TABLE OF CONTENTS

-

-

-

-

-

-

-

-

- Home

- content hub

- Paper for Printing Labels: The Ultimate Guide to Papers, Adhesives & Finishes

Paper for Printing Labels: The Ultimate Guide to Papers, Adhesives & Finishes

Emma Davis

Content Writer

Dec 21, 2025359 views

Dec 21, 2025359 views

TABLE OF CONTENTS

-

-

-

-

-

-

-

-

Picking the right paper for your labels is the very first—and most important—step to getting a professional-looking result. It sounds daunting, but it doesn't have to be. Let's break down exactly what goes into a great label, turning what feels like guesswork into a clear, simple choice.

Your Essential Guide to Selecting the Right Label Paper

The journey to the perfect label actually starts long before you even think about hitting the "print" button. It begins with the raw material itself. A label is so much more than just sticky paper; it's a critical piece of your product packaging, your branding, and your story. The choices you make about its construction will directly impact how it looks, feels, and holds up in the real world.

Nailing this first step ensures your labels are not just eye-catching but also durable and perfectly suited for their job. This guide will walk you through every critical element you need to consider.

Core Components of a Perfect Label

To make a smart decision, you really only need to think about three foundational pieces of any label stock:

- Material: Is this label going indoors on a dry product, or does it need to survive moisture, friction, and temperature changes? This is the first question to answer, and it will tell you whether a standard paper or a tough synthetic material is the way to go.

- Adhesive: Do you need this label to stay put forever, or should it peel off without a fight? Maybe you even need it to be repositionable. The glue is just as important as the paper it’s on.

- Finish: Are you going for a modern, subtle matte look, or do you want a vibrant, high-gloss shine that pops? The finish is all about aesthetics, but it also adds a layer of protection.

A well-chosen label does more than just provide information; it elevates your brand and ensures your message sticks—both literally and figuratively. It’s the handshake that introduces your product to the world.

When you're choosing the right label paper, it helps to understand the full picture of pricing solutions, including how paper price labels compare to electronic alternatives. Getting these fundamentals right means your labels will be perfectly suited for their role, from branding a new product to making sure a package gets where it needs to go. For businesses looking to dive into a wide variety of professional choices, you can find tons of options for online labels designed for specific needs. Once you master these basics, you'll have the confidence to pick the perfect paper every single time.

Choosing Your Label's Foundation Material Matters

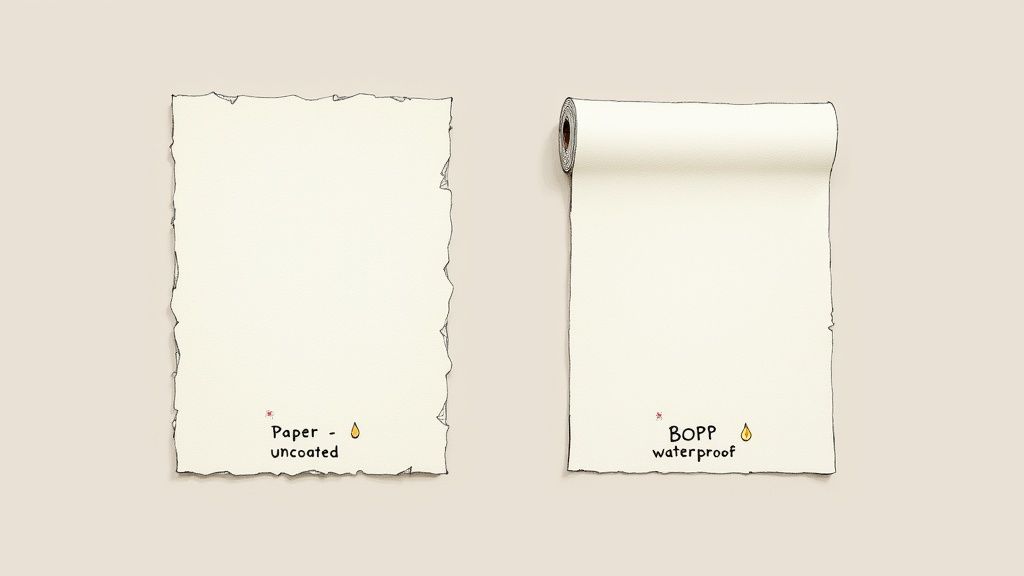

The very first decision you’ll make when printing labels is also the most important: the material. This choice is the foundation for everything else, dictating your label's final look, its feel, and just how tough it will be out in the real world. It all boils down to two main families—classic paper stocks and rugged synthetic films.

