- Home

- content hub

- Digital Printing vs Offset Printing Your Guide

Digital Printing vs Offset Printing Your Guide

Emma Davis

Content Writer

Oct 1, 2025406 views

Oct 1, 2025406 views

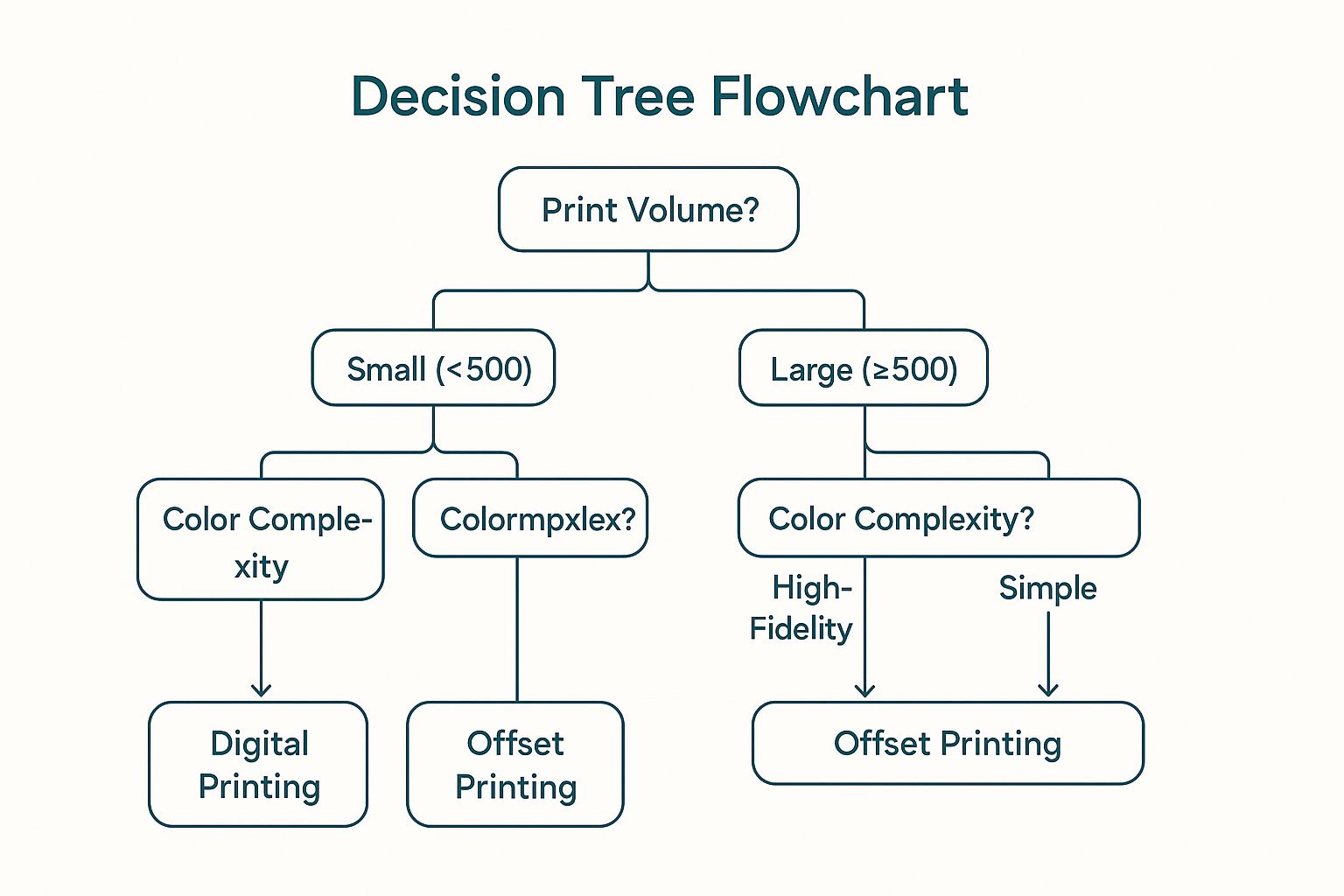

Here’s the bottom line: offset printing is your go-to for large, high-quality projects where the cost-per-piece is king. On the other hand, digital printing shines when you need smaller quantities, a quick turnaround, or personalized content. Your decision really boils down to what matters more for a specific job: volume and color precision or speed and customization.

