- Home

- content hub

- What Is a Die Cut Label? A Complete Guide

What Is a Die Cut Label? A Complete Guide

Emma Davis

Content Writer

Aug 21, 2025383 views

Aug 21, 2025383 views

So, what exactly is a die cut label? Instead of being a standard, off-the-shelf square or circle, a die cut label is cut precisely to the unique outline of your design.

Think of it like getting a custom-fit suit for your product. It's designed to perfectly match its specific contours and brand aesthetic, making it a powerful tool for creating packaging that truly stands out.

Why Custom Shapes Matter in Branding

Ever walked down a store aisle and had a product just leap out at you? More often than not, it’s the unique shape, not just the colors, that grabs your attention. Standard rectangular labels are functional, sure, but they rarely tell a story or leave a lasting impression. They do the job, but they're easily forgotten.

A die cut label, on the other hand, elevates your packaging from a simple container to a memorable brand experience. It’s the difference between using a generic stock photo and commissioning a custom piece of art. That unique shape doesn't just look different—it sends a clear message about creativity, quality, and attention to detail.

A custom shape is your silent brand ambassador. It speaks to the consumer before they even read a single word, suggesting that what's inside is just as special and well-crafted.

Building a Stronger Brand Identity

By breaking free from the boring box, a die cut label helps carve out a distinct visual identity that customers can recognize in an instant. This visual shortcut is crucial for making your products pop in a crowded marketplace.

Think about how a unique shape can work for you:

- Reinforce your product: A honey brand could use a label shaped like a honeycomb or a bee.

- Communicate your values: An organic soap company might opt for a label shaped like a leaf.

- Create an emotional connection: A playful, whimsical shape can make a product feel more fun and approachable.

This strategic approach to packaging is a big reason why the demand for these labels is on the rise. In fact, the global die cut label market is projected to hit around USD 175.2 million in 2025 and is expected to climb to USD 230.6 million by 2032.

Beyond just the physical appeal, understanding how unique branding contributes to your overall market presence is key. For brands aiming to make a real impact, mastering brand visibility is an essential piece of the puzzle.

How Die Cut Labels Are Actually Made

The term "die cut" sounds a bit industrial, but the idea behind it is actually pretty simple and clever. The whole process hinges on a custom tool called a die.

Imagine a super-sharp, industrial-grade cookie cutter. That's essentially what a die is. But instead of dough, it’s built to slice through label materials with incredible precision, creating any custom shape you can dream up.

Rather than just printing on a standard square or rectangular sheet, the label material is run through a press. The die then stamps down, punching out your specific design. This ensures every single label is a perfect match to your artwork, whether it's a simple circle or a complex custom contour.

