TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- What Is Flexographic Printing A Practical Guide for Modern Brands

What Is Flexographic Printing A Practical Guide for Modern Brands

Emma Davis

Content Writer

Dec 7, 2025505 views

Dec 7, 2025505 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Flexographic printing is a high-speed printing method that works a lot like a super-advanced rubber stamp. It uses flexible photopolymer plates and quick-drying inks to transfer images directly onto all sorts of materials, which is why it has become such a cornerstone of the packaging world.

The Workhorse of Modern Packaging

Picture a production line churning out thousands of snack bags, labels, or boxes every single hour. That incredible speed and versatility is the heart of what is flexographic printing. It’s the go-to technology for high-volume jobs, especially on materials that give other methods a hard time, like plastic films, foils, and corrugated cardboard.

This ability to produce consistent quality at lightning-fast speeds makes flexo the engine behind much of the packaging you see on store shelves every day.

But this method isn't brand new. While it feels modern, flexography's roots go back to the late 19th century, with the first press patented way back in 1890. It was first called "aniline printing" because of the inks used, but the process was officially renamed "flexography" in 1951. Today, flexography is responsible for roughly 60% of all global packaging printing, showing just how critical it is. For a deeper dive into its history, you can explore the inception and developments of flexo printing on flexopedia.net.

Why Flexo Dominates Packaging

Flexographic printing’s dominance comes down to a few core strengths that are perfectly matched for the demands of the consumer goods market. These traits allow brands to produce high-quality, durable, and cost-effective packaging solutions at a massive scale.

Flexo is particularly effective for:

- Speed and Efficiency: Flexo presses run at incredibly high speeds, making them perfect for long production runs where millions of identical items need to be printed fast.

- Material Versatility: It can print on a huge range of surfaces, both porous and non-porous. Think paper, cardboard, plastics, foils, and films.

- Durability: The inks are tough. They can stand up to abrasion, moisture, and fading, which is a must-have for product packaging that has to survive shipping and handling.

This adaptability is exactly why so many businesses turn to flexo for their custom packaging products.

At its core, flexography solves a critical business need: how to print high-quality graphics on diverse materials at a scale that keeps per-unit costs low. It strikes an exceptional balance between speed, quality, and economic viability for mass production.

To give you a quick snapshot of what flexo is all about, I've put together a simple table breaking down its key features.

Flexographic Printing At A Glance

| Characteristic | Description |

|---|---|

| Primary Method | A rotary relief printing process using flexible plates. |

| Best For | High-volume runs (thousands to millions of units). |

| Common Substrates | Flexible plastics, paper, cardboard, labels, foils. |

| Print Quality | High-quality, especially for solid colors and line art. |

| Cost Structure | Higher initial setup costs (plates), but very low cost per unit on long runs. |

| Speed | Extremely fast, making it one of the most efficient printing methods. |

This table gives you a great starting point for understanding where flexographic printing shines. It’s all about balancing that initial setup cost with the massive payoff in speed and low per-item cost for large orders.

How The Flexographic Printing Process Works Step By Step

To really get what flexographic printing is all about, let's walk a design from a digital file all the way to a finished product in your hands. The whole operation is a high-speed masterclass in precision, where every single part plays a vital role. It's like a perfectly choreographed dance between machines and materials.

The work starts long before the press ever roars to life. It begins with your digital artwork. This file gets transformed into a physical printing plate—a flexible sheet, usually made from a light-sensitive polymer. The easiest way to think about this plate is as a high-tech, super-detailed rubber stamp, where the parts that will print are raised up from the surface. For a full-color job, a separate plate has to be made for each and every ink color.

