TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- What Is Spot Color Printing for Perfect Brand Colors

What Is Spot Color Printing for Perfect Brand Colors

Emma Davis

Content Writer

Dec 9, 20251811 views

Dec 9, 20251811 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Spot color printing is a beautifully simple concept with powerful results. Instead of mixing tiny dots of different colors on the press to create a new one, this method uses a single, solid, pre-mixed ink for each color in your design.

The result? A pure, vibrant, and perfectly consistent color every single time.

Unlocking Perfect Brand Color Consistency

Think about painting a room in your house. You wouldn’t show up with separate cans of red, yellow, and blue to try and mix the perfect shade right there on the wall. Of course not. You’d go to the store and get a single can of paint that’s been professionally mixed to the exact color you want.

That’s the core idea behind spot color printing. It’s the professional printing world's version of buying that perfect can of paint, guaranteeing a flawless, uniform finish.

This is why spot color is the gold standard for maintaining brand integrity. It ensures that your company's signature blue—or Coca-Cola's iconic red—looks exactly the same on a business card printed in New York as it does on a product box in Tokyo. Its greatest strength is absolute consistency.

The Pantone Matching System Explained

To make sure everyone is on the same page, printers and designers worldwide rely on the Pantone Matching System (PMS). Think of PMS as the universal recipe book for color. Each shade has a unique code, like a recipe number, which tells any printer on the planet how to mix that exact ink formula.

The Pantone system removes all guesswork and subjectivity from color reproduction. It's not about what looks like your brand's color; it's about printing the exact Pantone-specified color every single time.

This level of precision became a game-changer in the mid-20th century, especially for brands needing colors that standard printing just couldn't replicate, like shiny metallics or blazing fluorescents. Today, spot colors remain absolutely critical for any project where color accuracy is non-negotiable.

Spot Color Printing vs CMYK Process At a Glance

So, how does this method stack up against the more common CMYK (or process) printing? While both have their place, their approaches are fundamentally different. The table below breaks down the key distinctions to help you decide which is right for your project.

| Attribute | Spot Color Printing | CMYK (Process Color) Printing |

|---|---|---|

| Method | Uses pre-mixed, solid inks applied one at a time. | Mixes tiny dots of Cyan, Magenta, Yellow, and Black to simulate colors. |

| Color Accuracy | Extremely high and consistent; perfect for brand colors. | Can vary slightly between print runs and different printers. |

| Vibrancy | Colors are cleaner, brighter, and more opaque. | Colors can appear less saturated as they are made of dot patterns. |

| Color Range | Can produce colors outside the CMYK gamut, like metallics and neons. | Limited to the colors that can be created by mixing C, M, Y, and K inks. |

| Best For | Logos, brand identity, designs with 1-3 specific colors, special effects. | Full-color photographs, complex images, designs with many colors. |

| Cost | More cost-effective for simple jobs; can be expensive for many colors. | Cost-effective for full-color designs, regardless of the number of colors. |

Ultimately, choosing between spot and CMYK printing depends entirely on your design's specific needs—whether you prioritize perfect color matching for a few key shades or the complexity of a full-color image.

Key Advantages of Spot Color Printing

Using pre-mixed inks brings some serious benefits to the table, especially for high-stakes projects. Here’s why so many top brands swear by this technique:

- Unmatched Accuracy: It delivers the most precise color match possible. Your brand colors will never be a shade off.

- Vibrancy and Purity: Colors look solid and incredibly clean because they’re laid down as a single, opaque layer of ink, not a pattern of tiny dots.

- Expanded Color Gamut: It opens the door to colors that are simply impossible to create with CMYK, including brilliant neons, rich metallics, and soft pastels. Check out our specialty printing collection to see how these unique inks can make a design pop.

- Consistency Across Materials: Spot colors hold their integrity beautifully across different paper stocks and finishes, from glossy business cards to uncoated cardboard packaging.

