demand for high-quality, visually appealing marketing collateral such as custom-designed promotional products and large-format prints. Print businesses that can provide innovative and eye-catching promotional solutions are poised for success.

Emerging Markets and Profit Potential

Looking beyond established niches, emerging markets offer significant profit potential. Areas like personalized print-on-demand products, short-run specialty publications, and localized printing services are prime examples. These sectors typically demand agile production and a strong customer focus.

The production printer market, essential for high-speed, high-volume output, is projected to experience substantial growth. Expected to reach $9,423.3 million by 2025, this market is forecasted to hit $18,886.4 million by 2035, demonstrating a robust compound annual growth rate (CAGR). This expansion is fueled by the growing demand for efficient print production management across various sectors, including commercial printing, publishing, packaging, and transactional printing. Learn more about this expanding market: Production Printer Market.

Adapting Production for High-Value Clients

Successfully capturing these opportunities requires adapting production capabilities to meet the specific needs of clients. This might involve investing in new technologies, providing staff training, or adjusting existing processes. The potential return on these investments, however, can be significant. By focusing on high-value clients and offering specialized services, print businesses can cultivate a sustainable competitive edge and enjoy healthier profit margins.

Diversification and Sustainable Growth

Thriving print businesses understand the importance of diversification. They are expanding their service offerings and exploring new revenue streams to mitigate risk and position themselves for long-term, sustainable growth. Staying ahead of market trends, proactively adapting to changing demands, and staying informed about shifting consumer preferences and technological advancements are key to building resilience and ensuring future success within the dynamic printing industry.

Quality Control Systems That Prevent Problems

Quality in print production isn't just a happy accident; it's the result of carefully constructed and diligently maintained systems. This exploration delves into how successful print operations leverage quality management strategies to not only meet but exceed customer expectations, all while minimizing waste and reducing the need for costly rework.

Automated Quality Checking Systems: Ensuring Precision

Leading print businesses are increasingly integrating automated quality checking systems into their workflows. These systems utilize advanced technologies like sensors and image recognition software to detect defects early in the production process, allowing for real-time adjustments. This proactive approach prevents errors from making their way to the final product.

For example, an automated system can pinpoint color inconsistencies or registration issues during a press run. Operators can then correct the problem immediately, saving valuable time and materials. Ultimately, this focus on early detection reduces waste and ensures adherence to stringent quality standards.

Color Management Protocols: Maintaining Consistency

Color management is paramount for accurate and consistent color reproduction in print. Achieving precise color matching is crucial for maintaining brand integrity and satisfying customer expectations. Effective color management protocols involve a multi-pronged approach.

This includes calibrating equipment, utilizing standardized color profiles, and conducting regular quality checks. These meticulous steps ensure that the colors displayed on a screen translate accurately to the printed piece, minimizing discrepancies and delivering consistent results across different print runs.

Inspection Procedures: Catching Errors Early

Thorough inspection procedures are essential for identifying errors before they affect the final deliverables. These procedures incorporate systematic checks at various stages of the production process, from pre-press all the way to post-press.

Trained inspectors carefully examine printed materials for a range of potential defects. This can include misregistration, color variations, and finishing flaws. This meticulous examination helps identify and rectify issues early on, preventing them from reaching the customer and reducing the need for costly reprints. For further reading, explore our article on quality control systems.

Statistical Process Control and Quality Metrics

Statistical process control (SPC) involves collecting and analyzing data to monitor and control the production process. By tracking key quality metrics, print operations can identify trends, predict potential problems, and make data-driven decisions to improve quality.

Tracking the number of misprints per run, for instance, can help identify patterns and address underlying issues that contribute to errors. Establishing meaningful metrics provides a quantitative basis for evaluating performance and implementing targeted improvements.

To illustrate the importance of tracking key metrics and maintaining industry standards, let's look at the following table:

Quality Control Metrics And Benchmarks: Key performance indicators for print production quality management with industry benchmarks and target ranges.

| Quality Metric | Industry Standard | Best Practice Target | Measurement Method |

|---|---|---|---|

| Color Accuracy | Delta E < 2.0 | Delta E < 1.5 | Spectrophotometer |

| Registration Accuracy | +/- 0.5 mm | +/- 0.25 mm | Registration Target |

| Dot Gain | 18-22% | 20% | Densitometer |

| Print Density | 1.6-1.8 | 1.7 | Densitometer |

| Ink Coverage | 95-105% | 100% | Image Analysis Software |

This table highlights some of the crucial measurements used in quality control. By striving to meet or exceed these benchmarks, print providers can ensure consistent, high-quality results.

Feedback Loops and Continuous Improvement

Integrating feedback loops into the quality control process is fundamental for continuous improvement. This means gathering feedback from various stakeholders, including customers, production staff, and other key players in the process. This feedback provides valuable insights into areas ripe for improvement.

Regularly reviewing quality metrics and feedback allows print operations to refine processes, enhance quality control procedures, and ensure the continuous evolution of print production standards. This commitment to ongoing improvement enables printers to adapt to changing market demands and maintain a competitive edge.

Balancing Speed and Precision in High-Volume Production

Leading print production managers excel at balancing speed and precision, even in high-volume production environments. This involves implementing quality control measures that don't significantly impede production speed.