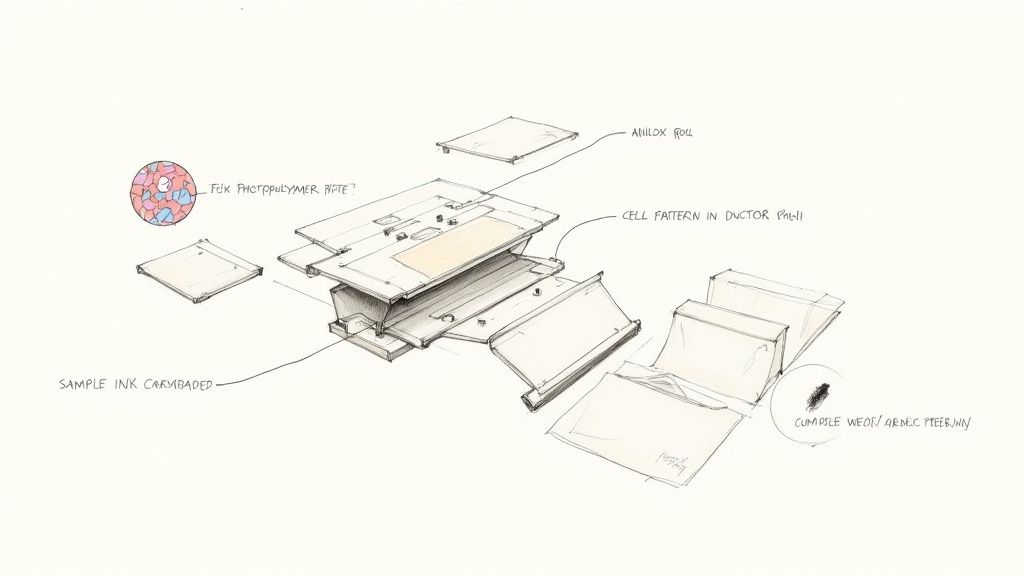

This diagram gives you a clean, simple look at the core of the process, showing how the plate, ink, and press work in harmony.

What this really shows is the continuous, rolling motion of the process. That rotary action is the secret sauce behind its incredible speed and efficiency.

Inside The Flexo Press

Once the plates are ready, they're carefully mounted onto a plate cylinder inside the press. This is where the real mechanical magic kicks off. For each color, the process unfolds in a rapid, non-stop sequence.

It starts with an ink fountain, which is just a reservoir holding the ink for one specific color. A roller dips into this fountain and picks up the ink, transferring it to the most critical component of all: the anilox roll.

The anilox roll is truly the heart of the whole flexo process. It’s a highly engineered, ceramic-coated cylinder engraved with millions of microscopic cells. These tiny cells act like little measuring cups, grabbing a precise, uniform volume of ink. This is what guarantees consistent color across thousands, or even millions, of prints.

From there, a doctor blade lightly scrapes across the anilox roll. Its job is to wipe away any excess ink from the surface, leaving ink only in those tiny engraved cells. This ensures only the exact amount of ink needed is carried forward. The anilox roll then rotates to make contact with the raised parts of the flexible printing plate, transferring its perfectly measured ink layer onto the design.

From Ink To Finished Product

With the plate now freshly inked, the substrate—the material being printed on, like a roll of paper or plastic film—is fed through the press. It travels between the inked plate cylinder and another cylinder called an impression cylinder. This second cylinder applies just the right amount of pressure, making sure the plate transfers its ink cleanly and evenly onto the material.

This whole sequence happens at mind-boggling speeds. After one color is laid down, the substrate zips over to the next printing station, which has its own unique plate, anilox roll, and ink for the next color. This repeats down the line until every color in the design is printed.

Between each of these color stations, high-intensity dryers blast the substrate with hot air or UV light to cure the ink instantly. This rapid drying is absolutely essential for a few key reasons:

- It stops the colors from smudging or bleeding into each other.

- It lets the press run at its blistering top speeds without issue.

- It ensures the material is perfectly ready for the next color application right away.

The genius of the flexographic printing process lies in its integration. Printing, drying, and finishing can all happen in a single, continuous pass, which is why it’s so incredibly efficient for large-scale production.

