- Home

- content hub

- How to Get Labels Off Bottles Without Leaving Residue

How to Get Labels Off Bottles Without Leaving Residue

Emma Davis

Content Writer

Jan 29, 20266 views

Jan 29, 20266 views

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in hot, soapy water, which works wonders on dissolving basic adhesives. For those stubborn plastic or foil labels, though, a hairdryer can be your best friend, gently heating the glue for a clean peel.

Your Guide to Flawless Bottle Label Removal

Before you can upcycle that beautiful wine bottle into a DIY project or prep your artisanal sauce jars for new branding, that old label has to come off cleanly. It sounds simple, but the reality can be a frustrating mess of torn paper and gummy residue.

Different labels and adhesives require different tactics. Choosing the wrong one is a recipe for disaster, leaving you with a sticky situation that’s a real headache to clean up.

Know Your Enemy: Label Types

The first step is figuring out what you're up against. Not all labels are created equal, and identifying the type will save you a ton of time and effort. You'll typically run into one of these:

- Simple Paper Labels: These are the easy ones, often found on wine and beer bottles. They usually have a water-soluble glue that gives up without much of a fight.

- Plastic-Coated Paper Labels: These have a thin, glossy film that repels water, making a simple soak less effective. You'll need to rough them up a bit first.

- Vinyl or Plastic Labels: Common on commercial food jars and plastic containers, these durable labels are waterproof and their strong adhesive often requires heat or a solvent.

- Foil Labels: You'll see these on specialty spirits or high-end products. They can be delicate, so gentle heat is usually the best approach to avoid tearing them.

