- Home

- content hub

- Your Guide to Custom Bumper Stickers

Your Guide to Custom Bumper Stickers

Emma Davis

Content Writer

Oct 4, 2025476 views

Oct 4, 2025476 views

Custom bumper stickers are one of the most effective, old-school ways to get a message out there. They turn any car into a moving billboard for your brand, your beliefs, or just a good laugh. They work because they're right in people's line of sight, surprisingly affordable, and—when done right—impossible to ignore.

Designing Bumper Stickers That Get Noticed

Let's be real for a second. Your bumper sticker has maybe three seconds to make an impression on someone driving behind you. This isn't about making something that looks pretty up close on your screen; it’s about designing for communication in motion.

We're going to move past the generic templates and dig into what actually makes a design pop from a distance. The idea here is to give you the strategic thinking you need to create a sticker that doesn't just look good, but actually delivers a message, instantly and clearly.

This isn't just a niche hobby, either. The global bumper sticker market was valued at around USD 2 billion back in 2022, and it's only projected to grow. People love personalizing their vehicles, and custom printing has never been more accessible.

The Foundation of an Effective Design

Before you even touch a color picker or scroll through fonts, you need to nail down your core message. What's the one single thing you want someone to remember after they see your sticker? Is it a website? A brand name? A political jab or a funny observation? Simplicity is your best friend here.

A cluttered design is the enemy of readability on the road. Too much text or a bunch of busy images just turns into a frustrating blur at 60 MPH. Think of your sticker as a tiny billboard—the best ones have a single, powerful focal point and just a few words.

- The Three-Second Rule: Can your message be fully understood in three seconds flat? If not, it’s too complicated.

- One Core Idea: Don't try to cram your company's entire mission statement onto a 3" x 11" space. Pick one thing and stick to it.

- Action-Oriented Goal: What do you want the viewer to do? Laugh? Visit a URL? Remember your name? Every design choice should serve that one goal.

Choosing a High-Impact Color Palette

Color is the very first thing that catches the eye, and for bumper stickers, high contrast is non-negotiable. This means pairing background and text colors from opposite ends of the spectrum.

You have to design for real-world conditions. Your sticker needs to be legible in blinding sunlight, on a gray overcast day, and even through a rain-streaked windshield. Low-contrast combos like light gray on white or dark blue on black will just vanish.

Pro Tip: When in doubt, go with the classics. There's a reason road signs and warning labels use them: black text on a yellow or white background is one of the most readable combinations known to man.

Here are a few high-contrast pairings that always work:

- Black on Yellow

- Black on White

- Dark Blue on White

- Red on White

- White on Black

Font Selection for Ultimate Readability

Your font choice can single-handedly make or break your design's effectiveness on the road. You absolutely must avoid thin, script, or overly decorative fonts. They might look slick on your monitor, but from 20 feet away, they become an illegible smudge.

You want bold, clean, sans-serif fonts. Think Helvetica, Arial, Franklin Gothic—typefaces built for pure clarity. Go as big with the font size as you can without making the design feel cramped. The text is your message; let it be the hero.

And if you really want to stand out from the sea of rectangles, think about the shape. A custom die-cut sticker that follows the contour of your design can be a real head-turner. Check out our custom shape diecut collection for some inspiration on how to literally break the mold.

By focusing on these fundamentals—a crystal-clear message, knockout color contrast, and a super-readable font—you'll create a bumper sticker that actually does its job. It'll get seen, it'll be understood, and it'll stick in someone's mind long after they've changed lanes.

Choosing the Best Materials for Durability

A killer design deserves to last. When you're creating custom bumper stickers, the material you pick is probably the single most important factor in how long it will survive out there on the road. It's the difference between a sticker that looks great for years and one that fades, peels, or cracks after just one harsh winter.

Think of the material as the sticker's foundation. It has to stand up to everything—UV rays, rain, road salt, you name it. That's why not all sticker materials are created equal, and getting this right from the start is key to making a lasting impression.

Why Vinyl Is the Undisputed Champion

For anything that lives outdoors, vinyl is the undisputed champion. Forget paper-based stickers; they'd dissolve in the first downpour. Vinyl is a type of plastic, which makes it inherently waterproof and tough enough to handle whatever the road throws at it.

