TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- A Business Guide to Print on PVC

A Business Guide to Print on PVC

Emma Davis

Content Writer

Nov 30, 2025346 views

Nov 30, 2025346 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Printing on PVC is really just a fancy way of saying we're creating graphics on a super durable plastic canvas instead of fragile paper. It’s the go-to process for businesses needing vibrant, long-lasting visuals that can handle just about anything—think weatherproof outdoor signs, professional event displays, or even the sturdy ID cards your team uses every day. Its toughness and high-quality finish make it the clear winner for projects that need to survive a little wear and tear and the great outdoors.

Understanding the Power of PVC Printing

Imagine your marketing materials had a built-in suit of armor. That’s pretty much what you get when you choose to print on PVC (Polyvinyl Chloride). Unlike paper that tears or cardboard that gets soggy and warps in the humidity, PVC gives your message a robust and professional home. It elevates standard print jobs into durable assets that look just as good on day one hundred as they did on day one.

This incredible durability is what makes PVC so versatile. From the rigid signs guiding customers through your store to the flexible banners announcing your grand opening, PVC is a reliable foundation. Its non-porous surface is perfect for capturing crisp details and brilliant colors, ensuring your branding always looks sharp.

It’s no surprise that the market for materials like this is growing. The printed plastic films sector is projected to hit USD 8.00 billion by 2035, which just shows how essential it's becoming for modern branding and packaging.

Why Businesses Choose PVC

The advantages of PVC go way beyond just being tough. Businesses are choosing it for a handful of key reasons that directly boost their brand perception and give them a better return on their investment.

Here's a quick rundown of why so many businesses are making the switch to PVC for their professional printing needs.

| Benefit | Why It Matters for Your Business |

|---|---|

| Longevity & Weather Resistance | Your signs and banners can handle rain, sun, and wind without fading or falling apart. Perfect for long-term outdoor use. |

| Professional Appearance | The material's smooth, uniform surface creates a high-end finish that makes your brand look polished and professional. |

| Versatility in Application | PVC can be rigid or flexible, thick or thin, opening up a huge range of product possibilities from signs to stickers. |

| Cost-Effectiveness | When you consider its long lifespan and resistance to damage, PVC offers incredible value compared to materials you'd have to replace constantly. |

These benefits combined make PVC a smart, strategic choice for any company looking to make a lasting impression.

Here are a few more reasons it's a popular pick:

- Longevity and Weather Resistance: PVC signs and banners can endure rain, sun, and wind, making them ideal for long-term outdoor use without fading or deteriorating quickly.

- Professional Appearance: The material’s smooth, uniform surface results in a high-end finish that elevates brand quality, whether it's for a trade show display or an in-store promotion.

- Versatility in Application: PVC can be rigid or flexible, thick or thin, allowing for a huge range of products. For a deeper look at the possibilities, our complete https://www.4over4.com/printing/category/pvc-collection showcases many options.

- Cost-Effectiveness: When you factor in its long lifespan and resistance to damage, PVC offers excellent value compared to materials that require frequent replacement.

To really see how far you can push the creative boundaries with this material, it’s worth checking out guides on creating unique designs with custom vinyl wall stickers and furniture wraps.

Choosing the Right PVC Material

When you decide to print on PVC, picking the right foundation for your project is easily the most important first step. Not all PVC is created equal. Think of it like choosing between different types of wood for a building project—you wouldn't use delicate balsa wood to build a sturdy deck, right? The same logic applies here. The type of PVC you select needs to align perfectly with your project's function, where it'll live, and the look you're going for.

Each kind of PVC brings its own unique mix of flexibility, thickness, and toughness to the table. Making the right choice ensures your final product doesn't just look professional but actually performs the way you need it to, whether that's a rigid sign standing tall at a trade show or a flexible banner toughing it out in the elements.