Making The Right Print Decision

Choosing between digital and offset isn't about which one is "better" in a general sense. It's about picking the right tool for the job. Think of it like transportation: an airliner (offset) is unbeatable for moving thousands of people across the country efficiently, driving down the cost per person. A private jet (digital) is perfect for a small group that needs to get somewhere fast, on their own schedule. Each serves a distinct purpose.

This guide will give you a practical framework to match the right technology to your project, so you get the best possible results. The main things you'll need to consider are your project's quantity, deadline, and creative demands. If you need a fast, flexible option for a smaller batch, exploring the world of digital printing services is a great place to start.

The core trade-off is simple: Offset printing has high setup costs but a low per-unit cost for large volumes. Digital printing has almost no setup costs, making it affordable for short runs, but the per-unit cost remains constant.

To make this even clearer, I've put together a quick comparison of the most important factors.

Digital vs Offset Printing At a Glance

This table breaks down the key differences to help you see which method aligns best with your project's needs at a single glance.

| Criterion | Digital Printing | Offset Printing |

|---|---|---|

| Ideal Volume | Best for short runs (typically under 500 units) | Most cost-effective for large runs (500+ units) |

| Cost-Per-Unit | Higher per unit, but low initial setup cost | Lower per unit on large runs, but high initial setup cost |

| Turnaround Time | Fast, often same-day or next-day delivery | Slower due to plate creation and setup (several days) |

| Color Accuracy | Good quality, but can have slight variations | Superior quality, precise Pantone color matching |

| Customization | Excellent for variable data (e.g., personalized names) | Static content; every print is identical |

This should give you a solid foundation for making your choice. If you're still weighing the options and want a more detailed breakdown, you can delve deeper into the nuances of digital vs. offset printing with this helpful resource.

How Each Printing Technology Works

To really get a handle on the whole digital vs. offset printing debate, it helps to understand how each one actually works. They’re built on completely different ideas, and those differences are what dictate their unique strengths in the real world.

Knowing the nuts and bolts is the key to seeing why cost, speed, and quality vary so much between them. So, let’s pull back the curtain and see what’s going on inside the machine.

The Mechanics of Offset Printing

Offset printing is the traditional, tried-and-true method that relies on a mechanical, multi-step process. It’s an indirect technique—your design isn't stamped directly onto the paper. Instead, the ink is "offset" through a few different stages to get to the final sheet.

It all starts by etching your digital design onto a set of custom metal plates, usually aluminum. A separate plate gets made for each of the four CMYK process colors: cyan, magenta, yellow, and black. These plates are then carefully loaded onto the printing press.

Once the press starts rolling, a series of rollers applies oil-based ink to the plates. At the same time, other rollers apply a water solution. Since oil and water don't mix, the ink sticks only to the etched image areas while the water coats the blank parts. This perfectly inked image is then transferred from the plate onto a rubber blanket. Finally, the paper zips between that rubber blanket and an impression cylinder, which presses the image cleanly onto the page.

This whole setup—making plates, calibrating the press, getting the ink-and-water balance just right—is a pretty big lift. It’s why offset has those higher upfront costs. But once it’s running, that press can churn out prints at lightning speed with incredible consistency, making it the undisputed champion for large volumes.

This meticulous, plate-based system is exactly what allows for the rich, vibrant colors and razor-sharp quality that defines professional offset printing.

How Digital Printing Works

Digital printing, on the other hand, is a much more straightforward affair. Think of it as a super-powered version of the laser or inkjet printer you have in your office. It takes a digital file, like a PDF or JPEG, and prints it directly onto the paper without any plates at all.

There are two main flavors of digital printing:

- Inkjet: Tiny nozzles spray liquid ink directly onto the paper to build the image. This is the go-to for really big stuff like banners or high-end fine art prints where detail is everything.

- Laser (Toner): This method uses static electricity to attract fine powder particles (toner) to a charged drum. The toner is then transferred to the paper and fused into place with heat, giving you a sharp, durable finish.

Because there are no plates to make, the setup is practically instant. The first print can be in your hands in minutes, not hours. This direct-to-paper process is also what makes Variable Data Printing (VDP) possible. You can change out names, addresses, or even images on every single piece without ever stopping the press—a game-changer for personalized marketing and a key advantage of the digital approach.