Spot Color vs CMYK: Unpacking the Technical Differences

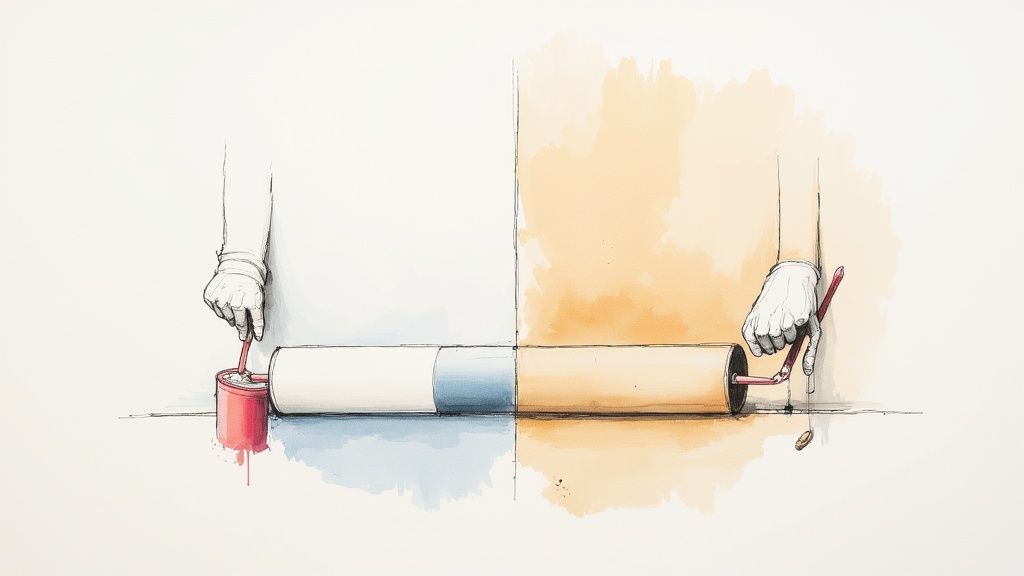

To really get what spot color printing brings to the table, it helps to zoom in on how it differs from its everyday cousin, CMYK. Think of it this way: a spot color is like a solid, perfectly even coat of pre-mixed paint. CMYK, on the other hand, is more like a delicate mosaic, painstakingly built from thousands of tiny dots of Cyan, Magenta, Yellow, and Black ink.

From a distance, that CMYK mosaic tricks your eye into seeing the color you want. But if you were to look up close, you’d see the individual dots that create the illusion. This dot-based method is fantastic for producing complex images with lots of tones, like photographs. But it has its limits when you need a pure, solid, vibrant block of color.

This image nails the concept perfectly. The spot color on the left is a solid, uniform layer, while the CMYK version on the right is just a pattern of dots. A spot color gives you an opacity and smoothness that’s simply impossible to get with a dot-based system.

The Science Behind the Color Gamut

Every color reproduction method has a certain range of colors it can create—this is called its color gamut. The CMYK color gamut is pretty impressive and can produce thousands of hues, but it’s not infinite. Some colors just plain fall outside of what’s possible when you’re only mixing four base inks.

This is where you start running into trouble when trying to print those very specific shades that are critical for a brand’s identity. Think of a vibrant, fiery orange, a deep electric blue, or even soft, delicate pastels. When you try to convert these colors to CMYK, they often come out looking duller or less saturated than you imagined because the necessary pigments just aren't there in the mix.

The core technical difference really boils down to the ink itself. A spot color is a specific, single-pigment formula engineered for purity and vibrancy. CMYK relies on a subtractive process where layers of translucent dots filter light to create the illusion of a color.

Digging into the fundamental differences in ink composition, like those between pigment vs dye-based inks, is key when you're comparing printing technologies. Spot colors, which often use robust pigment-based formulas, are designed for specific light-reflecting properties. That’s precisely why they can pull off effects like metallics or neons that CMYK can only dream of.

Why Consistency Is a Challenge for CMYK

Beyond the gamut limitations, CMYK printing can also be a headache when it comes to consistency. Since the colors are literally built by overlapping microscopic dots, even tiny variations in the printing process can cause noticeable shifts in the final output.

Several factors can throw off CMYK color consistency:

- Press Calibration: Minor differences in how a printing press is calibrated from one day to the next can alter the color.