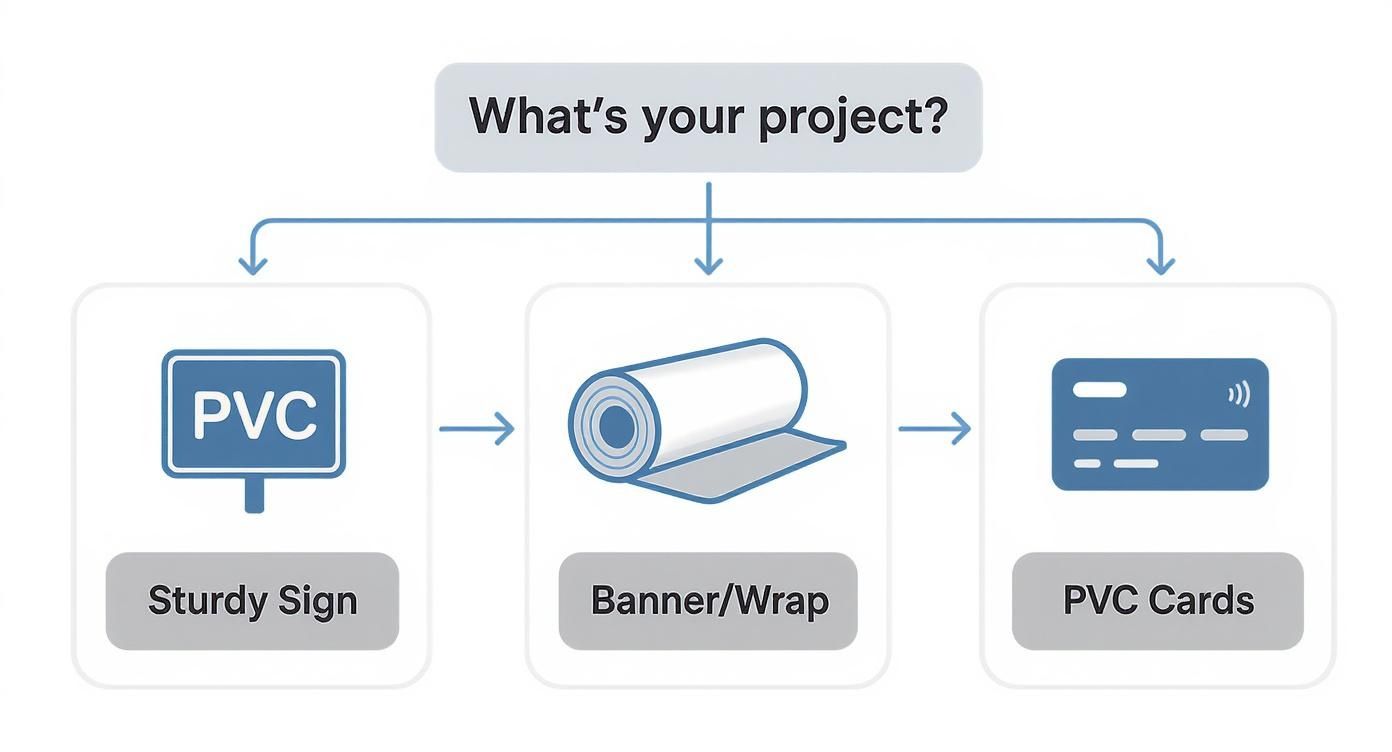

This handy little decision tree can help you quickly match your project to the right PVC type.

As you can see, what you're actually making—be it a sign, banner, or card—is the main driver behind your material choice.

Rigid PVC Sheets for Structure and Sophistication

When your project demands a flat, sturdy, and polished appearance, rigid PVC sheets are the answer. You might hear them called by brand names like Sintra or Komacel, but they're all a type of lightweight yet durable plastic foam board. It’s the gold standard for high-quality indoor signage that needs to resist warping and keep its shape over time.

