TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- Screen Print Vs Vinyl A Guide to the Best Printing Method

Screen Print Vs Vinyl A Guide to the Best Printing Method

Emma Davis

Content Writer

Jan 8, 2026320 views

Jan 8, 2026320 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

When you're trying to decide between screen printing and vinyl, the choice really boils down to two things: volume and design. If you're ordering a big batch of apparel with a simple, consistent look, screen printing is the undisputed winner for cost and durability. But for smaller, custom jobs or designs with tons of colors and personalization, vinyl's flexibility and speed are just unmatched.

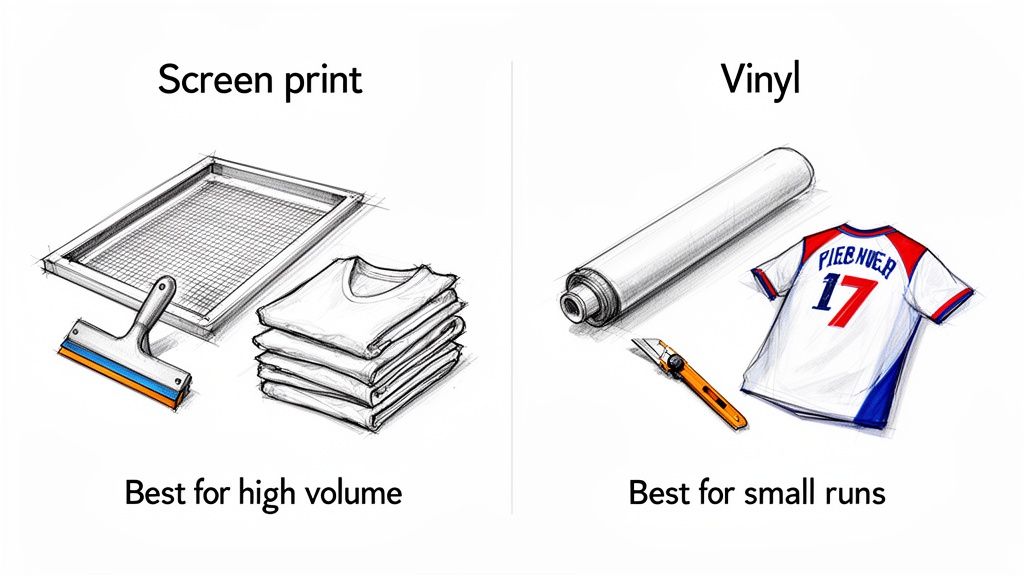

Choosing Your Printing Method: A Quick Comparison

"Should I go with screen printing or vinyl?" This is one of the first questions people ask when ordering custom apparel or signage. Both methods produce fantastic results, but they're engineered for completely different jobs. Knowing their core strengths is the key to avoiding a costly mistake, like overpaying for a small run or getting a product that doesn't hold up.

The main difference lies in the setup and production. Screen printing requires creating a stencil (or "screen") for each color in your design. This involves some upfront cost and labor, but it becomes incredibly efficient and cost-effective as your order size grows. Vinyl, on the other hand, is a digital process with almost no setup, making it perfect for one-offs or small batches.

Quick Decision Matrix: Screen Print Vs Vinyl

If you're in a hurry, this table will help you quickly match your project needs to the right printing method.

| Factor | Choose Screen Printing If... | Choose Vinyl If... |

|---|---|---|

| Order Size | You need 25+ identical items (like event shirts or staff uniforms). | You need just 1-24 items or pieces with personalization (like prototypes or team jerseys). |

| Design Complexity | Your design has 1-4 solid colors and no gradients. | Your design is full-color, photographic, or has intricate, fine details. |

| Durability | You need a long-lasting print that feels soft and can handle countless washes. | Customization is the priority; the print sits on top of the fabric and may not last as long. |

| Cost | Your goal is the absolute lowest cost per item on a bulk order. | Your priority is avoiding setup fees for a small, custom job. |

This practical divide is backed by market data. The global screen printing market is on track to hit around USD 11.92 billion by 2030, with textiles making up a massive 48.16% of that in 2024. That growth is all about bulk orders for promotional custom t-shirts and uniforms.

Meanwhile, the printed vinyl market is estimated at about USD 9.53 billion in 2024, and it thrives on custom signage and smaller, more detailed garment jobs. If you want to dive deeper, you can explore more insights about the printed vinyl market growth on grandviewresearch.com.

