- Home

- content hub

- A Guide to Custom Logo Shopping Bags

A Guide to Custom Logo Shopping Bags

Emma Davis

Content Writer

Oct 13, 2025277 views

Oct 13, 2025277 views

The material you choose for your custom logo shopping bags is the very foundation of the final product. It's so much more than just durability; the material is a tangible piece of your brand's identity and values. Get this right, and you communicate your commitment to sustainability, luxury, or practicality before a customer even peeks inside.

Choosing Materials That Reflect Your Brand

The first thing to do is align the bag's feel with your brand's personality. Is your company known for its eco-conscious mission? A natural cotton or jute bag instantly reinforces that message. Or are you a high-end boutique? A sleek, laminated paper bag with elegant ribbon handles whispers luxury and care.

You also have to think about how your customers will actually use the bag after they leave your store. A sturdy canvas tote is a fantastic "walking billboard" for a grocery store or farmer's market, giving you repeated brand exposure. On the other hand, a simple kraft paper bag works perfectly for a quick, one-time purchase from a local cafe or bookstore.

Comparing Common Bag Materials

To help you make the best decision, let's break down the most popular options out there. Each material brings something different to the table, suiting different business goals and budgets.

Cotton and Canvas: These natural fibers are soft, incredibly durable, and highly reusable. They're a perfect match for brands that want to emphasize sustainability and quality. The textured surface is also a fantastic canvas (pun intended) for screen printing, making logos pop with vibrant, long-lasting color. You can find a huge variety of options by exploring custom tote bags printing to see just how versatile this material is.

Non-Woven Polypropylene: This is your go-to for a budget-friendly and water-resistant option. It's a fantastic choice for large-scale giveaways at trade shows or events where you need to make a big impact without breaking the bank. While it doesn't have the premium feel of canvas, it's still surprisingly durable and provides a great surface for bold, colorful logos.

Paper (Kraft and Laminated): The classic retail choice for a reason—paper bags offer immense versatility. Brown kraft paper gives off a rustic, earthy vibe, while white or colored laminated paper provides a polished, high-end look. They are easily recyclable and can be customized with all sorts of handle types, from simple twisted paper to elegant grosgrain ribbon.

I've put together a quick-reference table to make comparing these materials even easier.

Bag Material Comparison Guide

| Material | Key Features | Best For | Eco-Friendliness | Price Point |

|---|---|---|---|---|

| Cotton & Canvas | Durable, reusable, soft, natural feel, great for screen printing | Eco-conscious brands, retail, grocery, promotional giveaways | High (Reusable, biodegradable) | $$ - $$$ |

| Non-Woven Polypropylene | Lightweight, water-resistant, budget-friendly, strong | Trade shows, large events, budget-conscious promotions | Medium (Reusable, recyclable) | $ |

| Kraft Paper | Recyclable, biodegradable, rustic look, affordable | Cafes, bookstores, boutiques, one-time use retail | High (Recyclable, compostable) | $ - $$ |

| Laminated Paper | Sleek, polished finish, moisture-resistant, durable | Luxury retail, high-end boutiques, gift bags | Low (Difficult to recycle) | $$ - $$$ |

As you can see, each material tells a slightly different story. Your choice will guide the customer's perception of your brand long after they've left your store.

A bag's material does more than carry a product; it carries your brand's story. Choosing a material that aligns with your values creates a cohesive and memorable customer experience that extends far beyond the point of sale.

The promotional products industry absolutely recognizes this power, with custom bags becoming a non-negotiable branding tool. In fact, this sector is forecast to hit USD 24 billion by 2025, a surge driven largely by the demand for personalized, sustainable items that boost brand recall.

Ultimately, the right material acts as a silent ambassador for your brand. It should feel like a natural extension of your products and the experience you work so hard to provide, ensuring your custom bags become a valued accessory, not just disposable packaging.

Designing a Logo That Prints Perfectly

The success of your custom logo shopping bags really boils down to one thing: your logo's print quality. A fantastic design can fall completely flat if it isn't set up correctly for production. The most common mistake I see is people using the wrong file format, which leads to blurry, pixelated logos that just don't look professional.

To sidestep this issue entirely, you have to provide your printer with a vector file. Unlike raster files (like JPEGs or PNGs) that are built from tiny pixels, vector files (think AI, EPS, or SVG) use mathematical equations. This means you can scale them to any size you want—from a tiny accent on a business cards printing to a huge print on a tote bag—without losing a single bit of clarity.