Its durability is a big reason the car decal market, a huge slice of the bumper sticker world, keeps on growing. The global market was valued at USD 2.3 billion in 2023 and is expected to climb to USD 3.4 billion by 2032. People want high-quality, long-lasting ways to personalize their vehicles, and vinyl delivers.

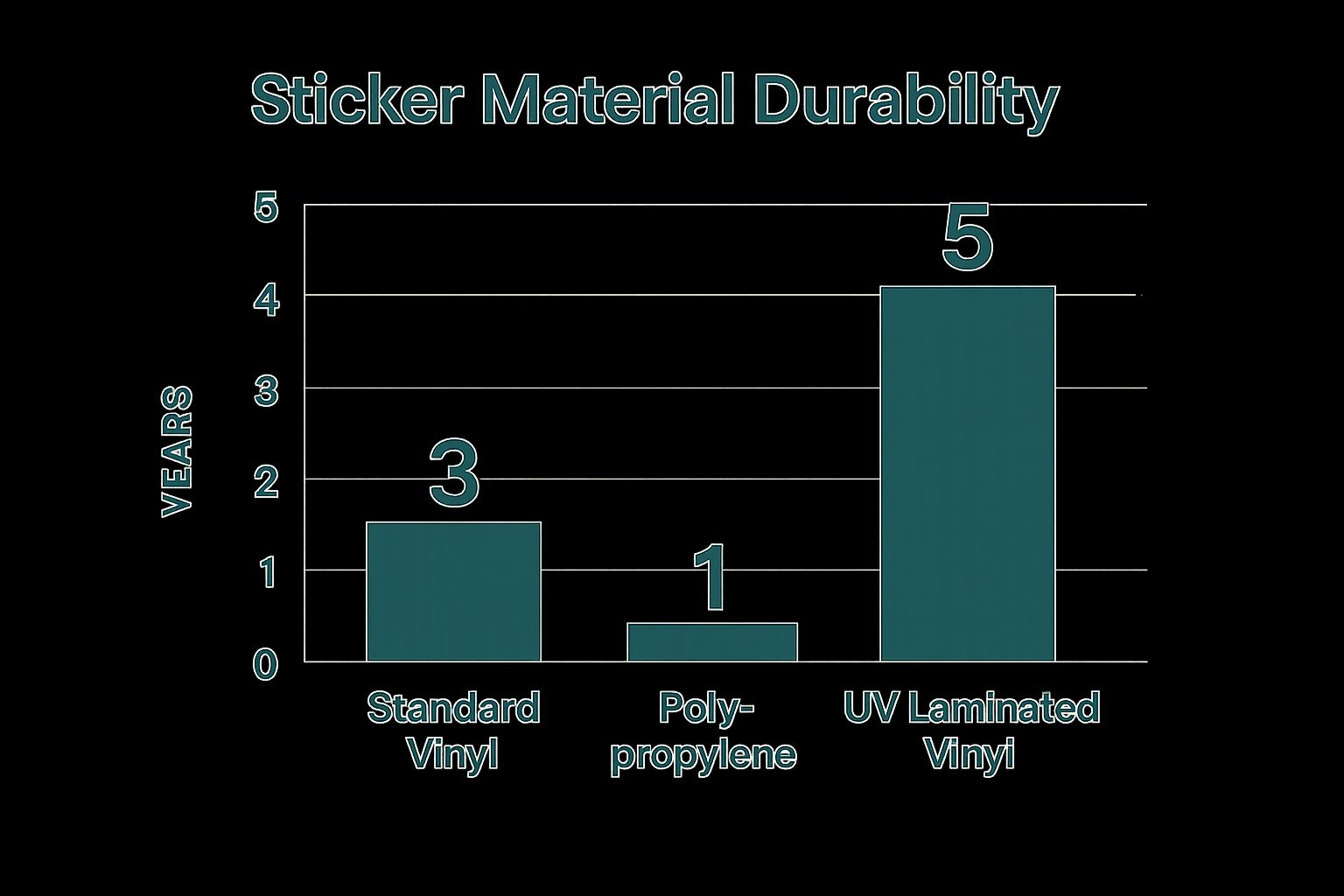

This chart breaks down just how different materials hold up over time.