Effective training programs for production teams are critical for maintaining consistent quality while preserving efficiency. By strategically integrating technology, print businesses can automate many quality control checks, reducing the dependence on manual inspection and facilitating faster production speeds without compromising quality.

Building Resilience Through Adaptive Management

The print industry is in constant flux. Recent challenges have underscored the importance of resilience in print production management. This isn't just about surviving tough times; it's about adapting and flourishing even when things are uncertain. Let's explore how successful print operations achieve this.

Strategic Planning and Adaptability

Resilient print businesses are proactive, not reactive. Strategic planning is essential. This means forecasting market trends and building flexibility into their operations.

This might involve diversifying product offerings, finding alternative suppliers, or investing in adaptable technology. This foresight allows print businesses to quickly adjust to disruptions and minimize any negative impact.

For example, if there are supply chain problems, having backup suppliers allows a print business to keep producing and fulfilling orders even when their main supplier is unavailable. For more helpful advice, check out our guide on training materials.

Real-World Examples of Resilience

Many print businesses have successfully weathered recent storms. Some have thrived by adopting flexible production models, allowing them to adjust to changes in demand. Others have solidified their market positions by providing reliable service and building stronger client relationships during uncertain periods.

Some businesses have created multiple revenue streams by expanding their print services. This diversification protects them against downturns in specific market segments, making them more stable overall.

Practical Strategies for Building Flexibility

Operational flexibility is crucial for resilient print production management. This involves creating contingency plans to handle potential issues, such as supply chain disruptions or equipment failures.

These plans should outline clear steps to take in different crisis scenarios, ensuring a rapid and effective response. Building relationships with multiple suppliers is also important.

This reduces reliance on a single source, lessening the impact of problems with any one supplier. This creates a stronger, more adaptable supply chain, contributing to overall resilience.

Leveraging Crisis as Opportunity

Resilient print managers see crises not as setbacks, but as chances to grow. They use difficult situations to improve their market position and build stronger customer relationships.

By consistently providing reliable service, even during disruptions, they build customer trust and loyalty. Industry surveys show that 14% of print businesses saw revenue increase by over 10% in 2024 compared to 2023, and 21% reported stable or slightly improved results.

This adaptability is a key characteristic of successful print production management. Companies using digital transformation and flexible models are best placed for future growth. Want to learn more? Take a look at this Printing Outlook.

These strategies enable print businesses not just to survive tough times, but to become stronger and better prepared for future success. By focusing on proactive planning, adaptable operations, and a customer-focused approach, they build resilience to thrive in a changing market.

Key Takeaways

Print production management isn't simply about overseeing the printing process. It's about strategically coordinating resources, technology, and workflows to deliver top-notch products efficiently and profitably. This section highlights actionable strategies for achieving excellence in print production, incorporating industry best practices and real-world examples.

Building a Strong Foundation

Effective print production management starts with a robust foundation built on efficiency, quality, and profitability. Just like constructing a building, a weak foundation compromises the entire structure. Prioritizing streamlined workflows, consistent quality control, and data-driven decision-making creates a solid base for your print operations.

Embracing Technological Advancements

Technology is essential in modern print production. Integrating AI-powered systems for predictive maintenance and inventory optimization can drastically improve efficiency. Automated quality control systems, like those offered by Enfocus, enhance consistency and reduce waste. Cloud-based platforms centralize operations and offer real-time insights. Adopting these technologies can significantly improve your print production process.

Optimizing Your Workflow

A well-optimized workflow operates like a well-oiled machine, with every component working seamlessly to maximize output. Identifying and eliminating bottlenecks is crucial. Standardizing processes and implementing lean manufacturing principles minimize waste and improve efficiency. Maintaining flexibility is key for adapting to various job requirements.

Identifying Growth Opportunities

While some print market segments might be stagnant, others are flourishing. Astute print managers focus on high-growth areas like custom packaging and specialized promotional materials. Identifying these profitable niches and adapting your production capabilities can unlock new revenue streams and bolster profitability.

Prioritizing Quality Control

Maintaining high quality standards isn't just about meeting customer expectations. It's also about minimizing costly errors and rework. Implement comprehensive quality control systems that include automated checks, robust color management protocols using tools like GMG Color, and thorough inspection procedures. This proactive approach ensures consistent quality, boosts customer satisfaction, and protects profits.

Adapting to Change

The print industry is dynamic. Resilience is essential for navigating uncertainty. Develop adaptable workflows, create contingency plans, and diversify your offerings to mitigate risk and ensure business continuity. Embracing change and proactively adapting to new market conditions positions your print operation for long-term success.

Implementing These Key Takeaways

Begin by evaluating your current operations. Identify areas for improvement and prioritize implementing these key takeaways based on your specific business needs and goals. Set realistic timelines and establish measurable milestones to track progress. Continuous improvement is an ongoing process. Celebrate successes and continually strive for operational excellence.

Ready to transform your print production? Explore the printing solutions offered by 4OVER4 and discover how we can help you achieve print production mastery.

More from print production management

10

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

22

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

86

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

97

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

122

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

108

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

373

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

337

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026