TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- What Is Saddle Stitch Binding a Complete Guide

What Is Saddle Stitch Binding a Complete Guide

Emma Davis

Content Writer

Nov 13, 2025706 views

Nov 13, 2025706 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Saddle stitch binding is one of the most popular and budget-friendly ways to bind a booklet. If you've ever held a high-quality magazine, a program, or a simple product catalog, chances are you've seen saddle stitching in action. It's known for its fast turnaround time and for letting pages lay almost perfectly flat when opened.

Understanding the Core Concept

At its heart, the process is pretty straightforward. The "saddle" in the name comes from the way the collated pages are draped over a saddle-like piece of equipment during production. From there, they get stitched together.

The whole thing is built on a simple foundation: large sheets of paper are printed, folded in half, and then "nested" one inside the other. These nested sets are called signatures. Once all the signatures for a booklet are assembled, they get stitched together with wire staples—usually two or three—right along that center fold.

The Rule of Four

There's one golden rule with saddle stitching: your final page count must be a multiple of four. Think about it—each sheet of paper is folded in half, which automatically creates four pages (a front and back on the left side, and a front and back on the right). This is a crucial detail to remember when you're planning out your design.

Introducing Key Terms

As you dive deeper into different binding options, you'll bump into a couple of key terms specific to saddle stitching. Getting familiar with them will make talking to your print provider a whole lot easier.

- Signatures: As we touched on, these are the printed sheets that get folded to create a section of the final booklet.

- Creep: Also called "binder's creep," this is what happens when the inner pages of a thicker booklet get pushed out a tiny bit farther than the outer pages. When the booklet is trimmed flush, those inner pages end up being slightly narrower.

This simple, efficient method is perfect for projects with lower page counts, offering a professional finish without the higher costs associated with more complex binding techniques.

How the Saddle Stitching Process Works

Getting from a digital file to a finished booklet is a surprisingly slick and automated process. It’s pretty cool to see how individual pages become a single, professional-looking product with such speed. The whole operation boils down to a few key stages that flow together seamlessly.

It all kicks off with something called imposition. This is a technical term for how we arrange your booklet’s pages onto large press sheets before printing. It’s not as simple as laying them out 1, 2, 3, 4. Instead, pages are positioned strategically so that once the sheets are printed, folded, and cut, everything lands in the correct sequence. For an eight-page booklet, you might see page 8 and page 1 printed side-by-side on the same sheet. It seems counterintuitive, but it’s the secret to making it all work.

From Printing to Finishing

Once the layout is locked in, the production line takes over, and things move fast. This is where high-volume printing really shines.

- Printing and Folding: First, the large press sheets are printed on both sides. Right after that, specialized machinery folds each sheet with perfect precision, usually in half. This creates what we call a "signature," which is essentially a four-page section of your booklet.

- Collating and Gathering: Next, all these folded signatures are gathered and nested in the correct order. A machine stacks them one inside the other, forming the complete, but still loose, pages of the booklet.

- Stitching and Trimming: The collated pages are then draped over a conveyor that looks a bit like a saddle—and that’s exactly where the name comes from. Industrial stitching heads drive wire staples right through the spine to bind it all together. The final touch is a three-knife trimmer that slices the top, bottom, and side edges for that clean, perfectly flush finish.

Saddle stitch binding is one of the most common and historically important bookbinding methods out there. It’s defined by the use of metal staples punched through the folded spine of a publication. The name is a direct reference to how the sheets are folded and draped like a saddle over the binding machine during production. Learn more about the history and specifics of saddle stitch binding from Walsworth.

This highly automated workflow is precisely what makes saddle stitching one of the fastest and most budget-friendly bookbinding methods you can choose. Whether it's for magazines, event programs, or product catalogs, this process delivers a reliable and professional result, especially for projects with a lower page count.

Deciding If Saddle Stitching Is Right for You

Every binding method has its own set of strengths, and picking the right one really boils down to your project's specific goals. Saddle stitch binding is a fantastic, workhorse option, but it's not a one-size-fits-all solution. Let's weigh the pros and cons to see if it truly lines up with what you need.

The biggest wins for saddle stitching are efficiency and cost. The whole process is highly automated and uses the simplest materials—just a couple of wire staples. This makes it one of the most affordable and fastest binding methods out there, which is a lifesaver for projects with tight deadlines.