As you can see, adding a UV laminate is the ultimate upgrade. It seriously extends the life of your sticker, giving it the best possible defense against the elements.

Gloss vs. Matte Finish: A Practical Comparison

Once you've landed on vinyl, your next choice is the finish. This is all about aesthetics and performance. Your main options are gloss and matte, and each has its own vibe.

High-Gloss Finish: This is that classic, shiny look you probably picture when you think of bumper stickers. A gloss finish makes colors feel more vibrant and saturated, giving your design a real "pop." It's perfect for grabbing attention and making bold graphics stand out. The slick surface also adds a bit of extra protection and is a little easier to wipe clean.

Matte Finish: A matte finish gives off a more modern, almost sophisticated feel. It has a non-reflective, satin-like surface that cuts down on glare, which can actually make text easier to read in direct sunlight. This finish is a great choice for designs going for a more understated or elegant look.

Let's put it in context: Say you're designing stickers for a high-end car detailing shop. A matte finish would probably align perfectly with that premium brand image. On the flip side, if you’re promoting a loud, colorful summer music festival, a high-gloss finish is going to capture that energetic vibe much better.

Bumper Sticker Material and Finish Comparison

To help you decide, here's a quick look at how the different options stack up. This table compares the most common material and finish combinations, highlighting what makes each one unique so you can pick the best for your project's durability and visual goals.

| Feature | Standard Vinyl (Gloss Finish) | Standard Vinyl (Matte Finish) | Reflective Vinyl |

|---|---|---|---|

| Best For | Bold, vibrant designs that need to pop | Understated, modern, and elegant looks | Safety, visibility, and 24/7 brand exposure |

| Look & Feel | Shiny, reflective, and slick | Non-reflective, satin, and smooth | Metallic sheen in daylight, brilliant at night |

| Durability | Excellent (approx. 3 years) | Excellent (approx. 3 years) | Superior (engineered for long-term use) |

| Readability | High, but can have glare in direct sun | Excellent, no glare issues | Exceptional, especially in low-light conditions |

Ultimately, the best choice depends entirely on your design and what you want to achieve. A gloss finish is a fantastic all-arounder, while matte offers a touch of class and reflective vinyl provides a powerful functional benefit.

Specialty Materials for Unique Needs

While standard vinyl gets the job done for most projects, sometimes you need something with a little extra punch. That's where specialty materials come in.

One of the most effective is reflective vinyl. This stuff is engineered with tiny glass beads that bounce light back to its source. In daylight, it looks pretty normal, but at night, it lights up like a beacon when headlights hit it. This is a game-changer for visibility and safety, making it a perfect fit for:

- Emergency service vehicles

- Construction or utility company branding

- Delivery vans that operate after dark

- Any design where the message has to be seen, day or night

If you're looking for versatile branding tools that go beyond just bumpers, it's worth checking out the full range of options. You can learn more about different adhesive vinyls and their applications to see what else is possible for your marketing. Choosing the right material ensures your message not only gets seen but also stands the test of time.

How to Get Your Artwork Ready for Perfect Printing

Even the most killer design for your custom bumper stickers can fall flat if the print file isn’t set up correctly. This is the single most important step bridging the gap between your digital idea and a real-world, high-quality product. Getting your artwork print-ready from the start saves you from common, costly mistakes that can totally tank the final result.

Let's cut through some of the technical jargon so you can prep your files with total confidence. We'll walk through the essentials of resolution, color mode, and the all-important "bleed." Getting these right means the sticker you get in the mail will look exactly like the one you designed on screen.

When you get to the 4OVER4 ordering page, you'll see a spot just like this to upload your final artwork file.

Having a properly prepared file ready to go makes this part of the process a breeze and prevents any last-minute headaches or surprises.

Mastering Resolution for Crisp Details

Ever seen a printed image that looked fuzzy or just plain pixelated? Nine times out of ten, that's a resolution problem. Resolution is measured in DPI (Dots Per Inch), which is exactly what it sounds like: the number of tiny ink dots a printer will lay down in a one-inch line.

