TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- what is die cutting in printing - Techniques & Tips

what is die cutting in printing - Techniques & Tips

Emma Davis

Content Writer

Nov 9, 2025781 views

Nov 9, 2025781 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

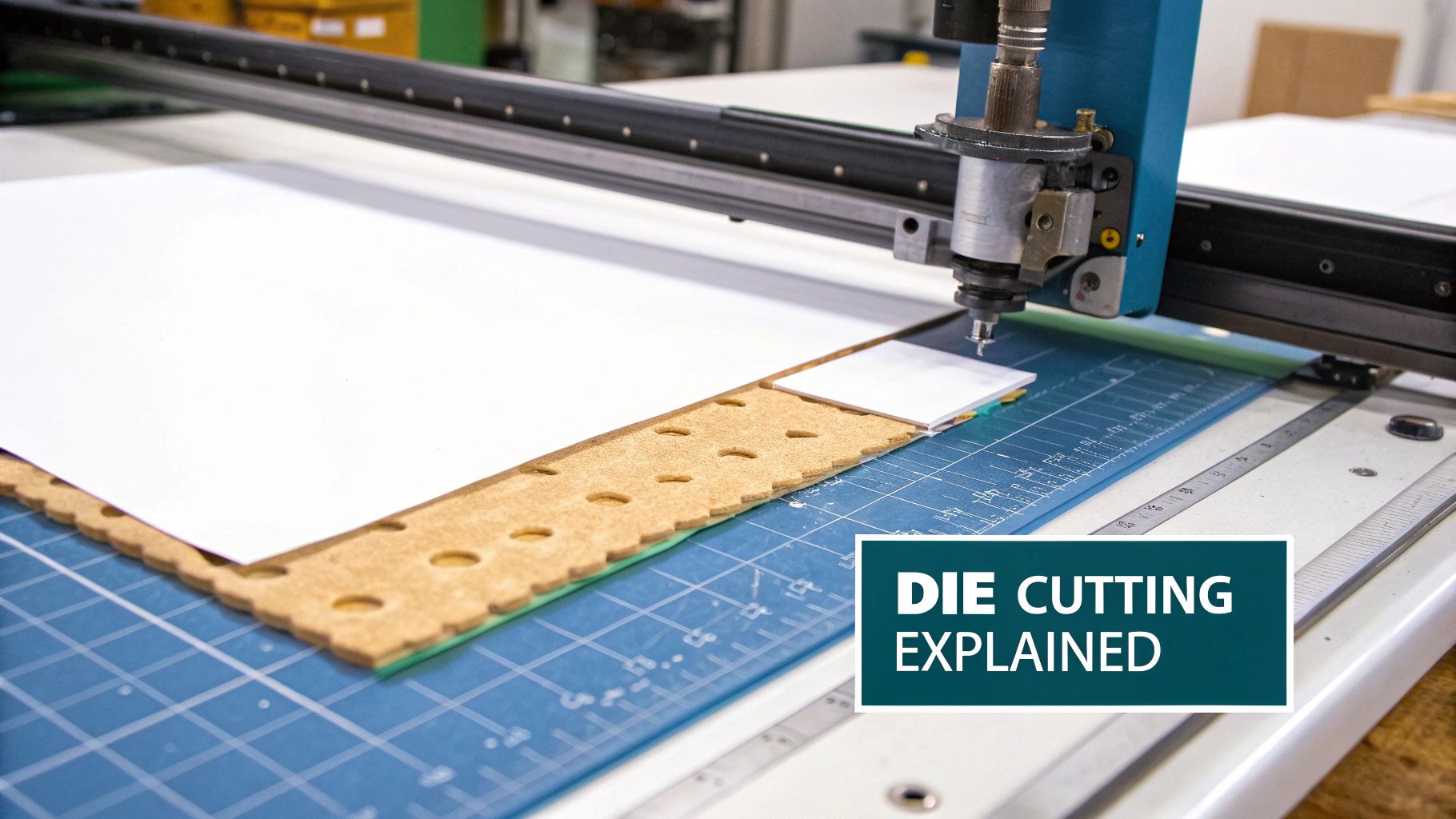

Ever wonder how printed materials get those unique, non-rectangular shapes? Think of it like using a cookie cutter on dough, but for paper and cardstock. That’s the basic idea behind die cutting. It's a finishing process that uses a sharp, custom-shaped tool—called a die—to cut materials into specific designs after they've been printed.