It’s like the difference between a photograph and a blueprint. You can't blow up a photo forever without it getting grainy, but a blueprint's instructions can build something massive with perfect precision.

Simplify for the Biggest Impact

Even if you have the right file format, a super complex logo with tiny details or subtle gradients might not print well on certain materials. A design that looks incredible on your computer screen can turn into a muddy mess on the textured surface of a canvas bag.

For the best results, you might need to simplify your design a bit. This isn't about losing your brand identity; it's about making smart adaptations for the specific medium.

- Cut Down on Colors: Screen printing is a really popular method for bags, but it often needs a separate screen for every single color. Sticking to one or two bold colors can save money and actually create a much stronger visual punch.

- Beef Up Fine Lines: Those elegant, whisper-thin lines in your logo? They can easily disappear or break apart during printing, especially on fabric. Make sure every element is thick enough to show up clearly.

- Ditch Complex Gradients: Solid colors just reproduce more reliably on bag materials than smooth gradients do. If you absolutely need gradients, it's worth talking to your supplier about other options, like digital printing.

Think About Color and Placement

Finally, you need to consider how your logo’s colors will look against the bag itself. A chic, light gray logo might be perfect on a crisp white paper bag, but it could become almost invisible on a natural-colored canvas tote. High contrast is your friend here; it’s all about visibility.

Positioning is just as critical. Slapping the logo right in the center is the classic move for a reason—it gets the most eyeballs. But don't be afraid to explore other options. A smaller, tastefully placed logo in a corner can give off a more minimalist, high-end vibe. Printing on the side gussets is another great way to add a subtle, unexpected touch of branding.

Your logo on a shopping bag is basically a walking billboard. Simplicity and high contrast are what make your brand instantly recognizable from across a crowded street. A clear, bold design will always win out over a complicated one in this arena.

No matter what you decide, always, always ask for a digital proof. This lets you see exactly how your design will look before you commit to a full production run, saving you from any costly surprises down the line.

Selecting the Right Printing Method

You’ve got your logo perfected and you know what kind of bag you want. Now comes the fun part: getting that design onto the bag. This isn't just a technical step; the printing method you choose for your custom logo shopping bags is what brings your brand to life. It affects the final look, the texture, the durability, and of course, the cost.

Choosing the right technique is a balancing act. What works perfectly on a smooth paper bag might be a disaster on a textured canvas tote. Your budget, the complexity of your logo, and your chosen material all have a say in this decision. Let's walk through the most common options to figure out what’s best for you.

Screen Printing For Bold Simplicity

Screen printing is an absolute workhorse, especially for fabric bags like cotton or canvas. It’s been around forever for a reason. The process involves pushing ink through a stenciled mesh screen directly onto the material, which creates a thick, vibrant, and incredibly durable print.

This method is king for logos with just one or two solid colors. Because a new screen has to be made for each color in your design, it’s most cost-effective for simpler graphics and larger orders. The result is a bold, slightly raised print that really lasts.

Heat Transfer For Colorful Detail

But what if your logo is a kaleidoscope of colors and fine lines? That’s where heat transfer comes in. This technique prints your design onto special transfer paper first, then applies it to the bag using—you guessed it—heat and pressure.

Think of it as a professional-grade, super-durable iron-on. It’s fantastic for full-color, photorealistic images without needing a dozen different screens. This makes it a smart choice for smaller print runs or complex artwork where screen printing would get way too expensive.

The best printing method is one that honors your design's intent while respecting your budget. A simple, bold logo shines with screen printing, while a complex, multi-hued design is best served by heat transfer or digital methods.

