- Home

- content hub

- Print Color Matching Tips: Your Professional Guide

Print Color Matching Tips: Your Professional Guide

Emma Davis

Content Writer

Jun 10, 20251554 views

Jun 10, 20251554 views

Why Print Color Matching Changes Everything

Imagine: you've spent weeks perfecting a client's logo. You finally landed on the perfect shade of teal—one that whispers tranquility and trust. But when the printed brochures arrive, that tranquil teal has become a screaming turquoise. Ouch.

This common scenario highlights why print color matching is so vital. It's the bridge between your digital vision and the tangible, printed reality.

And it's not just about aesthetics. Color mismatches directly impact your bottom line. Inconsistencies chip away at brand recognition. Think Coca-Cola's red or Tiffany's blue. These brands meticulously control their color reproduction. Why? Because accurate color strengthens brand identity and builds customer confidence.

In fact, studies reveal that color consistency can boost brand recognition by up to 80%. That translates into loyal customers and higher sales.

The Science and Psychology of Color

Print color matching isn't superficial; it taps into the psychology of color. Colors evoke emotions and create associations. A vibrant red can signal energy, while a deep blue might convey trust. But if these colors aren't reproduced accurately, the message gets muddled.

Our color perception is also shaped by things like lighting and surrounding colors. A color perfect on your monitor might look completely different under different lighting or printed on a different material. This is metamerism, a key challenge in print color matching.

The journey of color matching in printing has been fascinating. In 1908, Toyo Ink Manufacturing Co., Ltd. created the first color catalog—a swatch book of ink colors—in Japan. A big step towards standardization! But the real game-changer came in 1963 with the Pantone Matching System. Pantone gave the printing industry a universal color language. Want to dive deeper into color matching history? Check out this article: Visual Culture: Color Matching Systems.

Bridging the Gap: Screen to Print

So, how do we bridge the gap between screen and print? By understanding color models. Your screen uses RGB (Red, Green, Blue), mixing light to create colors. Printers use CMYK (Cyan, Magenta, Yellow, Key/Black), which uses ink to absorb light. This fundamental difference is a major culprit in color discrepancies.

Mastering print color matching blends technical know-how with artistic instinct. It involves understanding color theory, calibration techniques, and proofing strategies. By honing these skills, you can transform printing pitfalls into triumphs, ensuring your printed pieces reflect your vision and communicate your message effectively.

Navigating Color Systems Like a Pro

Think of color systems as different languages. Your computer screen speaks RGB, a vibrant language of light, while your printer uses CMYK, the more subdued language of ink. This difference can be a major source of frustration when you're trying to get your printed colors to match what you see on screen. Let's decode these languages and learn how to translate between them.

RGB: The Language of Light

RGB (Red, Green, Blue) is the language of screens. It's an additive color system, meaning colors are created by adding light. Imagine shining three spotlights – red, green, and blue – onto a white wall. Where the lights overlap, they create new colors: red and green make yellow, red and blue make magenta, and blue and green make cyan. RGB can create millions of colors, making it ideal for digital designs where vibrancy is key.

This huge range of colors is perfect for the digital world, but it poses a challenge when it comes to printing.

CMYK: The Language of Ink

CMYK (Cyan, Magenta, Yellow, Key/Black) is the language of print. It's a subtractive system, meaning colors are created by absorbing light. Think of it like mixing paint. CMYK inks absorb specific wavelengths of light, reflecting back the colors we see. For example, cyan ink absorbs red light, reflecting blue and green – what we see as cyan. CMYK has a smaller range of colors than RGB, and can't reproduce all the vibrant colors you see on screen. This is a core challenge in print color matching.

This limited color range is why a design can look vibrant on screen, but duller when printed.

