TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- The Complete Sticker Sizing Chart for Perfect Designs

The Complete Sticker Sizing Chart for Perfect Designs

Emma Davis

Content Writer

Dec 24, 20251451 views

Dec 24, 20251451 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Struggling to nail down the right dimensions for your next project? A sticker sizing chart is your best friend here. It’s designed to match common uses—think water bottles, laptops, or product packaging—with their perfect sizes, giving you measurements in both inches and centimeters. They often use real-world objects for scale, which makes it incredibly easy to visualize the final result before you even print.

Your Quick Reference Sticker Sizing Chart

Picking a sticker size can sometimes feel like a shot in the dark, but a good chart takes all the guesswork out of the equation. Think of it as a visual cheat sheet that turns abstract numbers into something you can actually picture. Instead of wondering if a 3" x 3" sticker is too big for your candle jars, a chart might tell you it’s about the size of a Post-it note. Just like that, you know exactly what you're getting.

Leaning on standard, industry-common dimensions is also a smart move. It simplifies your entire design and printing workflow and ensures your files will be compatible with most suppliers. To get a feel for what’s out there, it's always a good idea to explore a variety of sticker options to see what fits your project best.

Common Sizes and Their Uses

When it comes to product labeling, a few standard sizes have really taken over. In fact, 2-inch and 4-inch circles make up a whopping 60% of all stickers used for this purpose. A 2-inch circle is about the size of an Oreo, making it a go-to for sealing boxes or branding small items. On the other end, tiny 1" x 1" stickers, roughly the size of a quarter, are perfect for price tags or subtle branding and account for 25% of orders. These well-established standards bring a level of consistency that helps everyone, from designers to consumers.

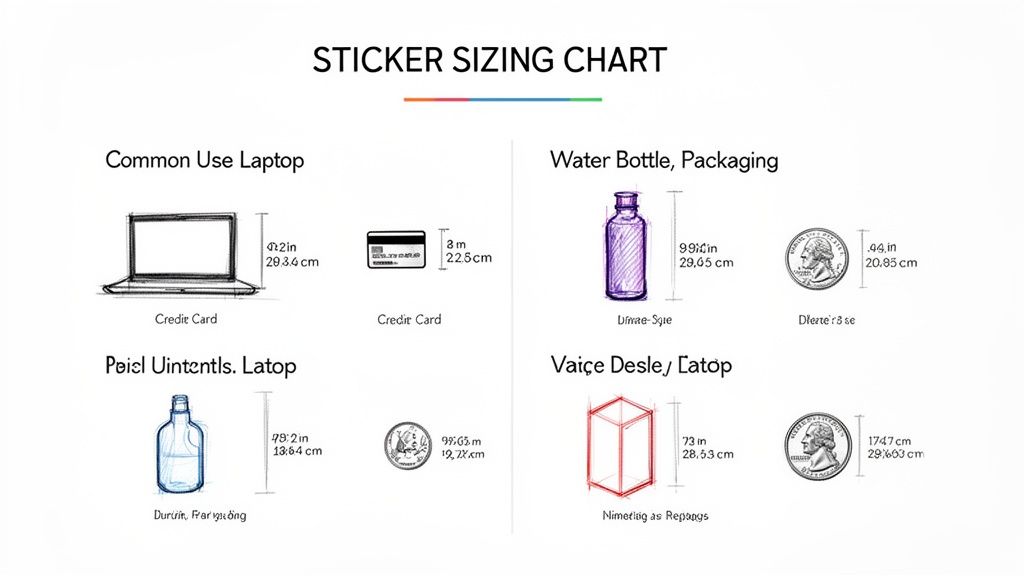

This chart gives you a quick visual rundown, comparing common product and label sizes against things you see every day.

As you can see, relating sticker dimensions back to familiar objects like coins and cookies just makes the whole process of choosing the right size that much easier.