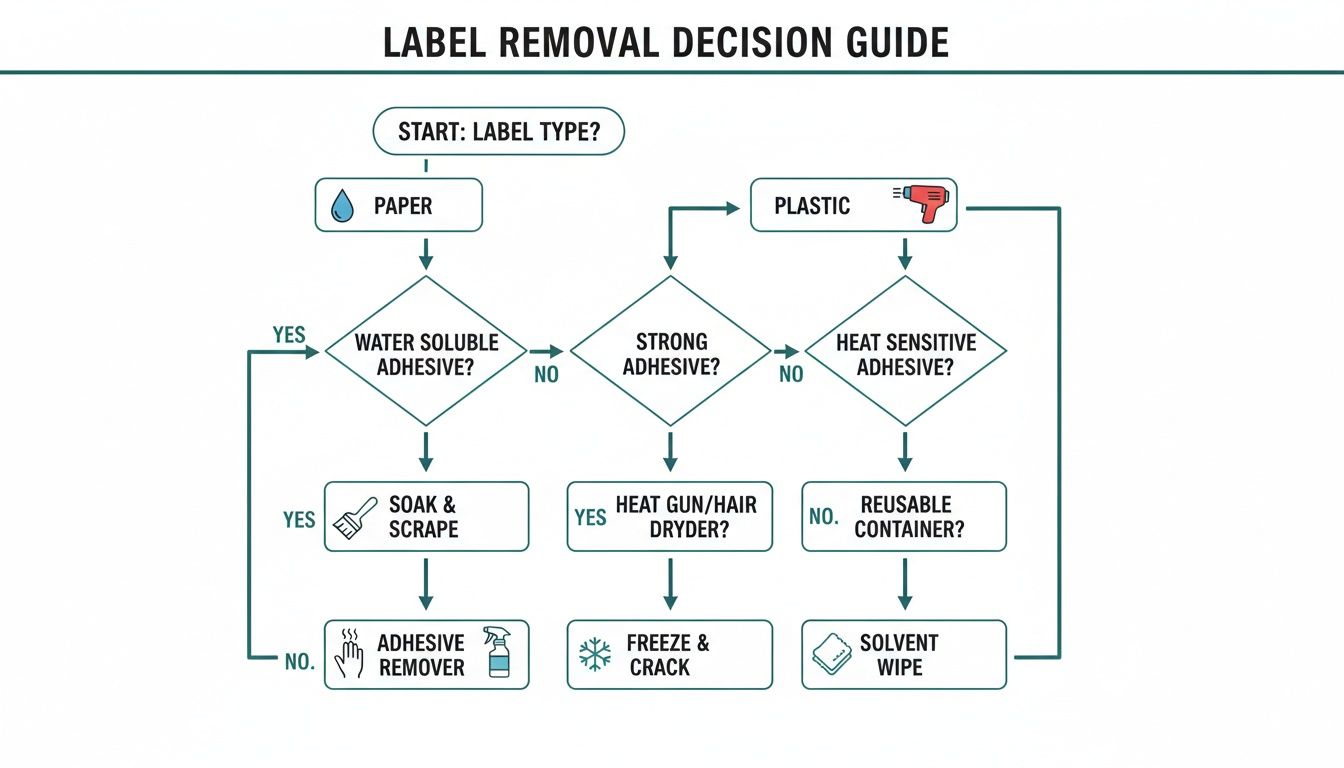

This simple decision tree can help you choose the right starting point for getting those labels off, whether you're dealing with a basic paper sticker or a heavy-duty plastic one.

As the chart shows, identifying your label material—paper versus plastic—is the critical first decision that dictates your entire removal strategy.

Matching The Method To The Material

It's not always about just cleaning a bottle for reuse. For many, there's a real art to it, like the fascinating hobby of wine label collecting, where careful removal is everything. The goal is always the same: get the label and adhesive off completely without scratching or damaging the bottle itself.

The demand for clean, removable labels is skyrocketing. The market is projected to hit USD 25 billion by 2032, with bottles and jars making up a huge 34.7% of that. This isn't just for crafters; it's driven by recycling needs and businesses wanting to ditch promotional tags that tear and leave a mess.

The secret to success isn't elbow grease; it's chemistry. You're not fighting the label—you're dissolving the bond of the adhesive holding it in place.

Whether you're prepping a single bottle for a weekend project or hundreds for your small business, the right technique saves time and guarantees a professional, residue-free finish. Once you've got that perfectly clean surface, you can start thinking about creating your own look with custom labels printing.

Ready to get started? Let's dive into the most effective methods, from simple soaking to more advanced tactics for the toughest jobs.

Quick Guide to Label Removal Methods

Feeling a bit lost? No problem. This table breaks down the best techniques based on your bottle and the type of label you're dealing with.

| Method | Best For | Time Required | Supplies Needed |

|---|---|---|---|

| Hot Water Soak | Paper labels on glass (wine, beer) | 30+ minutes | Sink/bucket, hot water, dish soap |

| Baking Soda Soak | Stubborn paper labels, some adhesives | 30 minutes | Sink/bucket, hot water, baking soda |

| Hairdryer / Heat Gun | Plastic, vinyl, & foil labels | 2-3 minutes per label | Hairdryer or heat gun, plastic scraper |

| Oil & Scraper | Sticky residue left after soaking | 10-15 minutes | Cooking oil, paper towels, scraper |

| Rubbing Alcohol | Stubborn residue, plastic/vinyl labels | 5-10 minutes | Rubbing alcohol, cotton balls, cloth |

Think of this as your cheat sheet. It’s a great way to quickly match your problem to the right solution without having to guess. Now, let’s get into the details for each method.

Removing Paper Labels with a Simple Soak

For most paper labels, especially the kind you find on wine or beer bottles, the simplest method is usually the best one. A classic hot water soak is my go-to starting point, and it relies on basic household items to do all the heavy lifting.

This technique is beautifully simple: the heat and water work together to soften the paper and, more importantly, dissolve the water-soluble adhesive holding it to the glass. It’s a low-effort solution that’s perfect for upcycling projects, like turning old wine bottles into tiki torches for the patio.

Optimizing Your Soaking Solution

While hot water alone often does the trick, adding a simple soaking agent will dramatically speed things up and handle more stubborn glues. You don’t need anything fancy; a few squirts of dish soap are usually enough to start breaking down the adhesive.

For an extra boost, especially with older or thicker labels, try adding a few tablespoons of baking soda or a splash of white vinegar to the mix. These ingredients help dissolve the glue more aggressively without harming the glass.

- Ideal Temperature: Use water that's hot to the touch but not boiling. Boiling water is overkill and a safety risk you don't need to take.

- Soaking Time: Let the bottles soak for at least 30 minutes. For really tough labels, I've found an overnight soak is sometimes necessary.

- Bottle Placement: Make sure the entire bottle is submerged so the water can work on the whole label evenly. If it tries to float, just weigh it down with a heavy mug.

