- Home

- content hub

- A Guide to Food Packaging Labels

A Guide to Food Packaging Labels

Emma Davis

Content Writer

Oct 14, 2025263 views

Oct 14, 2025263 views

Think of your food packaging label as your product's most important salesperson. It's also its legal passport. It’s the one tool you have to grab a shopper's attention with incredible branding, while at the same time, communicating all the critical safety and nutritional info required by law. Nailing this balance isn't just important—it's everything.

What Are Food Packaging Labels and Why Are They Critical?

Imagine your label as the silent ambassador for your product. In the few seconds a customer spends scanning a packed supermarket shelf, your label has to do all the talking. It’s a tiny but mighty marketing vehicle that tells your brand’s story, values, and personality through color, fonts, and imagery. A great label can make a product feel premium, healthy, or fun before a single word is even read.

But it’s so much more than just a pretty face. The label also acts as a crucial legal document—a pact of trust between you and your buyer. It has to accurately list all the legally required information to keep consumers safe and informed. This dual responsibility makes creating a label a delicate balancing act.

The Two Core Functions of Every Label

Every single effective food label does two things really well. If you drop the ball on either one, you're looking at poor sales, legal headaches, or a brand reputation that's hard to fix.

- Marketing and Branding: This is your label's "voice." It’s responsible for cutting through the noise, building brand recognition, and convincing a customer to put your product in their cart.

- Information and Compliance: This is your label's "passport." It guarantees the product meets all regulatory standards by providing key data like ingredients, allergens, and nutritional facts. Without this, your product can't legally make the trip from the shelf to the checkout line.

Your label isn't just another piece of your packaging; it is the direct interface between your product and your customer. It must be clear, compelling, and compliant to build the trust you need for a lasting relationship.

The sheer scale of the industry just magnifies how important this is. The global food packaging market was valued at USD 505.27 billion in 2024 and is expected to hit USD 815.51 billion by 2032. This explosive growth shows just how much we rely on packaged goods and, by extension, the labels that inform and protect us.

Ultimately, mastering the art and science of food packaging labels isn't optional. It’s a fundamental requirement for any food business that wants to build a loyal following and find real success. Whether you're an artisanal startup or a household name, getting your labels right is key, which is why exploring a wide range of custom packaging products is such a critical first step.

Understanding the Anatomy of a Food Label

Think of a food label as a contract between you and your customer. It’s a promise of what’s inside, presented in a very specific, legally-required way. This isn't just about good design; it’s about federal law and consumer safety. Agencies like the FDA have a list of non-negotiables—five core components that absolutely must be on your food packaging labels.

Getting these elements right is the bedrock of a compliant and trustworthy product. Let's break down each of these five critical pieces so you know exactly what’s required.

The Statement of Identity and Net Quantity

First things first, you have to answer two very basic questions for any shopper: "What is this?" and "How much am I getting?"

- Statement of Identity: This is simply the common name of the food. It needs to be front and center on the Principal Display Panel (PDP)—that’s the part of the package a customer is most likely to see on the shelf. You can't get creative here; if you're selling a fruit-flavored drink, you can't call it "juice" unless it legally meets that definition.

- Net Quantity of Contents: This tells the customer how much product is in the package. It must be stated in both metric (grams, milliliters) and U.S. Customary units (ounces, fluid ounces). Like the identity statement, this info has to live on the PDP, usually within the bottom third of the panel.

These two components are the most straightforward, but they're the essential handshake with your customer.

The Nutrition Facts Panel

This is probably the most recognized part of any food label. The Nutrition Facts panel is a standardized chart that gives consumers a consistent, easy-to-read breakdown of the product's nutritional content. Its format is strictly regulated for a reason—it allows shoppers to make quick, apples-to-apples comparisons between different products.

The panel lays out key information like serving size, calories, total fat, cholesterol, sodium, carbohydrates, and protein. The FDA has even updated the design to better serve today's health-conscious consumers.