How Each Printing Process Actually Works

To really get a handle on the screen print vs. vinyl debate, you have to understand how these two methods actually work. One is an old-school, hands-on craft that’s been perfected over centuries, while the other is a child of modern digital tech. The way they’re made is the reason for the big differences in cost, feel, and what jobs they’re best suited for.

This fundamental split is why screen printing absolutely dominates bulk orders and vinyl is the go-to for custom, small-batch jobs. When you see the labor involved, it starts to make sense why a quote for the same design can be worlds apart between the two.

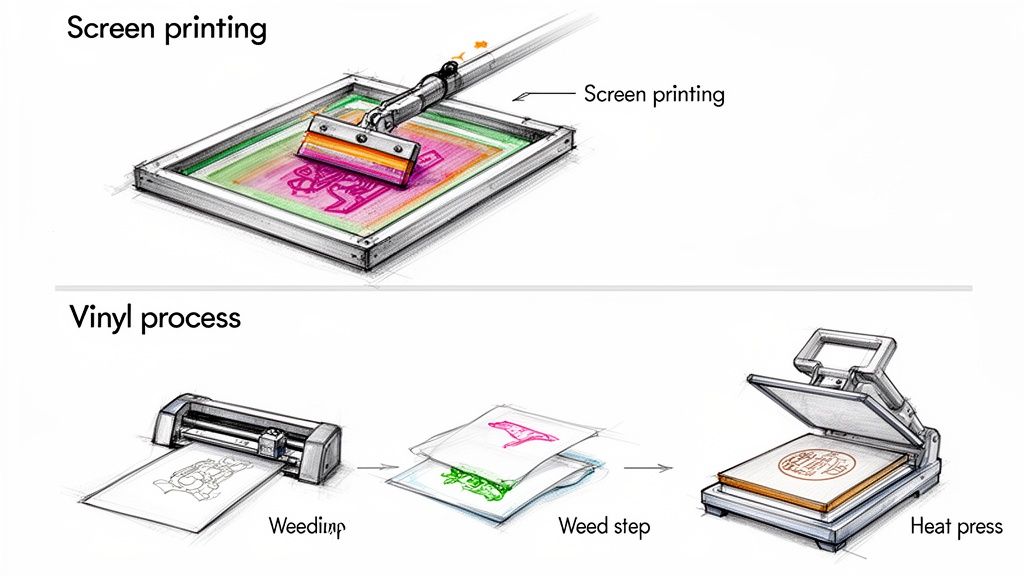

The Screen Printing Workflow

Screen printing is a classic, analog process where ink is pushed through a stenciled mesh screen right onto the product. Think of it like a highly refined stencil. It takes a good bit of prep work to get started, but once you’re set up, you can crank out prints incredibly fast. If you want to see just how much craft goes into it, you can explore the step-by-step process of screen printing at home and get a feel for the details.

Here's the rundown of the basic steps:

- Creating the Screen: First, a mesh screen gets coated with a light-sensitive emulsion. Your design is printed in solid black on a clear film, placed on the screen, and then blasted with bright light.

- Washing Out the Stencil: The light hardens the emulsion everywhere except where your black design blocked it. You take the screen to a washout booth, and the soft, unexposed emulsion rinses away, leaving a perfect stencil of your design in the mesh.

- Printing and Curing: The screen is laid over the t-shirt (or whatever you're printing on), and a squeegee is used to pull a layer of ink across it, pushing the ink through the stencil. If your design has multiple colors, you need a separate screen for each one. Afterward, the item goes through a big conveyor dryer to cure the ink and make it permanent.

The Vinyl Application Process

Vinyl is a completely different ballgame—it’s a digital process that’s much more agile for one-offs or designs with a ton of complexity. You’ll mainly see two types: Heat Transfer Vinyl (HTV) for apparel and fabrics, and self-adhesive vinyl for hard goods like signs, windows, and cars.

Key Takeaway: At its core, vinyl application is a high-tech sticker process. The design isn't printed onto the item. It’s cut from a sheet of colored material and then applied to the surface.

The typical workflow for a vinyl job looks like this:

- Cutting: You send your digital design file from a computer to a vinyl cutter (also called a plotter). This machine has a tiny, precise blade that zips around and cuts your design into a sheet of colored vinyl, but not through the backing paper.

