- Home

- content hub

- A Practical Guide to Graphic Design for Print

A Practical Guide to Graphic Design for Print

Emma Davis

Content Writer

Oct 8, 2025404 views

Oct 8, 2025404 views

Graphic design for print is a whole different ballgame. It’s the craft of making visuals for things you can actually hold—brochures, business cards, posters, you name it. To get it right, you have to nail the technical details like CMYK color modes, 300 DPI resolution, and precise physical dimensions. Unlike digital design, where you can fix a mistake with a few clicks, print involves real, tangible materials. Getting the setup perfect from the start is non-negotiable if you want the final product to look exactly like what you see on your screen.

Why Print Design Is a Different Beast

Before you even think about starting a print project, you need to wrap your head around the huge differences between designing for a screen and designing for paper. I’ve seen it happen a hundred times: a design looks absolutely brilliant on a backlit monitor but turns into a muddy, blurry, or misaligned mess on the printing press. This isn’t just about aesthetics; it’s about physics and mechanics.

The core of it is the medium itself. A digital screen creates color by emitting light using the RGB (Red, Green, Blue) model, which is why you get those vibrant, glowing visuals. Paper, on the other hand, absorbs light. Print uses the CMYK (Cyan, Magenta, Yellow, Key/Black) color model, where inks are layered on top of each other to subtract brightness from the white paper. That's exactly why that electric blue on your screen might come out looking much duller in your printed brochure.

Thinking in Physical Terms

When you’re designing for print, you have to think in tangible dimensions. Forget about pixels. Your new best friends are inches, millimeters, and picas. You need to consider how the final piece will actually be held, folded, and experienced by a real person.

- Tactile Experience: The weight and texture of the paper are part of the design. A glossy flyer feels completely different from a heavy, uncoated business card. These choices affect how the ink absorbs and what people think about the quality of your brand.

- Physical Constraints: A webpage can scroll forever, but a printed piece has hard edges. Every single element must fit neatly within a specific trim size, and you have to keep all your important info inside a "safe margin" to make sure nothing gets chopped off during cutting.

This shift from a fluid digital canvas to a fixed, physical object demands a different way of thinking. You're not just creating an image; you're engineering an object. For bigger jobs, knowing the ins and outs of different printing methods is crucial. For instance, https://www.4over4.com/printing/category/offset-printing is the go-to for large runs where you need consistent, high-quality results.

The Financial Stakes of Print Design

In digital design, mistakes are usually a quick fix. A typo on a blog post? A wrong color on a website? You can sort that out in minutes with almost no cost. But in the world of print, errors are permanent and painfully expensive.

A single oversight, like using a low-res image or forgetting to add a bleed, can turn thousands of flyers or brochures into a pile of expensive recycling. This is why the pre-press stage—where you check and finalize your files—is the most critical part of the whole process.

The global graphic design industry was valued at $43.4 billion in 2025, with the U.S. market alone making up $13.3 billion of that. This massive industry runs on precision because every print run is a real financial investment. Mastering the technical side isn't just about being a good designer; it's about being a responsible one. You can find more stats on the industry's scale over at Colorlib.

Getting Your Document Setup Right

Getting your document set up correctly from the very beginning is your first, and best, line of defense against costly print errors. This is where we stop talking theory and start putting it into practice, turning a blank digital canvas into a solid blueprint for a physical product.

Let's walk through creating a print-ready file using a standard tri-fold brochure as our example. It keeps things tangible and grounded in the real world.

Imagine you're designing that brochure for a local coffee shop. The final, folded piece will be a standard letter-sized page (8.5" x 11") creased into three panels. The absolute first thing you must do is plug those exact physical dimensions into your design software, whether it's Adobe InDesign or Illustrator. This isn't a suggestion—it's the foundation of the entire project.

The Holy Trinity: Bleed, Safe Zone, and Slug

Once your document dimensions are locked in, the next critical step is to establish the "holy trinity" of any print layout: the bleed, the safe zone, and the slug. These aren't just technical jargon; think of them as safety nets that guarantee your final printed piece looks sharp and professional.

First up is the bleed. This is a small, extra margin of your background color or image that extends beyond the final trim edge. The industry standard is typically 0.125 inches (or 1/8th of an inch) on all sides. Why does this matter so much? Printing and trimming are physical processes, and the cutting machines can have a tiny margin of error. Without that bleed, any slight shift during the cut could leave a glaring white sliver along the edge of your beautiful design.