For websites and screens, a resolution of 72 DPI is perfectly fine, but for print, it’s nowhere near enough. The industry standard for high-quality, professional printing is 300 DPI. If you submit a file with a lower resolution, you're going to get a blurry, unprofessional-looking sticker—no matter how sharp it looks on your monitor.

Key Takeaway: Always, always set up your design file at 300 DPI from the very beginning. You can't just increase the resolution of a low-quality image later; it has to be created at the proper resolution from the get-go.

Why You Need to Use CMYK Color Mode

Another common pitfall is designing in the wrong color mode. Your computer screen, phone, and digital camera all use the RGB (Red, Green, Blue) color model. It works by adding light together to create a huge spectrum of bright, vibrant colors.

Here's the catch: professional printers don't use light, they use ink. They operate in the CMYK (Cyan, Magenta, Yellow, Black) color model, which creates colors by subtracting or absorbing light on paper. This is the main reason a design can look incredibly bright on your screen but appear a little more subdued when it's actually printed.

To ensure your colors come out as you expect, you must design your artwork in CMYK mode. This gives you a much more realistic preview of the final printed colors and prevents those disappointing, unexpected shifts during production.

- RGB: Made for digital displays like websites and social media graphics.

- CMYK: The one and only choice for professional printing projects.

Most design software, like Adobe Illustrator or Photoshop, lets you easily set your document's color mode to CMYK. Make this one of the very first things you do when starting a new project.

The Secret to a Flawless Edge is Bleed

If there's one concept to burn into your memory for perfect printing, it's the bleed.

Picture your sticker design with a solid blue background that runs right to the very edge. During production, a massive, highly precise machine will cut each sticker out from a larger sheet of vinyl. But even the best machines have a tiny margin of error, sometimes shifting by a fraction of a millimeter.

If your blue background stops exactly at that cut line, any tiny shift will leave an ugly, thin white border along one or more edges. It's a dead giveaway of an amateur setup.

A bleed completely prevents this. It's simply an extra margin—we require 0.125 inches (or 1/8")—of your background color or image that extends beyond the final cut line.

Think of it as a safety net for the cutting machine. This extra area guarantees that even if the cutter is off by a hair, it's still cutting through your design's color, giving you a clean, professional, full-color edge every single time. For anyone looking to create uniquely shaped stickers, understanding bleed is even more critical. You can see how this concept applies to more complex shapes in our guide to professional die-cutting services. Taking a minute to add a bleed makes a world of difference in the final quality of your custom bumper stickers.

A Simple Guide to Ordering Your Stickers

You’ve designed a fantastic sticker, picked the perfect material, and prepped your artwork like a pro. Now for the most exciting part: turning that digital file into a real, tangible product you can hold. This is where your vision truly comes to life.

Navigating an online ordering system can feel a bit intimidating sometimes, but it doesn't have to be. We’ve designed the 4OVER4 process to be completely straightforward, giving you full control over every last detail of your custom bumper stickers without any guesswork.

Selecting Your Sticker Specifications

The first part of the process is all about locking in the physical properties of your sticker. This is where you finalize the decisions you made during the design and material selection phases.

You'll kick things off by entering your desired dimensions. Whether you’re going for a classic 3" x 11" rectangle or a totally custom die-cut shape, getting this right is key to making sure the final product fits its intended space perfectly.

Next up is your material. Here is where you’ll select that durable vinyl we talked about and specify if you want a vibrant high-gloss finish or a more modern, glare-free matte look. Just click on the option that best suits your design’s aesthetic and durability needs.

Finally, you'll specify your quantity. Whether you need a small batch of 50 for a local event or thousands for a nationwide campaign, our system is ready to handle it. Remember, ordering in larger quantities often brings down the cost per sticker, so it’s worth planning ahead if you think you'll need more down the road. To make the process of getting your unique designs a breeze, consider optimizing the custom ordering experience.

Uploading and Proofing Your Artwork

With your specs set, it's time to upload the print-ready file you prepared. Think of this as a critical checkpoint to ensure everything looks exactly as you intended before it heads to the press.

Our system accepts common file types like PDF, AI, and PSD. Once your file is uploaded, you’ll be directed to our online proofing tool. This is your chance to give the final green light with complete confidence. Don't rush this step!