The Foundation of Custom Printing

At its heart, die cutting is the secret sauce that lets businesses move beyond the standard square or rectangle. Instead of a plain business card, you can hand out one shaped like your company’s logo. Instead of a generic box, you can create custom packaging that perfectly fits your product. It’s the technique that turns an ordinary sheet of paper into something memorable.

Why It Matters for Branding

This isn't just about looking fancy; it's a smart branding move. A custom shape instantly grabs attention, making your marketing materials pop in a stack of mail or on a crowded shelf. That unique look and feel give off a premium vibe, boosting how people perceive both your products and your brand.

Here’s why it works so well:

- Enhanced Brand Recognition: A one-of-a-kind shape becomes a signature part of your brand.

- Increased Customer Engagement: An interesting shape is interactive. People want to touch it, look at it, and remember it.

- Perceived Higher Value: Customization shows you care about the details, which signals quality to your customers.

The goal is to create a physical experience that a digital ad simply cannot replicate. A uniquely shaped mailer or product tag provides a tactile connection that helps cement a brand in a customer's mind.

Die cutting really took off in the early 20th century with the rise of mass production and the need for more sophisticated packaging. The process allows for incredibly precise cuts, but it can also be used for creases (for folding) and even embossed effects. This versatility is what makes it so valuable for producing distinctive designs efficiently.

To get a better sense of what's possible, take a look at a custom shape die-cut collection to see how other businesses are using it to stand out. Once you understand what die cutting is, you'll start seeing a whole new world of creative opportunities for your own projects.

To help you remember the essentials, here’s a quick rundown of the core concepts.

Die Cutting at a Glance: Key Concepts

This table breaks down the main ideas we've covered so you can quickly reference them.

| Concept | Brief Explanation | Common Example |

|---|---|---|

| Die | A custom-made, sharp metal tool used to cut a specific shape into material. | A steel die shaped like a star to cut out star-shaped stickers. |

| Die Cutting | The process of using a die to cut shapes from paper, cardstock, or other materials. | Creating rounded corners on business cards or custom-shaped packaging. |

| Finishing Process | A step that happens after printing to complete the final product. | A printed sheet of invitations is die cut into a unique arch shape. |

| Custom Shape | Any shape that isn't a standard rectangle or square, created by a die. | A product tag shaped like a coffee cup for a local café. |

Wrapping your head around these terms is the first step. From here, you can start imagining all the ways die cutting can bring a unique, tangible flair to your brand's printed materials.

The Tools Behind the Perfect Cut

To bring a custom shape from a digital design into the real world, you need some serious hardware. In the printing industry, the two workhorses for this job are flatbed and rotary die cutters. Knowing the difference between them is key to understanding how your project gets made.

Think of a flatbed cutter as a giant, powerful cookie cutter press. A sheet of printed material is laid flat, and the custom die presses down on it, stamping out the shape with incredible force. This method is perfect for detailed, intricate designs, thicker materials, and smaller production runs where getting every detail just right is the top priority.

A rotary die cutter, on the other hand, is more like a high-speed, industrial-strength rolling pin. The die is actually a cylinder, and the paper or other material feeds through it, cutting the shape as it rolls. It's a continuous, lightning-fast process, making it the go-to for high-volume jobs like labels, stickers, and mass-produced packaging where speed is everything.

The Heart of the Process: The Die

No matter which machine is used, the real magic happens in the die itself. A steel-rule die is a custom-built tool. It starts with a sturdy base, usually made of wood, where sharp steel blades are carefully bent and set into place to form the exact outline of your design. These are the blades that do all the work—cutting, creasing, or even perforating the material.