Troubleshooting Common Soaking Issues

Sometimes, even after a good long soak, a label just peels off in frustrating little pieces. This usually happens when a paper label has a thin, glossy plastic coating that keeps the water from getting through.

If your label isn't budging, try giving it a gentle scrub with a scouring pad before you soak it. This creates tiny scratches in that protective layer, allowing the hot water to finally reach the paper and adhesive underneath.

The goal of the soak isn't just to make the paper wet—it's to fully saturate it so the underlying adhesive bond completely fails. Patience is your most important tool here; let the water do the work for you.

This focus on clean removal is becoming more important on a larger scale. The global bottle label market is projected to hit USD 18.7 billion by 2033, with a massive push towards sustainability. Since only 9% of plastic waste is recycled, labels that come off easily are essential for improving recycling rates. Brands are now designing labels that can boost recyclability by up to 95%.

After a successful soak, your bottles will be clean and ready for their next chapter. Whether you're a small business owner or a DIY enthusiast, prepping your containers for new jar labels printing is the final step toward a professional finish.

Using Heat to Peel Away Tricky Labels

When a good soak just won't cut it, it’s time to bring out the secret weapon: heat. This is my go-to method for labels that seem completely bonded to the bottle, especially those tough plastic, vinyl, or foil types designed to resist water. The logic is simple—heat softens the adhesive, making the label much easier to peel away cleanly.

I find myself turning to this technique a lot when prepping bottles for resale or custom branding. It’s perfect for situations where getting the surface wet is a bad idea. For instance, if I’m trying to save a beautiful foil label from a spirits bottle to repurpose it, heat is the only way. It loosens the glue without ruining the delicate material.

Applying Heat Safely and Effectively

You don't need fancy equipment; a standard hairdryer will do the trick.

Just set it to a medium or high heat setting and hold it about two to three inches from the bottle. You’ll want to move it back and forth over the entire label to warm it up evenly. Don't just hold it in one spot.

Pay close attention to the edges. After about 30 to 60 seconds of heat, you should see the corners start to lift or curl up a bit. That’s your sign. The adhesive is ready to give up.

Pro-Tip: As soon as you see an edge lift, slide the corner of a plastic scraper or an old credit card underneath. This gives you a solid grip and saves your fingertips from getting burned. It also helps prevent tearing the label if you're trying to save it.

Handling Different Bottle Materials

While this method is a dream for glass, you need to be careful with plastic bottles. Too much heat for too long can easily warp or even melt the plastic, which will ruin your container completely. Start with the lowest effective heat setting and keep the hairdryer moving.

Here are a few critical safety reminders:

- Glass gets hot: Seriously hot. Always use an oven mitt or a thick towel to handle the bottle right after you’ve heated it.

- Plastic can warp: Keep the heat low and brief. Check the plastic frequently for any signs of softening or distortion.

- Ventilate your space: Some glues can release fumes when heated, so crack a window or work in an area with good airflow.

Once the label is gone, you're left with a clean, smooth surface—the perfect canvas. Getting this prep work right is essential if you're applying new branding. A perfectly clean bottle is the first step to getting a professional finish with high-quality vinyl labels printing.

So, you’ve managed to peel off the label after a good soak or a blast of heat, but now you’re left with a sticky, gummy ghost of what was once there. This is where most people get frustrated and start scraping with their fingernails. But there's a much easier way.

The trick is to dissolve the adhesive using common household oils or, for the really tough jobs, a commercial solvent. It’s a bit of kitchen chemistry that works on the principle of "like dissolves like." Since most label adhesives are oil-based, applying another oil breaks them down, turning that stubborn gunk into a mess you can simply wipe away.

Harnessing Household Oils

You probably don't need a special trip to the store. Your kitchen pantry is likely already stocked with everything you need to tackle that sticky residue. Everyday cooking oils like vegetable, olive, or canola oil are surprisingly effective.

Just pour a generous layer of oil directly onto the sticky spot. Give it time to work its magic—let it sit for at least 15-30 minutes. You'll see the gummy residue start to soften and look more liquid. At that point, grab a paper towel or a plastic scraper and wipe it clean.