Picture a premium point-of-purchase display in a boutique or the main directional sign at a corporate event. These applications need a material that screams quality and stability. Rigid PVC delivers exactly that with its smooth, matte finish that cuts down on glare and makes printed colors pop with incredible crispness.

Consider rigid PVC for projects like:

- Trade Show Displays: Building backdrops and info panels that are a breeze to transport but look solid and professional once set up.

- Retail Signage: Crafting end-cap displays, shelf talkers, and hanging signs that can handle the daily hustle of a busy store.

- Real Estate Signs: Producing durable, weather-resistant "For Sale" or "Open House" signs that look sharp for months on end.

Flexible PVC Vinyl for Versatility and Resilience

For projects that need to bend, brave the weather, and adapt to different surfaces, flexible PVC vinyl is the undisputed champion. This material is basically a durable, pliable plastic fabric that you can roll up for easy transport and storage without it cracking or creasing. It's the powerhouse behind most of the banners, decals, and vehicle wraps you see every day.

Its natural flexibility and weather-resistant DNA make it perfect for outdoor advertising. A grand opening banner, for example, has to take a beating from wind and rain while staying bright and easy to read. Flexible PVC vinyl is engineered for just that kind of challenge, making it a smart, cost-effective solution for both temporary and long-term outdoor campaigns. To see the huge range of adhesive options out there, you can learn more about our adhesive vinyls collection for things like window graphics and wall murals.

PVC Cards for Durability in Your Pocket

Finally, for those small-format jobs that require extreme durability and a standardized, professional feel, PVC cards are the go-to. These are the same tough, credit-card-like plastics used for ID, access, and payment all over the world. They're specifically designed to resist bending, cracking, and fading from constant handling.

Because they combine rigidity with a compact form factor, PVC cards are the ideal substrate for items that need to last for years while being carried and used daily. Their non-porous surface is perfect for high-resolution printing of photos, logos, and intricate text.

This makes them the perfect choice for:

- ID Badges and Access Cards: Creating secure and long-lasting identification for employees, students, or event staff.

- Membership and Loyalty Cards: Producing durable cards that keep your brand right in your customer's wallet.

- Gift Cards: Offering a professional and reusable gift card that reflects the quality of your business.

While PVC is a fantastic all-rounder, it's worth noting that other plastics like acrylic are also popular for different display needs, offering their own unique look and feel. For instance, high-end applications like donor walls or premium office signage often use custom acrylic displays for a sleek, glass-like finish.

How Professional PVC Printing Works

Ever wondered how a vibrant, crisp logo ends up permanently stuck to a slick plastic surface? It's not like printing on paper, which just soaks up ink. PVC is non-porous, meaning it has nowhere for the ink to go. If you used a standard printer, you'd end up with a smeared, wet mess that would wipe right off.

To get a design to stick, professional printers have to get creative. The whole game is about adhesion, not absorption. It involves some seriously cool technology that essentially cures or chemically fuses the ink right onto the plastic's surface. Let's pull back the curtain on the two main ways we make this happen.

UV Flatbed Printing for Rigid Surfaces

Think of painting a wall with a special kind of paint that dries the second a flashlight beam hits it. That's the basic idea behind UV Flatbed Printing. This is our go-to method for anything rigid, like the thick PVC sheets used for high-end signage and displays.

A flatbed printer holds the PVC sheet perfectly still while a print head glides across it, jetting microscopic droplets of a special UV-curable ink. Right on its heels is a high-intensity ultraviolet (UV) lamp. This light instantly cures—or hardens—the ink, locking it onto the PVC.

This instant-drying trick comes with some major perks:

- Insane Durability: The cured ink creates a tough, resilient layer that laughs at scratches, fading, and scuffs.

- Jaw-Dropping Graphics: Because the ink has zero time to spread or bleed, the final print is incredibly sharp with colors that pop.

- Textured Finishes: We can even build up layers of ink to create tactile, 3D effects you can actually feel on the surface.