Next, you have to define the safe zone, sometimes called the live area. This is an internal margin—usually another 0.125 inches inside the trim line. You need to keep all your critical content, like text, logos, and key parts of images, well within this zone. It's a simple way to guarantee that nothing important gets accidentally chopped off.

Setting a proper bleed and safe zone is the single most effective way to prevent the most common print file rejection. It’s a non-negotiable step that separates amateur layouts from professional, press-ready artwork.

Finally, there's the slug. This is an optional area that sits outside the bleed where you can leave notes for your printer. You might include your contact information, specific folding instructions, or details about any special finishes you want. It's your direct line of communication with the person running the press.

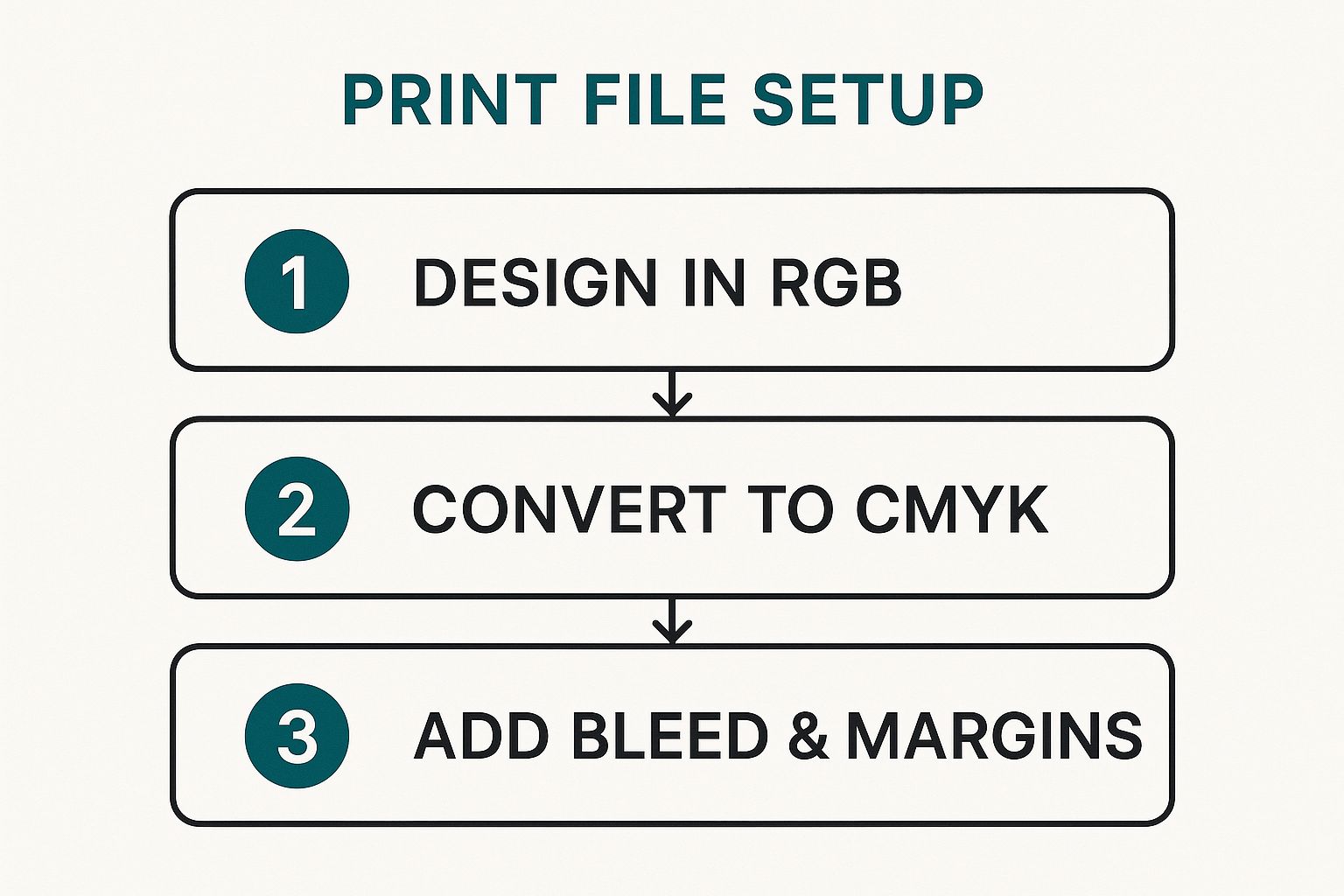

To make this a bit clearer, check out this quick visual summary of the workflow, from the initial design concept to the final, structured setup with bleed and margins properly in place.

