- Home

- content hub

- Offset Printing vs Digital Printing: Which Is Best for You?

Offset Printing vs Digital Printing: Which Is Best for You?

Emma Davis

Content Writer

Aug 27, 2025818 views

Aug 27, 2025818 views

When you're trying to decide between offset and digital printing, it often boils down to two things: how many you need and how fast you need them. For massive print runs, offset printing gives you beautiful quality and a lower price for each piece. But for smaller, personalized jobs where speed is everything, digital printing is the clear winner.

The right choice really depends on what your project demands.

Choosing the Right Print Method for Your Project

Picking a printing method isn’t about which technology is “better”—it’s about matching the right process to your specific goals. There’s no single correct answer, just the one that makes the most sense for what you're trying to accomplish. My goal here is to give you a solid framework for making a smart, cost-effective decision every single time.

Let's break down the key factors you need to think about, so you can see the trade-offs clearly.

- Project Volume: How many prints do you actually need? This is usually the biggest decider.

- Budget: Are you trying to keep the initial cost down, or are you focused on getting the best price per piece?

- Turnaround Time: Do you have weeks to spare, or do you need these in your hands by tomorrow?

- Customization: Does every single print need to be slightly different?

Key Differences at a Glance

Getting a handle on these foundational differences is the first step. Offset printing is the traditional method, using metal plates to transfer ink onto paper. The setup is intensive, but once it's running, it’s incredibly efficient for large quantities.

On the other hand, digital printing works more like your desktop printer—just on a much bigger, more sophisticated scale. It takes your digital file and prints directly onto the paper, skipping the whole plate-making process.

The real game-changer is the setup. Offset’s reliance on plates makes it a powerhouse for mass production. Digital’s plate-free approach gives it an unbeatable edge in speed and variability for smaller jobs.

This breakdown of offset vs digital printing will help you choose the perfect method for all your business needs, whether you're printing a few flyers for an event or a massive catalog run. A great way to see these principles in action is to check out different business and marketing materials and think about how they were likely produced.

| Feature | Offset Printing | Digital Printing |

|---|---|---|

| Best For | High-volume jobs (500+ pieces) | Low-volume, fast-turnaround jobs |

| Cost Structure | High setup cost, low per-unit cost | No setup cost, consistent per-unit cost |

| Turnaround | Slower (days) | Faster (hours to same-day) |

| Customization | Not suitable for personalization | Ideal for Variable Data Printing (VDP) |

Understanding the Core Printing Technologies

To really get a handle on the whole offset printing vs. digital printing question, you have to know how the machines actually work. They’re built on fundamentally different ideas, and once you understand the mechanics, it’s a lot easier to see why one is perfect for certain jobs and a total non-starter for others.

Let’s pull back the curtain on these two processes.

The Plate-Based Method of Offset Printing

Offset printing is the seasoned veteran of the industry, a time-tested method built for getting things just right, especially when you’re printing a lot of something. It's an indirect process, meaning ink doesn’t just get slapped onto the paper. It's a bit more intricate than that.

The process actually gives the method its name.

Offset printing starts with custom metal plates—usually aluminum—one for each of the four primary ink colors (cyan, magenta, yellow, and black). Your digital file gets etched onto these plates first.

From there, the inked image is transferred, or "offset," from the plate onto a rubber blanket. That blanket then rolls the final image onto the paper with incredible accuracy. This two-step transfer is the secret to its sharp, clean finish.

The use of plates is both offset printing's greatest strength and its biggest weakness. It’s what guarantees flawless consistency across thousands of copies, but it also creates the setup time and costs that make small jobs a no-go.

This whole system is engineered for pristine quality and perfect color matching over massive print runs. It's why offset remains the gold standard for projects that demand thousands of identical, high-quality pieces.

The Direct-to-Paper Speed of Digital Printing

Digital printing is a whole different ballgame—much more direct and streamlined. Just imagine a super-powered version of your desktop printer. There are no plates, no blankets, nothing in between. The printer simply takes your digital file and puts ink or toner directly onto the paper.