- Paper Stock: The way ink dots soak into coated versus uncoated paper can dramatically change how a color looks.

- Ink Density: Tiny fluctuations in the amount of each ink laid down during a press run can lead to color variations from the first print to the last.

This is exactly why spot color printing is the go-to choice for brand-critical elements. By using a single, pre-mixed ink from a standardized formula like the Pantone Matching System, you eliminate almost all of those variables. The process is much cleaner: the press just applies one solid layer of the exact correct color. This is a cornerstone of high-quality offset printing, where precision is everything.

Visual Impact and Special Effects

The final, and perhaps most exciting, difference is the ability to create unique visual effects. Since spot color inks are custom formulations, they can be made with special materials that go way beyond standard color.

This opens up a whole world of creative possibilities that are completely off-limits with CMYK alone:

- Metallic Inks: Gold, silver, and bronze inks contain real metal particles, creating a genuine shimmer and a premium feel.

- Fluorescent (Neon) Inks: These inks absorb and reflect more light, resulting in colors that practically glow and demand attention.

- Varnishes: A clear spot varnish can be applied to specific areas to create a glossy or matte contrast, adding subtle texture and sophistication.

Ultimately, choosing between spot color and CMYK is a strategic decision. CMYK offers incredible versatility for full-color imagery, but for projects that demand absolute color perfection, unwavering consistency, and access to special effects, the technical superiority of spot color printing is undeniable. It’s not just a different method; it’s a different class of color.

Why Brand Consistency Relies on the Pantone Matching System

Your brand’s color isn’t just some random choice from a color wheel; it’s one of your most powerful business assets. Think about it. That very specific robin’s egg blue instantly screams Tiffany & Co., and a certain vibrant red is undeniably Coca-Cola. This kind of immediate recognition is no accident. It’s the result of painstaking color consistency, made possible by the Pantone Matching System (PMS).

The PMS is essentially the universal language of color for printers and manufacturers everywhere. It gets rid of the risky game of guesswork, ensuring a brand’s unique shade looks exactly the same on a business card in New York, a billboard in Tokyo, or a delivery truck in London. It’s the ultimate source of truth for color.

Before Pantone stepped in back in the 1960s, trying to communicate color was a total nightmare. A designer might ask for "sky blue," but one printer's version could be worlds apart from another's. Pantone fixed this mess by creating a standardized library of colors, each with its own unique number.

The Power of a Universal Recipe

Using a PMS number is like following a precise, foolproof recipe. A chef doesn't just guess how much flour to use in a cake; they follow exact measurements to get the same delicious result every single time. In the same way, a printer uses the Pantone formula—a specific mix of base pigments—to perfectly create the ink for PANTONE 18-1663 "Fiery Red" or PANTONE 18-3838 "Ultra Violet".

This system ensures that color is no longer an opinion but a fact. When a company specifies a Pantone color, they are providing an unambiguous instruction that any professional printer, anywhere in the world, can replicate with absolute precision.

This level of control is absolutely critical for building a strong brand identity. In fact, studies show that a signature color can boost brand recognition by up to 80%. When customers see your specific shade of green or orange, their brain instantly links it to your products, services, and values. Any inconsistency just waters down that connection and erodes trust.

Real-World Examples of Color Mastery

Some of the world's most iconic brands have built their empires on the foundation of color consistency, all powered by spot color printing and the Pantone system.

- Tiffany & Co. (PANTONE 1837 Blue): The famous blue box is so tied to the brand that the color itself is trademarked. The number "1837" is a nod to the year the company was founded, and this exact shade is meticulously reproduced on every single thing they make.

- T-Mobile (PANTONE Rhodamine Red U): This electric, energetic magenta is simply impossible to miss. T-Mobile uses this spot color to project a bold, modern, and disruptive personality that cuts through the noise in a crowded market.

- UPS (PANTONE 072 C): The deep "Pullman Brown" was chosen to represent stability, reliability, and professionalism. For over a century, this specific spot color has been a constant, reassuring symbol of the company's promise to deliver.