Finally, after the last color is printed and dried, the roll of material can head to finishing. These steps can be built right into the press itself (inline) or handled on separate equipment (offline). This is where the printed roll is turned into its final form. Common finishing steps include laminating it for protection, adding a UV coating for a glossy look, or trimming it down to the final size.

One of the most common finishing moves is die-cutting, where a custom-shaped steel die punches labels or packaging out of the printed roll. For any business thinking about creating unique shapes for their products, learning more about what's possible with custom die-cutting services can open up a world of creative possibilities. It’s this final step that truly transforms a simple printed roll into finished, ready-to-use products.

A Look Inside The Core Components Of A Flexo Press

To really get what makes flexographic printing so fast and versatile, you need to meet the key players inside the press. It helps to think of a flexo press not as a single machine, but as a finely tuned team where every single component has a specific, critical job to do. When all these parts work together in perfect sync, the result is millions of consistent, high-quality prints.

This process is the product of decades of refinement. Early printing methods have come a long way, especially after World War II with breakthroughs like the engraved anilox roller, which completely changed the game for ink transfer. Later on, the arrival of photopolymer plates and laser etching technologies pushed print quality to levels that now go head-to-head with other high-end methods. The constant adaptation to new inks and materials is what keeps flexo at the forefront of the industry. To learn more about this journey, you can explore the history of flexographic printing on blog.focuslabel.com.

Let's break down the essential components that make all this possible.

The Flexible Photopolymer Plate

The journey begins with the photopolymer plate—think of it as a highly sophisticated, modern-day rubber stamp. This flexible, light-sensitive polymer sheet is what carries your design.

During pre-press, your digital artwork is used to create a raised image on the plate's surface. Every area that needs to be printed is elevated, while the non-print areas stay recessed. For a full-color design, a separate plate is made for each ink color—cyan, magenta, yellow, and black (CMYK), plus any spot colors you need.

These plates are then mounted onto a cylinder in the press. The quality of this mounting is absolutely critical for achieving a sharp, clear final print. If you're working with prints that will be mounted on rigid boards later, understanding the specifics of professional mounting services can help ensure your final product looks its best.

The Anilox Roll: The Heart Of Ink Control

If the plate is the stamp, then the anilox roll is the precision inkwell. This is arguably the most critical component for achieving consistent color and quality, run after run. It’s a hardened steel or aluminum cylinder coated with industrial-grade ceramic, which is then laser-engraved with millions of microscopic cells.

These tiny cells, completely invisible to the naked eye, are engineered to hold a very specific, measurable volume of ink.

Key Insight: The size and density of the cells on the anilox roll determine exactly how much ink is transferred to the plate. This precise metering is what allows a flexo press to maintain exact color consistency across millions of impressions, eliminating guesswork.

A thin steel "doctor blade" scrapes any excess ink from the roll's surface, making sure only the ink held within those tiny cells is passed on. This perfectly controlled transfer is the real secret behind flexo’s reliable quality.

Inks And Substrates: The Versatility Champions

Flexo’s reputation as a true workhorse comes from its ability to handle a massive range of inks and materials, also known as substrates. This incredible adaptability allows it to serve countless industries.

The primary types of inks used in flexography include:

- Water-Based Inks: These are environmentally friendly and are perfect for printing on porous materials like paper and corrugated cardboard. They're a popular choice for food packaging because of their low odor and safety.

- Solvent-Based Inks: Known for their excellent adhesion and durability, these inks are often used on non-porous materials like flexible films and foils. They are scratch-resistant and hold up incredibly well in harsh conditions.

- UV and EB Inks: These inks are "cured" (or dried) instantly using ultraviolet (UV) or electron beam (EB) light. This process allows for extremely fast press speeds and produces a durable, high-gloss finish that's perfect for high-end labels and packaging.