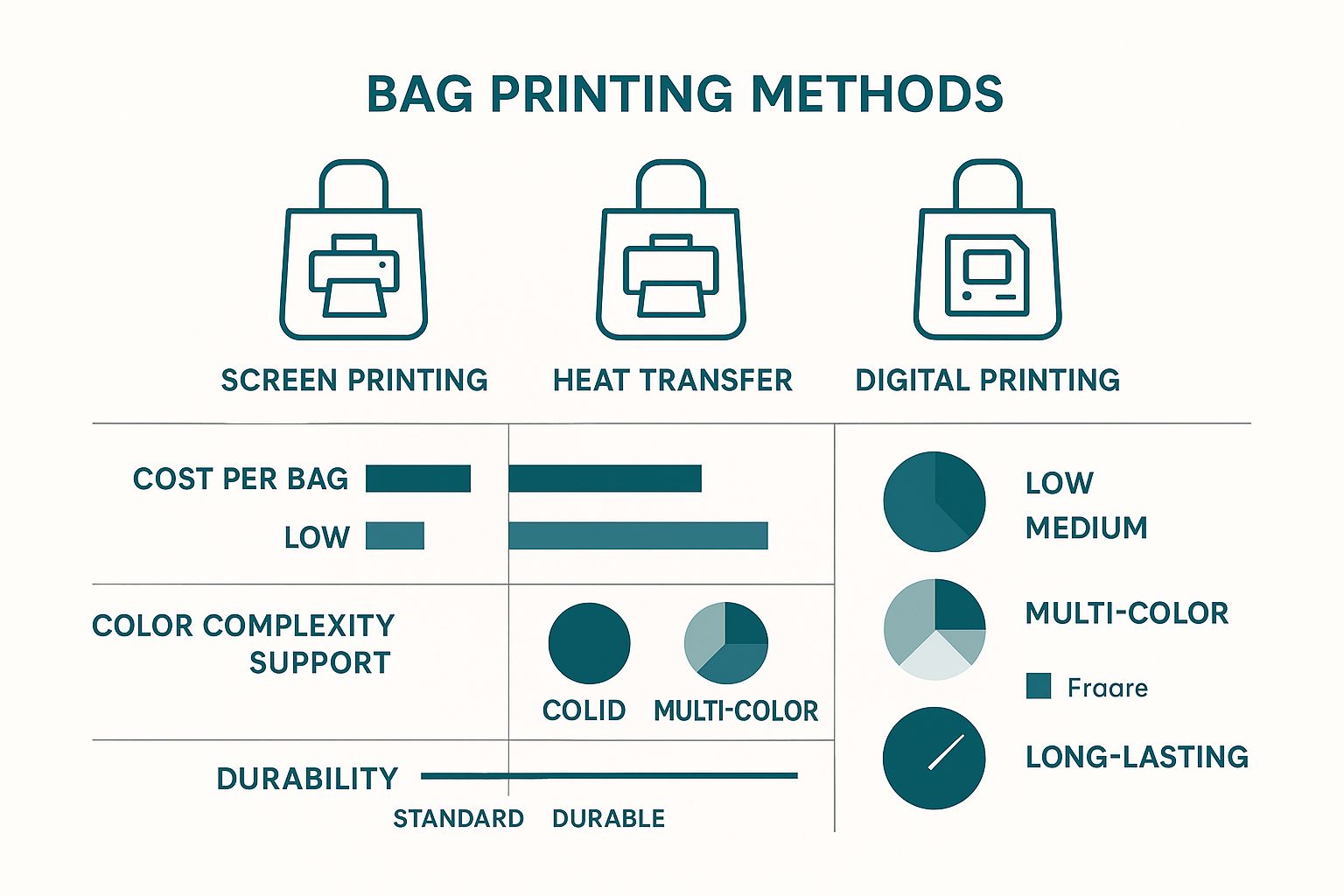

To give you a clearer picture, this infographic breaks down the key differences between printing methods at a glance.

As you can see, there are trade-offs. Screen printing gives you that rugged durability for simple designs at a great price, while digital printing is the champion for complex images, though it costs a bit more.

To help you weigh the options, here’s a quick breakdown of how these methods stack up against each other.

Printing Method Breakdown

| Print Method | Best for Designs | Material Compatibility | Durability | Cost Profile |

|---|---|---|---|---|

| Screen Printing | Simple graphics, 1-3 solid colors, bold logos | Cotton, canvas, jute, non-woven polypropylene | Very High | Low cost for large runs, high setup cost for small runs |

| Heat Transfer | Full color, complex details, photographic images | Cotton, polyester, blends, some plastics | Good | Moderate cost, great for small to medium runs |

| Digital (DTG) | Photorealistic, gradients, unlimited colors | Primarily cotton and natural fabrics | Good to High | Higher cost per item, no setup fees, ideal for small orders |

| Embroidery | Logos, text, simple graphics for a premium feel | Heavy canvas, denim, thick fabrics | Excellent | Highest cost, based on stitch count |

Choosing the right method ensures your investment pays off with a bag that looks fantastic and represents your brand well.