This direct approach is what makes it so fast and flexible. You'll generally see two types of digital printing:

- Inkjet: Works by spraying microscopic dots of ink onto the paper to build the image.

- Toner: Uses a fine, electrically charged powder that’s fused onto the paper with heat, common in laser printers.

Since there are no plates to create, setup is almost instant. You can make changes to a design right up until you hit "print." This also opens the door to some powerful customization that offset just can't do.

This incredible adaptability makes digital the clear winner for smaller, more personalized jobs. The ability to print a unique name, address, or image on every single piece is a key feature of variable data printing services—something only a digital press can pull off.

With these core differences in mind, we can start to really compare their specific strengths and weaknesses.

When you get down to brass tacks, the choice between offset and digital printing usually boils down to two things: how much it costs and how fast you need it. These two methods are built on completely different financial and production models. Think of them as serving opposite ends of the printing world.

Offset printing is all about economy of scale. The setup is a real process—it involves creating custom metal plates and getting a massive press calibrated just right. This means you're looking at a pretty high upfront cost. But here's the magic: once that press starts humming, the price per piece plummets with every copy you print. It's hands-down the most cost-effective way to produce large quantities.

Digital printing, on the other hand, is built for speed and simplicity. There are no plates to make, so the setup cost is practically zero. You get a consistent price for every single piece, whether you're printing one copy or a few hundred. It’s straightforward and immediate.

The Crossover Point: Where the Math Flips

The single most important financial concept to get your head around is the "crossover point." This is the exact quantity where offset printing actually becomes cheaper than digital.

For smaller jobs—say, anything from 50 to 500 pieces—digital is almost always going to be easier on your wallet because you skip those hefty setup fees. But as you start ordering more, you'll hit a tipping point where the super-low per-unit cost of offset finally outweighs its initial setup expense.

So, where is that magic number? It usually lands somewhere between 500 and 1,000 units, though this can shift depending on how complex your project is. If you're a small business that needs 250 flyers for an event, digital is the smart move. If you're a big corporation ordering 5,000 brochures, offset will save you a ton of money in the long run.