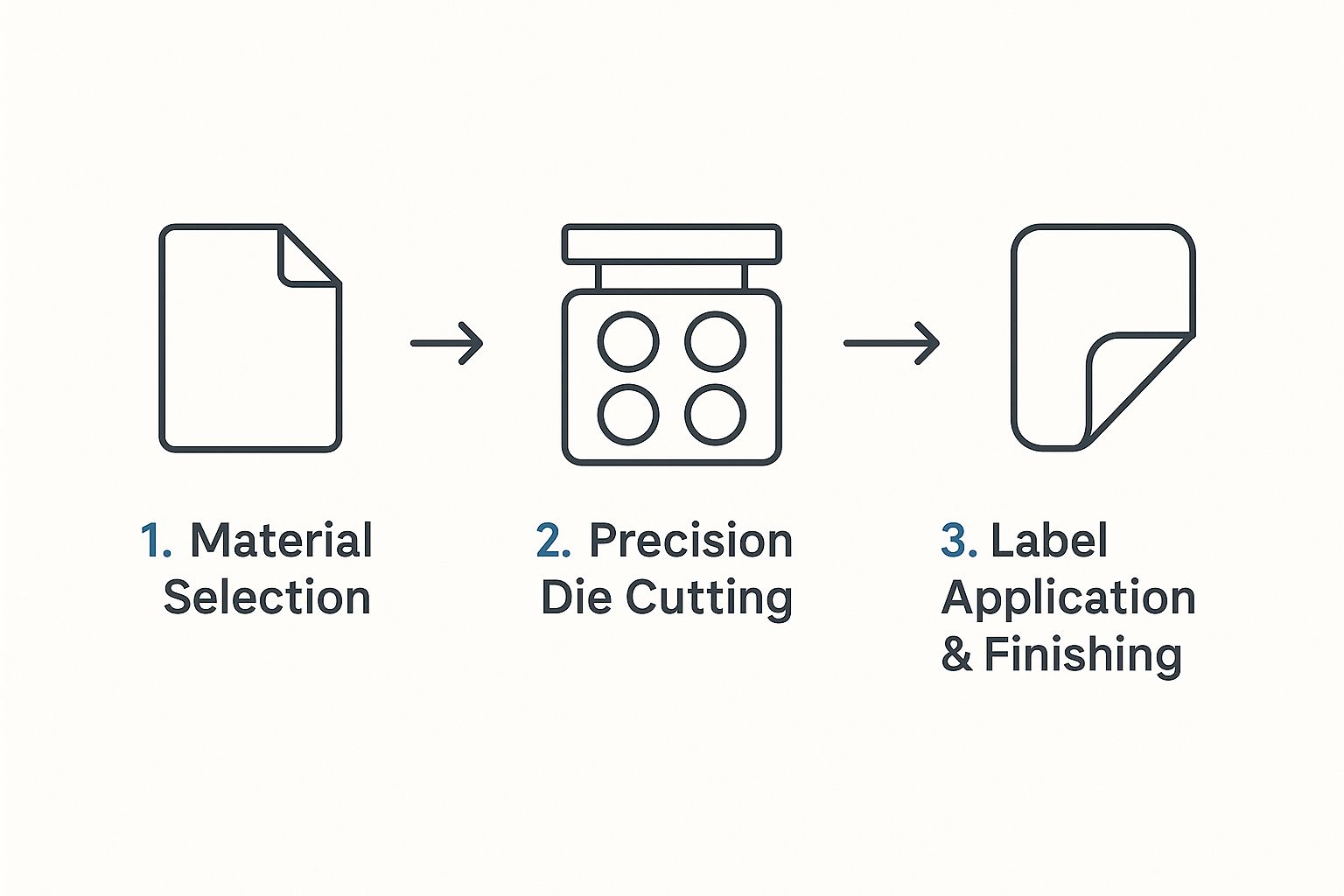

This visual breaks down the key stages in the journey of a die cut label.

As you can see, it's a straightforward path from a design concept to a finished, precisely cut label that's ready to go.

Key Die Cutting Methods

While the cookie-cutter analogy is a great way to start, printers have a few different techniques up their sleeves. The right method for your project really comes down to the order size, how intricate the design is, and your budget.

Here are the three main ways die cut labels are made:

Rotary Die Cutting: Think of this as the high-speed workhorse. It uses a cylindrical die that spins and cuts shapes from a continuously fed roll of label stock. This method is incredibly fast, making it the go-to for huge print runs—like the millions of labels a national soda brand might need.

Flatbed Die Cutting: This technique works more like a traditional press, where a flat die stamps down onto sheets of material. It's not as fast as rotary cutting, but it offers fantastic precision and is great for thicker materials or complex shapes on small-to-medium-sized orders.

Digital Die Cutting: This is the modern, no-die-required approach. Instead of a physical tool, it uses a computer-guided laser or a tiny blade to cut the design. Because there's no custom die to create, it’s extremely cost-effective for small batches, prototypes, and one-off projects. It's the perfect choice for a small business testing a new product with just 100 or 200 labels.

The choice of cutting method is strategic. It’s not about which is "best" overall, but which is best for your job. The goal is always to balance speed, precision, and cost to get the perfect result.

Knowing a bit about these methods helps pull back the curtain on the production process. A die cut label isn't just about getting a cool shape; it's about using the right tool to bring a brand's vision to life efficiently and accurately.

The Strategic Advantages of Custom Labels

Knowing how a die cut label is made is interesting, but the real power is in what it can do for your brand. Choosing a custom shape isn't just a fun design choice—it's a smart business move that can seriously influence how customers see your product and whether they decide to buy it.