This ink versatility is matched only by the variety of substrates flexo can handle. It prints effortlessly on everything from thin plastic films and metallic foils to thick corrugated board and paper label stock. This is exactly why flexographic printing is behind so much of the packaging you see and touch every single day. Each component—plate, anilox roll, ink, and substrate—plays an indispensable role in the final output.

Flexo vs. Other Printing Methods: A Head-to-Head Comparison

Choosing the right printing method can feel like a tough call, but it gets a lot easier once you understand the core strengths of each technology. Flexographic printing doesn't exist in a vacuum; it goes toe-to-toe with other industry giants like offset, digital, and gravure.

Think of each method as a specialized tool in a workshop. The best choice depends entirely on your project's DNA—from quantity and material to your budget and quality goals. Flexo is the undisputed champ for high-volume jobs on a massive range of materials, especially packaging. But other methods definitely have their moments to shine. Let's break down where each one wins.

Flexo vs. Offset Printing

Offset lithography is famous for its stunning print quality. When you need razor-sharp details, smooth gradients, and photo-realistic images on paper or paperboard, offset is your go-to. It’s the engine behind high-end marketing materials like glossy brochures, magazines, and books.

The main difference is how the ink gets on the paper. Offset is an indirect process: the image is transferred from a plate to a rubber blanket, and then to the substrate. Flexo, however, prints directly from the plate to the material. This direct-transfer superpower is what lets flexo handle rougher, more varied surfaces like corrugated cardboard and flexible films—materials that would give an offset press a serious headache. To see what top-tier offset work looks like, you can explore a wide range of professional offset printing services for projects that need that extra touch of finesse.

Flexo vs. Digital Printing

Digital printing is the king of short runs and personalization. Unlike flexo, digital printing is plateless, meaning setup is practically instant. This makes it incredibly cost-effective for small quantities, one-off prototypes, and any job requiring variable data, like printing a unique QR code or name on every single label.

The trade-off? Speed and per-unit cost on big runs. Digital is perfect for printing 500 custom labels, but its cost per piece doesn't really drop much as you scale up. Flexo’s initial plate costs make it a poor fit for small jobs, but its blistering speed means the per-unit price plummets as the quantity climbs into the thousands or millions.

- Choose Digital for: Short runs, samples, personalized products, and lightning-fast turnaround on small orders.

- Choose Flexo for: High-volume, standardized runs where hammering down the cost-per-unit is the main goal.

Flexo vs. Gravure Printing

When you need to print millions of something with flawless quality, you call in the heavy hitter: gravure. Also known as rotogravure, this method uses massive, engraved metal cylinders that can last for millions of impressions, delivering unbelievable consistency and image depth. It's the force behind long-run magazines, premium packaging, and decorative laminates.

Gravure is like the industrial forge of printing: incredibly powerful and durable, but it requires a massive initial investment. It's built for marathon runs where absolute consistency over millions of copies is non-negotiable.

While both flexo and gravure are rotary processes built for the long haul, the key differences are cost and accessibility. Gravure cylinders are far more expensive and time-consuming to create than flexo plates. This gives it the highest setup cost of any method, reserving it for only the most massive print jobs. Flexo offers a much more approachable entry point for high-volume printing and is generally more adaptable to a wider range of everyday packaging materials.

Printing Method Comparison: Flexo vs. Offset vs. Digital vs. Gravure

To make the decision clearer, it helps to see how these four methods stack up against each other across the factors that matter most to your business. This table breaks down their core strengths and weaknesses at a glance.

| Factor | Flexographic | Offset Lithography | Digital Printing | Gravure |

|---|---|---|---|---|

| Best Run Length | Medium to Very Long | Medium to Long | Very Short to Medium | Extremely Long |

| Setup Cost | Medium to High | Medium | Very Low | Very High |

| Print Quality | Good to Excellent | Excellent | Very Good | Excellent |

| Substrate Variety | Widest Range | Primarily Paper/Board | Wide, but can be limited | Wide, best on smooth |

| Ideal Use Case | Labels, Packaging, Bags | Catalogs, Books, Posters | Custom Labels, Prototypes | Magazines, High-end Wraps |

Ultimately, the right choice always comes back to your specific project needs. By weighing the run length, budget, substrate, and quality requirements, you can confidently pick the printing method that will deliver the best results for your investment.