Think of it this way: a standard paper label is like a versatile cotton t-shirt. It’s comfortable, affordable, and gets the job done for most everyday, indoor situations. A synthetic label, on the other hand, is like high-performance activewear. It’s engineered to handle the tough stuff—resisting water, oil, and tearing when durability is the name of the game.

The Classic Choice: Paper Labels

For a huge number of labeling projects, paper is the undisputed go-to, and for good reason. It’s an incredibly versatile and budget-friendly option, making it the perfect fit for everything from branding on dry goods to shipping labels and organizing your office. The global market for paper-based label stock pulled in roughly USD 15.8 billion in revenue, making up about 30–35% of the entire labels market. It's expected to hit USD 20.8 billion by 2030, driven by huge demand in food, pharma, and e-commerce. In these industries, paper's recyclability and lower cost—often 10–30% less than synthetics—make it the clear favorite.

But "paper" isn't just one thing. It comes in a few different flavors, each with its own unique finish:

- Uncoated Paper: With its natural, porous texture and matte feel, this stock is all about an organic, rustic vibe. It soaks up ink beautifully for a softer, more muted color palette and is a dream to write on.

- Semi-Gloss Paper: This is the crowd-pleaser, the perfect middle ground. It has a light coating that gives it a subtle sheen, making colors look more vibrant than on uncoated stock without any harsh glare. It’s a professional look that works for countless products.

- High-Gloss Paper: If you want your colors to scream from the shelf, this is your stock. The shiny, reflective surface makes colors pop with maximum impact. Just know that its slick finish makes it tough to write on.

When Durability Is Key: Synthetic Labels

When you know your labels are going to face moisture, friction, chemicals, or extreme temperatures, synthetic materials are the only way to go. These plastic-based films are built for pure durability, making sure your message stays put, no matter what.

Synthetics offer a level of toughness that paper just can't compete with. It's a similar principle to the careful paper selection for custom playing cards, where durability and finish are non-negotiable to withstand constant handling.

For products that will be exposed to the elements or rough handling, investing in a synthetic label isn't just a smart choice—it's a necessity. It guarantees your branding and crucial information survive the product's entire lifecycle.

Here are the most common synthetic options you’ll come across:

- Polypropylene (BOPP): This is one of the most popular synthetic materials out there. It’s resistant to water and oil, which is why you see it on everything from food and beverage containers to cosmetics and bath products. It’s also available in white, metallic, and even totally clear versions. If you’re going for that "no-label" look, you can explore options like our clear labels printing services.

- Polyester (PET): Seriously tough and heat-resistant, polyester is the material of choice for labeling electronics, appliances, and other assets in industrial settings. It can take on harsh chemicals and serious abrasion without breaking a sweat.

- Vinyl: Known for its flexibility, vinyl is fantastic for wrapping around curved surfaces. It's also a champ in outdoor applications and for warning labels because it’s highly resistant to UV fading and moisture. Think bumper stickers and outdoor equipment that need to last.

Mastering Adhesives and Finishes for Lasting Impact

If your label’s material is its body, then the adhesive is its handshake. It’s what connects your label to the world. A perfect label is totally useless if it peels off too soon or, just as bad, refuses to budge when it's supposed to. Getting the adhesive right means your label does its job flawlessly, from the moment it’s applied to the end of its life.

Then you have the finish, which is like the label’s outfit. It defines how it looks and adds a crucial layer of defense against the elements. These two things—the adhesive and the finish—work hand-in-hand to create a label that not only looks incredible but actually performs in its intended environment.