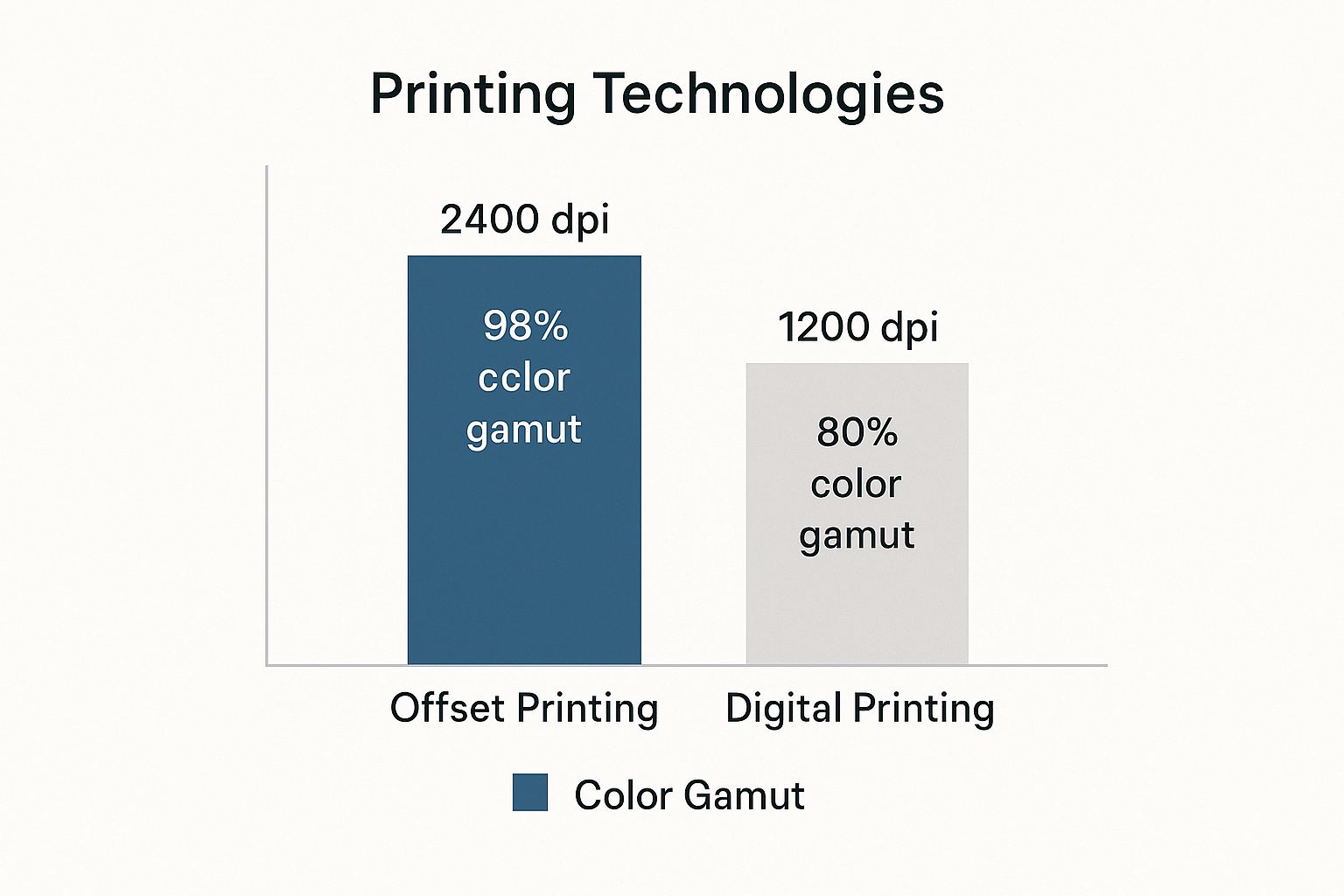

The infographic below gives a great visual breakdown of what you're getting with each method.

You can see how offset's superior resolution and color capabilities make it a premium choice for big projects, while digital holds its own for those faster, smaller jobs.

It's also worth noting that the financial landscape is changing. The total cost to own a high-production digital press has dropped by over 50% in the last decade, while the cost of materials for offset has crept up. This is starting to make digital a real contender for medium-sized runs that used to be strictly offset's game. You can dig deeper into how printing cost dynamics are changing on customdesignsboxes.com.

For a quick side-by-side look, here’s a table that breaks down the key differences.

At a Glance: Digital vs. Offset Printing

| Factor | Digital Printing | Offset Printing |

|---|---|---|

| Best For | Small to medium quantities (under 1,000) | Large quantities (1,000+) |

| Cost | Low setup cost, higher per-unit cost | High setup cost, very low per-unit cost |

| Turnaround | Very fast (hours to 1-2 days) | Slower (several days) |

| Color | Good, but can have slight variations | Excellent, precise color matching (Pantone) |

| Customization | Excellent for variable data (names, addresses) | Not possible; every piece is identical |

This should give you a clear, high-level view to help steer your decision based on what matters most for your specific project.

Comparing Production and Delivery Speed

Just like their cost models are night and day, so are their turnaround times. And when it comes to speed, digital printing is in a league of its own.

Digital Printing: You can literally have a finished product in a matter of hours, often on the same day. With no plates to create and no ink to dry, your files go from your computer to a finished stack of prints in a flash. This is a lifesaver for last-minute needs, like conference handouts or urgent promo flyers.

Offset Printing: This is a more deliberate process. Between making the plates, setting up the press, and waiting for the ink to fully dry, you’re measuring turnaround in days, not hours. A standard offset job might take anywhere from three to seven business days, so it’s definitely not the right choice for anything with a tight deadline.

When speed is your number one priority, digital printing is the undisputed champion. The ability to print on-demand gives you an agility that offset’s mechanical, setup-heavy process just can’t touch.