Here’s a look at the FDA’s updated label, which features bolder text for calories and more realistic serving sizes.

This new look makes it much easier for people to find the information they need to make healthy choices on the fly.

The Nutrition Facts panel is more than just a list of numbers; it’s a public health tool. Its standardized format empowers people to take control of their diet, turning a simple grocery run into an informed health decision.

Another key part of this panel is the Universal Product Code (UPC). This scannable barcode is the key to retail sales and inventory tracking. To get your products ready for the checkout line, it's crucial to understand the requirements for printing barcodes for your packaging.

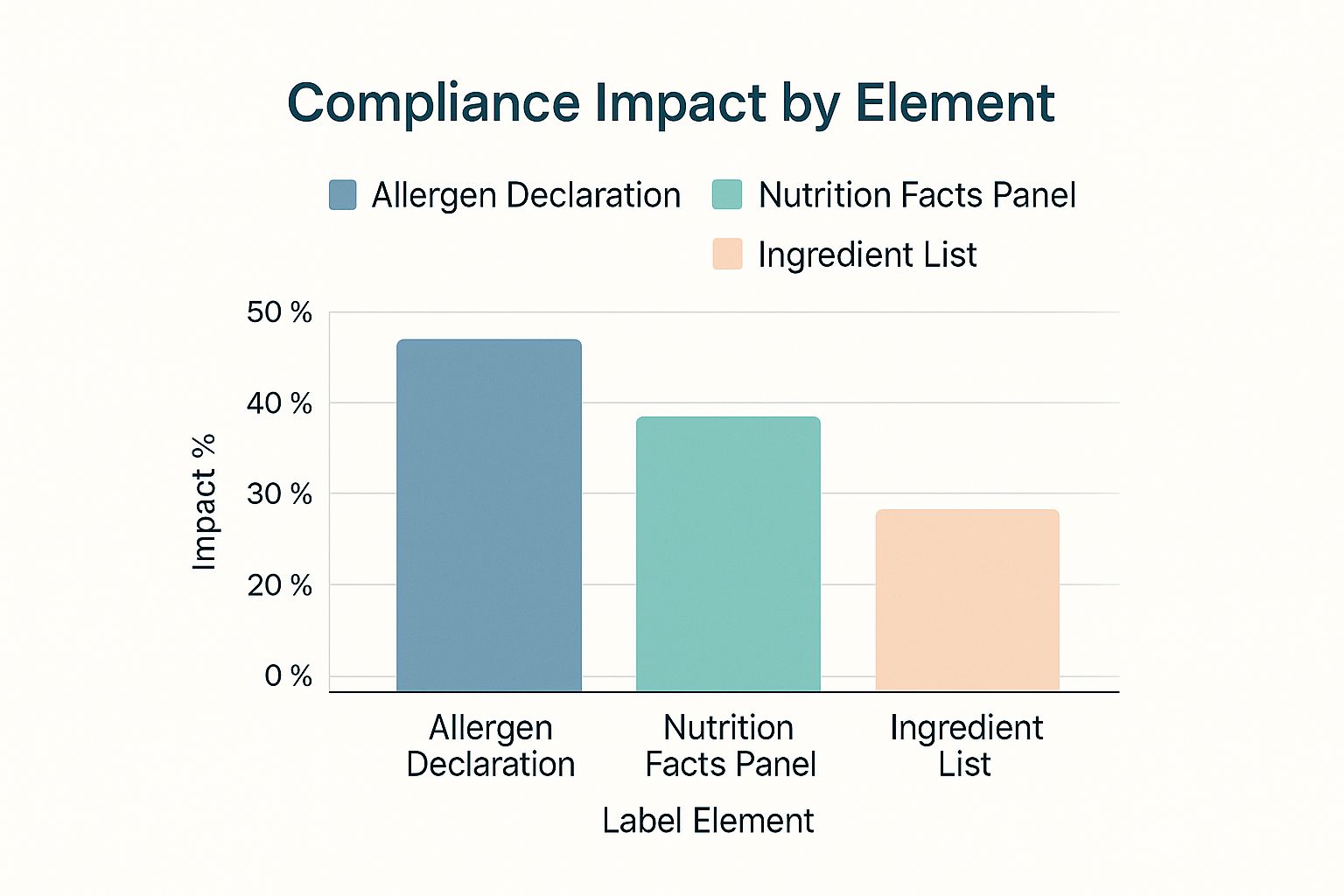

Ingredient List and Allergen Declaration

Now we get to the parts of the label that are most critical for consumer safety. The ingredient list and allergen declaration are all about transparency, giving people the information they need to avoid potentially life-threatening reactions.

Ingredient List: This section must list every single ingredient in the product. The catch? They have to be ordered by weight, from the most prominent ingredient down to the least. It’s a straightforward way to show customers exactly what they’re eating.

Allergen Declaration: This one is a huge deal. Federal law mandates that the eight major food allergens must be clearly called out. They are:

- Milk

- Eggs

- Fish

- Crustacean shellfish

- Tree nuts

- Peanuts

- Wheat

- Soybeans

You have to declare these using a "Contains" statement right after the ingredient list (for example, "Contains Wheat, Milk, and Soy"). This isn't optional, and getting it wrong is one of the fastest ways to trigger a product recall. These five elements form the foundation of a label that not only meets legal standards but also builds the trust you need to succeed.

Choosing the Right Materials and Finishes

The information on your label is critical, but the material it’s printed on is what makes sure that message actually survives the journey. Think of it this way: you wouldn’t wear a paper suit in the rain. Your label needs the right "outfit" for its environment, whether it's sitting pretty in the freezer aisle or getting splashed in a steamy kitchen.

