- Home

- content hub

- How Does Embossing Work? A Guide to 3D Textures

How Does Embossing Work? A Guide to 3D Textures

Emma Davis

Content Writer

Jul 13, 20251071 views

Jul 13, 20251071 views

Ever wondered how that raised lettering on a wedding invitation or a fancy business card is made? That's the magic of embossing, and it works like a high-tech, incredibly precise stamp. At its core, embossing is a physical process that reshapes a material—like paper or cardstock—using specialized metal plates and intense pressure to create a stunning three-dimensional effect.

How Embossing Creates Tactile Designs

Think of it like making a detailed impression in clay, but with paper. The entire process hinges on a pair of custom-milled metal plates, known as dies, to achieve its signature raised texture. It's a beautifully simple concept executed with incredible precision.

A sheet of paper is carefully positioned between these two dies inside a press. One die features a raised version of the design (the male die), while the other has a matching recessed impression (the female die). When the press applies force, the male die powerfully pushes the paper’s fibers straight into the female die’s cavity.

This action permanently molds the paper, creating a tangible design that literally stands out from the surface. The result is a sophisticated, touchable texture that adds a layer of quality and professionalism ink alone just can't match.

The Core Components of the Embossing Process

To really get a feel for how embossing comes to life, it helps to look at the key players involved. Each part has a critical job in producing a clean, crisp, and lasting impression.

Here’s a quick breakdown of what makes it all happen.

| Component | Function in the Embossing Process |

|---|---|

| Male Die | A metal plate with a raised (convex) version of the desired design. It pushes into the material. |

| Female Die (Counter-die) | A metal plate with a recessed (concave) version of the design. It receives the material as it's pressed. |

| Substrate | The material being embossed, most commonly paper, cardstock, or leather. Its properties affect the final look. |

| Press | The machine that applies controlled pressure, squeezing the substrate between the two dies to create the impression. |

Each of these elements works in concert to produce that premium, tactile feel.

This method gives a high-end touch to everything from luxury packaging to formal stationery. It’s no surprise that the demand for such quality is on the rise; the global automatic embossing press market was valued at USD 1.8 billion in 2023 and is projected to keep growing.

By the way, the opposite of this process is known as debossing. It creates a design that’s pressed down into the material instead of being raised from it. You can explore the differences and learn more about debossing techniques on our blog.

The Tools and Machinery Behind the Texture

To really get how embossing works, you have to look at the specialized hardware that brings these textured designs to life. The whole effect starts with embossing dies, which are custom-etched metal plates that act as a precision mold for paper or other materials.

The easiest way to think about these dies is as a perfectly matched puzzle pair. The male die has the raised, or convex, part of your design. Its partner, the female die (sometimes called a counter-die), holds the recessed, or concave, version. During the embossing process, the paper is literally sandwiched between them. Getting their alignment just right is absolutely critical for a sharp, clean impression.

The Foundation: Dies and Materials

The quality of the final embossed design is directly tied to the dies that create it. These aren’t just any old metal plates; they’re typically crafted from very specific materials chosen for their durability and how well they can hold fine detail.

- Brass Dies: Brass is the top-of-the-line choice. It's incredibly hard and durable, making it perfect for long production runs, super intricate designs, and any job that requires heat, since it conducts temperature so evenly.

- Magnesium Dies: As a more cost-effective and lighter option, magnesium is a fantastic pick for shorter runs and simpler designs. It’s also easier to etch, which makes it a go-to for projects that need a quick turnaround.

The way these plates are made is a fascinating craft in its own right. It’s a process closely related to other precise finishing methods. You can get a better sense of how custom shapes are created by exploring the world of custom die-cutting services.

From Hand-Cranked to High-Volume Presses

Once the dies are ready, they get mounted into an embossing press. The type of machine used really depends on the scale of the job, with options ranging from small-scale crafting setups to massive commercial production lines.

Hand-operated presses are great for artists, crafters, or small stationery projects. They give you total hands-on control but are naturally limited in their speed and the amount of pressure they can apply. On the complete other end of the spectrum, you have automated industrial presses. These are powerful machines that can exert tons of force, process thousands of sheets an hour, and often integrate heat to create deeper, more permanent impressions on tougher materials.

This huge range of equipment really shows how versatile embossing is, serving everyone from niche artisans to global brands. The embossing equipment market itself is proof of this, valued at an incredible USD 81.51 billion in 2023. This number highlights the massive demand for custom, textured finishes in packaging, print, and beyond. You can dive deeper into these market trends and insights at Wise Guy Reports.

At the end of the day, whether it’s done by hand or by a fully automated system, the basic principle is the same. It’s all about applying the right amount of controlled pressure to reshape the material and create a design you can not only see but also feel.