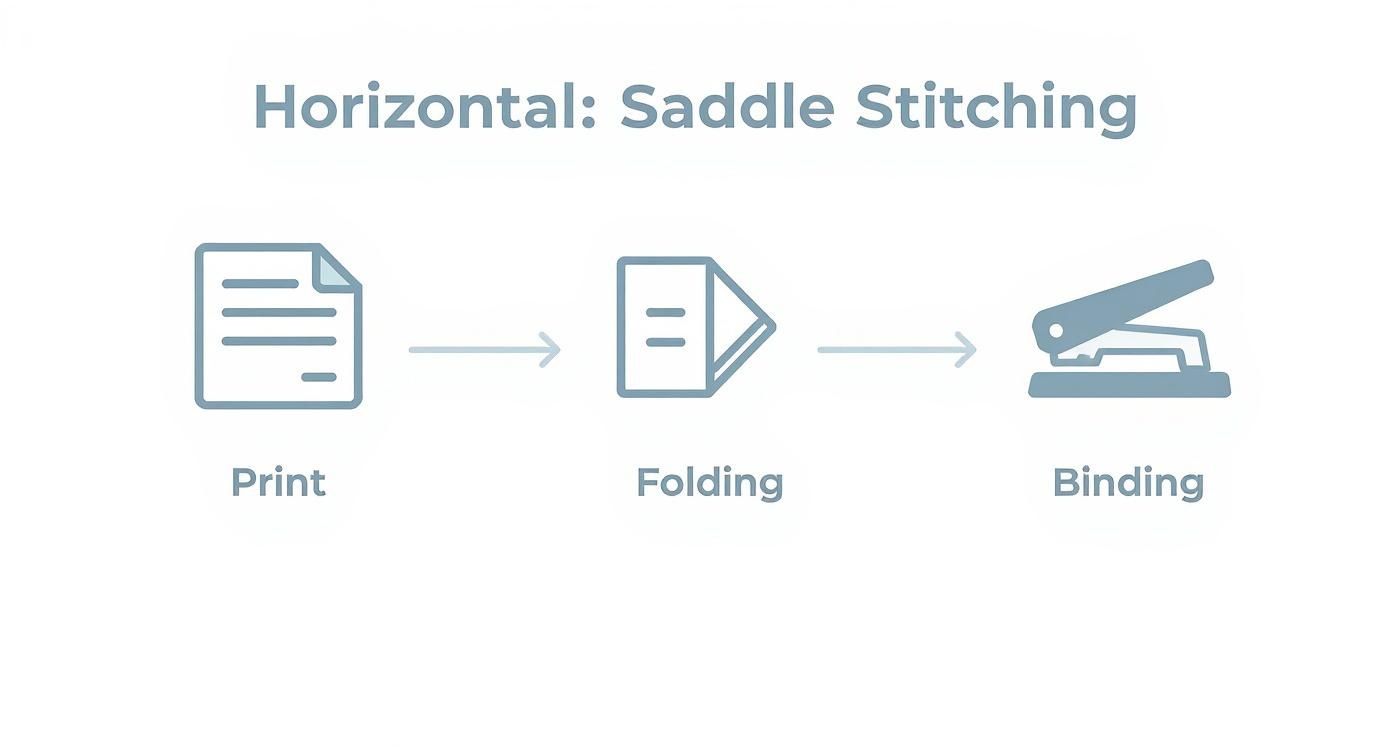

This infographic gives you a quick look at how straightforward the production process really is.

As you can see, that direct path from printing to folding and stapling is exactly what makes it so quick and easy on the wallet.

To help you decide, here’s a quick rundown of where saddle stitching shines and where it falls short.

Saddle Stitch Binding Pros and Cons

| Advantages | Disadvantages |

|---|---|

| Very cost-effective, especially for large runs | Limited page count, typically under 80 pages |

| Fast turnaround times due to a simple process | Lacks a flat spine for printing a title |

| Lightweight which reduces shipping costs | Less durable than other binding methods |

| Lays flat when opened, great for workbooks | Can suffer from page creep on thicker booklets |

Ultimately, weighing these points against your project's needs will lead you to the best decision.

Key Considerations and Limitations

Now, let's talk about a couple of constraints you absolutely need to keep in mind.

The most critical one is page count. Saddle stitching works beautifully for documents with fewer than 80 pages. Once you go beyond that, the booklet gets too bulky for the staples to hold everything together securely, and it won’t lay as flat as it should.

The other thing to watch out for is a little something we in the print world call "creep." This is where the inner pages of a thicker booklet stick out just a bit farther than the outer ones. After trimming, this can leave your inner pages slightly narrower, potentially chopping off text or images if you didn't plan for it in your design.

For anyone looking to get into publishing, understanding these kinds of technical details is crucial. This excellent guide on how to become a publisher is a great resource for navigating production choices like this.

Key Takeaway: Saddle stitching is your go-to for low-cost, quick-turnaround projects with a modest page count. Its ability to lay flat makes it perfect for things people will write in, like workbooks, manuals, and journals.

If your project fits neatly within these parameters, saddle stitching offers a professional and incredibly practical solution. It's the top choice for many types of booklets and catalogs for good reason—it delivers a clean finish without breaking the bank.

Where You Will See Saddle Stitch Binding

Once you know what you’re looking for, you'll start spotting saddle stitch binding everywhere. It strikes a perfect balance between being affordable and looking professional, making it the go-to choice for tons of printed materials we handle every day. From the glossy magazine in a doctor's office to the seasonal catalog that lands in your mailbox, this method is incredibly common.