This flow really highlights how essential it is to move from a creative digital space (RGB) into a technical, print-ready format (CMYK) while building in those crucial structural elements like bleed and margins.

Before you jump into the creative side of things, it's a good habit to double-check these foundational settings. This simple checklist can save you a world of headaches later on.

Essential Print Setup Checklist

| Setting | Purpose | Common Standard |

|---|---|---|

| Document Size | Defines the final trim dimensions of the printed piece. | Matches the final product size (e.g., 8.5" x 11"). |

| Color Mode | Ensures colors will print accurately on a press. | CMYK (not RGB). |

| Bleed | Prevents white edges after trimming by extending the design. | 0.125" (1/8th inch) on all sides. |

| Safe Zone | Protects critical content from being trimmed off. | 0.125" or more inside the trim line. |

| Resolution | Guarantees images are sharp and not pixelated. | 300 DPI (Dots Per Inch). |

Running through this list ensures your file is built on a solid, professional foundation from the get-go.

Applying It to the Brochure Project

Let's circle back to our tri-fold brochure. With a final trim size of 8.5" x 11", your document setup in InDesign should look something like this:

- Page Size (Trim Size): 8.5" width x 11" height.

- Bleed: 0.125" on all four sides. This makes your actual document size 8.75" x 11.25".

- Margins (Safe Zone): At least 0.125" inside the trim edge. I often use 0.25" just to give everything more breathing room.

You'd also add guides to mark the fold lines, ensuring your panels align perfectly. A little-known fact about a standard letter tri-fold is that the panels aren't all equal; one is slightly shorter so it can fold inside neatly. A quick search or a template from your printer will give you the exact measurements for these fold lines.

These initial setup steps are universal, whether you're designing a business card or a massive catalog. Mastering them is what builds the foundation for every successful print project. The precision you establish here directly impacts the quality of the final product. And for those projects that need to break out of the standard rectangle, exploring options like custom die cutting can add a truly memorable touch.

Mastering Color and Resolution

Once you've got the basic structure of your document nailed down, it's time to tackle the two elements that can truly make or break a print job: color and resolution. Getting these right is the difference between a project that looks professional and one that’s a huge disappointment.

We've all been there, especially early in our careers. You design something with vibrant, glowing colors on your screen, only to get the printed version back looking flat and muddy. This gut-wrenching moment almost always comes down to one fundamental misunderstanding: screens and printers speak two completely different color languages.

The Great Divide: RGB vs. CMYK

Your monitor, phone, and TV create images by emitting light. They use the RGB (Red, Green, Blue) color model, which is additive. When you combine red, green, and blue light, you get pure white. It’s why colors on a screen can look so bright and luminous.

Printing is the total opposite. It's a subtractive process that works by putting ink on paper. Printers use the CMYK (Cyan, Magenta, Yellow, Key/Black) model, where inks are layered to subtract brightness from the white paper. Combine them all, and you get a dark, murky brown—which is why a true black ink (Key) is essential.

Because of this, the range of colors CMYK can produce (its "gamut") is much smaller than RGB's. Those electric blues and neon greens you love on screen? They simply don't exist in the world of ink. When you convert an RGB file to CMYK, the software does its best to find the closest match, but it often leads to a noticeable—and usually disappointing—color shift.

Here’s the single most important takeaway: Always, always, always start your print projects in CMYK mode. Designing in CMYK from the beginning means the colors you see are the colors you'll get. No more nasty surprises.

Achieving Perfect Brand Consistency with Pantone Colors

So, what if a brand's specific shade of "Coke Red" needs to be perfect every single time, no matter what? Mixing cyan, magenta, yellow, and black can get you close, but slight variations are inevitable from one print run to the next.

That's when you bring in the big guns: the Pantone Matching System (PMS), also known as spot colors.