To make things even simpler, we've put together a quick-lookup table matching popular applications with the sticker sizes we recommend.

Common Applications and Recommended Sticker Sizes

| Application (e.g., Laptop, Water Bottle) | Recommended Size (Inches & CM) | Popular Shapes | Real-World Size Comparison |

|---|---|---|---|

| Laptops & Tech | 3" x 3" (7.6 x 7.6 cm) or 4" x 4" (10.2 x 10.2 cm) | Circle, Square, Die-Cut | Coaster or a baseball |

| Water Bottles & Tumblers | 2.5" x 4" (6.4 x 10.2 cm) or 3" x 5" (7.6 x 12.7 cm) | Rectangle, Oval, Die-Cut | A deck of playing cards |

| Product Packaging (Boxes, Bags) | 2" x 2" (5.1 x 5.1 cm) or 3" x 2" (7.6 x 5.1 cm) | Circle, Square, Rectangle | An Oreo cookie or a standard business card |

| Car Bumpers & Windows | 10" x 3" (25.4 x 7.6 cm) or 5" x 5" (12.7 x 12.7 cm) | Rectangle (Bumper), Die-Cut | A standard envelope (#10) |

| Phone Cases & Small Items | 1" x 2" (2.5 x 5.1 cm) or 1.5" x 1.5" (3.8 x 3.8 cm) | Die-Cut, Circle, Rectangle | A large postage stamp |

| Hard Hats & Helmets | 2" x 2" (5.1 x 5.1 cm) | Circle, Die-Cut | A golf ball |

| Mailing Envelopes & Flyers | 1.5" Circle (3.8 cm) or 2.5" x 1" (6.4 x 2.5 cm) | Circle, Rectangle | A bottle cap |

Hopefully, this table gives you a solid starting point and a bit more confidence when deciding on the perfect dimensions for your stickers.

Navigating Standard Sticker Dimensions

Picking the right sticker size from the get-go simplifies your printing process and makes sure your final design looks sharp and professional. When you stick with industry-standard dimensions, you often end up saving both time and money. These common sizes are already optimized for cost-effective printing, whether on sheets or rolls, making them a smart choice for most projects.

For instance, a tiny 1-inch (2.5 cm) circle is perfect for a minimalist logo on small product packaging, like a lip balm tube or the lid of a small jar. It’s subtle but gets the job done. On the other hand, a larger 3-inch (7.6 cm) circle makes a much bigger splash and works great for more visible branding on things like laptops or takeout containers where you want the design to be noticed immediately.

This same logic applies no matter the shape. Getting familiar with the typical use for each size is really the key to making a decision you'll be happy with.

Common Round and Square Sizes

Round and square stickers are the workhorses of the sticker world—incredibly versatile and always popular. Their symmetrical shape is a natural fit for logos, QR codes, and social media icons.

1-Inch to 2-Inch Circles: These are your go-to for small-scale applications. Think of them as seals for envelopes, little price tags, or a touch of branding on the back of a product. A 2-inch circle, for reference, is about the size of an Oreo cookie.

3-Inch Circles: This size has more visual weight, making it a favorite for promotional giveaways, laptop decals, and branding on medium-sized packaging.

2x2 Inch & 3x3 Inch Squares: Just like their round cousins, 2x2 inch squares are fantastic for QR codes or compact logos. The bigger 3x3 inch size gives you more room to play with detailed artwork or bolder branding, and it's roughly the same size as a standard drink coaster.

Knowing these common dimensions helps you zero in on a size that is both visually appealing and perfectly functional for whatever you have in mind.

Standard Rectangle and Oval Dimensions

When your design needs a bit more text or has a horizontal layout, rectangles and ovals are the perfect solution. They give you that extra real estate without looking bulky or oversized.

A standard 2x3.5 inch rectangular sticker is the exact same size as a business card, which makes it a natural choice for adding contact info or detailed product instructions. For bigger jobs, like shipping labels or prominent branding on boxes, a 4x6 inch rectangle can handle more complex designs and plenty of text.