Thanks to its precision and toughness, UV flatbed printing is the only way to go for professional-grade rigid signs you see at trade shows, in retail stores, or as architectural displays.

Solvent and Eco-Solvent Printing for Flexible Media

Now, switch gears and think about dyeing a t-shirt. The color doesn't just sit on top; it sinks in and becomes part of the fabric. Solvent and Eco-Solvent Printing works a lot like that, but for flexible PVC vinyl—the stuff used for banners, vehicle wraps, and durable stickers.

With this method, the ink contains solvents that ever-so-gently soften and etch the surface of the PVC. This opens the door for the color pigments to actually bite into the material instead of just laying on top. As the solvents evaporate, the pigments are locked in for good, embedded right into the vinyl.

This chemical bond is the secret sauce that makes solvent-printed graphics so ridiculously resilient outdoors. The print literally becomes one with the PVC, so it won't crack, peel, or fade when battered by sun and rain.

Eco-solvent inks are the newer, smarter version of this. They deliver the same permanence but with far fewer volatile organic compounds (VOCs), making them a much better choice for the environment and for indoor air quality. This is the perfect method for anything that needs to be rolled up, stretched out, or left to fend for itself in harsh weather.

Comparing Printing Technologies

So, which method is right for your project? It all comes down to what you're trying to create. Each technique has its own strengths, costs, and benefits built for specific jobs.

| Feature | UV Flatbed Printing | Solvent & Eco-Solvent Printing |

|---|---|---|

| Best For | Rigid PVC Sheets, Dibond, Acrylic | Flexible PVC Vinyl, Banners, Wraps |

| Durability | Excellent scratch & fade resistance | Excellent weather & water resistance |

| Finish | Matte or gloss, can be textured | Typically a smooth, satin finish |

| Process | Ink is cured on the surface by UV light | Ink etches into and bonds with the material |

This kind of specialized tech is a huge reason why the global printed vinyl market, where PVC is king, is so massive. Valued at roughly USD 9.53 billion in 2024, the market is set to keep growing, pushed by the advertising world's endless need for top-quality banners and wraps. Knowing how these prints are made helps you see the true value and quality behind the finished product.

Setting Up Your Design Files for Flawless Prints

Even the most stunning design on your screen can turn into a costly printing mistake if the digital file isn't prepared correctly. To make sure your final PVC product looks exactly how you imagined it, getting your artwork ready for professional printing is a non-negotiable step. This is the bridge between your digital idea and a perfect physical product.

Think of it like handing over a blueprint for a construction project. Any flaws in that plan are going to show up in the final building. By following a few key best practices, you can send your files with confidence and sidestep common issues like blurry images, weird color shifts, or important details getting cut off.

Master Your Resolution and Color Mode

The two absolute fundamentals of any print-ready file are its resolution and color mode. Getting these wrong is the fastest way to a disappointing result.

First off, your file's resolution must be 300 DPI (dots per inch) at its final print size. This is the industry standard for a reason—it guarantees crisp, sharp graphics that look professional, even up close.

Next, you have to design in CMYK (Cyan, Magenta, Yellow, Key/Black) color mode, not RGB (Red, Green, Blue). Your screen creates colors with light using the RGB model, but printers mix physical inks using the CMYK model. If you design in RGB, the file will be converted during printing, which often leads to dull, muddy, or just plain inaccurate colors.

Setting your design software to CMYK from the very start is the only way to get a predictable color outcome. It ensures that the vibrant colors you see on screen have the best possible chance of being faithfully reproduced on the final PVC print.

Respect the Bleed and Safe Zone

Ever framed a picture? The "safe zone" is the main area inside the frame where you want your most important art to be. The "bleed" is that little bit of extra image that goes past the frame's edge, just in case the picture shifts a tiny bit, so you don't see any ugly white borders. Print production works exactly the same way.