- Weeding: This is the manual part. You have to peel away all the excess vinyl that isn't part of your design. For intricate designs, this can be painstaking work, which is why it's called "weeding."

- Application: For HTV on a shirt, the weeded design is placed on the garment and pressed with a heat press, which activates the adhesive and bonds it to the fabric. For signs or decals, you might want to look into the versatility of different adhesive vinyls that are applied directly to hard surfaces.

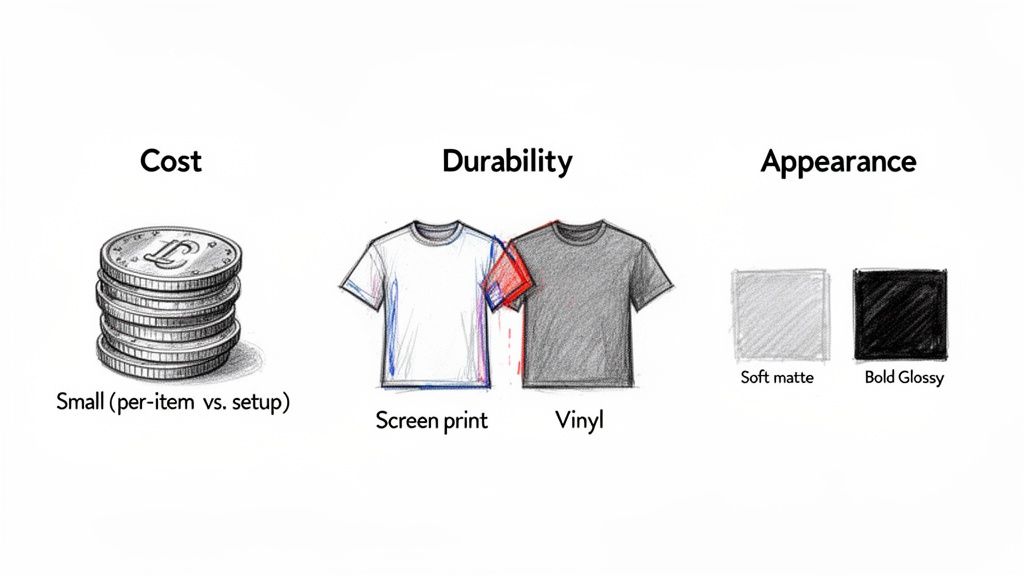

Comparing Cost, Durability, And Final Appearance

The real heart of the screen print vs. vinyl debate comes down to three things that directly impact your budget and brand: cost, how long the design will last, and what the final product actually looks and feels like. These are the pillars that should guide your decision, ensuring you get the best value and quality for your project. One method is built for economies of scale, while the other shines with predictable pricing on smaller, more custom jobs.

This isn't just about which one is cheaper overall, but when each becomes the smarter financial choice. Getting this right is key to maximizing your investment, whether you're ordering five custom jerseys or 500 t-shirts for a big event.

The Economics Of Scale

Screen printing comes with a higher upfront setup cost. There’s no getting around the fact that creating and aligning screens for each color in your design takes time and resources. This makes it a tough sell for just a single shirt.

However, once that setup is done, the cost per shirt plummets with every additional piece you print. It’s what makes screen printing incredibly cost-effective for bulk orders. On the flip side, vinyl—specifically heat transfer vinyl (HTV)—has almost zero setup cost but a steady material and labor expense for every single item. This makes it the undisputed winner for small runs, one-off prototypes, or personalized apparel.

When you look at the cost-per-impression, screen printing holds a clear advantage once you get above a few dozen items. The initial setup cost can make up 40–60% of the total job labor on an order under 25 pieces. But that same cost drops to less than 10% of the unit cost once you're printing over 250–300 garments. Heat transfer vinyl has a nearly flat cost-per-unit, making screen printing 20–40% cheaper on any run of 100+ identical items.

Durability And The Test Of Time

How long will your design hold up? This is a major point of difference, and for apparel, screen printing generally takes the crown.

The plastisol ink used in screen printing actually soaks into the fabric's fibers a bit during the heat-curing process. It essentially becomes part of the shirt, giving you a finish that can handle dozens—if not hundreds—of washes without cracking or fading away.