Think about it. A simple shape change can turn your product from just another box on the shelf into something that catches the eye.

A custom label is a shortcut to powerful brand recall. When a local honey brand uses a hexagon-shaped label, or a pet grooming company opts for a label shaped like a paw print, the packaging instantly tells a story. That visual cue sticks in a customer’s mind long after they’ve walked out the door.

This need to stand out is why the market is booming. The die cut label market has grown right alongside the wider adhesive label industry, which is expected to jump from USD 4.1 billion to a whopping USD 6.8 billion by 2033. Brands are increasingly turning to die cut labels because they offer a level of uniqueness that standard labels just can't match. You can dig deeper into data on this industry trend to see how it's shaping modern branding.

Maximizing Shelf Appeal and Perceived Value

Walk down any retail aisle and you'll see a sea of sameness. You have only a few seconds to grab a shopper's attention, and a die cut label is your secret weapon for making them stop and look. Its unique silhouette instantly breaks up the visual monotony of all those squares and rectangles, making people curious.

But it’s about more than just getting noticed. A custom shape elevates the perceived value of what you're selling. A well-designed, unique label sends a subtle message of quality and attention to detail. It tells the customer you’re a professional brand that cares about the entire experience, not just what's inside the package.

A custom die cut label isn't just packaging—it's part of the product experience. It implies that the quality inside the container is just as exceptional as the presentation on the outside.

Let's take a quick look at how die cut labels stack up against their standard counterparts.

Standard Labels vs Die Cut Labels at a Glance

| Feature | Standard Label | Die Cut Label |

|---|---|---|

| Shape | Limited to squares, rectangles, circles, ovals. | Virtually any shape imaginable. |

| Visual Impact | Blends in easily; relies solely on graphic design. | Immediately stands out on the shelf. |

| Brand Recall | Generic shapes are less memorable. | Unique shapes create strong visual associations. |

| Perceived Value | Can look basic or generic. | Suggests a premium, high-quality product. |

| Versatility | Can be awkward on unconventional packaging. | Can be designed for a perfect fit on any container. |

| Cost | Generally lower initial cost. | Higher initial die cost, but often better ROI. |

While a standard label might get the basic information across, a die cut label truly becomes part of your brand's identity, delivering a much stronger punch.

Functional and Practical Benefits

Beyond just looking great, die cut labels solve real-world packaging problems. Because they're made to order, you can design them to handle very specific challenges.

- Perfect Fit for Contoured Surfaces: They're a dream for wrapping around curved bottles, tapered jars, or other tricky containers where a standard rectangle would wrinkle or peel.

- Accommodating Unique Packaging: Got a product with a weird recess or an odd-shaped lid? A die cut label can be cut to fit that exact space flawlessly.

- Integrated Design Elements: The shape can do more than just sit there. Imagine a label with a built-in tab that folds over the lid, acting as a tamper-evident seal.

This mix of beautiful form and smart function is what makes a die cut label so effective. It’s an investment that works hard for you, creating a brand presence that’s cohesive, professional, and truly unforgettable.

Choosing the Right Materials and Finishes

A great shape is just the beginning. The material and finish you choose for your die cut label are what really bring your design to life, making sure it not only looks fantastic but also holds up wherever it ends up. Getting this combination right is what separates a good idea from a truly professional product.

Think of the material as the very foundation of your label. It’s what determines the durability, the texture, and even how it feels in a customer’s hands. For anything that's going to be exposed to moisture, changing temperatures, or a lot of handling, picking the right material isn't just a suggestion—it's essential.

Selecting the Perfect Label Material

The single most important question to ask is: where will this label live? A label for a soy candle sitting on a shelf has entirely different needs than one for a beer bottle that's going to be dunked in an ice bucket.

Here are a few of the most popular choices for die cut labels:

- BOPP (Biaxially-Oriented Polypropylene): This is a tough, plastic-based workhorse. If you need a label that’s waterproof, oil-resistant, and won’t tear, BOPP is your go-to. It’s the perfect choice for products like shampoo bottles, cold-brew coffee, and gear meant for the outdoors.