A label’s physical makeup—its base material, adhesive, and top finish—dictates how it looks, feels, and performs. Nailing this choice is about more than just aesthetics; it’s what prevents annoying issues like peeling, smudging, or fading that can make a great product look cheap. Getting this right is fundamental to creating effective food packaging labels that look professional from your facility all the way to a customer’s pantry.

Common Label Materials And Their Best Uses

While the world of label materials is huge, most food products stick to a handful of tried-and-true options. Each one has its own personality and purpose, and understanding the differences is the first step to making a smart investment in your product's presentation.

Here’s a look at the most popular choices:

- Paper Labels: This is the classic, go-to option for dry goods. It’s cost-effective and perfect for things like coffee bags, snack packaging, and spice jars. Paper gives off a natural, sometimes rustic vibe, but it’s the worst enemy of moisture and oil, making it a no-go for refrigerated or wet products.

- Polypropylene (BOPP) Labels: Biaxially-Oriented Polypropylene is a tough plastic film that shrugs off water, oil, and most chemicals. This makes it the champion for anything that might face condensation, refrigeration, or spills—think beverage bottles, sauce jars, and frozen foods.

- Vinyl Labels: Known for its killer durability and flexibility, vinyl is the material you choose for the toughest jobs. It’s perfect for outdoor use or for labels that need to hug a weirdly curved surface without complaining. It’s a more premium choice that stands up to harsh conditions without tearing or fading.

For any items that will live in a damp environment, exploring a range of custom waterproof labels is the only way to guarantee your branding stays sharp and intact.

To help you visualize the trade-offs, here’s a quick comparison of the most common materials used for food packaging labels.