Comparing Critical Performance Factors

Choosing between digital and offset printing isn't about which one is flat-out better; it's about which one is the right tool for your specific job. The decision really comes down to what you need your final product to achieve—whether that’s hitting a tight deadline, staying on a shoestring budget, or nailing a perfect brand color.

Let's break down the real-world differences across four key areas: cost, quality, speed, and material options. Getting these details right is how you make a smart, strategic decision that saves you time, money, and headaches down the road.

Cost Effectiveness and The Break-Even Point

More than anything else, the cost debate between digital and offset printing boils down to one thing: volume.

Digital printing has a very straightforward, almost flat cost curve. The price for your first print is pretty much the same as your 500th. Why? Because there are no custom plates to create or complex press setups involved. This makes it a no-brainer for small jobs.

Offset printing plays by a different set of rules. You've got significant upfront costs tied to making the printing plates and getting the press perfectly calibrated. But once that machine is humming, the per-unit cost plummets. This is where offset shines—on large-scale projects where you can spread those initial setup costs across thousands of pieces.

So, where's the tipping point? The "break-even point"—where offset becomes the cheaper option—is usually somewhere between 500 and 2,000 units. If you’re printing less than that, digital is almost always your most economical path. Printing thousands? Offset will give you a much friendlier per-piece price.

Key Takeaway: For short runs, digital is king for your budget. For large runs, the per-unit savings from offset printing are impossible to beat. If your quantity is anywhere near that break-even zone, always get quotes for both.

Print Quality and Color Fidelity

While modern digital presses are incredibly good, offset printing still wears the crown for pristine color accuracy and sharpness. It’s all in the process. Using ink on plates allows for incredibly crisp lines and rich images, eliminating any risk of the subtle streaking or banding that can sometimes pop up in digital prints.

Even more important is offset's mastery of color matching. It uses the Pantone Matching System (PMS), which means specific ink colors are mixed to hit a brand’s exact color specifications. This isn't just a "nice to have"; it's non-negotiable for large companies where brand consistency is everything.

Top-tier digital presses can get incredibly close, achieving up to 96% of Pantone colors, but they’re simulating them with a CMYK process—not using the pure, pre-mixed spot inks that offset does.

For most day-to-day business materials, the quality from a good digital press is more than enough. But for anything high-end—luxury brand lookbooks, fine art reproductions, or projects where perfect color is the top priority—offset is the safer bet.

Turnaround Time and Project Speed

When the clock is ticking, digital printing is your best friend. Hands down. With no plates to make and minimal setup time, a job can often be printed the very same day you send the file. This agility is perfect for last-minute flyers for an event, urgent proposals, or any on-demand printing needs.

Offset printing is a much more deliberate, methodical process. Creating the plates, setting up the press, and allowing time for the ink to fully dry all add to the timeline. A standard offset job usually takes several days to move through production, which just won't work for projects that need to be in hand now.

- Digital Printing: The go-to when your deadline is measured in hours or a couple of days.

- Offset Printing: Best suited for projects where you have a week or so in your production schedule.

Material Versatility and Finishing Options

If you want to print on something unique, offset printing opens up a world of possibilities. It can handle a massive range of paper weights, textures, and custom finishes without breaking a sweat. From super-thick cardstock to delicate specialty papers—and even non-paper surfaces like plastic or metal—offset presses are workhorses.

Digital presses, especially toner-based ones that use heat, can be a bit more selective. They run best on smoother paper stocks and can sometimes struggle with very thick or heavily textured materials. That said, the technology is always improving and closing this gap.

Each method also has a different environmental story. Digital printing naturally creates less waste because there are no plates to produce and far less paper is used during setup. For businesses focused on sustainable practices, exploring options in green printing can show how digital often leaves a smaller footprint, especially on those smaller jobs.

To make the choice even clearer, here’s a quick breakdown of common scenarios and which method usually comes out on top.

Situational Breakdown Digital vs Offset

| Scenario | Recommended Method | Key Justification |

|---|---|---|

| Urgent event flyers (250 count) | Digital | Unbeatable speed for tight deadlines and cost-effective for low volume. |

| Company-wide training manual (5,000 copies) | Offset | The per-unit cost will be significantly lower at this volume. |

| Luxury brand catalog with exact Pantone color | Offset | Guarantees perfect color fidelity using true Pantone spot inks. |

| Personalized direct mail campaign (1,000 unique letters) | Digital | Variable data printing makes customizing each piece easy and affordable. |

| Printing on heavily textured, thick cardstock | Offset | Greater versatility with specialty paper stocks and materials. |

| Proofing a single copy of a new book cover | Digital | The only economical way to produce a one-off print for review. |

This table should help you quickly map your project's needs to the right technology, ensuring you get the best possible result for your budget and timeline.