Common Embossing Techniques and Styles

Embossing isn’t just one trick—it’s a whole family of techniques, each with its own personality and feel. Getting to know these different styles is the key to picking the perfect finish, whether you’re creating an elegant wedding invitation or high-impact business collateral.

Embossing isn’t just one trick—it’s a whole family of techniques, each with its own personality and feel. Getting to know these different styles is the key to picking the perfect finish, whether you’re creating an elegant wedding invitation or high-impact business collateral.

The most direct approach is single-level embossing. This creates a design where every raised part sits on the same plane, giving you a clean and uniform texture. Just imagine a simple, bold logo standing out consistently across a business card.

For designs that need more flair, printers turn to multi-level embossing. This method uses a more intricate, sculpted die that pushes different parts of the design up to various heights. The outcome is a stunning 3D effect with real depth and detail, making it perfect for complex images like a floral pattern or an ornate family crest.

Key Styles And Their Unique Aesthetics

Beyond just how high the design is raised, a few distinct styles really define the final look. Each one has a different job, from quiet elegance to bold, attention-grabbing shine.

Blind Embossing: This is probably the most sophisticated style of them all. It’s all about pressing a design into paper without any ink or foil. The magic is in the texture alone—the way light and shadow dance across the raised surface creates a subtle, timeless look.

Debossing: As the name suggests, this is the complete opposite of embossing. Instead of raising the design, debossing presses it down into the stock, creating an indentation. It gives a distinct, sunken-in feel that can be just as striking, often used for a classic, letterpress-style effect.

Combination Stamping: Also known as foil embossing, this powerful technique pulls double duty. It applies shimmering metallic foil and embosses the design in a single pass of the press. The result is a raised, brilliant finish that demands attention and adds a sense of luxury to any piece.

These methods are the building blocks for creating print that people want to hold onto. Diving into a wide range of options, like those in a specialty printing collection, can be a great way to find inspiration for your next project.

Embossing vs Debossing A Quick Comparison

While they’re two sides of the same coin, knowing the difference between embossing and its counterpart, debossing, is essential for getting the exact finish you envision. Here's a quick rundown to make it clear.

| Feature | Embossing | Debossing |

|---|---|---|

| Design Effect | The design is raised up from the surface of the material. | The design is indented or sunken into the material. |

| Visual Feel | Creates a 3D, pop-out effect that catches the light. | Produces a subtle, letterpress-style recess. |

| Reverse Side | Leaves an indented (debossed) impression on the back. | Leaves a raised (embossed) impression on the back. |

| Common Use | Logos, monograms, formal invitations, premium packaging. | Stationery, leather goods, minimalist designs. |

By getting a handle on these techniques, you can better explain your vision and choose a style that truly elevates your design. It's how you turn a simple piece of paper into a memorable tactile experience.

Choosing the Right Materials for a Perfect Impression

The quality of your embossed design hinges just as much on the material you choose as it does on the machinery or technique. Think of your substrate as the canvas for the final texture; its unique properties will either create a crisp, deep impression or cause the whole thing to fail. The wrong material can lead to cracking, tearing, or a faint design that completely lacks impact.

Paper and cardstock are the classic choices for a reason. Their fibrous nature is practically built for being reshaped under pressure. But not all papers are created equal. The two most important factors to keep in mind are weight and fiber content. As a rule, heavier paper stocks are a better bet because they have enough body to hold a deep impression without showing stress or tearing on the other side.

In the same way, papers with longer fibers provide more flexibility, allowing the material to stretch and mold into the die rather than breaking. This is a big reason why uncoated stocks often produce far superior results. Coated, glossy papers have a smooth, sealed surface that can easily crack under the intense pressure of embossing, which ruins the clean finish you’re going for.

Paper Properties for Optimal Results

For projects where the feel is just as important as the look—like custom greeting cards or high-end business stationery—picking the right paper is everything. Here are the key characteristics you should be looking for:

- Weight (GSM/Cover): Heavier stocks, like 100 lb. cover or higher, are robust enough to prevent the debossed side (the indent on the back) from showing through too prominently.

- Finish: Uncoated papers have a natural, porous surface that takes an embossed impression beautifully, creating a rich, tactile feel you can’t get with coated stocks.

- Fiber Content: Papers made from cotton or other long-fiber pulps offer the best malleability, which is exactly what you need for deep, finely detailed impressions.

Understanding these details is what separates good print from great print. When you're designing something personal, the paper choice directly shapes the final aesthetic and feel. You can see some fantastic examples of how materials impact the final product by exploring different options for custom greeting cards.