The craftsmanship that goes into making the die is what separates an okay result from a great one. A well-made die ensures that every single piece is cut identically, which is crucial for maintaining consistency across a run of thousands of items. While there's an initial setup cost for creating the die, its durability makes it a smart investment for repeat orders.

A precisely crafted die is the difference between a rough, amateurish final product and a sharp, premium-feeling piece. It ensures every edge is clean and every fold is exact, reflecting the quality of your brand.

Material Versatility and Industry Growth

One of the biggest advantages of die cutting is just how versatile it is. This process isn't just for paper and cardstock. You can shape a whole range of materials to fit your vision, including:

- Corrugated Cardboard: For sturdy custom boxes and retail displays.

- Adhesive Vinyl: To create custom stickers and decals.

- Plastics and Foils: For unique specialty packaging and promotional items.

- Fabric: For one-of-a-kind apparel tags or craft projects.

This technology has even expanded beyond traditional printing, with specialized tools like electric fabric die cutters like the Accuquilt Go Big offering incredible precision for all sorts of materials. Driven by the boom in e-commerce and creative packaging, the market for this technology is growing fast. The automatic die-cutting machine market was valued at $1.8 billion in 2024 and is expected to hit $3.1 billion by 2034.

This ability to cut so many different materials opens up a world of creative possibilities far beyond simple shapes, including practical finishes like custom hole drilling for tags and binders.