Digital Printing And Other Options

For designs that need to look like a photograph, Direct-to-Garment (DTG) or other benefits of digital printing are the way to go. This process works a lot like your office inkjet printer, applying ink directly onto the fabric. It’s unmatched for reproducing gradients, subtle shadows, and incredibly detailed images with pinpoint accuracy.

And for a truly premium, textured finish, you could even consider embroidery. While it’s less common for shopping bags and more suited for heavy-duty canvas totes, it adds a touch of class that printing can’t replicate. Each method has its place, ensuring there’s a perfect technique out there to make your brand’s vision a reality.

Getting Your Order Just Right

Alright, you've got your design dialed in and you know how you want it printed. Now comes the part where we turn that digital file into a stack of real-life custom logo shopping bags. This stage is all about the details and making sure you and your supplier are on the same page.

The first hurdle is getting your artwork submitted correctly. Every supplier has its own preferences for file formats and resolutions, and they're usually not shy about listing them. Take a minute to double-check those specs before you upload. It’s a simple step that can save you a world of back-and-forth emails and delays down the line.

Confirming Every Detail Before Production

Before you give the green light for a full production run, you absolutely must review a proof. This is non-negotiable. Think of it as your final safety check. Suppliers typically offer a couple of different proofing options, and each one has its place.

- Digital Proof: This is usually a PDF or an image that shows you exactly how your logo will be sized and placed on the bag. It’s your last chance to catch a typo, fix a color issue, or tweak the layout before it's too late.

- Physical Sample: If you're placing a large order or just want that extra peace of mind, ask for a physical sample. It might cost a little extra, but holding an actual bag lets you feel the material, see the true print colors, and confirm the quality with your own hands. It’s a smart move.

Once you sign off on that proof, your order is officially in the production queue. After that point, fixing a mistake becomes a much bigger—and more expensive—headache.

Understanding Costs and Timelines

The price you see per bag isn't always the full story. When you get a quote, you'll likely see a few other charges, and it's important to know what they are. For instance, a setup fee is pretty standard; it’s a one-time charge for getting the printing press calibrated and ready for your specific design.

Also, don't forget to ask about price breaks for larger quantities. The cost per bag almost always drops as you order more. This is key when you're looking at the Minimum Order Quantity (MOQ), which is the smallest order a supplier is willing to run for you.

Always get a detailed quote that breaks down everything: setup fees, the per-bag cost at different quantities, and an estimate for shipping. Getting that clarity upfront saves you from any nasty budget surprises later on.

Finally, have a clear conversation with your supplier about turnaround times. Ask for their production schedule and get an estimated delivery date. This lets you plan your marketing launches or events without guessing when your bags will show up. The demand for shopping bags is no joke—the market was valued at around USD 18.71 billion in 2025, with a huge chunk of that coming from the Asia Pacific region. That high volume means you need to lock in your production slot early. You can dig into more of the numbers in this shopping bag market research report. By handling these details proactively, you’re setting yourself up for a smooth process and a final product that truly represents your brand.

Turning Your Bags into Marketing Assets

Here's a little secret: your investment in custom logo shopping bags doesn't end when a customer walks out the door. In fact, that's exactly where the real work begins. The smartest brands know these bags aren't just packaging. They're mobile advertisements, a tangible reminder of a great experience, and a surprisingly effective way to build a community.

When you start thinking strategically about distribution, you turn a simple carrier into a dynamic marketing asset. The goal is pretty straightforward—get your bags seen in as many places as possible. Every customer becomes a walking billboard for your brand.

Beyond the Checkout Counter

If you're only giving out custom bags at the point of sale, you're leaving money on the table. It's time to think bigger. Where does your audience hang out, and how can your branded bag add real value to their experience there?

Local Events and Sponsorships: Are you sponsoring a local farmer's market, a 5K charity run, or a community festival? Hand out your high-quality totes. They’re infinitely more useful than another flyer and will carry your brand all over the event and long after it's over.

Trade Show Giveaways: At a busy conference, a sturdy, stylish bag is one of the most sought-after pieces of swag. Attendees are desperate for something to carry all the brochures and samples they collect. Your bag can be the one they grab, giving you visibility across the entire show floor.

Customer Loyalty Programs: Why not reward your best customers? Include a premium reusable bag when they hit a certain spending threshold. It’s a great way to show you appreciate their business, and it encourages them to bring your brand along on their future shopping trips.