- Textured Paper: For a more high-end, tactile feel, nothing beats textured paper. It adds a touch of craft and elegance. Materials like felt, linen, or vellum are fantastic for wine bottles, artisanal foods, and any luxury item where a sophisticated feel is part of the brand’s story.

- White Vinyl: This is a crowd-pleaser for a reason. White vinyl is incredibly versatile, giving you a bright, solid background that makes your colors pop. It’s durable and weather-resistant, making it a solid all-around pick for everything from product labels to promotional stickers.

It's no surprise that the demand for this kind of custom branding is exploding. The global market for custom die cut stickers was valued at around USD 48.39 million in 2023 and is on track to hit USD 75.67 million by 2032. Much of that growth comes from e-commerce brands looking for clever ways to make their products stand out. You can dive deeper into this market trend and its drivers.

Applying the Final Touch with Finishes

If the material is the foundation, the finish is the final coat of paint—it gives the label its personality. This protective top layer, often called a laminate, does more than just shield the ink from the elements; it completely changes the final look and feel.

A finish doesn’t just change how a label looks; it changes how it feels. This tactile element can seriously elevate the perceived quality of your product before a customer even opens it.

Think about which of these common finishing options fits your brand:

- Gloss Finish: This high-shine finish makes colors look deeper and more vibrant. It’s great for creating a bold, eye-catching look that screams for attention and offers great protection against scuffs and moisture.

- Matte Finish: For a more modern, subtle vibe, a matte finish gives you a smooth, non-reflective surface. It cuts down on glare and lends your die cut label a sophisticated, almost premium feel.

- Soft-Touch Finish: This one is all about the experience. It adds a unique velvety, almost rubbery texture that people can't help but touch. It’s an amazing choice for high-end products where you want to leave a memorable, sensory impression.

In the end, the perfect choice is always a mix of function and style. By thinking carefully about your product’s journey and your brand’s personality, you can land on a material and finish combination that creates a label that's durable, beautiful, and does its job perfectly.

Designing a Die Cut Label That Works

A truly great die cut label is more than just a cool shape with your logo slapped on it. It’s where the shape and the artwork feel like they were made for each other—a perfect marriage, really. The secret is to think of the custom outline not just as a container, but as a core part of the design story itself.

To get your vision from the screen to the finished product without a hitch, you’ll need to nail a few design fundamentals. This is what separates an amateur-looking label from one that looks polished, professional, and captures exactly what your brand is all about.

Mastering the Technical Details

Before you let your creativity run wild, it’s crucial to get the technical basics right. These small but vital steps are your best defense against common printing errors and the disappointment that comes with them.

First up is the bleed. Think of it like coloring a picture as a kid. You’d often color a little bit over the lines to make sure there were no white gaps at the edges. A bleed works the same way for printing. You need to extend your background color or image about 1/8th of an inch past the actual cut line. This simple step ensures that even if the cutting die is off by a hair, you won't get any ugly white slivers on the edge of your label.

Seriously, forgetting the bleed is the number one cause of printing headaches. It's a tiny bit of extra effort that acts as a safety net, guaranteeing a clean, edge-to-edge finish.

Then there’s the safety margin. This is the opposite of a bleed. It’s an invisible border inside the cut line where you need to keep all your important stuff, like text and logos. If you place critical elements too close to the edge, you risk them getting trimmed off during the cutting process. A proper safety margin keeps your message intact.

Making Shape and Artwork Work Together

With the technical groundwork laid, now comes the fun part: making the shape and artwork feel like a single, cohesive unit. The goal is for them to be inseparable. For instance, if your label is shaped like a guitar, your text and graphics should flow with its curves, not just sit there in a boring rectangular block.

Here are a few practical tips to help you get there:

- Legibility is Non-Negotiable: That fancy, swirly font might look great on your monitor, but on a small or oddly shaped label, it can become a mess. Stick to clean, clear typefaces and make sure there’s plenty of contrast with the background.

- Use Color to Guide the Eye: Your color choices should be strategic. Use bright, bold colors to make your brand name pop or to highlight a key feature, letting the unique shape of the label draw attention right where you want it.