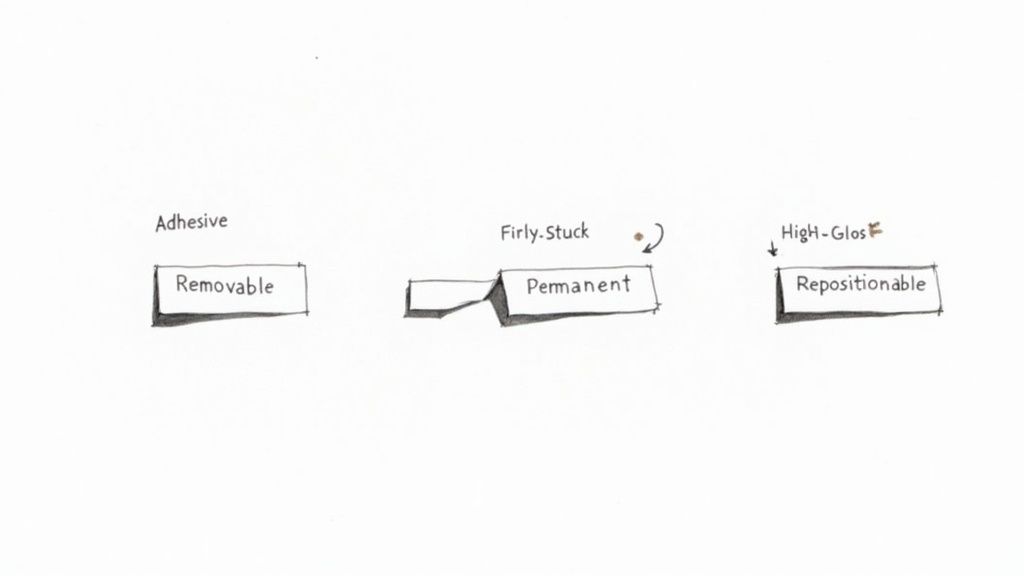

Choosing the Right Adhesive for the Job

Think of label adhesives like the different tapes in your toolbox. You wouldn't use delicate washi tape to hold together a heavy box, and you definitely wouldn't use industrial duct tape on a beautifully wrapped gift. Every adhesive is engineered for a specific purpose, and picking the right one is absolutely essential.

Permanent Adhesive: This is the superglue of the label world. It creates a powerful, long-lasting bond that isn’t meant to be broken. It’s the go-to for safety warnings, asset tracking, and product branding where the label needs to stay put for the life of the item.

Removable Adhesive: Built for temporary jobs, this adhesive sticks firmly but can be peeled away cleanly without leaving that frustratingly sticky residue behind. It's the perfect solution for temporary price tags, promotional stickers on book covers, or organizational labels you might want to change later.

Repositionable Adhesive: This one offers the best of both worlds, giving you some initial wiggle room. You can apply the label, peel it off, and stick it back down within a short window to get the alignment just right. It's a lifesaver for planner stickers, wall decals, and any other time when perfect placement is key.

The right adhesive isn't just a nice-to-have; it's a core part of your label's function. A mismatch can lead to peeling, sticky residue, or a label that just fails completely, undermining your product's professional look and the message it's trying to send.

Enhancing Your Label with Coatings and Finishes

Once you know how your label will stick, it’s time to think about how it will look—and how well it will hold up. Finishes and coatings are applied to the surface of the paper for printing labels, completely transforming its appearance and boosting its durability.

The finish you choose has a massive impact on the final vibe. Just like picking a paint sheen for a room, it can totally change the mood.

- Matte: This non-reflective, flat finish gives off a sophisticated, modern, and even organic feel. It’s easy to write on and has zero glare, making it perfect for wine bottles, artisanal food products, and minimalist designs.

- Semi-Gloss: A popular and versatile middle-ground. It has a subtle sheen that makes colors look more vibrant than matte but without the intense reflection of a high-gloss finish.

- High-Gloss: If you’re going for maximum visual punch, a high-gloss finish is your best bet. Its shiny, reflective surface makes colors pop dramatically, grabbing attention on a crowded shelf. It’s excellent for any product label that needs to stand out.

Adding a Layer of Armor with Laminates

For an extra layer of durability, you can go beyond the basic finish and add a protective laminate. Lamination is simply applying a thin, transparent plastic film over the printed label, which effectively seals it from the outside world. This is a non-negotiable step for labels that are going to face tough conditions.