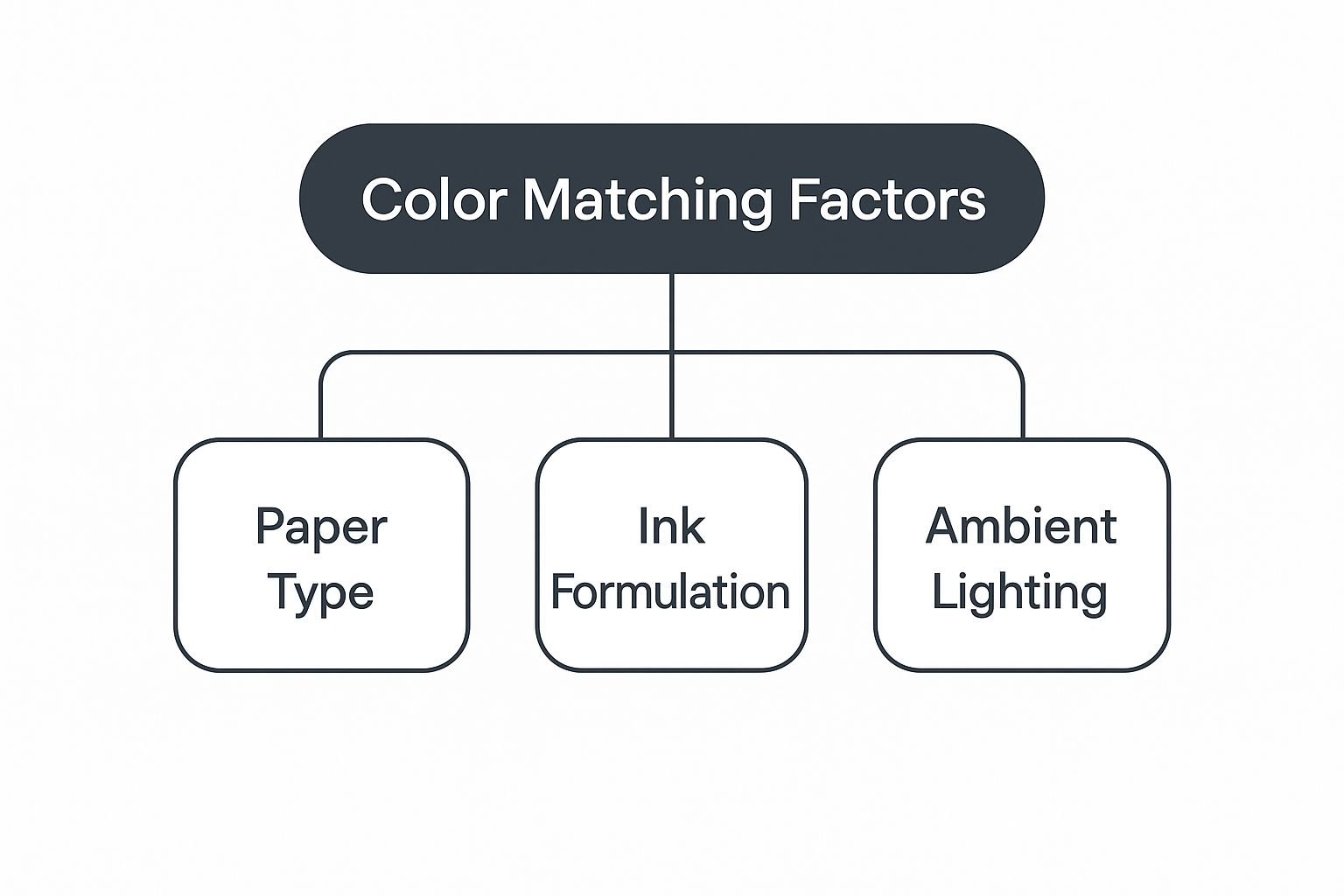

The infographic above illustrates how different factors influence the final printed color. It shows how the paper you choose, the specific ink formulation, and even the lighting in the room can affect the way the color looks. All these elements work together, highlighting the importance of considering every aspect of the printing process.