- Bleed: This is an extra border of your design (usually 0.125 inches) that extends beyond the final trim line. It gets cut off, but it's what ensures your background color or image goes right to the very edge without any slivers of white.

- Safe Zone: This is an inner margin (also typically 0.125 inches inside the trim line) where all your critical text, logos, and contact info should live. Keeping everything important inside this zone guarantees it won't get accidentally sliced off.

For projects with custom shapes, knowing how these margins work is even more critical. Proper file setup is absolutely essential for precise results, especially if you're looking into advanced options like our die-cutting services.

Your Print-Ready File Checklist

Follow these best practices to optimize your design files for professional PVC printing.

| Checklist Item | Best Practice | Why It's Important |

|---|---|---|

| Resolution | Set to 300 DPI at final print size. | Ensures sharp, high-quality images and text without blurriness. |

| Color Mode | Design in CMYK, not RGB. | Prevents unexpected color shifts and ensures accurate ink reproduction. |

| Bleed | Add a 0.125" bleed on all sides. | Guarantees edge-to-edge color without white borders after trimming. |

| Safe Zone | Keep text/logos 0.125" inside the trim line. | Protects critical elements from being accidentally cut off during finishing. |

| File Format | Submit a print-ready PDF. | Embeds fonts and images, preserving layout and ensuring consistency. |

| Vector Graphics | Use vector format (.AI, .EPS) for logos & text. | Allows for infinite scaling without any loss of quality. |

| Outline Fonts | Convert all text to outlines before saving. | Prevents font substitution errors if the printer doesn't have your specific font. |

By running through this checklist before you submit your files, you're setting your project up for a smooth, error-free production run.

Choose the Right File Format

Finally, the type of file you send over to your printer matters. A lot. Graphics generally come in two flavors: raster and vector.

Raster images (like JPEGs or PNGs) are built from pixels. They’re perfect for photographs, but they’ll get fuzzy and pixelated if you try to blow them up larger than their original size. Always double-check that any raster images are 300 DPI at the size they'll be printed.

Vector images (like AI or EPS files) are made from mathematical paths. This means they can be scaled to any size—from a tiny PVC card to a massive billboard—with zero loss in quality. For this reason, all logos, icons, and text should ideally be in a vector format.

When it's time to submit, a high-quality, print-ready PDF is the gold standard. It neatly packages all your fonts, images, and vector graphics into one reliable file, locking in your layout and ensuring everyone sees the same thing. Submitting files in professional formats like PDF or native Adobe Illustrator (.AI) files gives your printer the best possible blueprint to work from.

Finishing Touches and Environmental Impact

Once your design is printed, the final details can turn a good project into something truly exceptional. These finishing touches do more than just make your PVC print look professional; they add critical layers of durability that protect your investment and extend its lifespan. It's the difference between a standard sign and a custom-shaped, resilient display that really commands attention.

At the same time, you can't talk about plastic without considering its environmental footprint. For businesses that are serious about sustainability, understanding the greener side of PVC printing is a must. The good news is that advancements in materials and inks are making it easier to make responsible choices without giving up quality or performance.

Adding Professionalism and Durability

The right finish can dramatically change both the look and the longevity of your PVC prints. Two of the most impactful options are custom cutting and lamination, and each serves a distinct purpose.

Custom Shape Cutting, often called die-cutting, is a fantastic way to break free from the usual rectangle. By cutting your PVC signs into unique shapes—like your company logo, a specific product, or an eye-catching symbol—you create a piece that is instantly more memorable. This technique is perfect for point-of-purchase displays, event signage, and any branding that needs to stand out.

Lamination is like a protective shield for your print. It involves applying a thin, transparent plastic film over the printed surface, and it offers several key benefits:

- Enhanced Durability: It provides a tough barrier against scratches, scuffs, and moisture, which is crucial for items in high-traffic areas.

- UV Protection: A UV-resistant laminate acts like sunscreen for your print, significantly slowing down the fading that sunlight causes.