Think of it like buying a specific can of paint at the hardware store. Instead of mixing inks on the fly, a Pantone color is a single, pre-mixed ink created from a precise formula. You get the exact same shade every time.

Here's when you'll want to use Pantone colors:

- Logos and Branding: To guarantee absolute color consistency across business cards, brochures, and signage.

- Limited Color Palettes: If a design only uses one or two colors, printing with spot inks can sometimes be cheaper than a full four-color job.

- Colors Outside the CMYK Gamut: Need a metallic silver, a fluorescent orange, or another color CMYK just can't handle? A spot color is your only option.

When working with spot colors, you have to be crystal clear with your printer. Make sure to specify the exact Pantone code (like PANTONE 185 C) in your design file so they know precisely which ink to load into the press.

The Non-Negotiable Rule of 300 DPI

Now let's talk clarity. The sharpness of your printed photos and graphics all comes down to resolution, which we measure in DPI (Dots Per Inch). This number literally tells the printer how many tiny dots of ink to place within a one-inch line.

For the web, 72 DPI is the standard. It looks perfectly fine on a screen because monitors have a relatively low pixel density. But if you try to print a 72 DPI image, you're in for a world of hurt. The result will be a blurry, pixelated mess as the printer struggles to stretch just a few dots over a large physical area.

For professional-quality print, 300 DPI is the unbreakable rule. At this resolution, the ink dots are so small and packed so tightly together that our eyes perceive them as a crisp, continuous image. There's no room for negotiation on this one.

The Visual Impact of Resolution

The difference between low-res and high-res in print is night and day. Imagine you're designing a restaurant flyer and you grab a photo of their signature pasta dish from their website.

- The Low-Res Mistake: That website photo is almost certainly 72 DPI. It looks great on your monitor. But when you place it in your 300 DPI print file, it will appear tiny. If you try to scale it up to fit the space, it instantly becomes a blocky, unprofessional-looking disaster that makes the food look unappetizing.

- The High-Res Solution: A photo taken with a decent camera and saved at 300 DPI will look sharp, detailed, and delicious in print. Every noodle and basil leaf will be clear, making the dish—and the restaurant—look professional.

Before you ever send a file off to be printed, double-check the resolution of every single image. In tools like Adobe Photoshop, you can easily see the image size and resolution to ensure everything is set to that magic number: 300 DPI. For projects where sharpness is paramount, especially for smaller batches, high-quality digital printing services can beautifully reproduce every detail of your high-resolution files.

Choosing Fonts and Paper for Impact

A design isn't truly finished until it becomes a physical object. That final piece—the feel of the paper in your hands, the crispness of the text—is just as critical as the digital file you spent hours perfecting. Let's get into typography and paper stock, the two elements that turn a great concept into a tangible experience.

Choosing fonts for print is a whole different ballgame than designing for a screen. On paper, you’re dealing with physics. Ink bleeds into the paper’s fibers, a phenomenon called ink spread or dot gain, which can cause the fine details in a font to vanish or make thin letters look muddy and unreadable.

Crafting Legible Print Typography

That delicate, wispy font that looks so elegant on your monitor? It might just turn into a blurry mess on an uncoated, porous paper. The ink will naturally spread out, thickening every stroke. Because of this, it's almost always a safer bet to choose fonts with a sturdier build and clear letterforms, especially for smaller body text.

Your choice between serif and sans-serif fonts should really be guided by the project’s overall vibe and where it will be seen.

- Serif Fonts: Think Times New Roman. Those little decorative strokes, or "feet," are traditionally loved for long blocks of text in books and newspapers. The serifs are thought to help guide the eye along each line, making for an easier read.

- Sans-Serif Fonts: Think Helvetica or Arial. Without the strokes, these fonts have a clean, modern feel. They shine in headlines and captions but work just as well in print when you give them enough breathing room.

A crucial rule of thumb I always follow is to never go below 8 to 10 points for body text. Anything smaller is a huge risk, especially with serif fonts where the tiny details can easily get lost in the ink.

Imagine a high-end fashion catalog. It might use a crisp, elegant serif for its descriptions to broadcast sophistication. On the other hand, a tech startup’s flyer would probably go for a clean, bold sans-serif to feel modern and straight to the point.