Laminates and varnishes offer vital protection against:

- Moisture and Spills: A must-have for beverage labels, bath products, and anything else that might get wet.

- Abrasion and Scuffing: Protects labels on products that get handled a lot or jostled around during shipping.

- UV Light: Keeps your inks from fading on products that will spend time in the sun.

- Chemicals and Oils: Essential for industrial labels, cleaning products, and automotive applications.

For projects that demand the ultimate durability, especially outdoors, you might need to look beyond paper. You can learn more about tough, weather-resistant options by checking out materials like our adhesive vinyls, which are built to withstand the harshest conditions.

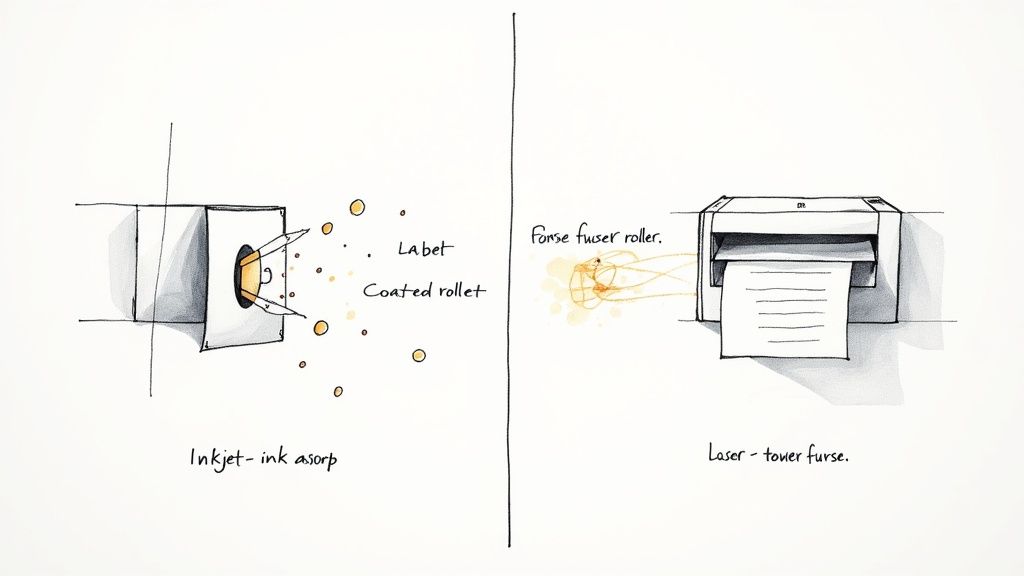

Matching Label Paper to Your Printer Technology

The secret to a flawless, professional-looking label isn't just in the design—it's in the perfect partnership between your paper and your printer. Think of it like a dance; if both partners aren't in sync, the result is clumsy at best. Using the wrong paper can lead to smudged ink, peeling toner, or even costly damage to your machine.

To get it right, you first need to know the fundamental difference between the two most common desktop printers: inkjet and laser. They use completely different methods to get your design onto the label, and that dictates the kind of paper they need to perform at their best.

The World of Inkjet Label Paper

Inkjet printers work by spraying microscopic droplets of liquid ink right onto the paper. For this to work as intended, the label paper needs a slightly porous surface—almost like a high-tech sponge—that can absorb the ink quickly and precisely.

This special coating is what prevents the liquid ink from bleeding or smearing, locking the colors in place for sharp, vibrant images. This makes inkjet printers a fantastic choice for labels with detailed graphics or photos where color accuracy is everything.

But using the wrong paper here is a recipe for disaster. If you feed a laser-compatible sheet into an inkjet printer, its smooth, non-porous surface will just repel the ink. The ink will bead up, sit on top, and smudge at the slightest touch, ruining your entire print run.

The Power of Laser Label Paper

Laser printers operate on a totally different principle. Instead of liquid ink, they use a fine, dry powder called toner. The printer uses static electricity to arrange this powder into your design, then sends the sheet through a high-heat fuser unit. This roller melts and bonds the toner permanently to the paper's surface.