- Finish Options: You can choose between a gloss laminate, which makes colors pop and look more vibrant, or a matte laminate, which cuts down on glare for better readability under bright lights.

Navigating the Environmental Side of PVC

The conversation around plastics and the environment is an important one. While traditional PVC production has raised valid concerns, the industry is actively adapting to meet the growing demand for sustainable solutions. This shift means environmentally conscious businesses can use the benefits of PVC printing more responsibly.

A key development is the growing availability of recycled PVC. These materials use post-consumer or post-industrial waste, which cuts down on the need for new plastic production and keeps waste out of landfills. The global market for PVC packaging film is expected to hit USD 17.48 billion by 2034, and it has already seen a 15% increase in the use of recycled content.

Choosing recycled PVC is a practical step toward minimizing environmental impact. It supports a circular economy where materials get a second life, reducing both resource consumption and the carbon footprint tied to manufacturing new plastics.

Another critical piece of the puzzle is the ink. Eco-solvent inks are a much greener alternative to traditional solvent inks. They contain far lower levels of Volatile Organic Compounds (VOCs)—harmful chemicals that contribute to air pollution. Working with a printer that prioritizes eco-solvent inks is a smart move for both the planet and workplace safety. For businesses that want to make sustainability a core part of their marketing, exploring a provider's full range of green printing services can uncover even more eco-friendly options.

Common Questions About Printing on PVC

Even with the best game plan, a few questions always seem to pop up right before you pull the trigger on a new project. To wrap things up, we’ve put together answers to the most common things businesses ask about PVC printing. Getting these final details ironed out will give you the confidence to move forward.

Think of this as a quick-reference guide to clear up any last-minute uncertainties. Our goal is to make sure you have everything you need to kick off your next project without a hitch.

How Long Does a Print on PVC Last Outdoors?

The real-world lifespan of an outdoor print on PVC comes down to a few key variables: the type of PVC you choose, the ink it’s printed with, and how harsh your local weather is. As a general rule, a print made with UV-cured inks on a rigid PVC sheet can easily last 3-5 years with only minimal fading.

For flexible vinyl banners printed with tough solvent inks, you can expect them to hold up for 2-3 years, especially if they’re soaking up direct sunlight day after day. The single best thing you can do to extend the life of any outdoor PVC print? Add a UV-protective laminate. It’s like sunscreen for your sign, acting as a powerful shield against sun damage and physical scuffs.

Can You Print on Both Sides of a PVC Sheet?

Absolutely. Double-sided printing is incredibly common and effective, especially for things like hanging signs, point-of-sale displays, or any signage that people will see from multiple angles.

The key to getting a great result is using an opaque PVC material. You'll often hear these called "blockout" vinyls because they have a special layer inside that stops the design on one side from ghosting through to the other. This ensures both graphics stay crisp and vibrant.

When you're getting your files ready, just remember to create two separate designs—one clearly labeled for the front and the other for the back.

What Is the Main Difference Between PVC and Acrylic Printing?

The biggest distinctions between printing on PVC and acrylic boil down to three things: looks, durability, and cost. They each have their own strengths and are suited for very different jobs.

Here’s a quick side-by-side:

- Acrylic Printing: This gives you a high-gloss, premium finish that almost looks like a photo mounted behind glass. It's a fantastic choice for high-end office decor and fine art prints, but it's more rigid and can be brittle if it takes a hard hit.

- PVC Printing: This usually provides a more professional matte or satin finish. It's much more flexible and impact-resistant, which makes it the go-to material for durable signage, event displays, and pretty much any outdoor application.

At the end of the day, PVC is significantly more budget-friendly and versatile for the vast majority of business marketing needs. Acrylic, on the other hand, really shines when you want to create that luxurious, gallery-quality look for specific interior projects.

Ready to create durable, high-impact marketing materials? The experts at 4OVER4 are here to bring your vision to life with professional PVC printing services. Start your project today!

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026