Each of these brands gets it: their color is a promise. When you see that familiar brown, you know exactly what to expect. This consistency is especially vital for printed materials where the brand has to make a physical impression—from marketing flyers to the final customer experience. For any business that deals in physical goods, getting the color perfect on all custom packaging products is a non-negotiable part of their strategy.

The Pantone Matching System, brought to life through the precision of spot color printing, is far more than just a technical tool. It's the guardian of a brand’s most recognizable asset, turning a simple color into a symbol of quality, trust, and identity that connects with customers all over the world. It makes sure your brand speaks the same visual language, every single time.

When to Choose Spot Color Printing for Your Project

Understanding the technical side of spot color versus CMYK is one thing, but knowing when to use it is what separates a good design from a great one. Opting for spot color isn't an accident; it's a strategic move you make when you need absolute precision, rock-solid consistency, and serious visual punch. It's the right call when "close enough" just isn't going to cut it for your brand.

The choice really boils down to a few key priorities. If your project demands perfect color accuracy, has to look identical across thousands of prints, or needs a special effect that CMYK just can't pull off, then spot color is almost always the way to go.

When Unmatched Color Accuracy Is Non-Negotiable

The number one reason to choose spot color printing is for unwavering color accuracy. This is absolutely critical for brand identity, where even a tiny color shift can weaken brand recognition and make you look less professional.

Think about these common situations where precision is everything:

- Logos and Brand Elements: Your logo is your company’s handshake. Using a specific Pantone color ensures it looks exactly the same on your premium business cards, your letterhead, and your envelopes. It all works together to create a polished, cohesive brand experience.

- Color-Critical Packaging: Picture your product on a crowded store shelf. The color of its packaging is what makes it pop. A specific spot color guarantees your brand gets noticed and is instantly recognizable, print run after print run.

- Official Corporate Materials: For things like annual reports, formal documents, or company stationery, sticking to the official corporate color isn't just about looks—it's about projecting professionalism and authority.

This flowchart maps out a simple way to decide if Pantone colors are the right move, hinging on whether color is a critical part of your brand’s identity.

As you can see, when your brand's color integrity is on the line, the precision of the Pantone system is the clear winner. For projects that are less color-sensitive, CMYK is a perfectly suitable option.

Projects with Limited and Bold Color Palettes

Believe it or not, spot color printing can often be more budget-friendly for designs using only one, two, or three distinct colors. Each spot color gets its own printing plate, so a simpler design can actually be more efficient to produce than setting up a full four-color CMYK job.

This makes it a perfect fit for minimalist designs where the colors themselves are the main event. Think bold, graphic T-shirts, striking posters, or simple, elegant product labels. The purity and vibrancy of a solid spot ink create a much stronger visual punch than a CMYK equivalent.

For startups and small businesses looking for high-quality results without breaking the bank, this cost-effectiveness on limited-color jobs is a huge plus.

Creating Premium Effects with Specialty Inks

Sometimes, you need to go beyond the standard rainbow to create something truly memorable. This is where spot color printing really shows off, offering a whole range of specialty inks that are simply impossible to recreate with CMYK.

Choose spot colors when your project needs that extra "wow" factor:

- Metallic Inks: Add a touch of luxury with gold, silver, or bronze. These inks contain actual metallic particles, giving you a genuine, eye-catching shimmer.

- Neon and Fluorescent Inks: Want to grab attention immediately? These intensely bright colors almost seem to glow, making them perfect for event flyers, posters, or safety warnings.

- Pastel Inks: Achieve soft, delicate shades with a beautiful, creamy opacity that CMYK often struggles with, which can sometimes look washed out in comparison.

The global digital printing market, which is projected to grow to USD 48.51 billion by 2030, relies heavily on advanced ink technologies like these to deliver vibrant, consistent results. Innovations in modern printing allow for incredibly precise reproduction of spot colors, fueling the demand for high-impact printing across countless industries.

Ultimately, choosing spot color printing is an investment in your brand's integrity and the visual impact of your final product. When color is a core part of your message, spot color ensures that message is delivered perfectly, every single time.