Where You'll Find Flexography in the Wild

The best way to really get what flexo is all about is to see where it shows up in your daily life. This printing method is the unsung hero behind tons of products on store shelves, and it’s chosen for one simple reason: it’s a powerhouse combination of speed, toughness, and the ability to print on almost anything.

Flexo is everywhere, from the wrapper on your granola bar to the Amazon box on your porch.

It’s an absolute giant in the packaging world. Flexo’s rise in the 1970s, thanks to new rotary presses, completely changed the game by allowing non-stop printing on flexible materials like plastic films and foils. Today, flexographic printing is behind a whopping 60% of the global packaging printing market. That’s a massive footprint. If you're curious about the history, the Weber company's historical timeline of labeling offers some cool insights.

Flexible Packaging and Food Wrappers

Take a walk down any supermarket aisle. Nearly all of that flexible packaging—chip bags, stand-up pouches for granola, candy wrappers, and shrink sleeves on bottles—gets its vibrant look from flexography.

It’s the perfect tool for the job. Here’s why:

- Blazing Speed: The consumer goods industry needs to pump out products by the million, and flexo presses are built for that kind of insane volume.

- Material Versatility: It sticks beautifully to the non-porous plastics and foils that are essential for keeping food fresh and safe.

- Food-Safe Inks: Flexo can use modern, food-grade, water-based inks that meet the stringent safety standards for anything that touches what we eat.

Labels and Barcodes

When it comes to making labels, flexography is an absolute beast. Think about the glossy, colorful label on a shampoo bottle or the simple, scannable barcode tag on a new shirt. Flexo delivers the sharp clarity and resilience they both need.

The inks used in flexo are tough, meaning they can stand up to moisture, friction, and sunlight without smudging or fading. For any business that needs huge quantities of durable product labels, looking into printing online labels via flexography is usually the smartest path forward.

Key Takeaway: If a product label needs to stay bright and readable for its entire journey—from the factory floor to a customer's pantry—flexography is a go-to choice because its inks are built to last.

Corrugated Boxes and Cartons

Trying to print directly onto the rough, bumpy surface of a cardboard box can be a nightmare for most printing methods. But not for flexo.

Its rubbery, flexible plates act like a stamp, conforming perfectly to those uneven surfaces. This allows for crisp, bold printing of logos, shipping info, and branding directly onto cartons. It's the reason flexo has become the standard for the e-commerce shipping boxes and retail-ready packaging you see stacked high in Costco. It’s simply the most cost-effective way to brand cardboard at scale with simple, durable graphics.

Key Advantages And Limitations Of Flexo Printing

No single printing method is the perfect tool for every job. Flexographic printing is a true production powerhouse, but you need to understand its specific strengths and weaknesses to know if it's the right strategic fit for your project. Flexo offers a compelling mix of speed, versatility, and cost-effectiveness, but it comes with some important upfront trade-offs.

The headline advantage of flexo printing is its incredible production speed. Once a press is humming along, it can churn out prints at an astonishing rate, making it the undisputed champion for mass production. This is exactly why it's the go-to method for industries that need millions of labels, packages, or wrappers printed quickly and consistently.

That speed is matched by some serious versatility. Flexo can print on a massive range of materials (or substrates), handling both absorbent and non-absorbent surfaces with ease.

- Porous Materials: Think corrugated cardboard, paper bags, and kraft paper.

- Non-Porous Materials: This includes plastic films, shiny metallic foils, and cellophane.

This adaptability makes it one of the few methods that can reliably handle such a diverse mix of materials.