Pantone: The Universal Translator

Imagine trying to describe a specific shade of blue to someone. Difficult, isn't it? That's where Pantone comes in. Pantone is a standardized color matching system that uses pre-mixed inks called spot colors. Each Pantone color has a unique code, ensuring that "Pantone 185 C" is the same vibrant red, no matter who prints it or what material it's printed on. Pantone is a popular choice for brand colors, ensuring consistency across different media. Precise color matching is especially important for things like business card printing.

To help you understand the differences between these color systems, take a look at the table below. It compares their primary uses, color ranges, and best applications.

Color System Comparison Guide Comprehensive comparison of major color systems including their applications, color gamuts, and best use cases.

| Color System | Primary Use | Color Range | Best For | Industry Standard |

|---|---|---|---|---|

| RGB | Digital displays (screens, monitors) | Millions of colors (additive) | Web design, digital photography | sRGB, Adobe RGB |

| CMYK | Print materials (magazines, brochures) | Smaller range than RGB (subtractive) | Print publications, marketing materials | ISO Coated v2 (ECI), Fogra 39 |

| Pantone | Specific color matching | Pre-mixed spot colors | Branding, logo reproduction, consistent color across different print runs | Pantone Matching System (PMS) |

This table summarizes the key differences between the three color systems and helps you choose the right one for your project. While RGB is ideal for digital, CMYK is the go-to for print. Pantone offers a way to achieve consistent color, especially for brand elements.

Beyond Pantone, the Natural Colour System (NCS) provides another method for color matching. Launched in 1979 in Scandinavia, NCS describes millions of perceivable colors. It's commonly used in architecture and manufacturing. Discover more insights into color theory. Choosing the right color system depends on your project's specific needs and your budget.

Calibration Secrets That Actually Work

Let's be honest: the colors you see on your monitor aren't always what you get in print. That vibrant design might look dull, or even completely off, once it's on paper. That's where calibration comes in. It's the foundation of accurate print color matching, making sure your digital creation translates correctly into the physical world.

Why Calibrate? The Monitor Deception

Think of your monitor like a musical instrument. A tuned piano sounds beautiful, but an out-of-tune piano, well, it's a mess. A calibrated monitor displays true colors. An uncalibrated one can be misleading, resulting in prints that aren’t quite what you envisioned. This can be due to differences in screen technology, factory settings, or even just the age of your monitor. Even the finish of a surface can impact how color is perceived. For example, check out these tips on cabinet wood stain colors to see how finish choices influence the final look.

The Calibration Toolkit: Software vs. Hardware

You don't necessarily need fancy hardware to calibrate your monitor. Most operating systems have built-in tools that can drastically improve color accuracy. These tools guide you through adjustments for brightness, contrast, and color balance. It’s a great starting point, especially if you’re just beginning with print color matching.

Taking Calibration Further With a Colorimeter

For more precise color control, a colorimeter is your best friend. This device measures the colors your screen displays and creates a custom ICC profile. This profile is a file that tells your computer exactly how to display colors for your specific monitor. Think of it as a personalized language translator between your monitor and your computer. A colorimeter is a worthwhile investment for professional print color matching, especially when working with clients who need spot-on color accuracy.

Printer Calibration: The Other Half of the Equation

Calibrating your monitor is only half the battle. Your printer needs calibration too. This involves adjusting the printer’s settings to work perfectly with your chosen paper and ink. Many printers have built-in calibration routines that can really improve your color matching.

Creating custom printer profiles for different paper types is also helpful. This optimizes color reproduction for each material. It also saves ink and money in the long run, preventing costly reprints and keeping clients happy. Just like advancements in color matching systems, technology has played a big role in color accuracy. For example, Benjamin Moore’s computerized color-matching system, introduced in 1982, greatly expanded color options beyond traditional color chips.

Maintaining Calibration: A Long-Term Commitment

Calibration isn't a one-and-done deal. Monitors and printers change over time. Regular recalibration is essential, just like regular tune-ups for your car. It keeps things running smoothly and prevents surprises. Recalibrate your monitor every month or two. For printers, recalibrate when you switch to a new paper or if you notice the print quality dropping. This regular maintenance will keep your color matching on point, giving you accurate and predictable results every time.