When to Choose Offset Printing for Your Project

Offset printing is the undisputed champion when volume, precision, and quality are your top priorities. It's the go-to method for projects where compromising on color or finish just isn't an option, and the scale of the job justifies the initial setup investment.

Think about large-scale marketing collateral, like a national retailer's seasonal catalog or a high-circulation magazine. For these kinds of jobs, the sheer quantity makes offset the only sensible economic choice. While the upfront costs for plates and press setup are higher, the per-unit cost drops dramatically as the print run gets bigger.

Large Volume Projects

The number one reason to choose offset is for big print runs, which usually means anything over 500 to 2,000 pieces. The math is pretty simple: the more you print, the cheaper each individual piece becomes. This makes it perfect for projects that need wide distribution.

Offset printing continues to dominate these large-scale jobs because of its raw efficiency. When a professional association needs to produce a quarterly magazine for its 150,000 members, offset ensures both cost control and rock-solid quality across every single copy. Likewise, a B2B company printing 500,000 seasonal catalogs relies on offset to maintain precise color for product images while keeping expenses in check. You can learn more about why offset printing remains effective for high volumes.

The takeaway is clear: if your project involves thousands—or even millions—of identical copies, from books and manuals to brochures and corporate reports, offset printing delivers unbeatable value and consistency.

Uncompromising Color and Quality

Another huge advantage of offset printing is its superior color fidelity. This method uses the Pantone Matching System (PMS), allowing printers to mix specific inks to match your brand’s colors with absolute precision. For corporations where brand identity is everything, this is non-negotiable.

On top of that, offset excels with specialty materials and finishes. It can handle a much wider array of paper stocks—from heavily textured paper to ultra-thin sheets—without breaking a sweat. This versatility extends to finishing options that can add a truly premium feel to your materials.

Consider these scenarios where offset is really the only way to go:

- Metallic Inks: Adding a true silver or gold shimmer to invitations or packaging.

- Varnishes: Applying a spot gloss or matte finish to highlight specific design elements.

- Custom Coatings: Using unique finishes like scratch-and-sniff for promotional materials.

When your project demands a tactile, high-end finish designed to make a powerful impression, offset printing provides the tools and quality to bring that vision to life. The whole digital printing vs offset printing decision often comes down to this need for specialized, premium results.

When Does Digital Printing Make the Most Sense?

While offset printing is the undisputed king of high-volume jobs, digital printing shines when it comes to speed, flexibility, and personalization. Its real power is in handling short-run projects with incredible efficiency. This makes it the go-to choice when you need smaller quantities without a huge upfront investment.

Think business cards, event flyers, or boutique product packaging where you might only need a few hundred pieces. For businesses built around custom products or small-batch runs, services like Printify Print On Demand are a perfect example of digital printing in action. Because there are no plates to create, the setup is almost instant, getting high-quality prints into your hands in record time.

Personalization on a Whole New Level

One of the coolest things you can only do with digital printing is Variable Data Printing (VDP). This technology lets you change text, graphics, or images on each individual piece as it prints, without ever slowing down the press. It’s what turns mass communication into a personal conversation.

Imagine sending out 1,000 direct mail postcards, but each one has the recipient's name, a unique offer based on their buying history, and an image of a product they’ve looked at before. That level of one-to-one marketing is simply impossible with offset. If you're a marketer trying to drive real engagement, our guide on Variable Data Printing shows just how powerful this can be for boosting response rates.

Digital printing’s ability to customize each print makes it an invaluable tool for targeted marketing. It allows brands to connect with customers on a one-to-one basis, making every piece of communication feel relevant and unique.

The Need for Speed and Sustainability

The digital printing process is also faster and greener by its very nature. By skipping the plate-making and long press calibrations, projects can go from a digital file to a finished product in hours, not days. This kind of rapid turnaround is a lifesaver for businesses on a tight deadline or those that need to react quickly to what's happening in the market.