Don’t be afraid to get creative. Things like peanut butter or mayonnaise work wonders, too. Their high oil content is fantastic for breaking down stubborn glue, making them an unexpectedly powerful cleaning tool.

Once all the gunk is gone, give the bottle a final wash with hot, soapy water. This will cut through any leftover oily film, leaving you with a perfectly clean surface ready for its next life.

When to Use Commercial Solvents

For the most stubborn, industrial-strength adhesives, sometimes a kitchen staple just won’t cut it. This is when it’s time to reach for a commercial adhesive remover like Goo Gone or even a multipurpose product like WD-40. These are specifically formulated to dissolve tough glues in a hurry.

When you’re working with these stronger products, a little extra care goes a long way.

- Ventilation is Essential: Always use chemical solvents in a well-ventilated area. Open a window or turn on a fan to avoid breathing in the strong fumes.

- Test a Small Spot: Before you douse the whole bottle, test the solvent on a small, hidden area. This is especially important for plastic, as some chemicals can cause damage.

- Follow Directions: Read the label. Apply the solvent as directed, let it sit for the recommended time, and then wipe the residue away with a clean cloth.

Of course, choosing the right label from the start can prevent this headache altogether. With the beverage labeling market expected to hit USD 9.2 billion by 2030, more brands are shifting to easy-off designs. Considering only 9% of plastic waste is recycled globally, labels with 95% removal efficiency are becoming critical for producing pure, food-grade recycled materials.

To help you decide which approach is best for your sticky situation, here’s a quick comparison of common solutions.

Solvent and Oil Effectiveness Comparison

| Solution | Best For | Safety Considerations | Cleanup Required |

|---|---|---|---|

| Cooking Oil | Light to moderate, everyday residue on glass or plastic. | Food-safe and non-toxic. Safe for all surfaces. | Requires a thorough wash with soap and water to remove oily film. |

| WD-40 | Tougher, more resilient adhesive on non-porous surfaces. | Use in a well-ventilated area. Avoid contact with skin. | Wash with soap and water to remove chemical and oily residue. |

| Goo Gone | Very stubborn, thick, or aged-on adhesive. | Requires good ventilation. Test on plastics first. | Must be cleaned thoroughly with soap and water. |

| Rubbing Alcohol | Lighter residue, especially on plastics where oils are not ideal. | Flammable. Use in a well-ventilated space. | Evaporates quickly, often requiring just a quick wipe-down. |

No matter which method you use, a final, thorough wash is non-negotiable. This last step ensures no chemical or oily residue remains. It’s especially important if you plan to reuse the bottle for food, drinks, or apply new waterproof labels for your products. Getting the surface perfectly pristine guarantees your bottle is ready for whatever you have planned for it next.

Prepping Your Bottles for a Flawless New Look

Getting that old label off is a great start, but the job isn't quite done. If you want your new branding to look truly professional, you have to create the perfect canvas.

Even the slightest bit of lingering oil from a solvent or a simple fingerprint can stop your new label from sticking properly. This is what leads to those frustrating bubbles and peeling edges that make a project look cheap.

This final prep stage is what separates an amateur DIY job from a high-quality finished product. It’s the secret to that smooth, seamless application you see on items you buy in a store. The goal here is simple: get the surface squeaky clean and totally free of anything that could mess with the new adhesive.

The Final Wash and Wipe

First, give the bottle a thorough wash with warm water and dish soap. This is essential for cutting through any oily film left behind by things like cooking oil or commercial solvents. A bottle brush for the inside and a soft cloth for the outside will do the trick without leaving scratches.

Once the bottle is completely dry (use a lint-free towel), it's time for the most important step: a final wipe-down with rubbing alcohol, also known as isopropyl alcohol.

This isn't just about cleaning; it's about degreasing. Rubbing alcohol evaporates in a flash, lifting away any stubborn oils, dust, and fingerprints without leaving a single streak behind. It’s the key to getting that surface absolutely pristine.

On plastic bottles, this alcohol wipe has another neat benefit—it helps temporarily cut down on static electricity, which can be a magnet for dust and make applying the label a real headache. After you've prepped your bottles, you might find yourself looking at labels differently. For instance, knowing how to read a quality olive oil label can help you spot the good stuff on the shelf.