Take a moment to double-check everything: Confirm that your text is sharp, your colors look right (remembering the CMYK shift), and your bleed is correctly in place. This final review is your best defense against any potential printing errors.

The proofing tool shows you a digital representation of your sticker, including the final cut line. This is especially important for custom shapes, as it lets you verify that the die-cut path perfectly follows the contours of your design.

Finalizing Your Order with Confidence

Once you’re happy with the digital proof, you’ll give your final approval. This sends your design right into our production queue, and your part of the creative process is officially done.

The demand for personalized products is surging. The personalized stickers market was valued at USD 4.58 billion in 2024 and is projected to reach an impressive USD 7.99 billion by 2034. The convenience of online platforms like ours has made it easier than ever for businesses and individuals to create high-quality, custom items.

Here’s a quick recap of the key actions you'll take in the ordering process:

- Specify Dimensions: Enter the exact height and width for your sticker.

- Select Material & Finish: Choose between options like gloss or matte vinyl.

- Determine Quantity: Input the total number of stickers you need.

- Upload Your File: Add your print-ready artwork (300 DPI, CMYK, with bleed).

- Approve Your Proof: Carefully review the digital proof and confirm the cut lines.

This streamlined system is designed to put you in control, removing the typical friction points of custom printing. The goal is a smooth transition from design to delivery, leaving you feeling fully informed and excited about the final product. For an even broader look at your options, you can explore the full range of custom sticker printing services we offer.

You've got your custom bumper stickers, and they look fantastic. Now for the fun part: getting them on your car so the whole world can see your message. A good application is what makes a sticker go from a cool design to a professional-looking statement that lasts.

It's tempting to just peel and stick, but trust me, a few extra minutes of prep work makes a world of difference. Getting it right the first time prevents annoying bubbles, crooked placement, and peeling edges, which helps your sticker stick around for the long haul.

The Perfect Application Process

Getting that smooth, bubble-free finish is way easier than you think. You don't need a bunch of fancy tools—just a little patience and a couple of things you probably already have at home. The whole point is to get a solid bond between the sticker and your car, with no air or dirt trapped underneath.

First, scout out the perfect spot. Look for a smooth, flat, or just slightly curved part of your bumper or back window. Try to steer clear of deep grooves, heavily textured plastic, or any spots where the paint is already chipped or damaged. Those areas can mess with how well the sticker adheres.

Here’s a tried-and-true method that works every time:

- Clean the surface like you mean it. Grab some rubbing alcohol or a simple mix of soap and water and give the area a good wipe-down. This gets rid of any wax, road grime, or oil that could stop the adhesive from working its magic. Just make sure the surface is completely dry before you move on.

- Use tape to create a hinge (optional, but a great trick). For bigger stickers, this is a lifesaver. Position the sticker exactly where you want it, then run a piece of masking tape along the top edge to hold it in place. This makes sure it doesn't shift around while you're applying it.

- Apply from the center out. If you used the hinge method, just flip the sticker up, peel off the backing paper, and then slowly lower it back down. For any sticker, the key is to start by pressing down in the middle and working your way out to the edges.

- Squeegee it down. Grab a credit card or a small plastic squeegee and use it to smooth the sticker onto the surface. Use firm, even pressure and push from the center outwards. This little step is what forces out any trapped air bubbles and guarantees a perfect, full-contact stick.

Keeping Your Sticker Looking Vibrant

Once your sticker is on, a little bit of care will keep its colors popping and its edges locked down for years. Our high-quality vinyl is built to be tough, but it's not totally invincible against the elements.

The biggest thing to watch out for is how you wash your car. Try to avoid blasting the edges of the sticker with a high-pressure washer. That intense spray can get under the edge and cause it to start peeling over time. If you're handwashing, just a gentle wipe over the sticker with a soft cloth or sponge is all it needs.

Pro Tip: Stay away from harsh chemical cleaners or abrasive waxes and polishes right on the sticker. They can dull the glossy finish or even start to break down the ink. Good old-fashioned car soap and water is the safest bet.

When It’s Time for a Change

Sooner or later, you might want to switch things up with a new design or get your car ready to sell. Taking an old sticker off the right way is key to avoiding any paint damage. The secret is to soften up the adhesive before you start pulling.