Proofing Strategies That Prevent Disasters

Imagine a surgeon stepping into an operating room without first checking the X-rays. Sounds risky, right? Skipping the proofing process before sending a print job to press is just as dangerous. Let's explore the different kinds of proofs, how they fit into your workflow, and how they impact your bottom line.

Soft Proofing: Your Dress Rehearsal

Soft proofing is like a dress rehearsal on your computer screen. It simulates what your final printed piece will look like, letting you check for color accuracy and any potential problems. This is your first chance to catch glaring errors. But remember, soft proofing is only as good as your monitor’s calibration. If your monitor isn't correctly calibrated, you could still be misled.

Desktop Proofing: Getting a Feel for It

Desktop proofing takes it a step further by creating a quick physical sample on a color-managed printer using the intended paper stock. This lets you assess the color and feel directly, providing a tangible preview. It’s a cost-effective way to handle internal reviews and make minor tweaks.

Contract Proofing: The Final Say

For critical projects where color precision is paramount, contract proofing is non-negotiable. Think of it as the final word. This high-quality proof uses the exact same printing process, inks, and paper as your final production run. It's the closest you'll get to the finished product before the presses start rolling. Contract proofs serve as a critical reference point for you and your client, ensuring everyone's happy with the final look before you commit to a full print run.

Proofing: More Than Just a Technical Check

Proofs aren't just about catching technical glitches; they're a vital communication tool. Showing a proof to your client shows you’re professional and builds trust. It provides a clear visual of the end product, managing expectations and avoiding misunderstandings. This proactive approach strengthens client relationships and builds confidence in your expertise. You can even use this opportunity to showcase other offerings, like exploring options for printing vinyl banners.

The Value of Proofing: Saving Money in the Long Run

While proofing might seem like an extra expense upfront, it can save you a lot of money (and headaches) down the line. Imagine the cost of reprinting an entire job due to a color error, not to mention the damage to your client relationship. By including proofing costs in your initial pricing, it becomes a valuable investment, not a burden.

Choosing the Right Proofing Method

The best proofing strategy depends on the job’s complexity and your budget. For straightforward projects, soft or desktop proofing might be enough. But for complex projects with tight color requirements, contract proofing is essential. This balanced approach ensures you deliver excellent results without breaking the bank. It's about making smart choices that benefit both your client and your business. Remember, effective proofing and accurate print color matching aren't just about getting the colors right. They protect your reputation and ensure consistent, high-quality work. It's an investment in client satisfaction and your business's long-term success.

Mastering Light and Environment Variables

Ever bought a shirt that looked amazing in the store, only to discover it was a completely different color back home? That's metamerism in action – the tricky phenomenon where two colors look identical under one light source, but drastically different under another. It’s a major player in print color matching, making your workspace lighting incredibly important.

This means the lighting you have during design, proofing, and even client sign-off can dramatically change how colors are perceived.

The Science of Light and Color Perception

Think of light as a messenger carrying information about color. Different light sources send out different wavelengths, and these wavelengths interact with the pigments in your ink and paper. Incandescent light, for example, is warm, emitting more red and yellow wavelengths. Fluorescent light, on the other hand, is cooler with more blue and green. It's why photographers are so picky about their lighting setups – they need to control how colors appear in their final images. The same principle applies to print color matching.

This seemingly simple difference in lighting can have a huge impact. A print viewed under incandescent light might appear warmer and more yellow, while the same print under fluorescent light could look cooler and more blue. This inconsistency makes accurate color evaluation a real challenge.

Creating Consistent Viewing Conditions

You don't need a high-tech lab to get consistent viewing conditions. But aiming for standardized lighting is key for accurate print color matching. Standard viewing booths or light boxes, which often use D50 or D65 light sources to simulate daylight, offer a controlled lighting environment. These setups ensure consistent color evaluation across different locations and times of day.