Oval stickers are especially handy for curved surfaces like bottles and jars, since their shape flows with the container's form. Browsing different online labels can give you a much better feel for what will fit your specific product.

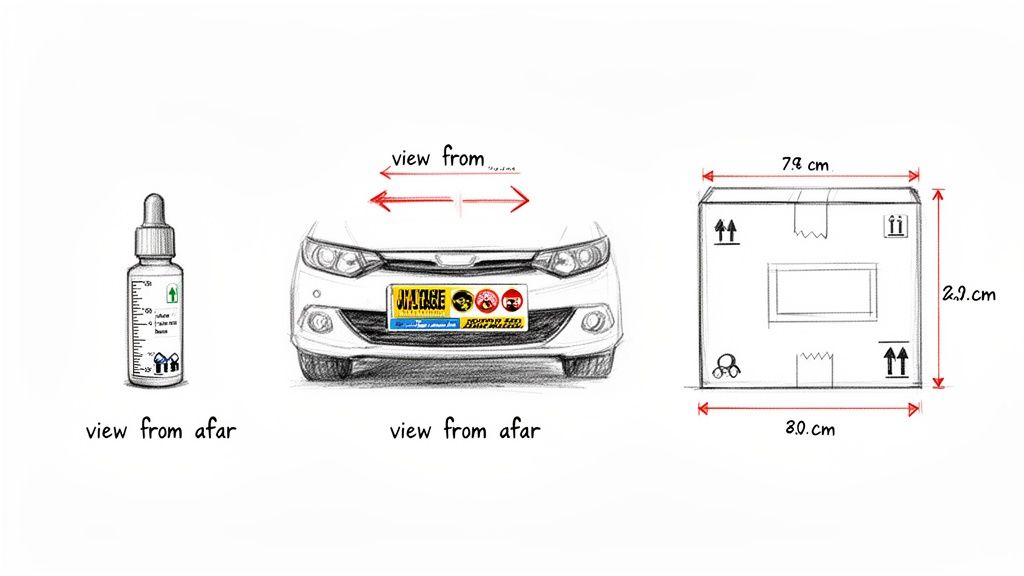

Pro Tip: Always think about the viewing distance when you're choosing a size. A bumper sticker needs big, readable text that can be seen from far away, while a small product label will be viewed up close, which allows for much finer details.

How to Choose the Right Size for Your Project

Picking the right sticker size is about more than just what looks good on your screen. It's a strategic decision that dictates how well your sticker actually works in the real world. A size that seems perfect in your design software can completely fail once it's stuck to its final surface. The trick is to think about function first.

Your number one consideration has to be the application surface. Is it going on something flat like a laptop, or does it need to wrap around something curved like a water bottle? A big, rigid rectangular sticker will probably peel or bubble on a curved surface, but a smaller, more flexible oval or die-cut shape will hug it perfectly. The material matters, too. For bigger jobs like vehicle graphics, you'll want to look into heavy-duty options like https://www.4over4.com/printing/category/adhesive-vinyls, which are built to last and stand up to the weather.

Another huge factor is how far away people will be when they see it. A sticker on a tiny cosmetic jar is going to be viewed up close, so you can get away with finer details and smaller fonts.

Factor in Viewing Distance and Design Complexity

On the flip side, a bumper sticker or a logo on a delivery van needs to be readable from several feet away. For those situations, simplicity and scale are your best friends. Go with bold, high-contrast designs and keep the text to a minimum to make sure your message is crystal clear and instantly recognizable from a distance.

The complexity of your artwork also sets the minimum size you can get away with. An intricate illustration or a design loaded with text needs more room to breathe to avoid looking like a cluttered mess. A simple logo or a single icon, however, can still pack a punch even when it's tiny. Before you pull the trigger on a full print run, always ask yourself if your design's most important elements will get lost if you shrink it down too much.