Your best tool for this job is a hairdryer. Gently heat the sticker for about 30-60 seconds, moving the hairdryer back and forth so the warmth spreads out evenly. This will loosen the adhesive's grip just enough.

Once the sticker feels warm, use a plastic scraper (or even just your fingernail) to carefully lift one of the corners. From there, peel the sticker back slowly and at a low angle—as close to 180 degrees as you can get. If you feel it fighting you, just hit it with a little more heat.

For any sticky residue left behind, a bit of goo remover or rubbing alcohol on a soft cloth will take care of it in seconds. If you're looking for inspiration for your next sticker, you can explore our full range of custom decals and printing options.

Got Questions? We’ve Got Answers

Stepping into the world of custom bumper stickers for the first time? It's totally normal to have a few questions. From picking the right materials to making sense of some of the printing lingo, getting the details straight is what separates a good project from a great one. We’ve rounded up some of the most common questions we hear to give you clear, straightforward answers.

Think of this as the final check-in before you hit "order," making sure you have all the info you need to create a sticker that looks awesome and holds up for years on the road.

What Is the Most Durable Bumper Sticker Material?

When it comes to durability, one material stands head and shoulders above the rest: vinyl. It's the undisputed champion for any sticker that needs to live outdoors and face the elements. Vinyl is basically a type of plastic, which makes it inherently waterproof, weatherproof, and tough against fading from harsh UV sunlight.

This resilience is exactly why it's the industry standard. A well-made vinyl bumper sticker is built to handle years of rain, snow, and road grime without peeling, cracking, or turning into a faded mess. It ensures your message stays vibrant and intact, unlike paper-based stickers that would disintegrate after the first storm.

How Can I Make Sure My Text Is Easy to Read?

Readability is everything for a message that's literally on the move. To guarantee your custom bumper sticker is legible from a distance, you need to nail two things: font choice and color contrast.

First up, go with a bold, clean font. Simple sans-serif typefaces like Helvetica, Arial, or Franklin Gothic are fantastic choices because they don’t have the little decorative strokes (serifs) that can blur together from afar. Steer clear of thin, delicate, or script-style fonts—they become nearly impossible to decipher when you're driving.

Next, you need to maximize the contrast between your text and the background. The classic combinations are popular for a reason: they work.

- Black text on a white background

- Black text on a yellow background

- White text on a dark blue or black background

These high-contrast pairings cut through visual noise and stay clear in all kinds of lighting, from bright sun to overcast days.

Will a Custom Bumper Sticker Damage My Car's Paint?

This is a common—and completely valid—concern. The short answer is no, a high-quality vinyl bumper sticker will not damage your car's paint when it's applied and removed the right way. The key is to start with a clean, healthy paint surface that isn't already chipped, peeling, or rusted.

The modern adhesives we use are designed to be strong enough to last for years but are also formulated to be removable without taking the paint with them. When it’s time for a change, the process is simple and safe.

The secret is to gently warm the sticker with a hairdryer for about 30-60 seconds. This heat softens the adhesive, allowing you to peel the sticker off slowly and cleanly without leaving a mess or harming the paint.

What Is a Design Bleed and Why Do I Need It?

A "bleed" is a small, extra margin of your design's background that extends beyond the sticker's final cut line. Think of it as a safety buffer for the printing and cutting process. We require a bleed of 0.125 inches (or 1/8") on all sides of your artwork.

So, why is it so important? It’s all about preventing an unprofessional-looking white border from appearing on your final sticker. Even the most precise cutting machines can have tiny, microscopic shifts during production.

Without that bleed area, any slight misalignment could leave a sliver of unprinted white vinyl showing along an edge. By extending your design into the bleed, you guarantee that the cutting blade slices through solid color, giving you a clean, professional, edge-to-edge finish every single time. It's a small step in file prep that makes a huge difference in quality.

Ready to bring your vision to life? At 4OVER4, we make creating high-quality, durable, and eye-catching custom bumper stickers simple. Explore our options and start your project today.

More from custom bumper stickers

10

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

61

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

88

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

104

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

104

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

326

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

332

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026

179

A QR code business card does more than just share your name and number; it cleverly merges your physical card with your digit

Emma Davis

Emma Davis

Jan 21, 2026