What if you don't have a viewing booth? Choose a dedicated workspace with consistent lighting. Avoid mixing different light sources in the same area. Neutral-colored walls and surfaces will also minimize color reflections that can skew your perception. For some real-world examples of creating a consistent viewing area, even with simple materials, check out our guide on printed door hangers.

Communicating Lighting Requirements

When it comes to client approvals, communicating your lighting requirements is essential. Make sure your client views proofs under the same lighting conditions you used. This prevents misunderstandings and ensures everyone agrees on what the final product will actually look like. Clearly documenting the lighting conditions used for approvals can also prevent issues down the line.

Standard Lighting Conditions for Color Evaluation

To get a better grasp of industry standards for lighting, take a look at the table below:

Standard Lighting Conditions for Color Evaluation Comparison of different lighting standards and their applications in professional color matching workflows

| Light Source | Color Temperature | CRI Rating | Best Use Case | Industry Standard |

|---|---|---|---|---|

| D50 | 5000K | 90+ | Graphic arts, printing, photography | ISO 3664 |

| D65 | 6500K | 90+ | Textile, paint, plastics | ISO 10526 |

| Incandescent | 2700-3000K | Low | Not recommended for color-critical work | N/A |

| Fluorescent | Varies | Varies | Can be suitable with high CRI bulbs | N/A |

As you can see, standardized light sources like D50 or D65 are essential for reliable color evaluation, leading to more consistent print color matching.

By understanding and controlling lighting variables, you take a significant step towards making your digital vision a printed reality. Remember, even small changes in your environment can have a big impact on your final results.

Solving Print Color Matching Problems Fast

Ever feel like you're wrestling with a particularly stubborn print job, where the colors on screen just won't translate to the page? We've all been there. Even seasoned print pros occasionally hit these color roadblocks. But don't worry, a systematic approach to troubleshooting can be your secret weapon. It's all about saving you time, reducing wasted materials, and keeping your clients smiling. Let's dive into some common color matching challenges and how to tackle them head-on.

Identifying the Source of the Problem: Playing Detective

The first step is figuring out where things are going wrong. Is the issue lurking in the original file? Maybe your monitor is playing tricks on you. Perhaps it's the printer itself, or even the materials you're using. Put on your detective hat and let's investigate.

File Issues: Start with the basics. Double-check your file's color mode. Remember, it needs to be in CMYK for print. Also, check for any embedded color profiles that might be causing conflicts. Something this simple can easily throw your colors off.

Monitor Calibration: Remember how we talked about the importance of monitor calibration? A miscalibrated monitor can make a file look perfect on screen, even if it's way off in reality. Recalibrating your monitor can be a quick fix that prevents major color headaches down the line.

Printer Problems: Your printer needs some TLC too. Is it properly calibrated? Are the ink levels sufficient? Sometimes, a simple printer head cleaning can work wonders and resolve color inconsistencies.

Material Mismatches: Think about it – different papers and substrates absorb ink differently. Make sure you're using the right paper type for your project. Consider creating custom printer profiles for different materials to really dial things in. For example, if you're working on packaging, you might want to check out the different options available from packaging products.

Nightmare Scenarios: Out-of-Gamut Colors and Substrate Shifts

Some color challenges are definitely trickier than others. Let's talk about out-of-gamut colors. These are colors that simply can't be reproduced using standard CMYK inks. They might look vibrant and dazzling on your screen, but they'll appear duller when printed. So, what's the solution? Try finding the closest possible CMYK match. If the color is absolutely crucial to the design, consider using spot colors.

Another headache? Matching colors across different substrates. A color that pops on coated paper might look completely different on uncoated stock. The key here is testing. Create separate profiles for each substrate you regularly use.

Managing Client Expectations: The Art of Communication

Sometimes, a perfect color match is just not possible. That's where communication with your client becomes paramount. Explain the limitations of print color matching in simple terms – no technical jargon allowed. Offer alternative solutions or compromises. Showing your client several proof options and explaining the reasons behind any color variations can build trust and manage expectations.