From Digital File to Finished Product

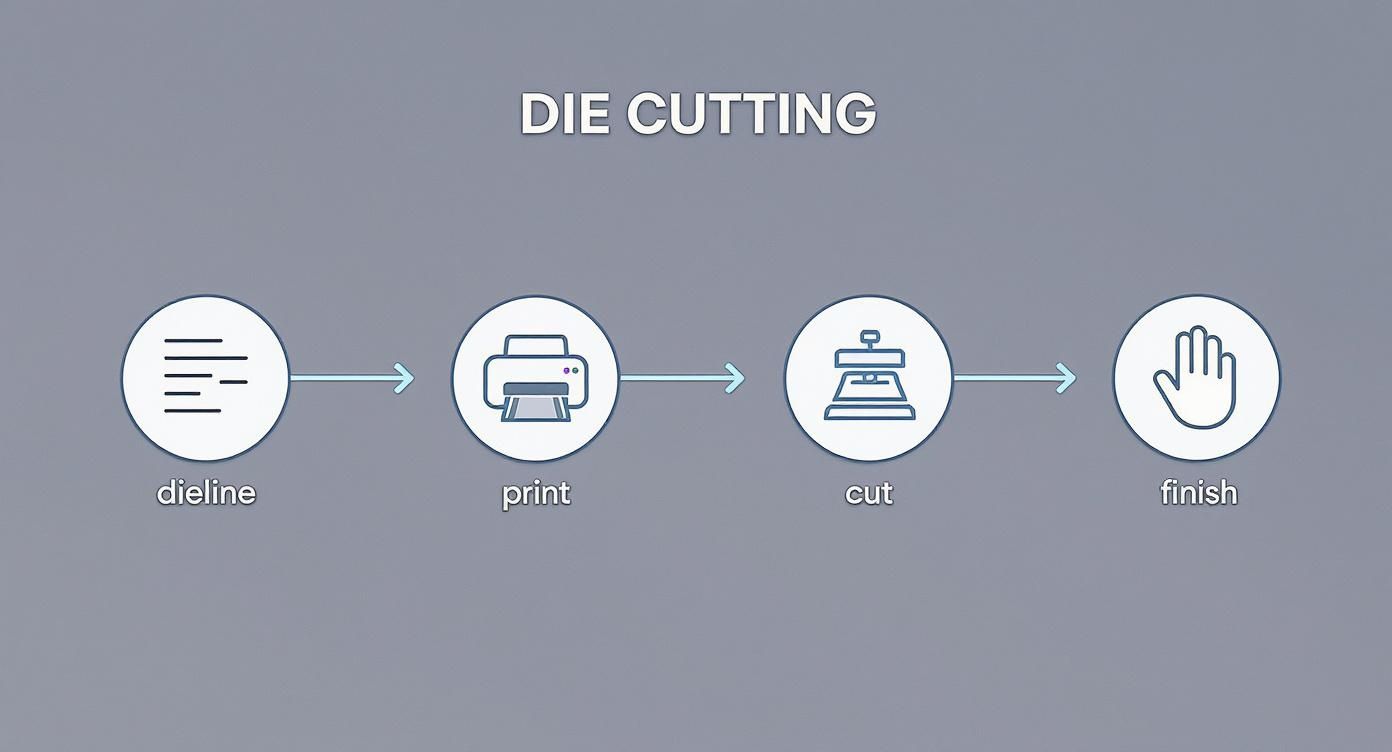

Ever wonder how a design on your screen becomes a physical, custom-shaped object? It's a journey that moves from a digital concept to a tangible product through a super precise, multi-stage process. And it all starts not with the printer, but with a critical digital blueprint known as a dieline.

Think of a dieline as the architectural plan for your printed piece. It’s a vector file that shows exactly where the machine needs to cut, crease, or perforate the material. This blueprint is the guide for the entire production run, ensuring every detail—from intricate cuts to simple folds—is perfectly placed.

The Dieline: The Digital Blueprint

Creating the dieline is the foundational first step. This digital template maps out every single cut and fold needed to bring the final shape to life. We typically build these in design software like Adobe Illustrator, using different line styles to tell the machinery what to do.

- Cut Lines: These are solid lines that indicate exactly where the die will slice right through the material.

- Crease/Fold Lines: Dashed or dotted lines mark where the material should be folded, like on a custom box or presentation folder.

- Perforation Lines: These show where to create a series of tiny cuts for tear-off sections, like you'd find on a ticket stub.

Once the dieline is finalized and approved, it’s sent off to manufacture the custom steel-rule die. This is the physical tool, crafted to perfectly match the digital blueprint. The vector lines become sharp steel blades, ready for action. This step is where the digital design truly begins its transition into a physical tool.

From Printing to Precision Cutting

With the custom die ready to go, the next stage is printing. We run large sheets of the chosen material—whether it's cardstock, vinyl, or corrugated board—through the press with the artwork. It’s absolutely crucial that the printing aligns perfectly with the dieline to ensure the cuts land exactly where they need to.

To boost durability and appearance, finishes are often applied at this stage. You can learn more about how different coatings can protect your print job by exploring options for laminating printed materials.

After printing and finishing, the sheets are moved to the die cutting machine. Here, the custom die is pressed onto each sheet with immense pressure, stamping out the desired shape with incredible precision. This is the moment the magic happens, as the flat, printed sheet is instantly transformed into a custom-cut piece.

The final stage is what we call 'stripping.' This is the process of removing all the excess waste material from around the cut shapes, leaving behind only the finished, perfectly formed products ready for folding, assembly, or shipping.

This meticulous workflow ensures that what starts as a simple digital file ends up as a high-quality, uniquely shaped product that can capture attention and represent your brand with style.

Why Die Cutting Is a Smart Business Move

Die cutting is more than just a fancy finishing touch; it’s a strategic business decision that pays off in real, measurable ways. Let’s be honest, the world is flooded with standard, rectangular marketing materials. A custom shape is one of the most powerful ways to get noticed. It’s what makes your product literally jump off the shelf and your business card the one that doesn’t get tossed.

Breaking out of the boring box immediately tells your customers you care about creativity and pay attention to the little things. This unique presentation automatically boosts the perceived value of whatever you're selling. When people see that you’ve invested in cool, custom-shaped packaging or brochures, they connect that same level of quality to your brand as a whole.