- Balance Complexity with Simplicity: An intricate shape can be a showstopper, but it can also make your design feel cluttered if you’re not careful. Leave enough "negative space"—or breathing room—to keep the overall look clean and focused.

By blending these technical must-dos with a bit of creative flair, you'll be well on your way to designing a die cut label that’s not only beautiful but prints perfectly every time.

So, are die cut labels the right call for your brand?

You've got the essentials down now. You know that a unique shape can make your product jump off the shelf, that the process isn't some mystical, unobtainable thing, and that the real magic happens when you pair a great design with the right material.

This isn't just about sticking a label on a bottle. It's about turning your packaging into a silent salesperson. A clever die cut label can stop a busy shopper in their tracks and scream "quality" or "creativity" before they’ve even read your product's name. The trick is to make sure the shape isn't just different for the sake of it—it needs to connect back to what your brand is all about.

Making the Final Call

To nail down whether a custom die cut label is your best move, run through these questions. If you find yourself nodding "yes" to most of them, you can be pretty confident that going custom will pay off in a big way.

- Brand Identity: Does a custom shape actually amplify my brand's personality or connect to the product itself (like a honeycomb shape for a honey jar)?

- Shelf Impact: Is my product fighting for attention in a super crowded aisle where looking different is the only way to get noticed?

- Product Environment: Will this label have to survive the shower, a cold fridge, or rough handling? Do I need a specific material and finish to make it last?

- Perceived Value: Am I trying to position my product as a premium, handcrafted, or high-end item where the packaging needs to match the price tag?

A die cut label isn't just an expense; it's an investment in making your brand unforgettable. When the shape tells a story, the product sticks in the customer's mind.

At the end of the day, opting for a die cut label is a choice to lead with creativity and forge a connection that lasts long after the purchase.

Answering Your Top Questions About Die Cut Labels

Diving into custom labels for the first time? It's completely normal to have a few questions. Let's walk through some of the most common things people ask when they're getting started with die cut labels.

Aren't Die Cut Labels Way More Expensive?

It's a common misconception that custom shapes will break the bank. While there is a one-time setup fee for creating the unique metal die, the price per label evens out pretty quickly, especially on larger runs.

Think of it as a small investment in making your product impossible to ignore. For smaller batches, modern digital die cutting is a fantastic, budget-friendly option that skips the physical die altogether, opening up custom shapes for everyone. That tiny bit of extra cost often pays for itself many times over in brand recognition.

What’s the Smallest Order I Can Place?

This really depends on the technology used. Older, traditional methods like rotary cutting often need larger minimums—sometimes in the thousands—to make the setup worthwhile.

But digital die cutting has completely changed the landscape. Now, it's totally possible to order as few as 50 or 100 labels at a time. This is a huge advantage for small businesses, seasonal product launches, or if you just want to test a new design without a massive commitment.

The best part about modern printing is its flexibility. You don’t need a huge budget or a warehouse full of inventory to get a professional, custom-shaped label that makes your product pop.

How Well Do These Labels Hold Up?

The durability of your label all comes down to your choice of material and finish. It's all about matching the label to its future environment.

For instance, a BOPP label with a gloss laminate is a real workhorse. It's waterproof, shrugs off oil, and can handle the friction and condensation of being in a fridge or a shower. It’s perfect for something like a craft beer bottle or a body scrub. On the other hand, a classic paper label is less rugged but gives a beautiful, tactile feel for dry goods like coffee bags or candle jars.

Can You Really Make Any Shape?

Pretty much! The technology today is incredible and can handle some seriously complex designs.

That said, there are some practical limits. Designs with extremely thin, wispy lines or very sharp, inward-pointing corners can be tricky. These delicate areas can be prone to tearing during application or peeling later on. A good rule of thumb is to keep your overall shape clean and solid. Your printer can always take a look at your artwork and suggest tiny adjustments to make sure it cuts perfectly and looks amazing on your product.

Ready to create a label that truly reflects your brand? At 4OVER4, we specialize in turning unique ideas into high-quality, precision-cut labels. Explore our die cut label options and get an instant quote today!

More from die cut label

11

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

25

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

91

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

100

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

123

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

111

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

388

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

345

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026