For example, a 2” x 2” sticker might be perfect for a QR code, but it would render a detailed paragraph of instructions completely unreadable.

You also have to think about the sticker's job. If you're using them as trade show giveaway ideas, a tiny sticker might get lost in a goodie bag, while a larger, well-designed one becomes a piece of swag people actually want to keep.

To make sure you nail it every time, just follow these quick steps:

- Measure the Surface: Grab a ruler and figure out the absolute maximum and minimum space you have to work with on the final product.

- Print a Test: Print your design on regular paper at the actual size you're considering and physically place it on the surface.

- Check for Legibility: Step back to the distance someone would normally see it from. Are the text and graphics still sharp and impactful?

This simple reality check takes all the guesswork out of the equation, guaranteeing the size you choose is a perfect match for its purpose.

Setting Up Your Print Files for Flawless Stickers

A killer sticker design is only half the battle. The real magic happens when you properly prep that design for print, and this is where a lot of projects go sideways. But with a little technical know-how, you can make sure your stickers look just as amazing in your hand as they do on your screen.

Think of it like learning the language your printer speaks. Terms like bleed, safe area, and resolution aren't just jargon; they're the rules of the road for professional printing. Get them right, and you're golden. Get them wrong, and you could end up with blurry images, chopped-off text, or weird white borders.

Let’s walk through the essentials so your files are print-ready right from the get-go.

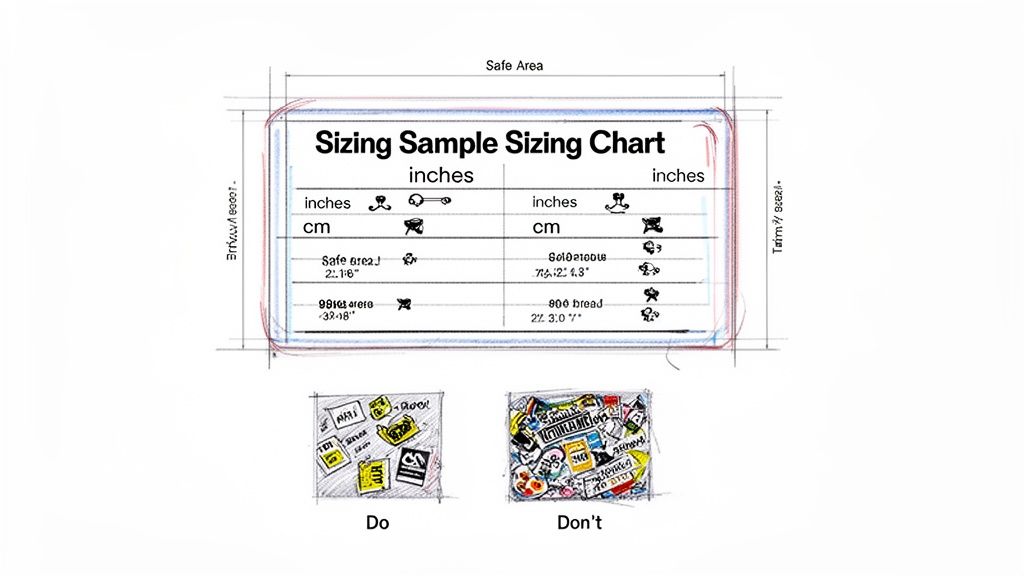

Understanding Bleed and Safe Area

Picture a machine cutting out hundreds of stickers at lightning speed. It's incredibly precise, but even the best machines can have tiny, microscopic shifts. That's where bleed and safe area come in—they're your design's safety net.

Bleed Area: This is a little bit of extra artwork that extends beyond the sticker's final cut line. The standard is 0.125 inches (or 1/8") on all sides. If the cutting blade shifts just a hair, it slices through this extra color instead of leaving an ugly white sliver along the edge.