Comparison of Common Food Label Materials

This table breaks down the characteristics, ideal use cases, and cost implications of popular label materials to help you make an informed choice for your product.

| Material Type | Key Features | Best For | Cost Level |

|---|---|---|---|

| Paper | Cost-effective, natural look and feel, easy to print. | Dry goods, short-term use, products not exposed to moisture. | Low |

| Polypropylene (BOPP) | Water and oil-resistant, durable, clear or opaque. | Beverages, refrigerated items, sauces, cosmetics. | Medium |

| Vinyl | Extremely durable, flexible, weatherproof, UV-resistant. | Outdoor products, curved surfaces, long-term applications. | High |

| Recycled Paper | Eco-friendly, rustic aesthetic, good for branding. | Dry goods, organic products, brands with a sustainability focus. | Medium |

Choosing the right material is a balancing act between performance, aesthetics, and budget. BOPP often hits the sweet spot for many food products, but don't discount paper for dry goods or vinyl when you need something truly indestructible.

Selecting The Perfect Adhesive And Finish

Okay, so you’ve picked your base material. Now for the next layers: the adhesive that sticks it on and the finish that gives it that final pop. The adhesive is the unsung hero holding everything together, while the finish is the final touch that defines the label’s entire look and feel.

The right glue needs to work with both your label material and your container’s surface. A standard permanent adhesive handles most jobs just fine, but you'll need specialized options for tricky surfaces or conditions. For instance, a freezer-grade adhesive is non-negotiable for products headed for cold storage—otherwise, you’ll find your labels peeling off and lying sadly at the bottom of the freezer.

The finish, on the other hand, is all about visual appeal and adding an extra layer of protection.

The finish on a food label is like the final coat of paint on a car. It not only provides the desired sheen but also protects everything underneath from the elements, ensuring the design stays vibrant and scuff-free.

Here are the main players when it comes to finishes:

- Gloss: A shiny, reflective finish that makes colors explode off the label. It’s fantastic for grabbing attention on a crowded shelf and adds a nice bit of moisture resistance.

- Matte: A smooth, non-reflective finish that gives off a more subdued, elegant, and modern vibe. It cuts down on glare, which makes text much easier to read.

- Lamination: This involves applying a thin plastic film over the entire label for maximum-security protection. It shields against moisture, scuffs, and UV light, making it the top choice for products that will be handled a lot or exposed to the elements.

The Growing Importance Of Eco-Friendly Options

Sustainability isn't just a buzzword anymore; it’s a major driver in how people shop. Because of this, the demand for eco-friendly label materials is through the roof. Options like recycled paper, compostable PLA (polylactic acid), and other biodegradable materials are becoming mainstream, letting brands match their packaging to their green values.

This isn’t a small trend. The global labels market, valued at USD 43.21 billion in 2024, is expected to hit USD 64.97 billion by 2032. A huge part of that growth is fueled by innovations in printing and a massive push toward sustainable materials. Choosing eco-friendly labels isn't just good for the planet—it can seriously boost your brand's reputation and win over the ever-growing crowd of environmentally conscious shoppers.

Designing a Food Label That Captures Attention

Once you’ve navigated the maze of regulations, it’s time to shift gears from the science of compliance to the art of attraction. A legally perfect label is completely wasted if it just blends into the background on a crowded grocery store shelf. Your design is your first handshake with a potential customer, telling your brand's story in a split second and convincing a busy shopper to stop, look, and choose your product over all the others.

Think of your label's design as a conversation starter in a very loud room. You have just a few seconds to make an impression. It's not just about looking good, either—research shows that 72% of American consumers say a product's packaging design directly influences their decision to buy it. Powerful visuals aren't just a nice-to-have; they are a core driver of sales for all types of food packaging labels.

Establishing a Clear Visual Hierarchy

Visual hierarchy is the secret sauce to a clean, effective label. It's simply the practice of arranging design elements to guide the viewer’s eye, making sure they see the most important information first. Without a clear hierarchy, your label becomes a cluttered mess of text and images that just overwhelms and confuses the customer.

Your brand name and the product's identity should be the undisputed heroes of the label. Make them the most prominent elements, followed by any key selling points or certifications that set you apart. The mandatory info, while crucial, can be smaller and placed where it doesn’t fight for attention with your main marketing message.