Breaking Down the Cost of Spot Color Printing

Let's talk budget—it's often the first thing on everyone's mind when planning a print project. Figuring out how spot color printing will affect your final bill is key to making smart decisions. The pricing isn't as simple as "more colors, more money"; it’s really a balancing act between the number of colors you need and the complexity of the printing setup.

At first glance, spot color printing might seem more expensive. After all, it uses specialty, pre-mixed inks. But here’s a surprise: for designs with a limited color palette—say, one to three colors—it can actually be more cost-effective than a full-color CMYK job. Why? Because each spot color requires its own printing plate. Fewer plates mean lower setup costs.

For example, a simple two-color logo on a flyer only needs two plates for two spot colors. To print that same logo in full-color CMYK, you'd need four separate plates (Cyan, Magenta, Yellow, and Black). In this case, the spot color route is both more efficient and more affordable.

This is exactly why spot color is a fantastic choice for minimalist designs where color precision is non-negotiable but the palette is simple.

When Costs Start to Climb

The cost equation flips once your design gets more colorful. Since every single spot color in your artwork needs its own custom printing plate, the expenses can add up fast. A design calling for five or six distinct Pantone colors will require five or six separate plates. This dramatically increases the setup time and material costs compared to a standard four-plate CMYK process.

This is a critical factor to keep in mind during the design phase. If you're curious about how different elements like plates, ink, and setup influence print pricing in general, check out this handy book printing cost calculator. While it's tailored for books, the core principles apply across the board in printing.

The Hybrid Approach: A Smart Compromise

So, what do you do when your project needs both vibrant, full-color photos and a perfectly matched brand color? You don't have to choose. A popular and highly effective solution is hybrid printing, where you add a crucial brand color as a fifth spot color to a standard CMYK job.

This "best of both worlds" method works like this:

- All your photographic and multi-tonal elements are printed using the standard four CMYK plates.

- A fifth (or even sixth) plate is added, dedicated solely to printing your specific Pantone color for logos, text, or other key brand assets.

This strategy ensures your images look fantastic while your brand color remains absolutely perfect. You get that flawless match where it matters most, without incurring the expense of running every single color as a separate spot. It’s a smart way to balance your budget against the undeniable power of perfect color accuracy.

The demand for this kind of color precision, especially in industries like packaging and labeling, is driving serious growth. The label color printing market, which relies heavily on spot colors, was valued at USD 3.33 billion in 2024 and is projected to hit USD 4.67 billion by 2030. This growth shows just how much the industry is investing in technologies that deliver perfect color matching. You can dive deeper into these trends and learn about the label printing market on nextmsc.com.

Getting Your Artwork Ready for Spot Color Printing

Proper file preparation isn't just a technical step; it's the single most important thing you can do to make sure your spot colors print exactly how you imagined. This is where your creative vision gets translated into a technical blueprint for the press. Nail this part, and you'll save yourself from costly mistakes and ensure the whole process runs smoothly.

Think of this as a practical, step-by-step guide for designers using Adobe Illustrator. If you follow these best practices, your files will be print-ready and those crucial brand colors will come out perfectly every time.

Defining and Applying Your Spot Color

First things first, you need to properly define your spot color inside your design software. This is how you tell the program—and later, the printer—that a specific color isn't supposed to be mixed from CMYK. Instead, it needs its own unique, solid ink.

- Open the Swatches Panel: In Adobe Illustrator, you'll find this under

Window > Swatches. - Create a New Swatch: Look for the "New Swatch" icon at the bottom of the panel and give it a click.

- Set Up the Spot Color: The "New Swatch" dialog box is where the magic happens. Here’s what to do:

- Swatch Name: Be precise. Enter the exact Pantone name, like "PANTONE 286 C". This name is critical because it's what the printer uses to find the right can of ink.

- Color Type: This is the big one. Change the dropdown menu from "Process Color" to "Spot Color".

- Color Mode: You can pull your color from a library (like Pantone's) or just plug in CMYK/RGB values that look good on your screen. The on-screen look is just for you; the Swatch Name is what really matters for printing.

- Apply the Swatch: Select the parts of your design, like a logo or some text, and apply your newly created spot color swatch.