Beyond Traditional Paper

While paper is easily the most common material, embossing is a versatile technique that can be applied to a whole range of other substrates. The process is just adapted to suit the unique properties of each one. For example, leather goods are frequently embossed using heat, which creates a permanent, branded mark sometimes known as blind stamping.

You can even emboss thin sheets of metal. This is a more industrial application that uses powerful stamping technology on materials like aluminum, brass, and steel to create product tags, nameplates, and decorative panels. The global market for metal embossing machines is massive, and it's projected to hit around USD 67.34 billion by 2028. This growth is really being driven by its use in branding and industrial parts across the automotive and construction industries. You can dive deeper into these market trends on Data Bridge Market Research.

The Embossing Process: From Design to Final Product

Ever wonder how a flat, ordinary piece of paper becomes a stunning, textured masterpiece? The journey from a simple design to a finished embossed product is a fascinating blend of artistic vision and technical skill. Let’s pull back the curtain and look at the craftsmanship behind every raised detail.

It all starts well before anything hits the press. The first step is what we call design translation. This is where a digital artwork file is turned into a physical tool. A specialized manufacturer meticulously etches the design onto metal plates, creating a matched set of male and female dies. These two pieces will work together to press the design into the paper. The complexity of the artwork—whether it's simple text or an intricate logo—determines the time and skill needed for this crucial first stage.

From Preparation to Press

With the dies made, the action moves to the production floor. First, the material (or substrate) is chosen and prepped. Then comes one of the most critical parts of the whole process: machine calibration. The press operator has to painstakingly align the male and female dies so they meet perfectly. Even a hairline of misalignment can create a blurry, weak impression and ruin the entire effect.

Once everything is perfectly aligned, the press run can begin. This is where the magic really happens.

- Material Feeding: Sheets of paper or cardstock are fed into the press, positioned just right between the open dies.

- Impression: The press applies a precise amount of force, squeezing the material between the dies. Often, heat is used along with the pressure to help soften the paper fibers, which allows for a much deeper and more permanent impression.

- Release: The press opens, and the freshly embossed sheet is ejected, making way for the next one. This can be a methodical, single-sheet process or a high-speed run pumping out thousands of impressions an hour on industrial machines.