Trim Line: This is the line where the sticker will actually be cut. It represents the final, finished dimensions of your product. For stickers with unique shapes, it's worth learning about how to create perfect cut lines for custom die-cutting services.

Safe Area: This is an inner margin—also typically 0.125 inches (1/8")—inside the trim line. You absolutely have to keep all your important stuff, like text and logos, inside this zone to make sure nothing gets accidentally trimmed off.

Essentially, the bleed is your buffer on the outside, and the safe area is your protected zone on the inside. They work together to guarantee a perfectly finished sticker every time.

Resolution and File Formats

The sharpness of your printed sticker all comes down to its resolution, which we measure in DPI (dots per inch). For professional print quality, 300 DPI is the non-negotiable industry standard. A file with a lower resolution, like the 72 DPI often used for web images, will look fuzzy and pixelated when printed. Always, always start your design document at 300 DPI.

The file format you send to your printer is just as important. Vector formats are king here because you can scale them up or down to any size imaginable without losing a shred of quality.

Print File Technical Requirements Checklist

Before you hit "export," run through this checklist. Getting these settings right from the start is the key to a professional-looking final product and saves a ton of headaches down the line.

| Specification | Recommended Setting | Why It Matters |

|---|---|---|

| Resolution | 300 DPI | Ensures sharp, clear, and professional-quality printing without any pixelation. |

| Color Mode | CMYK | Matches the four-color process used by commercial printers for accurate color reproduction. |

| Bleed | 0.125" (1/8") | Prevents white edges by extending the design beyond the final cut line. |

| File Formats | PDF, AI, EPS | Vector formats are scalable and preserve text and line art quality perfectly. |

Nailing these four specs—resolution, color mode, bleed, and file format—is the foundation of any great print file. It tells the printer exactly how you want your design to look, leaving no room for error.

When you're ready to break free from the usual squares and circles, custom-shaped stickers are where the real fun begins. Your design literally becomes the shape of the sticker, creating something memorable that people will actually want to use. The two main ways to achieve this are with die-cut and kiss-cut stickers.

It's super important to know the difference so you can pick the right one for your project. A die-cut sticker is cut straight through both the sticker vinyl and the paper backing, matching your design's exact outline. This gives it a sharp, high-end look from the get-go.

On the other hand, a kiss-cut sticker is only cut through the vinyl layer itself. The paper backing stays intact, usually as a square or rectangle. This makes peeling intricate designs a whole lot easier and gives you some extra real estate on the backing for branding or instructions.

Setting Up Your Custom Dieline

To get a custom shape, you'll need to give your printer a dieline. Think of it as a vector path in your design file that shows the cutting machine precisely where to make the slice. If you're using a program like Adobe Illustrator, setting one up is pretty straightforward.

- Finalize Your Artwork: Once your design is perfect, lock that layer. You don't want it shifting around by accident.

- Create a New Layer: Make a new layer on top of your artwork. Name it something obvious like "Dieline" or "Cut Line."

- Outline Your Shape: Using the Pen Tool or other shape tools, trace a clean path exactly where you want the sticker to be cut.

- Set the Stroke: Give this new path a unique spot color (bright magenta is a common choice) and set it to a 0.25 pt stroke. This is a signal to the printer's software that this line is a cutting instruction, not something to be printed.

A quick pro-tip: try to avoid super sharp corners or skinny, delicate parts that could easily tear. Smoother, simpler outlines tend to produce a tougher, more durable sticker. And while the dieline is critical, don't forget that solid design principles for print-on-demand are the foundation for any artwork that looks amazing in print. Need some inspiration? Check out our custom shape diecut collection to see just how impactful a unique shape can be.

Getting Your Sizing Chart Sticker Design Just Right

When your sticker is the sizing chart, its design has one job: be crystal clear. If it’s confusing or tough to read, it’s not just a bad sticker—it’s a one-way ticket to customer frustration, wrong orders, and costly returns. The goal here is to turn a simple label into a genuinely helpful tool that builds trust.