Die cutting transforms a disposable piece of marketing into a memorable physical experience. It’s the difference between being glanced at and being truly seen, creating a tactile connection that digital efforts can't replicate.

This technique is also incredibly practical. Think about custom presentation folders with uniquely cut pockets, hang tags that perfectly mirror a product's silhouette, or intricate box tabs that deliver that oh-so-satisfying unboxing experience. These details don't just look professional—they genuinely improve how customers interact with your brand.

Boosting Brand Recognition and Engagement

The biggest win with die cutting is its power to build instant brand recognition. A unique shape can become just as iconic as a logo, creating a visual shorthand that helps customers spot your products in a split second. That’s a massive leg up in today's crowded retail spaces.

This infographic breaks down how a digital concept is transformed into a finished, custom-shaped product.

Every step in the process, from creating the initial dieline to making the final cut, is carefully planned to guarantee a perfect result, time after time. What you get is a consistently high-quality product that not only grabs attention but also shows that your brand is committed to excellence. So, what is die cutting in printing at the end of the day? It's a marketing tool that makes your brand unforgettable.

Inspiring Ways to Use Die Cutting

Now that we’ve covered the mechanics, let’s get into the fun stuff—the creative side of die cutting. Moving beyond a simple rectangle is where an ordinary print job transforms into a memorable brand experience. The applications are everywhere, from your marketing materials to product packaging, and are really only limited by your imagination.

Think about the first impression you want to make. Instead of a standard business card, what if you handed someone a card shaped like your company logo or your best-selling product? That small detail makes your business instantly memorable and ensures your card gets a second look instead of getting lost in a stack.

The same idea works for brochures, flyers, and mailers. A custom silhouette can grab someone's attention long before they’ve even read a single word.

Elevating Product Packaging and Presentation

Custom packaging is easily one of the most powerful ways to use die cutting. A uniquely shaped box, a sleeve with a delicate cutout, or a window offering a sneak peek of the product—it all comes together to create an unforgettable unboxing experience. This is a huge deal in e-commerce, where that package is the very first physical interaction a customer has with your brand.

In fact, die cutting is the backbone of die-cut cartons, which are just custom-shaped boxes used in practically every industry you can think of. The global market for these cartons was valued at around USD 39.96 billion in 2024 and is expected to climb to USD 58.01 billion by 2032. That growth really underscores how much brands are relying on unique packaging in sectors from food and beverage to consumer electronics. You can dig into more insights about this expanding market on fortunebusinessinsights.com.

This technique also shines when creating marketing tools that are as practical as they are stylish.

- Custom Presentation Folders: Imagine folders with die-cut pockets designed to perfectly hold your business cards and brochures. It’s a small touch that makes your whole package feel organized and professional.

- Uniquely Shaped Invitations: An invitation for a special event can be cut into a shape that reflects the theme, building excitement from the moment it lands in someone's hands.

- Perfectly Formed Labels and Stickers: Think about product labels that trace the exact contour of your container or stickers cut into intricate, eye-catching designs that boost your branding.

Die cutting isn't just about looking good; it's about building a cohesive brand story. When the shape of your marketing material reinforces your message, it creates a much stronger and more memorable impact on your audience.

Making Marketing Collateral Unforgettable

Beyond packaging, die cutting brings that "wow" factor to your everyday marketing materials. A door hanger with a custom shape is way more likely to get noticed than a generic rectangle.

It's the same for product tags. A tag cut into a shape that complements the item itself adds a touch of sophistication and shows you care about the details. If you want to see how this works in practice, explore our guide on creating unique hang tags for your products.

Ultimately, knowing what die cutting can do means seeing its potential to turn a simple piece of paper into a powerful communication tool. By thinking outside the box—literally—you can create materials that don't just inform, but also delight and engage your customers.

How to Prepare Your Design for Die Cutting

A great die-cut project is decided long before the press ever starts running—it all begins with a solid design file. Taking a few extra moments during the design phase is the real secret to avoiding common headaches like tearing or cuts that don't quite line up. It's what makes the difference between "good enough" and something that looks truly professional.