Achieving a Perfect Surface

A meticulously prepped bottle is your best defense against the most common labeling mistakes. This simple but critical process ensures your new custom bottle labels stick perfectly for a polished, long-lasting finish.

Here’s a quick checklist for that final prep work:

- Thorough Wash: Use hot, soapy water to get rid of all visible grime and oily residue.

- Complete Dry: Dry the bottle inside and out with a clean, lint-free microfiber cloth to avoid leaving any fuzz behind.

- Alcohol Wipe-Down: Moisten a cotton pad with rubbing alcohol and wipe down the entire area where the new label will go.

- Hands-Off: Once it’s clean, don't touch the surface with your bare hands. You’ll just transfer oils right back onto it.

Following these steps creates the ideal surface, guaranteeing your new label sticks firmly and looks flawless from every angle.

Got Questions About Removing Bottle Labels?

Even when you follow all the steps, some labels just don't want to cooperate. You might be left with a stubborn patch of sticky residue, or a paper label that seems fused to the glass. It happens.

Think of this as your troubleshooting guide for those moments. Here are a few of the most common snags I've run into and how to get past them.

What’s the Absolute Fastest Way to Get a Label Off a Glass Bottle?

When you’re in a hurry, heat is your secret weapon. The fastest method, hands down, is using a hairdryer. Forget waiting around for a bottle to soak—this trick can soften the adhesive in less than a minute.

Just aim the hairdryer at the label and apply steady heat for about 30-60 seconds, keeping it a few inches from the surface. You'll know it's ready when the corners start to peel up on their own. Grab a plastic scraper or an old gift card, lift an edge, and pull the label away while the glue is still warm and pliable. Any little sticky spots left behind can be zapped with a quick wipe of rubbing alcohol.

Can I Use the Same Tricks on Plastic and Glass Bottles?

Not really. You have to be way more careful with plastic. While the basic principles are the same, plastic bottles can easily warp, melt, or get cloudy with methods that glass handles perfectly. Soaking plastic in boiling water, for example, is a great way to end up with a misshapen bottle.

A heat gun is especially dangerous, as it can melt through a plastic bottle in just a few seconds if you’re not watching it like a hawk. And harsh chemical solvents? They can weaken or even dissolve the plastic itself.

My rule for plastic is simple: start gentle. Try a warm—not hot—water soak first. For residue, stick with mild oils or a commercial remover that specifically says it's "safe for plastics." And always, always test any new product on a small, out-of-the-way spot first.

How Do I Get Rid of That Annoying Sticky Residue?

Ah, the gummy, tacky mess left behind. It’s often the most frustrating part of the job, but it’s easier to deal with than you think. The trick is to use something that breaks down oil-based glue.

Here are a few things that work like a charm:

- Kitchen Oils: Grab some cooking oil, peanut butter, or even mayonnaise and smear a layer over the sticky patch. Let it sit for 15-30 minutes to dissolve the adhesive, then scrub it away with a paper towel.

- Rubbing Alcohol: For a cleaner, faster fix, a cotton ball soaked in isopropyl alcohol will cut through most residues in seconds. It’s my go-to for a quick cleanup.

- Heavy-Duty Removers: If you're dealing with industrial-strength glue, you might need to bring out the big guns. Products like Goo Gone or even WD-40 are incredibly effective. Just make sure you wash the bottle thoroughly with soap and water afterward.

Why Won’t My Paper Label Budge, Even After Soaking?

If you’ve soaked a bottle for what feels like an eternity and that paper label is still clinging on, you're almost certainly dealing with a waterproof coating. It’s a thin, nearly invisible layer of plastic or varnish that’s shielding the paper and glue from the water.

The fix is to break through that barrier before you soak it. Take a scouring pad, some steel wool, or even a handful of coarse salt and give the label a good scrub. This creates tiny scratches in the coating, letting the hot water seep in and work its magic. For an extra boost, toss a spoonful of baking soda into the soaking water to help break down the stubborn adhesive.

At 4OVER4, we know a clean, professional look is everything for your brand. Whether you’re upcycling bottles for an event or getting products ready for the shelf, our high-quality custom labels are the perfect final touch. Explore our huge range of printing options to bring your vision to life.

More from how to get labels off bottles

14

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

27

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

121

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

117

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

133

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

119

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

434

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

389

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026