Thoughtful design is what makes a sizing chart sticker work. It all starts with choosing a clean, legible typeface. You can't go wrong with classic sans-serif fonts like Helvetica, Arial, or Open Sans. Their simple, clean lines stay crisp even at tiny sizes, which is crucial for preventing numbers like ‘8’ and ‘6’ from turning into indistinguishable blobs.

Structure for Maximum Clarity

How you organize the information is just as critical as the font you pick. A logical structure makes the chart feel intuitive, letting customers find what they need in seconds without having to decipher it.

Here are the non-negotiables for a user-friendly chart:

- Logical Data Flow: Always arrange sizes in a sequence, like smallest to largest. That predictable order lets a user’s eye scan right to their potential fit.

- Dual Units: This is a simple one but so important. Include both imperial (inches) and metric (centimeters). Instantly, your chart is useful to a global audience.

- Visual Cues: Don't just say "bust." Show it. Use simple icons or line drawings to point out exactly where someone should measure. This removes all the guesswork and helps your customers get it right the first time.

There's a long history of bad sizing info, and it has a real business impact. The first attempt at a national sizing system back in 1939 was a mess from the start and was eventually dropped, leading to the inconsistent "vanity sizing" we see today. This chaos is a big reason why 25-30% of clothes bought online get returned. A clear, reliable sizing chart sticker is your first line of defense against that. Learn more about the evolution of clothing sizing and its impact on e-commerce.

Design Do's and Don'ts

Do: Use high-contrast colors. Think black text on a white or light-colored background. Readability is king.

Don't: Get fancy. Avoid cluttering the design with decorative fonts or graphics that don’t add value. For a tool like this, clean and functional always wins.

By sticking to these fundamental design principles, you'll create a sizing chart sticker that not only looks professional but also acts as an indispensable guide for your customers. It's a small detail that makes a huge difference in their buying experience and confidence.

Frequently Asked Questions About Sticker Sizing

When you're getting down to the nitty-gritty of sticker printing, a few technical questions almost always pop up. We get it. Getting these details right is the key to a professional-looking sticker, so we've put together clear, straightforward answers to the most common queries we see.

This section covers the essential specs that guarantee your sticker looks just as sharp in your hand as it does on your screen.

What Is the Best Resolution for Printing Stickers?

For the best possible print quality, your design file needs to be set to 300 DPI (dots per inch). This is the industry standard for a reason—it ensures your images and text come out crisp and clear, with zero blurriness or pixelation.

If you submit a file with a lower resolution, like the 72 DPI standard for web images, you'll end up with a fuzzy, low-quality sticker. It’s a small detail that makes a huge difference.

How Much Bleed Should I Add to My Sticker Design?

You'll want to add a standard bleed of 1/8 inch (or 0.125 inches) to all sides of your artwork. Pretty much every printer will ask for this. The bleed is just a little extra bit of your design that extends past the final trim line.

Think of it as a safety net. It gives the cutting machine a tiny margin for error, guaranteeing your design goes all the way to the edge without any weird white borders showing up.

A properly set up bleed is your design's best friend. It compensates for tiny mechanical shifts during the cutting process—that's the secret to getting that flawless, edge-to-edge color you see on professionally printed stickers.

Can I Make a Sticker from a Photo on My Phone?

Yes, you definitely can, but there's one critical step: check the photo's resolution first. Most modern smartphone cameras take high-resolution pictures that work perfectly for small to medium-sized stickers.

Before you go to print, always check the file's properties to make sure it meets the 300 DPI requirement at the size you want your sticker to be. If the photo’s resolution is too low for your chosen dimensions, the final print will look blurry and pixelated.

Ready to bring your perfectly sized designs to life? At 4OVER4, we offer a huge range of high-quality, custom sticker printing options to fit any project. Start your order today!

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026