Vinyl is a different animal. It's a layer of material that sits on top of the fabric, held on by a heat-activated glue. While high-quality vinyl is certainly tough, it’s more likely to peel or crack over time, especially if it's not cared for properly or gets blasted with high heat in the wash. For items that aren't laundered often, like signage, adhesive vinyl is exceptionally durable. For more on creating signage that lasts, take a look at our guide on printing vinyl banners.

Final Look And Feel

The final appearance is about more than just what you see; it’s about the tactile experience and how the design feels on the product.

Screen Printing: This method gives you a soft, breathable finish that you can barely feel on the shirt. The ink stretches and moves with the fabric, so the garment keeps its natural comfort and drape. It's the go-to for any retail-quality apparel where a "soft hand feel" is a top priority.

Vinyl: This produces a sharper, often bolder look with incredibly crisp edges. However, it also creates a distinct, less breathable layer sitting on the fabric. While it’s perfect for the clean, sharp look of athletic jerseys or vibrant, multi-layered graphics, it can sometimes feel stiffer and heavier than a screen-printed design.

Navigating Design Complexity And Color Options

Your creative vision is a huge factor in the screen print vs. vinyl debate. One method is built for bold, punchy colors, while the other handles endless detail and photos with ease. For designers and brand managers, this is a make-or-break comparison.

Screen printing is the undisputed champ of spot color printing. The process uses pre-mixed inks to nail specific Pantone colors, giving you incredibly vibrant, solid, and accurate shades that really pop, especially on dark fabrics. The catch? Each color needs its own screen.

This setup makes screen printing perfect for designs with one to four solid colors. Once you start adding more, the setup costs and labor stack up fast, making it a poor choice for photorealistic images or designs with subtle color fades.

Handling Intricate Details And Full-Color Graphics

This is where vinyl, especially modern printable vinyl, really comes into its own. Since it's a digital process, vinyl can reproduce just about any design you can cook up on a computer. We're talking everything from complex logos with fine lines to full-color photographs with seamless gradients.

When your design needs photographic realism or intricate, multi-color elements, vinyl is almost always the way to go. It completely skips the color separation and screen setup of screen printing, giving you total design freedom without paying a penalty for complexity.

This makes it ideal for small runs of highly detailed merch or one-off custom pieces. While screen printing can manage some detail, tiny text or thin lines can get lost as the ink bleeds slightly into the fabric—a little quirk known as "dot gain." Vinyl, being a precision-cut material, holds a crisp, sharp edge for even the most delicate designs.

Here's a quick guide for designers:

- Choose Screen Printing for: Bold logos, text-heavy designs, and graphics with a limited, solid color palette. Think classic band tees or corporate logos.

- Choose Vinyl for: Full-color photos, artwork with gradients and shading, and designs with extremely fine, detailed linework. This is your go-to for custom photo gifts or intricate branding.

Basically, if your design can be broken down into a few distinct color layers, screen printing delivers unmatched vibrancy and longevity. But if your artwork depends on a full spectrum of color and detail, the power of modern digital printing through vinyl is unbeatable. Let your design's complexity be your guide, and you'll end up with a final product that perfectly captures your original vision.

Matching The Method To Your Project Use Case

Knowing the technical specs of screen printing and vinyl is one thing, but figuring out which one actually works for your project is where it really counts. The best choice always comes down to the specifics. Once you look at a few real-world situations, you can move from theory to practice and pick the method that nails your goals for cost, look, and longevity.

Let's walk through a few common business scenarios. This will help clear up any guesswork and make sure what you get is exactly what you wanted.

Large-Scale Event Merchandise

Picture this: you need 500 t-shirts for a big corporate event or a music festival. Every single shirt gets the same two-color logo on the front. In this case, screen printing is the undisputed champion.

Yes, there's an initial setup cost to create the two screens, but when you spread that cost across hundreds of shirts, it becomes tiny. The cost per shirt drops way below what you'd pay for vinyl, and once the press is running, production is incredibly fast. Plus, the ink becomes part of the fabric, giving you a durable, soft-to-the-touch print that holds up wash after wash—a total must for quality merch.

Custom Team Jerseys And Prototypes

Now, let's flip the script. You're outfitting a local basketball team and need 15 jerseys. They all need the team logo on the front, but each one also needs a unique player name and number on the back.