Because of this intense heat, paper for printing labels designed for laser printers has to be engineered to withstand high temperatures without melting, curling, or discoloring. Their surfaces are smooth and treated to make sure the toner fuses evenly for crisp text and clean lines.

Trying to use inkjet paper in a laser printer is a serious risk. The porous coating designed for ink absorption can't handle the heat. It can actually melt inside your printer, gumming up the fuser and other critical parts, leading to an expensive repair bill.

Key Takeaway: Always match your label paper to your printer type. Inkjet labels are made to absorb liquid ink, while laser labels are built to withstand the heat that fuses toner. Mismatching them guarantees poor results and can even break your equipment.

Before we move on, let's break down the key differences in a head-to-head comparison.

Inkjet vs Laser Label Paper Comparison

This table gives a quick overview of what sets these two paper types apart.

| Feature | Inkjet Label Paper | Laser Label Paper |

|---|---|---|

| Surface Finish | Porous and absorbent to soak up liquid ink. | Smooth and heat-resistant to fuse toner powder. |

| Printing Process | Absorbs tiny droplets of sprayed ink. | Withstands high heat to melt and bond toner. |

| Best For | High-resolution photos, vibrant graphics, and detailed color work. | Crisp text, sharp lines, and high-volume black-and-white printing. |

| Potential Mismatch | Inkjet paper can melt and damage a laser printer's fuser unit. | Laser paper will cause ink to bead up and smudge when used in an inkjet printer. |

| Durability | Can be prone to smudging if exposed to moisture (unless waterproofed). | Generally more durable and resistant to moisture and smudging. |

| Cost | Often slightly more affordable for specialty finishes like glossy photo paper. | Can be more cost-effective for large runs of standard labels. |

Knowing which paper works for your machine is half the battle won.

Professional Printing Technologies

Beyond the printers on your desk, professional print shops use specialized technologies for high-volume, top-tier label production. These methods require their own unique label stocks to get the job done right.

- Thermal Printers: These are the workhorses for shipping labels and barcodes. They use targeted heat to activate a special chemical coating on the paper, creating the image without a drop of ink or a grain of toner. They require specific thermal-sensitive paper to function.

- Digital Presses: For high-quality commercial runs, digital presses offer incredible precision and color quality. This technology is booming; industry reports show digital label printing growing at a nearly 9% CAGR, outpacing older methods thanks to the rising demand for short runs and custom data. This growth requires specialized digital stocks with tight thickness tolerances and high brightness, often commanding a 5–20% price premium over standard papers. You can find out more about the advantages of professional digital printing services and the advanced materials they use.

Choosing the right paper is the final, crucial step to ensure your printed labels look exactly as you envisioned. By understanding how your printer works, you can confidently select a compatible paper that delivers crisp, durable, and professional results every single time.

Making Sustainable Choices in Label Paper

In a world where customers care more and more about the planet, the paper you choose for your labels can say a lot about your brand. Opting for an environmentally friendly label stock isn't just a niche move anymore; it’s a smart way to connect with your audience and shrink your carbon footprint, all without giving up an inch on quality.

This isn’t just a passing trend, either. It’s being pushed forward by some serious regulatory shifts. With stricter recycling rules popping up across the EU, UK, and North America, the demand for recyclable paper label stocks has jumped by an estimated 8–12% each year. We're also seeing brands that make the switch from plastic film to paper labels improve their product's recyclability rate by a massive 60–90%, slashing their carbon emissions in the process. For a closer look at what's driving these changes, you can explore the full analysis on the labels market.

Understanding Eco-Friendly Credentials

When you start looking into sustainable options, you'll hear a lot about two things: responsible sourcing and recycled content. These aren't just buzzwords. They represent real, tangible commitments to doing better for the environment. The easiest way to know you're getting the real deal is to look for official certifications.

One of the big ones to know is the Forest Stewardship Council (FSC). If you see that FSC logo on a roll of label stock, it's a solid guarantee that the paper came from responsibly managed forests. That means the timber was harvested in a way that protects biodiversity, respects the rights of indigenous communities, and keeps the forest ecosystem healthy.