Pro Tip: You'll know you've set up a spot color correctly in Illustrator when you see a small white triangle with a dot in the corner of its thumbnail in the Swatches panel. That little icon is your visual confirmation that the color is set to print on its own plate.

Verifying Your File Before You Export

Once your colors are in place, you absolutely have to double-check that they are separating correctly before you send anything to print. This is your chance to catch any colors that might have been accidentally converted to CMYK.

For this, the Separations Preview panel is your best friend. In Adobe Illustrator, you can open it by going to Window > Separations Preview.

When you open this panel, you’ll see a list of every color plate that will be created for your print job. A file that's set up right will show individual plates for Cyan, Magenta, Yellow, Black, and each of your named Pantone colors. You can toggle the little eye icon next to the CMYK plates off. If your spot color elements are still visible, you’re good to go! But if your logo vanishes along with the CMYK colors, it means it was accidentally set as a process color and you need to go back and fix it.

Finally, when you're ready to export your artwork as a PDF, always choose a print-quality preset like "High Quality Print" or "Press Quality." Most importantly, dig into the settings and make sure spot colors are being preserved, not converted to CMYK. This ensures all your careful setup work makes it into the final file you send us. This same level of detail applies to more complex jobs, too, like making sure spot colors are correctly defined for projects involving unique finishes. To see how specialized processes work, you can learn more about preparing files for custom die-cutting services.

Common Questions About Spot Color Printing

Even when you've got a good handle on the basics, a few specific questions always seem to come up when planning a print project. Think of this as your go-to guide for those nagging details, with clear answers to help you make the right call for your next job.

Let's clear up any lingering confusion so you can be sure your final product nails your vision and brand standards.

Can You Mix Spot Colors and CMYK?

Yes, you absolutely can! It’s a pretty common move in the industry, often called a 'five-color' or 'six-color' job. This hybrid approach is perfect when you need the best of both worlds—say, a design that features full-color photos alongside a perfectly matched brand color.

Imagine a real estate brochure. You'd want to use CMYK to get vibrant, realistic photos of the properties. But for the agency's logo, you'd want their specific Pantone blue to be exact. This method gives you that flexibility, just remember to set up your artwork files correctly and chat with your printer about the cost of adding that extra printing plate.

How to Choose the Right Pantone Color

The only truly reliable way to pick a Pantone color is with a physical Pantone swatch book, like the classic Pantone Formula Guide. One of the biggest mistakes we see is people trying to eyeball it on their computer screen. Screens use RGB light to display color, and what you see can look wildly different from one monitor to the next. It’s just not a trustworthy method.

A physical swatch book eliminates the guesswork. It shows you exactly how that ink will look on both coated (glossy) and uncoated (matte) paper, so you can make a precise decision that guarantees the final printed piece matches what you had in mind.

Is Spot Color Only for Offset Printing?

While spot color is most famous for its role in traditional offset printing—where those custom-mixed liquid inks are loaded into massive presses—the game has changed a bit. Modern digital printing has come a long way.

Many high-end digital presses can now simulate Pantone colors with impressive accuracy. They often use an extended color gamut, adding inks like orange, green, and violet to the standard CMYK mix. On top of that, other methods like screen printing and flexography have always relied heavily on spot colors. The right process for you really boils down to your project's size, budget, and the quality you're aiming for.

What if I Send a Pantone File for a CMYK Job?

This happens all the time. If you send a file that has a Pantone spot color but you've ordered a standard CMYK-only print job, the printing software will automatically convert it. It will find the closest possible CMYK equivalent for that Pantone shade. But here’s the catch: it will not be a perfect match.

Many of the most vibrant Pantone colors—think electric oranges, bright greens, and deep, rich blues—simply don't exist within the CMYK color range. When they get converted, they often come out looking a bit duller or slightly off. To avoid any unwelcome surprises, it’s always best to design in CMYK mode from the get-go if you know that's how your project will be printed.

Ready to bring your brand’s colors to life with flawless precision? At 4OVER4, we specialize in high-quality spot color printing that ensures your business cards, packaging, and marketing materials look perfect every time. Explore our printing services and see the difference that perfect color makes.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1311

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

321

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026