This is a textbook job for Heat Transfer Vinyl (HTV). Trying to make a separate screen for every player's name and number would be outrageously expensive and slow. With vinyl, each personalization is just a different file sent to the cutter. It's a nimble, cost-effective process for small batches and perfect for handling unique details on every item. The bold, sharp look of vinyl is also a great fit for athletic gear. Getting the hang of different printing techniques is key when you're designing unique apparel, like these popular graphic cat tees.

Key Insight: The real difference isn't just the tech—it's scalability. Screen printing is built for volume and repetition. Vinyl shines when it comes to customization and small-run flexibility. Your order size and need for personalization are the two biggest factors in your decision.

Durable Vehicle Graphics And Signage

But what if you're not making apparel at all? Let's say you need to brand a fleet of company vehicles with your logo or create a vibrant storefront display. When you put screen print vs vinyl head-to-head for things that aren't fabric, adhesive vinyl wins by a landslide.

Adhesive vinyl is engineered for exactly this. It’s made to be weather-resistant, UV-stable, and tough enough to handle years of sun and rain without fading or peeling. It produces brilliant, full-color graphics with crisp edges that look sharp and professional on surfaces like metal, glass, and plastic. For businesses aiming to make a big visual splash, custom window graphics can open up a world of new marketing avenues. Screen printing just isn't built for these kinds of one-off, large-format jobs on hard surfaces. When you match your project's needs to the right method's strengths, you're guaranteed to get the best result every time.