To create a food label that truly stands out, it needs to be part of a cohesive brand identity. For great insights on building a strong brand from the ground up, it's worth developing a winning branding strategy.

Leveraging Color and Typography

Color and font choices are the emotional heart of your design. They communicate your brand’s personality long before a single word is ever read. Are you a fun, kid-friendly snack? Bright, bold colors might be your ticket. An organic, all-natural product? Muted, earthy tones will probably connect better with your audience.

The psychology of color is a powerful tool in your design kit:

- Green: Almost universally signals health, nature, and organic qualities.

- Red: Can create feelings of excitement, energy, and even stimulate the appetite.

- Blue: Tends to convey a sense of trust, reliability, and calm.

- Black/Gold: Often used together to create a feeling of luxury and premium quality.

Typography works the same way. A playful, rounded font is a great fit for a candy brand, while a clean, elegant serif font might feel more at home on a bag of artisanal coffee. The key is choosing a font that’s not only on-brand but also highly legible, even at a small size.

Your label's design isn't just decoration; it's a strategic communication tool. Every color choice, font selection, and element placement should work together to tell a cohesive story that resonates with your target audience.

The Power of Finishes and Embellishments

Sometimes, what a customer can feel is just as important as what they can see. Special finishes add a layer of sophistication that can elevate a product from ordinary to premium, making your package stand out in a truly tangible way. These extra touches signal high quality and a keen attention to detail.

Consider incorporating elements that catch both the light and the eye:

- Foil Stamping: Adds a brilliant metallic shine to logos or text, creating an instant look of luxury.

- Embossing/Debossing: Creates a raised or recessed 3D texture that adds physical depth and a premium feel.

- Spot UV: Applies a glossy, reflective coating to specific areas, making them pop against a matte background.

These techniques can turn a standard label into a memorable sensory experience. For brands looking to add that extra sparkle, exploring options like custom metallic foil printing can make a huge difference in shelf appeal. At the end of the day, a well-designed label balances legal requirements with creative flair, turning a simple package into a powerful sales tool.

Selecting the Best Printing Method for Your Needs

Once your design is locked in and you’ve picked your materials, the last piece of the puzzle is bringing it all to life. Choosing the right printing method for your food packaging labels isn't just a technical detail—it’s a major business decision. It directly impacts your cost per label, how fast you can get them, and the final look of your branding on the shelf.

Think of it like picking a vehicle. You wouldn't take a race car on a cross-country family road trip, and you wouldn’t use a moving van for a quick run to the corner store. The two main printing methods, digital and flexographic, are just like that—perfectly suited for very different jobs.

The Rise of Digital Printing

Digital printing is the modern champ when it comes to flexibility and speed. It works a lot like a high-end desktop printer, transferring your digital design file directly onto the label material using inks or toners. The magic here is that there are no custom plates involved, which means setup is almost instant.

This is a complete game-changer for startups, seasonal product launches, or any business that needs small-to-medium batches of labels. Got a new hot sauce with five different flavors? Digital printing lets you produce a short run of each without a huge upfront investment. You can get a closer look at how it works by exploring our guide to custom digital printing services.

Digital printing gives you incredible agility. It’s the perfect tool for brands that need to test new designs, react quickly to market trends, or produce vibrant, multi-colored labels in smaller batches without breaking the bank.

With no plate fees and minimal setup, digital is the clear winner for quick turnarounds and cost-effective small orders.

The Power of Flexographic Printing

Flexographic printing, or "flexo" for short, is the time-tested workhorse of the label industry. This method is more like a classic printing press. It uses flexible photopolymer plates to transfer ink onto the label stock at incredibly high speeds. Each color in your design needs its own custom plate, which means there are significant initial setup costs and a bit of a wait.