This isn’t a coincidence. Saddle stitching has a firm foothold in the modern printing industry because it just works. The fast production times and low setup costs give it a huge advantage, especially for items printed in high volumes.

Common Examples in Print

Saddle stitching is the unsung hero behind many familiar products. Its practical benefits line up perfectly with what these projects need, making it a no-brainer.

- Magazines and Comic Books: These are the classics. The ability to lay relatively flat and the low cost per piece are perfect for publications that aren't meant to last forever.

- Event Programs: Think concerts, plays, or conferences. You need to get programs into people's hands quickly and affordably, and saddle stitching delivers on both.

- Workbooks and Manuals: The lay-flat design is a must-have for any material people need to write in or reference easily without wrestling with the spine.

- Marketing Booklets and Catalogs: Because it's so lightweight, saddle stitching helps keep mailing costs down—a major win for direct mail campaigns. You can dig deeper into creating effective marketing brochures and booklets with this method.

Key Insight: The real magic of saddle stitching is in its practicality. It perfectly balances cost, speed, and function for short-to-medium-length documents meant for wide distribution or temporary use.

For projects like these, understanding the typical formats of softcover books and booklets is key, as saddle stitching is often the most sensible and cost-effective binding choice.

The History Behind Stitched Booklets

Saddle stitching might seem like a modern, efficient binding method, but its core idea is anything but new. Its roots stretch back centuries, connecting today's high-speed print shops to the meticulous work of early craftsmen. Long before machines and metal staples, people were already binding folded pages along the spine by hand. It was a simple, smart way to get information out quickly and affordably.

Believe it or not, this method has been around for a surprisingly long time. We have historical evidence showing pamphlets and small books being stitched together as far back as the 16th century in Europe. Some of the earliest examples from the mid-1500s used a basic two-hole stitch, while more complex patterns, like the figure-eight stitch, appeared later on. The technique was proven, even if the tools were simple.

From Thread to Wire

The Industrial Revolution was the game-changer. It introduced machinery and wire that completely transformed the process from a manual craft into a high-speed, automated system. What was once painstakingly done by hand with a needle and thread could now be done in a flash. This is when the "saddle" machine was born, designed to hold pages perfectly in place for precise, rapid stapling.

This leap from hand-sewn pamphlets to machine-stitched booklets shows how a brilliant, fundamental idea—securing folded pages at the spine—has been continuously perfected for speed and scale over 500 years.

This long and storied history gives saddle stitching a certain gravity. It isn't just a budget-friendly choice; it's a time-tested solution for book printing. It's a method that has proven its value for centuries, adapting its tools while holding onto its brilliantly straightforward and practical core.

Your Top Saddle Stitching Questions, Answered

As you get your print project ready to go, a few practical questions almost always pop up. Knowing the ins and outs of saddle stitch binding is the key to making sure your final product looks just as polished as you imagined.

This is your go-to guide for quick, clear answers on the stuff that trips people up. Getting these details right from the start will save you a ton of headaches and help you prep your files like a pro.

What Is the Maximum Page Count for Saddle Stitching?

While there's a little wiggle room, page count is the biggest limitation of saddle stitching. The sweet spot for this method is typically between 8 and 64 pages. Some printers might be able to push that up to around 80 pages, but it all comes down to how thick your paper stock is.

Once you go beyond that range, the booklet starts getting too bulky. The staples have a hard time holding everything together securely, and the finished product just won't lay flat like it's supposed to.

For bigger projects like thick reports, training manuals, or novels, you’ll want to look at perfect binding instead. It uses a strong adhesive to create a flat, printable spine that can handle hundreds of pages with ease.

Why Must My Page Count Be a Multiple of Four?

This is the golden rule of saddle stitching—and it’s a hard and fast one. The entire binding process is built on a simple foundation: sheets of paper folded in half.

Every single sheet you fold automatically creates four pages—a front and back on the left, and a front and back on the right. Since the final booklet is just a collection of these folded sheets nested together, the total page count has to be divisible by four. If your document has 22 pages, you'll need to add two blank pages somewhere to hit 24.

What Is Creep and How Do I Plan for It?

Creep is a huge deal, especially when you’re working with thicker booklets. It’s what happens when the inner pages of a saddle-stitched document get pushed outward, away from the spine. Picture a thick stack of folded paper—the sheet in the very middle has to wrap around a much thicker fold than the one on the outside.

This means when the booklet is trimmed for that nice, clean edge, the inner pages end up slightly narrower than the outer pages. If your text, images, or page numbers are too close to that edge, they could get sliced right off.

The solution is a technique called shingling, which just means using larger margins on the innermost pages to create a safe zone for the trim. Most professional print shops will handle this adjustment for you, but it’s always smart to be aware of it during the design phase.

Ready to create stunning, professional booklets for your business? At 4OVER4, we specialize in high-quality saddle stitch binding that delivers a polished look on time and on budget. Explore our options and start your next project today at https://4over4.com.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026