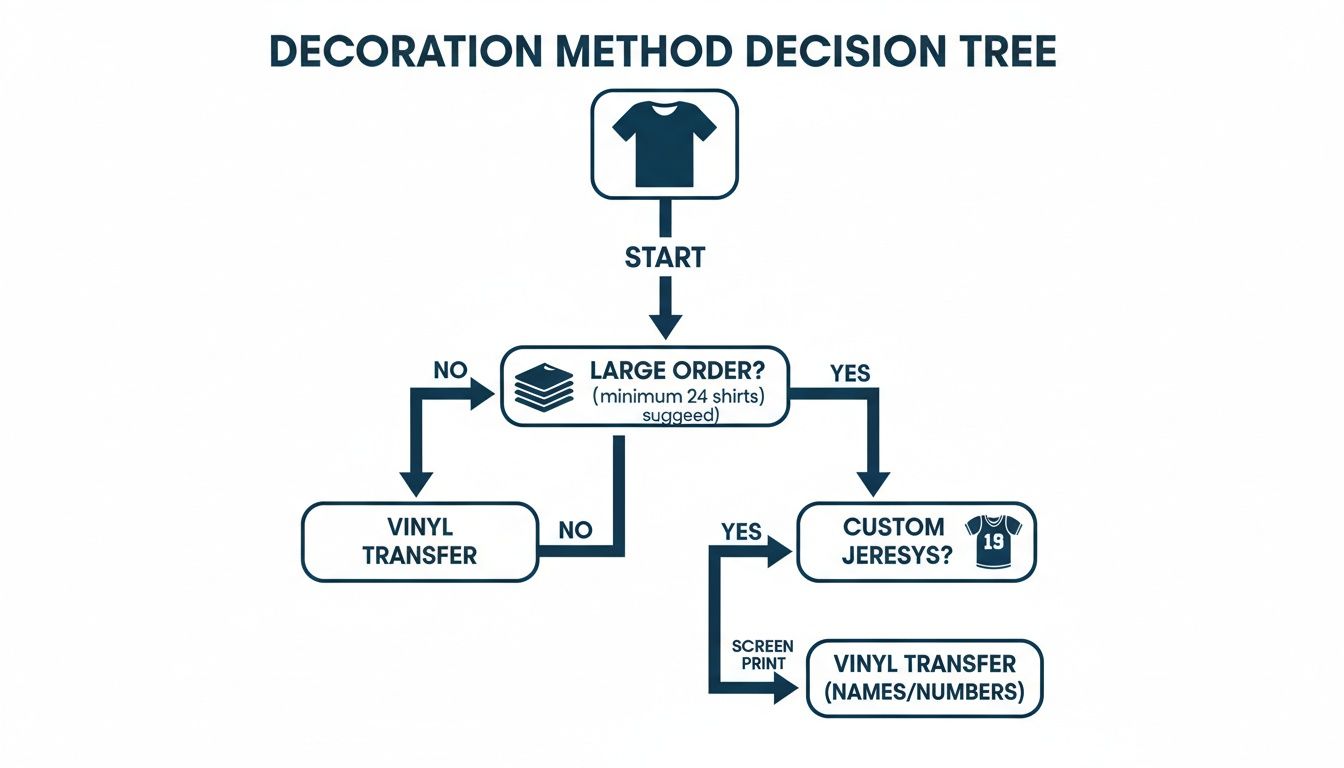

How To Make Your Final Decision

So, you've seen how screen printing and vinyl stack up on cost, durability, and design. Choosing between them really just boils down to the specific needs of your project. The best way to land on the right choice is to ask a few straightforward questions about what you're trying to accomplish. Your answers will point you directly to the smartest, most cost-effective solution.

Before you pull the trigger on an order, run through this quick mental checklist. It will clear up any confusion and ensure your investment is a wise one.

Your Final Project Checklist

- What's my total quantity? If you need more than 25 identical pieces, screen printing is almost always the way to go. Its economy of scale really starts to pay off. For anything less than that, vinyl is going to be your most cost-effective friend.

- How complex is the design? Got a bold, simple graphic with one to four solid colors? Screen printing will deliver an unmatched vibrancy. But for full-color photos, smooth gradients, or designs with tiny, intricate details, vinyl is the clear winner.

- What's my top priority? If maximum durability and a soft, breathable feel are non-negotiable, you want screen printing. If you need a super-fast turnaround, easy personalization for names or numbers, or cool special effects like glitter, then vinyl's flexibility is what you need.

- What fabric am I printing on? Screen printing is the gold standard for cotton and cotton blends. Vinyl, on the other hand, is much more versatile and works great on a wider range of materials, including polyester, nylon, and those tricky heat-sensitive performance fabrics.

Final Recommendation: Honestly, it almost always comes down to two things: your order size and your design's complexity. A large batch of simple, identical shirts screams screen printing. A small run of detailed or personalized gear is a perfect job for vinyl.

This decision tree helps visualize the main questions that will guide you to the right decoration method for your project.

The flowchart just reinforces the core idea: big, simple orders are built for screen printing, while personalized or complex designs are a job for vinyl.

Frequently Asked Questions

When you're trying to decide between screen printing and vinyl, a few practical questions always seem to pop up about ordering, materials, and how long everything takes. Getting straight answers is the key to picking the right method for your project and avoiding any expensive do-overs.

Here are some of the most common queries we hear.

Which Method Is Better For Different Fabric Types?

Screen printing really shines on natural fibers. Think 100% cotton and cotton blends. The ink sinks into the material and bonds with it, creating a design that's soft, breathable, and feels like it’s part of the shirt itself.

On the flip side, Heat Transfer Vinyl (HTV) is usually the better bet for synthetic fabrics like polyester and nylon. Certain types of vinyl are specifically made to stretch and stick to these technical fabrics, which is why HTV is the go-to for performance wear and athletic apparel where you need that flexibility.

How Should I Care For Printed Garments?

Screen-printed apparel is tough. You can generally wash and dry it with the rest of your laundry without much fuss. For the absolute best results and longevity, we recommend washing your items inside out in cool water.

Vinyl-printed garments need a little more TLC. Always wash them inside out in cold water, and either tumble dry on a low setting or hang them up to air dry. High heat from a dryer is vinyl's enemy—it can weaken the adhesive over time and lead to cracking or peeling.

Pro Tip: Never, ever iron directly on a vinyl graphic. If you need to get wrinkles out, turn the garment inside out and use a low heat setting to keep the design looking sharp.

What Is The Turnaround Time For Each Method?

For smaller orders, vinyl is almost always faster. The setup is completely digital, so a printer can get a design cut and pressed in a remarkably short amount of time.

Screen printing has a more involved setup process—you have to create the screens, mix the inks, and get the press ready. But once it's up and running, it's incredibly fast for printing large quantities. That initial time investment pays off big time on bulk orders, making it far more efficient.

At 4OVER4, we offer a huge range of custom printing solutions to bring any brand's vision to life. Whether you need thousands of vibrant, screen-printed shirts for a big event or a few highly detailed vinyl graphics for a special project, we have the expertise and equipment to deliver incredible quality every single time. Explore our full range of printing services at https://4over4.com and let's get started.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026