But here’s the trade-off: once that press starts rolling, the cost per label drops dramatically. This makes flexo the undisputed king for massive print runs. If you're a national brand cranking out hundreds of thousands of identical labels for a flagship product, the efficiency and rock-bottom per-unit cost of flexo are impossible to beat.

This method really shines with simpler designs and is amazingly consistent over long runs, ensuring every single label looks exactly like the last.

Making the Right Choice for Your Business

So, how do you decide? The best method comes down to your specific needs, balancing your order volume, budget, and design complexity. The demand for great food packaging labels is a huge driver in the global packaging market. The sector was valued at about USD 58.2 billion in 2025 and is expected to hit around USD 91.2 billion by 2035. This growth is almost entirely fueled by the food and beverage industry's need for high-quality, efficient labeling. You can check out more insights on this growing market and its trends.

Here’s a quick breakdown to help you make the call:

Choose Digital Printing if you:

- Need small to medium quantities (think under 10,000 labels).

- Need a fast turnaround. Like, yesterday.

- Have complex, photo-quality designs with lots of colors.

- Are printing several variations of a single label design.

Choose Flexographic Printing if you:

- Need massive quantities (tens of thousands or more).

- Have a simpler design with fewer colors (1-3 is the sweet spot).

- Are laser-focused on the lowest possible cost per label.

- Can wait a bit longer for the initial setup and plate creation.

Ultimately, this decision will shape your production budget and how quickly you can adapt to change. A startup thrives on digital's low barrier to entry and flexibility, while a large-scale producer cashes in on flexo's unbeatable economy of scale.

Frequently Asked Questions About Food Labels

Once you start digging into the world of food packaging, a lot of specific questions pop up. Let's tackle some of the most common ones I hear from brands to help you sidestep any expensive compliance headaches.

What If My Package Is Too Small for a Standard Label?

This is a classic problem for anyone selling things like spice jars, lip balms, or those single-serving snack packs. The good news is the FDA knows you can't shrink text to an unreadable size and offers a few workarounds for small packages.

For instance, if your total label space is less than 12 square inches, you might be allowed to put the manufacturer's contact info on the package and then provide the full Nutrition Facts panel online or via a phone number. Just be sure to comb through the specific regulations to make sure your product actually qualifies for these exemptions.

What Are the Rules for "Natural" or "Organic" Claims?

These are powerful words on a label, but you can’t just slap them on your packaging. Using them the wrong way is a surefire way to land in legal trouble.

- Organic: This one is tightly regulated by the USDA. To call your product "organic," it has to be certified by a USDA-accredited agent. It's not an all-or-nothing claim, either—there are different tiers like "100% Organic," "Organic" (at least 95% organic ingredients), and "Made with Organic Ingredients" (at least 70%).

- Natural: This term is a bit fuzzier. The FDA's general take is that a food is "natural" if it doesn’t contain artificial or synthetic stuff. The catch? This policy doesn't cover production methods, like the use of pesticides, which makes it a hotly debated and sometimes confusing claim for shoppers.

While "natural" can be a valuable descriptor, the term "organic" carries the weight of a federally regulated and verified certification. This makes the organic seal a much stronger signal of specific production standards to consumers.

Do I Need a "Made in USA" Label?

Putting "Made in USA" on your product is totally voluntary. But if you decide to go for it, you have to play by the Federal Trade Commission's (FTC) very strict rules.

The standard is that "all or virtually all" of the product must be made right here in the United States. This isn't just about final assembly; it means all the major parts and processing that go into creating the product have to be from the U.S.

Ready to create food packaging labels that are compliant, beautiful, and effective? At 4OVER4, we offer a huge range of materials, finishes, and printing options to bring your vision to life. Explore our custom label printing services today.

More from food packaging labels

8

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

Emma Davis

Emma Davis

Jan 30, 2026

14

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

Emma Davis

Emma Davis

Jan 29, 2026

35

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

46

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

177

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

164

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

145

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

129

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026