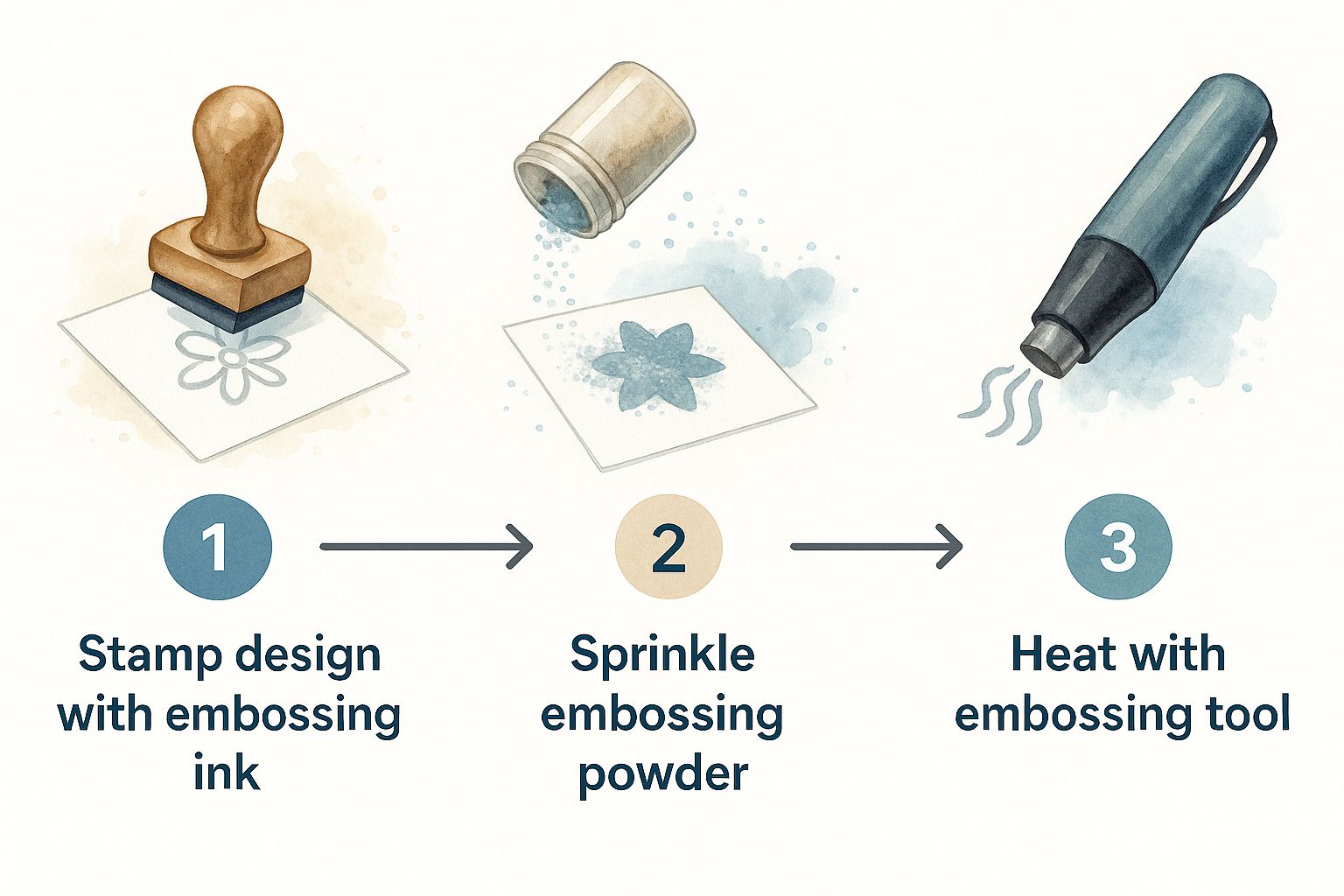

The infographic below gives a great visual of the core actions—stamping, applying powder, and heating—which is a common method for smaller-scale, craft-level heat embossing.

While this image shows a simplified workflow for heat embossing, the fundamental idea of using pressure to create a raised design is the same across all professional embossing methods.

Ensuring a Perfect Finish

The job isn't done when the press stops. The final, and arguably most important, stage is rigorous quality control. Every single piece is inspected for even the smallest flaws.

Quality checks are non-negotiable. Inspectors are trained to spot common issues like "bruising" (a faint halo around the design), "cracking" (when the paper fibers actually break), or registration errors where the emboss doesn't line up perfectly with any printed ink.

This meticulous attention to detail ensures that every item, from a wedding invitation to a product box, meets the highest possible standard. It’s this level of care that gives products like professionally embossed custom business card printing their premium, unforgettable feel. Only after passing this final inspection is the product considered complete—a successful transformation from a simple design into a tactile experience that people remember.

Got Questions About Embossing? We’ve Got Answers.

Once you start exploring what embossing can do, a few questions almost always pop up. Getting these cleared up from the get-go is key to planning your projects well and talking shop with your printer. Let's tackle some of the most common points of confusion.

One of the biggest mix-ups? Embossing versus foil stamping. Here’s the simple difference: embossing physically reshapes the paper, creating a raised, three-dimensional texture you can feel. Foil stamping, on the other hand, is all about the shine—it applies a thin layer of metallic or colored foil onto the paper’s surface using heat and pressure, but it doesn't alter the paper's shape.

Of course, you don’t have to choose. The two can be combined in a technique called foil embossing. This gives you a raised design with a brilliant, metallic finish, delivering the best of both worlds.

Can Any Design Be Embossed?

While it’s an incredibly versatile technique, embossing does have its limits. Not every design is a great candidate. Designs with extremely fine lines, tiny text, or overly busy patterns often lose their definition when pressed into paper. The details can get muddy or just fail to stand out.

What works best? Bold shapes, clean lines, and simpler graphics. These elements produce the most striking and effective results.

A good rule of thumb is that if a design feels too crowded on your screen, it will likely struggle to translate well into a physical emboss. It’s always smart to run your artwork by your printer to make sure it’s a good fit for the technique.

Does Embossing Show Through on the Back?

Yes, a standard emboss will always leave a reversed, indented impression on the back of the paper. This isn't a flaw; it's just a natural part of how the process works. The male die pushes the paper into the female die, which inevitably leaves a debossed mark on the reverse side.

The good news is that the thickness of the paper stock can dramatically minimize how noticeable this is. For two-sided items like business cards or invitations, designers have a clever workaround: using an extra-thick stock or mounting two embossed sheets together. This creates a flawless, premium finish on both sides.

Ready to add a touch of elegance to your next project? The experts at 4OVER4 can help you choose the perfect embossing technique to make your designs stand out. Explore our high-quality custom printing options at https://4over4.com today.

More from how does embossing work

12

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

Emma Davis

Emma Davis

Feb 1, 2026

24

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

Emma Davis

Emma Davis

Jan 31, 2026

39

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

Emma Davis

Emma Davis

Jan 30, 2026

41

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

Emma Davis

Emma Davis

Jan 29, 2026

112

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

92

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

321

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

203

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026