Real-World Troubleshooting: A Practical Example

Imagine this: a client's logo is a vibrant, eye-catching orange. But when the business cards arrive, the logo looks dull and muddy. Yikes! After some digging, you discover the file was accidentally saved in RGB. A simple conversion to CMYK and a new proof saves the day (and the project). This kind of color detective work is what sets skilled print professionals apart.

By developing a systematic troubleshooting approach and mastering clear communication, you can turn print color matching challenges into opportunities to showcase your expertise and build strong client relationships. It's all about problem-solving, managing expectations, and consistently delivering high-quality results, even when faced with tricky color puzzles.

Building Your Print Color Matching Workflow

Getting print colors to match perfectly isn't about mastering one technique; it's about building a solid workflow where each step supports the others. Think of it like building a house – a strong foundation is key. This section brings everything together into a practical, repeatable process for consistent, accurate results. We'll explore essential tools and software, from simple setups for smaller studios to robust systems for large-scale printing.

Structuring Your Process: From Consultation to Delivery

A clear workflow ensures both efficiency and accuracy, like a well-oiled machine. Here's a typical structure:

Client Consultation: Start by truly understanding your client's vision and color expectations. Imagine trying to paint a room without knowing what color the client wants! Is it for indoor or outdoor display? Will it be seen under specific lighting? This initial consultation sets the stage for color accuracy from the outset.

File Preparation: Make sure your design files are in the correct color mode (CMYK for print). It's like speaking the right language for your printer. Ensure any color conversions are done precisely.

Proofing and Approval: This crucial stage is where you and your client confirm the color is spot-on before going into full production. It's like a test drive before buying a car. There are several proofing methods—from quick soft proofs on your monitor to more precise contract proofs.

Production and Quality Control: During the actual printing, keep a close eye on things with regular quality checks to catch any color deviations early. Think of it as ongoing course correction during a long journey. Document everything for future reference and consistent results across projects.

Final Delivery and Review: After printing, review the finished product with your client under the agreed lighting conditions. This is the final unveiling. Confirm they’re happy and address any last concerns.

Essential Tools and Software

Having the right tools is crucial for an efficient workflow. Check out this helpful resource: Essential Tools to Master Remote Work. While it focuses on remote work, the idea of having the right tools applies directly to print color matching.

Software is essential, from design software like Adobe Photoshop and Illustrator, to specific color management software for calibration and profiling. For basic needs, free or built-in tools might suffice. For advanced control, consider investing in professional software and hardware like spectrophotometers.

Workflow Examples: Learning from the Pros

Let’s look at two different scenarios:

Small Studio Workflow: A small design studio might use calibrated monitors, design software, and a desktop printer with color management for proofing. They work closely with their print provider, sharing detailed color specs and proofs. It's a collaborative approach.

High-Volume Operation Workflow: A large printing company uses a more complex system with spectrophotometers for precise color measurement, advanced RIP software for color management, and standardized viewing booths for consistent color evaluation. Think of it as a finely tuned orchestra playing in perfect harmony. They follow strict quality control throughout.

Documentation and Training: Building a Consistent System

Documenting your workflow is essential, particularly when you have a team. Create a detailed process manual outlining each step. It's like having a recipe everyone can follow for consistent results. Regular training keeps everyone on the same page and up-to-date on best practices.

Staying Current: Adapting to Evolving Technologies

Print color matching is always evolving. Stay informed about new tech, software updates, and industry standards. It's like keeping your toolkit updated. Workshops, webinars, and industry events will keep your skills sharp and your results top-notch. Need fresh ideas for your next event? Check out these event marketing materials.

By creating a well-defined workflow and staying current with industry changes, you guarantee color accuracy and consistency, delivering high-quality prints that meet client expectations every time.

Ready to take your printing projects to the next level? Visit 4OVER4 today and explore our comprehensive printing solutions.

More from print color matching

10

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

22

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

86

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

97

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

122

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

108

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

373

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

337

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026