Balancing Cost And Volume

Another huge benefit is the low per-unit cost on high-volume runs. Yes, there’s an initial investment to create the flexible printing plates, but that cost gets spread so thin over thousands or millions of units that it becomes negligible. As the production run gets longer, the price for each individual item plummets, delivering economies of scale that few other methods can touch.

The core trade-off with flexo is simple: you invest more in the initial setup (plates and press preparation) to achieve a much lower cost per piece on large orders. This makes it a strategic choice for high-volume, repeatable jobs.

But that strength also shines a light on its main limitation. Those upfront costs for plates and setup make flexo printing less economical for short runs. If you only need a few hundred or a couple of thousand items, the initial investment can drive the per-unit price way too high. For these smaller jobs, digital printing is almost always a more cost-effective option because it has practically zero setup cost.

On top of that, while flexo quality has improved dramatically over the years, it can sometimes struggle to reproduce the ultra-fine detail and subtle color gradients that offset printing is famous for. If your design features complex, photo-realistic imagery, you might get better results from offset or gravure. The plate-making process also takes more time than the instant setup of digital, so it’s not the best choice if you need a brand-new design turned around at lightning speed. Understanding this balance is the key to using flexo's power correctly.

Frequently Asked Questions About Flexographic Printing

After diving into the nuts and bolts of flexo, you probably still have a few practical questions. That’s completely normal. Moving from theory to a real-world project always brings up new things to consider.

Let's clear up some of the most common questions we hear from businesses trying to figure out if flexo is the right move for them.

What Kind Of Artwork Files Are Best For Flexo Printing?

Hands down, you want to use vector files. Think files created in a program like Adobe Illustrator, which usually end in .ai or .eps. Unlike pixel-based images (like a JPEG), vector graphics can be scaled to any size without getting blurry or losing their sharpness. This is absolutely critical for creating clean, crisp printing plates.

For color, always stick with a spot color system like the Pantone Matching System (PMS). This is how you guarantee your specific brand colors look exactly the same on the first print and the millionth. Your printer will also give you a few technical specs, like minimum line thickness, to make sure every detail of your design comes out perfectly.

Key Insight: Always start with vector artwork and specify Pantone colors. Getting this right from the start prevents the most common headaches—like fuzzy text or off-brand colors—and will save you a ton of time and money down the road.

How Do I Know If Flexo Is Cost-Effective For My Project?

Flexo is all about volume. The real magic of its cost-effectiveness kicks in when you start printing a lot of something. The main upfront costs are in the setup—creating the custom printing plates for your design and getting the press ready to go.

Because of that initial setup, flexo isn't the best choice for very small orders. For those, digital printing is usually cheaper. But once the press starts running, the price for each individual label or package drops like a rock.

Here’s a simple rule of thumb:

- For a few hundred to a few thousand units: Digital printing will likely be your most affordable option.

- For tens of thousands to millions of units: Flexography is almost always going to give you the lowest cost per piece.

Can Flexographic Printing Be Environmentally Friendly?

Yes, absolutely. The flexo industry has come a long way in becoming more sustainable. The shift toward water-based and UV-curable inks has made a huge difference, dramatically cutting down on volatile organic compounds (VOCs) compared to the old solvent-based inks.

On top of that, modern plate-making technology is designed to reduce chemical waste, and the process itself is so efficient on long runs that it minimizes wasted material. Many printers now offer a huge selection of recycled, recyclable, and even biodegradable substrates, making flexo a solid choice for brands that put a focus on being green. It's a great way to meet consumer demand for responsible packaging without giving up an inch on quality or speed.

At 4OVER4, we specialize in turning your vision into high-quality printed reality. Whether you need custom labels, professional packaging, or vibrant marketing materials, our state-of-the-art printing solutions and expert team are here to help you succeed. Explore our full range of services and start your next project today at https://4over4.com.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026