The Power of Paper Stock

Paper isn't just a background; it's an active part of your design. The weight, finish, and texture you select will dramatically change how the final product looks and feels, directly influencing how people perceive your brand.

Paper weight is measured in GSM (Grams per Square Meter) or Points (pt). A flimsy 90 GSM paper might be okay for a throwaway flyer, but a premium business card needs to feel substantial. We're talking 350 GSM (16 pt) or even heavier. The weight alone communicates quality before a single word is even read. For something that makes a serious statement, you can explore options like our ultra-thick collection.

Matching Finish to Function

The paper's finish is another make-or-break decision that directly affects how your colors and images come to life. Each type serves a different purpose and creates a totally different mood.

| Paper Finish | Best For | Characteristics |

|---|---|---|

| Glossy | Photo-heavy brochures, flyers, posters | Shiny, reflective surface that makes colors pop. Shows fingerprints easily. |

| Matte | Business cards, invitations, art prints | Smooth, non-reflective finish for a sophisticated, modern look. Less vibrant than gloss. |

| Uncoated | Letterheads, notebooks, eco-friendly branding | Natural, textured feel. Ink absorbs more, softening colors. Easy to write on. |

Let's think through a couple of real-world scenarios. For a luxury wedding invitation, you want something that feels special. A heavy, uncoated cardstock with a subtle texture immediately signals elegance. In contrast, for a mass-produced pizza menu, a lightweight, glossy paper is perfect—it makes the food photos look amazing and it’s cheap to print in bulk.

Ultimately, great print design is all about making intentional choices that honor the physical medium. Staying on top of what works is key, too. Studies show that 94% of first impressions are design-related, and 38% of people will toss a printed piece if the layout is unattractive. By getting your typography and paper choices right, you create more than just marketing material—you create a memorable experience.

Your Final Prepress Checklist

You’ve poured everything into this design. It looks absolutely perfect on your screen. But now comes the moment of truth: the handoff. This final stage is all about a meticulous preflight check to make sure your beautiful digital file becomes a flawless physical print.

Think of yourself as a pilot doing a final inspection before takeoff. This is not the time to rush. It's your last chance to hunt down any gremlins hiding in your file—the kind that cause expensive, soul-crushing reprints. We're talking about sneaky RGB elements, missing fonts, or a low-res image that somehow slipped through the cracks.

Conducting a Thorough Preflight Check

Your design software is your best friend here. Adobe InDesign, for instance, has a fantastic built-in "Preflight" panel that acts like an automated quality control inspector. It’ll flag most of the common problems, but you still need to know what to look for. Trust me, you can't rely on it completely.

Here’s a quick list of what I always check manually, no matter what the software says:

- Color Mode Confirmation: Go through your document and swatches with a fine-tooth comb. Is every single element, from photos to tiny vector icons, in CMYK? One stray RGB logo can throw off the entire color balance of a print run.

- Resolution Audit: Click on every single placed image. Check its "effective" resolution. Is it at least 300 DPI at the size it's being printed? This is non-negotiable for sharp, professional results.

- Bleed and Safety Margins: Visually confirm that every element touching the page edge extends all the way to the bleed line. Even more important, make sure no critical text or logos are creeping into that safety margin.

- Ink Coverage: Take a look at your rich blacks and other dark areas. You need to make sure the total ink coverage (the sum of C+M+Y+K values) doesn't go over the printer's limit, which is usually around 300% to 320%. Too much ink leads to muddy colors and frustrating drying issues on press.

This is where you catch the tiny mistakes that become huge problems. Taking an extra ten minutes here can save you hours of headaches and hundreds of dollars down the line.

Packaging Files and Outlining Fonts

Once your file passes inspection, it's time to get it ready for the printer. There are two main ways to do this, and it usually depends on your software and what your printer prefers.

If you're in Adobe InDesign, the "Package" feature is your absolute go-to. This command is a lifesaver—it gathers your InDesign file, all linked graphics, and every necessary font into one neat folder. This is the gold standard because it guarantees the printer has every single asset they need.

Alternatively, if you're in a program like Adobe Illustrator or if the printer specifically asks for it, you might need to "Create Outlines" for your text. This essentially turns your text into vector shapes, so it no longer needs a font file to be viewed correctly. The upside? No more font issues. The downside is that the text is no longer editable, so always save a separate version with live text before you do this.