Comparing Print Quality and Customization Options

When you're deciding between offset and digital printing, the conversation around quality goes much deeper than just how sharp an image looks. It's really about precision, color fidelity, and the flexibility to customize your message. Both methods deliver professional results, but they shine in different ways. Your project's specific needs will be the deciding factor.

For decades, offset printing has been the gold standard for quality. There's a reason for that. Its plate-based system produces exceptionally crisp text and fine details, giving everything a rich, premium finish. The ink is actually absorbed into the paper, which creates a smooth, almost organic look that designers often prefer.

Digital printing, however, has come a very long way. Modern digital presses can churn out work that's nearly indistinguishable from offset to the average person. But for a trained eye, subtle differences remain. Digital printing typically lays toner or ink on top of the paper, which can sometimes create a slight sheen. It might also struggle to reproduce perfectly smooth color gradients without some minor banding.

Achieving Perfect Brand Colors

One of the biggest differentiators is color matching. This is where offset printing truly shows its strength.

Offset presses use the Pantone Matching System (PMS), which means they can mix custom inks to hit an exact color formula. If your brand lives and dies by a specific shade of teal, offset guarantees that color is perfectly replicated every single time, on every single piece. For large corporations where brand consistency is non-negotiable, this level of precision is everything.

Digital presses, on the other hand, primarily use a four-color process (CMYK) to simulate colors. While some high-end digital systems use up to seven colors and can match up to 96% of Pantone colors, they're still creating an approximation, not using a pre-mixed, pure ink. For most jobs, this is more than good enough. But for brands that demand absolute color perfection, offset is the clear winner.

The ability to use true Pantone inks is offset printing's killer feature for brand-centric projects. It takes the guesswork out of color and ensures your brand is represented with flawless accuracy.

The Power of Personalization

While offset takes the crown for color fidelity, digital printing completely dominates when it comes to customization. The secret weapon here is a technology called Variable Data Printing (VDP).

VDP is a game-changer. It lets you change text, graphics, or images on each individual printed piece without ever stopping the press. This is simply impossible with offset printing, where every impression from a static plate has to be identical.

Here’s what VDP opens up:

- Personalized Direct Mail: Greet each recipient by name and tailor offers based on their past purchases.

- Customized Invitations: Print event tickets that already have individual names and seat numbers on them.

- Targeted Marketing: Create different versions of a brochure with images or services that appeal to specific customer groups.

This kind of one-to-one marketing can massively boost engagement and response rates, giving digital printing a powerful advantage. For projects that need that unique touch, exploring what's possible within a specialty printing collection can unlock even more creative ideas.

Ultimately, your choice boils down to what you prioritize: the unmatched color precision of offset or the dynamic, personalized marketing power of digital.

When to Choose Offset Printing for Your Project

Offset printing is the undisputed champion when your project needs to go big—really big—without sacrificing a drop of quality. If you're talking about printing thousands of pieces, not just a few hundred, this is where offset's economic model starts to make perfect sense.

Yes, there's a higher upfront cost to create the custom plates, but that investment pays for itself quickly. As your print run gets larger, the price for each individual piece plummets, making it incredibly cost-effective for mass production.

Ideal Scenarios for Offset Printing

So, when does it make the most sense to go with offset? Think of it as the go-to choice for projects where the stakes are high and the numbers are even higher.

- Large-Scale Publications: This is offset's home turf. For magazines, books, or hefty product catalogs, it's the industry standard for a reason. You get crisp, sharp text and vibrant, consistent color across tens of thousands of copies—something digital just can't match at that scale.

- Brand-Critical Marketing Materials: If your brand lives and dies by a specific Pantone color, offset is your only real option. For corporate brochures, annual reports, or high-end packaging, it guarantees that exact color match every single time.

- Projects with Specialty Finishes: Offset presses are built to handle a much wider range of paper stocks, weights, and textures. This opens the door for high-end jobs that need special touches like a spot gloss, a metallic ink, or a unique coating.