First off, think about durability. While those super intricate, delicate designs might look incredible on screen, they can be a nightmare in real life. Thin little bridges of paper and sharp, narrow points are just asking to tear, either during the cutting process itself or with just a bit of handling. Always design with stability in mind by beefing up any weak spots and avoiding overly complex cuts that push the material to its limits.

Setting Up Your Dielines Correctly

Your dieline is literally the blueprint for the cutting machine, so there’s absolutely no room for error here. To guarantee a clean, crisp result, you have to include both a bleed margin and a safety margin in your artwork file.

- Bleed Margin: Make sure you extend your background colors or images at least 1/8th of an inch beyond the final cut line. This simple step prevents any ugly white slivers from showing up if there's a tiny shift during cutting.

- Safety Margin: On the flip side, keep all your critical elements—like text, logos, or key parts of an image—at least 1/8th of an inch inside the cut line. This ensures nothing important gets accidentally chopped off.

Think of your dieline as a fence. The bleed is the buffer zone outside the fence, and the safety margin is the safe area inside. Keeping your prized possessions inside that fence is the only way to ensure a perfect finish.

Finally, don't forget to talk to your printer. It's a simple step, but it's crucial. The thickness of the material you choose has a big impact on how well sharp corners and fine details will come out. This is especially true for projects where you're aiming to create a stunning unboxing experience. Clear communication can make all the difference.

To see how these principles play out in the real world, check out our options for custom box printing. It’s a perfect example of how great design prep translates into a flawless final product.

Frequently Asked Questions About Die Cutting

Even after you get the hang of the basics, a few questions always pop up when it's time to apply die cutting to a real-world print project. Let's clear up some of the most common ones so you can feel confident you're making the right call.

Die Cutting vs. Laser Cutting: What's the Difference?

Think of it this way: die cutting is like using a metal cookie cutter, while laser cutting is like using an incredibly precise beam of light. Both create custom shapes, but they get there in completely different ways, each with its own strengths.

Die cutting is a physical process. It uses a custom-made steel die to press shapes out of a material like paper or cardstock. Once that die is created, it can stamp out thousands of identical pieces incredibly quickly. This makes it the champion for high-volume jobs where you need speed, consistency, and a great price per piece.

Laser cutting, on the other hand, is entirely digital. It uses a high-powered laser to burn or vaporize the material along a path programmed into a computer. This method is perfect for ridiculously intricate or delicate designs, and it’s a go-to for one-off prototypes since you don't need to create a physical die. The trade-off? It’s much slower and generally more expensive for larger runs.

The bottom line is simple: Die cutting is built for speed and scale, making it the workhorse for most commercial print jobs. Laser cutting offers unmatched detail for custom, low-volume projects.

How Does Die Cutting Affect the Cost?

The main cost driver in a die-cutting project is the creation of the custom die itself. This is a one-time setup fee to manufacture the physical tool that will cut your unique shape.

Because of this initial investment, a small batch of 50 custom-shaped flyers will have a much higher per-unit cost than an order of 5,000. Once the die is made, though, the actual cutting process is super efficient, and the price per piece plummets as your order quantity goes up.

So while die-cut projects are more expensive than standard rectangular printing, the cost becomes far more reasonable at higher volumes.

Are There Minimum Order Quantities?

Yes, almost every printer will have a minimum order quantity (MOQ) for custom die-cut jobs. This is tied directly to the setup costs we just talked about.

The time, materials, and labor involved in making a custom die and getting the machinery calibrated just doesn't make sense for only a handful of items. The MOQ exists to make sure the production run is cost-effective for both you and the printer.

By spreading that initial setup fee across a larger number of pieces, you get a much better value, and the per-item price becomes way more affordable.

Ready to bring your unique vision to life? At 4OVER4, we specialize in creating high-quality, custom-shaped print materials that make your brand stand out. Explore our wide range of die-cutting options and get an instant quote for your project today at https://4over4.com.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026