Another fantastic option is paper made from recycled materials. These labels are crafted from post-consumer waste, which keeps paper out of landfills and cuts down on the need for virgin tree pulp. The whole process uses less water and energy, making it a huge win for the circular economy. If you're serious about sustainability, it's worth exploring a full range of green printing options to see how all your materials can reflect your brand's values.

Designing for Recyclability

A truly sustainable label is about more than just where the paper comes from—its end-of-life matters just as much. For a package to be recycled smoothly, the label can't get in the way. This reality has sparked some brilliant innovations in both adhesives and the way labels are constructed.

A sustainable label should not become a contaminant at the recycling facility. The goal is to create a product that can be fully recovered, closing the loop and contributing to a circular economy.

Here are a couple of key features that make a label much more recyclable:

- Wash-Off Adhesives: These are specialized glues designed to completely dissolve during the recycling process. This allows the label to separate cleanly from a glass bottle or plastic tub, leaving no sticky gunk behind.

- Mono-Material Construction: Think paper on paper. Using a paper label on a cardboard box or paper bag is the ideal scenario. When the label and the package are made of the same material, the entire thing can be recycled as one piece, which makes the whole process a lot simpler.

By focusing on these features, you’re not just using sustainable materials—you’re designing a product that's built to be successfully recycled, completing its environmental journey the right way.

Bringing It All Together for the Perfect Label

Okay, we've covered a lot of ground. Choosing the right paper for your labels can feel like you're staring at a giant wall of options, trying to figure out where to even start. But it doesn't have to be complicated. The secret is to stop thinking about all the technical specs at once and instead, break it down into a few simple questions.

Think of it like you're building the perfect tool for a specific job. You wouldn't grab a sledgehammer to hang a picture frame, right? In the same way, you wouldn't pick a standard paper label for a shampoo bottle that’s going to live in a steamy shower. Every choice you make, from the material itself to the final glossy finish, should be a direct answer to what your label needs to do and where it's going to live.

Your Final Label Selection Checklist

To nail the right choice every single time, just run through this quick checklist. Answering these questions will point you straight to the perfect combination of features for your project.

- Where will the label live? First things first, think about its environment. Is it going to be exposed to moisture, harsh sunlight, oils, or constant handling? This one question immediately helps you decide between a basic paper stock and a more durable synthetic material like BOPP or vinyl.

- How long does it need to stick around? Consider the label's purpose. Is it a permanent warning sticker, a temporary price tag that needs to come off cleanly, or a repositionable label for a planner? Your answer here leads you directly to a permanent, removable, or repositionable adhesive.

- What's the vibe you're going for? Now, think about your brand's personality. Do you want an earthy, natural look with a matte finish? A versatile semi-gloss that works for almost anything? Or a vibrant, eye-popping high-gloss that screams for attention?

- What printer are you using? This is the one you can't compromise on. Are you printing with an inkjet or a laser printer? Make sure the paper for printing labels you choose is specifically made for your machine. The wrong choice can lead to smudging, peeling, or even printer jams.