Pro Tip: I always send both. Send the printer the packaged file and a press-ready PDF. The packaged file is a great backup in case they need to make a tiny, last-minute fix on their end, while the PDF is the locked-and-loaded file they'll actually print from.

Exporting a Bulletproof Press-Ready PDF

The final, most critical step is creating that high-quality, press-ready PDF. This is the universal format that printers love because it locks everything in place.

When you export, don't just hit "Save." Use the "Adobe PDF Presets" and choose [Press Quality]. This preset does most of the heavy lifting for you, but you still need to tweak a couple of things.

Navigate to the "Marks and Bleeds" tab. You absolutely must check the boxes for:

- Crop Marks: These little lines tell the printer exactly where to trim the final piece.

- Use Document Bleed Settings: This ensures the bleed you so carefully set up is actually included in the final file.

Forgetting these settings is one of the most common reasons files get rejected. The standards for print are only getting more important as digital printing evolves. In fact, the digital graphic printing market is expected to grow at a CAGR of 5.2% from 2025 to 2030, showing just how critical these technical skills are.

Finally, if your project has a special touch, like a unique finish, double-check that you’ve set up your files correctly for that process. For example, learning more about laminating options for your prints can add incredible durability and a premium feel, but it requires the right setup from the start.

Once you’ve gone through this checklist, you can send your file off with total confidence, knowing you’ve done everything possible to guarantee a perfect print.

Common Print Design Questions

Even the most seasoned designers hit a wall with certain technical print questions. A few key issues tend to pop up time and again, often standing as the final hurdle between a brilliant idea and a perfect print run. Let's clear up some of the most frequent queries that land in our inbox.

Vector vs. Raster: What’s the Real Difference for Print?

This is probably the single most important concept to nail down for print design.

Think of a raster image (like a JPG or PNG) as a detailed mosaic made from thousands of tiny colored squares, called pixels. At its original size, it looks fantastic. But the second you try to make it bigger, you're just stretching those little squares out. The result? That blurry, jagged-edged mess that every printer dreads seeing.

A vector file (think AI, EPS, or SVG) works in a totally different way. Instead of pixels, it’s built from mathematical paths, points, and curves. This means you can scale a vector logo from the size of a postage stamp to a building-sized billboard with absolutely zero loss in quality.

Here's the golden rule for print: Logos, typography, and any kind of line art must be in a vector format. This is the only way to guarantee they’ll print with perfectly sharp, clean edges. Reserve raster images exclusively for photographs.

How Do I Get a True, Deep Black?

One of the most common rookie mistakes is assuming that setting your color to 100% Black (K) in a CMYK file will give you a solid, deep black. On paper, it just doesn't work that way. Pure 100% K ink often comes out looking more like a dark charcoal gray, especially over larger areas. It can look washed out and weak.

The secret is to create a "rich black" by supporting the black ink with other colors. When you mix in a little cyan, magenta, and yellow, you create a black that’s much deeper, darker, and more saturated. It just pops off the page.

A safe, industry-standard formula for rich black is:

- C: 60%

- M: 40%

- Y: 40%

- K: 100%

It's always a good idea to check with your printing partner for their preferred rich black values. Different presses and paper stocks can sometimes require a slightly tweaked formula to get the best results.

What Is Overprinting and When Should I Use It?

Overprinting is a setting that tells the printing press to lay one color of ink directly on top of another. By default, programs are set to "knockout," which means the bottom color is cut out to make a blank space for the top color to be printed into.

So, when would you use it? The most critical and practical application is for small black text. If that tiny text is set to knock out, even a microscopic misalignment of the printing plates can create a thin white halo around the letters. This makes the text look fuzzy and difficult to read.

By setting small black text to overprint, you’re telling the press to print the black ink directly over whatever colors are in the background. This completely eliminates the risk of those ugly gaps, keeping your text perfectly crisp and legible. As a general rule, you should only use this for black elements—avoid it for other colors unless you get specific instructions from your printer.

At 4OVER4, we're obsessed with bringing your designs to life just as you pictured them. From business cards to massive banners, our team’s expertise ensures your print projects always look professional and make an impact. Explore our full range of high-quality printing services at 4over4.com and see the difference precision makes.

More from graphic design for print

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

61

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

104

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

104

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

326

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026