The rule of thumb is simple: when quantity and quality are equally non-negotiable, offset printing delivers. It’s an investment in flawless replication for your most important large-scale work.

Imagine a national retail chain planning to distribute 500,000 seasonal catalogs. They'll choose offset without a second thought. It keeps costs manageable at that volume and ensures the colors look exactly the same from the first catalog to the last—a vital detail for any brand. For more on this, Walsworth offers a great breakdown of why offset remains effective for large jobs.

When your project's success depends on achieving massive scale and perfect visual consistency, exploring the world of offset printing solutions is the right strategic move. It remains the powerhouse for large-scale production.

When to Choose Digital Printing for Your Project

Digital printing shines when you need speed, flexibility, and a personal touch. Its biggest advantage is how efficiently it handles smaller print jobs. Since there are no plates to create—a major step in the offset process—setup is incredibly fast, making it a lifesaver for last-minute needs.

If you’re up against a tight deadline, digital is almost always the way to go. Imagine you need 200 high-quality flyers for a trade show this weekend, or a handful of business cards for a new hire who starts Monday. These are the exact situations where digital’s on-demand capability wins, delivering finished products in hours, not days.

Leveraging Speed and Customization

That flexibility isn't just about speed; it's also about agility. Spot a typo or need to update a date just before you hit "print"? With a digital file, it's a simple fix. Try doing that with offset once the plates are made—it's just not possible.

Digital is also the magic behind one of the most effective tools in modern marketing: Variable Data Printing (VDP). This technology lets you customize every single piece in a print run without stopping the press.

With VDP, you can print unique names, images, or offers on each mailer, turning a generic blast into a one-to-one conversation. This level of personalization can seriously lift your campaign's engagement and response rates.

The Power of Print-On-Demand

Finally, digital printing makes a true print-on-demand strategy possible. This is perfect for materials with a short shelf life, like event programs or special offer handouts. You order precisely the quantity you need, which cuts out waste and saves you from paying to store boxes of outdated prints. It’s a lean approach that keeps your marketing fresh and your budget in check.

For any business that thrives on being quick and personal, exploring the world of digital printing services is a no-brainer. When the job is small and the clock is ticking, the choice is clear.

A Few Lingering Questions

Even after breaking down the nitty-gritty of offset vs. digital printing, a couple of specific questions always seem to pop up. Let's tackle those head-on so you can feel completely confident in your final decision.

Which Printing Method Is More Eco-Friendly?

For smaller print runs, digital printing is usually the greener choice. There's way less paper waste since there’s no big setup process, and you skip the chemicals needed to create offset plates. If you're running a small, eco-conscious project, digital is a solid bet.

But here's the twist: for massive jobs, an offset press becomes so efficient that its environmental impact per piece can actually be lower. Both methods now work well with recycled papers and soy-based inks, so you have sustainable options either way.

Can I Get a Proof Before Committing to a Large Order?

Absolutely, but how you get it varies a lot.

With digital printing, seeing a single, perfect proof is a breeze. It's cheap and easy because there are no plates to make. For offset printing, getting a true "press proof" is a huge deal—it means setting up the entire machine, which is expensive. What you'll usually get instead is a high-end digital proof that's been carefully calibrated to show you what the final offset version will look like.

Does My Paper Choice Limit My Printing Options?

Sometimes, yes. Offset printing has historically been the champ here, handling a massive range of paper stocks, unique textures, and heavy weights without breaking a sweat. If you're dreaming of a really high-end project with special, textured paper, offset often gives you more creative runway.

That said, modern digital presses have come a long way and can handle more specialty papers than ever before. The best advice? Just talk to your print provider. They'll tell you straight up if the paper you love will work with the printing method you want.

Ready to bring your vision to life with the perfect printing method? At 4OVER4, we offer a full spectrum of both digital and offset solutions to match any project, budget, or timeline. Explore our printing services today!

More from offset vs digital printing

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

61

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

104

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

104

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

326

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026