For any print job under 2,000 copies, digital is almost always the more economical and flexible option. Plus, the direct-to-paper process cuts down on paper waste and uses less energy, which is a big win for any company focused on sustainability.

The Evolving Landscape of Commercial Printing

The old debate of digital versus offset printing isn't what it used to be. It’s a conversation that’s constantly changing, driven by new tech and what the market demands. We're seeing a major shift where digital printing isn't just playing catch-up anymore—it's starting to set new standards for all kinds of projects.

The numbers tell a compelling story. While offset is still the undisputed king for massive print runs, digital is quickly closing the gap. Projections show global sales for sheetfed offset presses are expected to slip from $2.6 billion to $2.25 billion between 2021 and 2026. On the flip side, the digital print market is on track for some serious growth, predicted to reach $251.1 billion by 2035. That's a massive 50% jump from its 2025 estimate. This shift really highlights how digital's speed and adaptability are hitting the mark for modern business needs.

The Rise of Hybrid and High-Fidelity Digital

A huge part of this evolution is that the quality gap is shrinking—fast. Thanks to innovations like nanography, today's digital presses can produce resolutions and color vibrancy that were once only possible with offset. Top-of-the-line digital systems can now accurately hit up to 96% of Pantone colors, making them a perfectly solid choice for brands that can't afford to compromise on color.

This has also opened the door for hybrid printing solutions. Think about it: you can run the bulk of a project on an offset press for cost efficiency, then switch to a digital press to add variable data like individual names or unique QR codes. It’s a smart approach that blends the best of both worlds—offset’s affordability at scale with digital’s power of personalization.

The future of commercial printing isn't about one method wiping out the other. It’s about being smarter with our choices, picking the right tool for the job based on speed, volume, customization, and cost.

As the technology keeps getting better, the lines between digital and offset will only get blurrier. For businesses, this is great news. It means more options and more creative freedom to produce stunning materials, including the unique finishes you'll find in our specialty printing collection. The conversation is no longer about "which is better" but about understanding how to strategically use each technology to get the best possible result.

A Few Common Questions About Printing

When you're trying to decide between digital and offset printing, a few questions always seem to pop up. Getting straight answers is the best way to make sure your project gets off on the right foot.

What Is the Break-Even Point for Offset vs. Digital Printing?

There isn't one perfect number, but from my experience, the sweet spot where offset starts to make more financial sense is somewhere between 500 and 2,000 units.

If you're printing fewer than 500 copies, digital is almost always the cheaper route. You get to skip all the expensive plate and setup fees. Once you cross that threshold, however, the lower per-unit cost of offset printing really starts to kick in, making the initial setup cost worthwhile. The exact number depends on your paper, the colors you're using, and the overall complexity. If you're anywhere in that 500-2,000 range, do yourself a favor and get quotes for both.

For projects with quantities hovering around the 500-2,000 mark, comparing quotes is crucial. A slight change in paper stock or color requirements can easily tip the economic scale from one method to the other, potentially saving you a significant portion of your budget.

Can Digital Printing Match Offset Quality for High-End Projects?

This is a big one. Modern, high-end digital presses have gotten incredibly good, and honestly, for most projects, you'd be hard-pressed to spot the difference.

That said, for those jobs where every tiny detail matters—like precise Pantone color matching or printing on really unique, textured papers—offset still has a slight advantage. It tends to produce ever-so-slightly sharper images and text, which can be a deciding factor for luxury brands or fine art prints. But for the vast majority of business materials, today's digital quality is more than up to the task.

How Should I Prepare Files for Digital vs. Offset Printing?

The basics are the same for both: you always want to use high-resolution (300 DPI) images and design in CMYK color mode. But after that, the specifics start to matter.

- For Offset Printing: You need to be incredibly precise. Because plates are being physically created, your color profiles and any specified Pantone colors must be perfect from the get-go.

- For Digital Printing: If you're doing anything with variable data (like names or addresses), the real trick is setting up your data sheets and files so the press can pull that information in without a hitch.

No matter which method you choose, the best first step is to check your printer’s specific file guidelines. It’ll save you a ton of headaches and potential delays.

Ready to turn your designs into high-quality printed materials? 4OVER4 offers a full range of both digital and offset printing solutions to match any project, budget, or timeline. Start your next print project with us today!

More from digital printing vs offset printing

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

61

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

104

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

104

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

326

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026