To get the most mileage out of your bags, think of them as the centerpiece of a broader strategy that uses unique promotional swag to build your brand identity.

Encouraging Reuse and Social Sharing

The ultimate win? When a customer loves your bag so much they start using it in their daily life. This creates organic, repeated brand exposure at zero extra cost to you. A fantastic design is the first step, but you can also give them a little nudge.

Consider adding a small, discreet message on the bag itself. Something like, "Tag us in your travels with #YourBrandAdventure!" or "Show us how you reuse your bag!" This simple call-to-action can spark a wave of user-generated content, turning a physical item into a social media conversation starter. Pairing these bags with other high-quality marketing materials creates a cohesive brand experience that people remember.

The real value of a custom bag isn't just in the initial transaction. It's in every subsequent use—at the grocery store, the gym, or the park—where your brand becomes a visible part of your customer's life.

This focus on reusability is what's driving major market growth. The global tote bag market, a huge piece of the custom bag world, is projected to hit USD 6.94 billion by 2025. Why? Because people want sustainable, stylish accessories. By tapping into this trend, your bags become more than just packaging—they become a lasting symbol of your brand's quality and values.

Common Questions About Custom Bags

When you're jumping into the world of custom logo shopping bags, a few questions pop up almost every single time. Getting good answers to these can save you a ton of time, money, and headaches, making sure your project goes off without a hitch.

Let's dive right into the most common ones we hear.

What Is The Best File Format For My Logo?

This is probably the most important technical detail to get right. For the sharpest, cleanest print, you absolutely want to use a vector file. That means files ending in .AI, .EPS, or .SVG.

Think of it this way: vector files are built with math, not pixels. That means you can blow them up to the size of a billboard or shrink them down to fit on a pen, and they will never, ever get blurry. The lines will always be crisp.

Now, if all you have is a JPG or a PNG, don't panic. It's not the end of the world, but it’s not ideal either. You’ll need to send the highest resolution file you can find—we’re talking at least 300 DPI (dots per inch)—to have a fighting chance against a blurry or pixelated final print. Still, your printer will always prefer a vector file to guarantee a professional result.

How Do I Choose The Right Bag Material?

Finding the perfect material for your bags comes down to a balancing act between three things: your brand's vibe, your budget, and how your customers will actually use them.

For an upscale or eco-conscious brand: You can't go wrong with natural fibers like cotton or canvas. They have a premium feel, they're built to be reused over and over, and they send a strong message about sustainability. You can explore plenty of options that fit this mission in our guides on eco friendly printing.

For big promotions and giveaways: When budget is the name of the game, non-woven polypropylene is a fantastic choice. It’s surprisingly durable for its low cost, making it a true workhorse for trade shows.

For that classic retail experience: You can never go wrong with paper. It's incredibly versatile. You can get that earthy, rustic feel with kraft paper or go for a sleek, high-end look with a laminated finish.

Think about the bag's second life. A sturdy canvas tote becomes a walking billboard at the grocery store, while a beautiful paper bag from a boutique makes the whole purchase feel like a special event.

What Is A Setup Fee In Custom Printing?

A setup fee is a totally standard, one-time charge in the printing world. It covers the cost for the printer to get all their equipment prepped and calibrated specifically for your design.

For a process like screen printing, for example, this fee pays for creating the physical screen for each individual color in your logo.

It’s a necessary step and is billed separately from the price you pay per bag, so make sure you factor it into your initial budget. You might see it waived for huge reorders of the exact same design, but you should always plan for it on a new project.

What Does Minimum Order Quantity Mean?

The Minimum Order Quantity (or MOQ) is simply the smallest number of bags a supplier will print for you in one go. They set these minimums to make sure that each production run is efficient and covers their own setup costs.

MOQs can be all over the map depending on the bag material, the printing method, and the supplier themselves. It’s really important to ask about the MOQ right at the start to make sure it works for your needs and budget.

While it can be tempting to go with a lower MOQ for a small project, just remember that the price per bag almost always drops as your order gets bigger. Larger runs usually offer a much better value in the long run.

Ready to create custom bags that get your brand noticed? 4OVER4 offers a wide range of high-quality, customizable shopping bag options perfect for any business. Start designing your bags today at https://4over4.com

More from custom logo shopping bags

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

64

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

106

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

105

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

332

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026