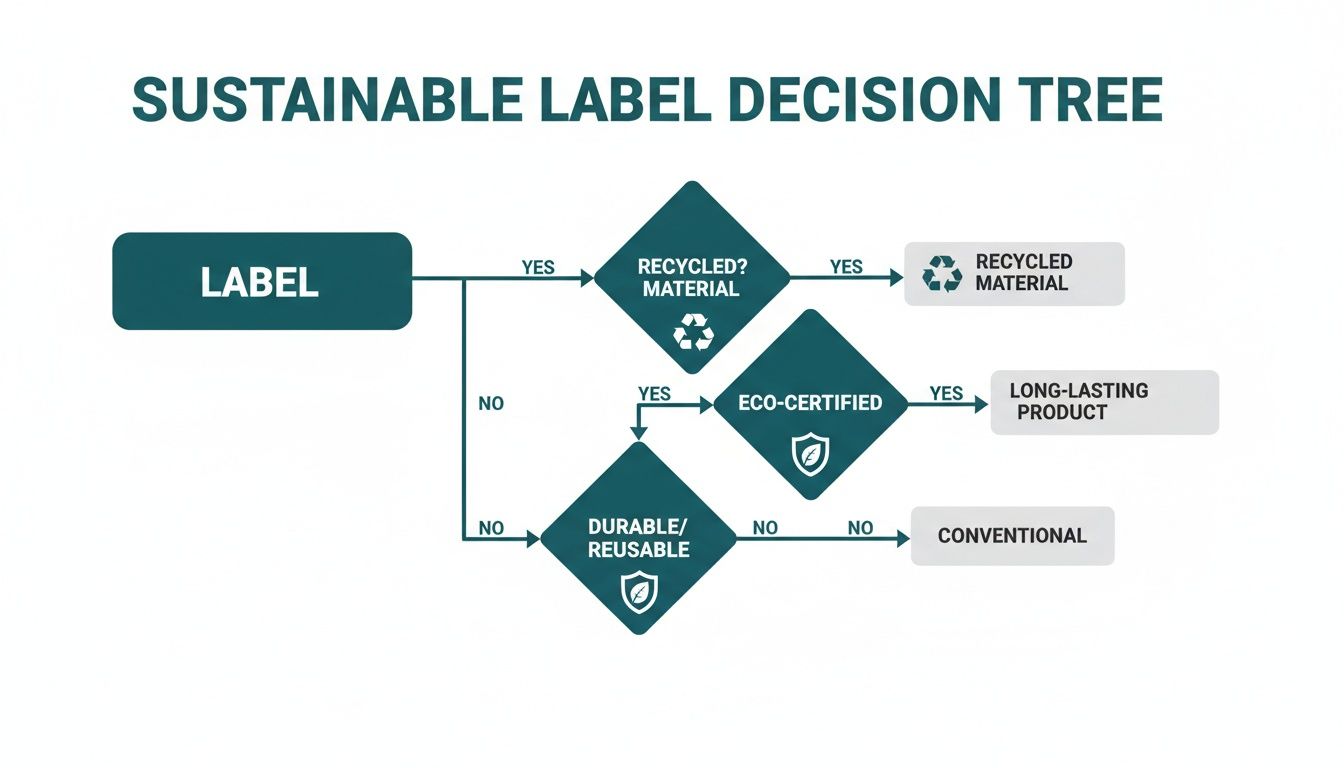

Walking through these steps helps you build a picture of your ideal label, whether you're focused on sustainable, eco-friendly materials or need something that can withstand a hurricane. This flowchart is a great way to visualize the decision-making process for sustainable options.

As you can see, factors like whether the final product needs to be recycled will guide you toward the right sustainable choice for your brand’s mission.

From DIY Printing to Professional Production

Once you've got this knowledge down, you have two great paths forward. For smaller batches, prototypes, or home projects, you can now confidently shop for the right label sheets and print them yourself. You'll know exactly what to look for on the packaging to get crisp, professional-looking results every single time.

For larger orders or more complex jobs, you’re now perfectly prepared to have a clear, productive conversation with a professional printer like 4OVER4. You can walk in (or email) with a precise brief, telling them exactly what material, adhesive, and finish you need. This clarity gets rid of all the guesswork, prevents expensive mistakes, and guarantees that the labels you get back are exactly what you pictured—flawless, functional, and ready to make your brand shine.

Label Paper FAQs

Diving into the world of label paper can definitely bring up a few questions. Whether you're trying to nail down the right finish or just trying to make sense of a technical term, getting clear answers helps you make that final call with confidence. Here are some of the most common questions we hear when it comes to choosing the right paper for printing labels.

Can I Use Regular Paper with an Adhesive Backing?

It’s tempting to think you can MacGyver a solution with regular office paper and some spray adhesive, but trust me, it’s not the professional workaround you’re hoping for. Specially designed label paper is a complete, engineered system. The top layer, called the face stock, is made to perfectly absorb ink or toner, which is key to preventing smudges and getting those vibrant colors to pop.

On top of that, the adhesive is formulated for a specific job—whether it’s permanent sticking power or easy removal—and the release liner is coated to peel away smoothly every time. Regular paper just doesn't have these features, which almost always leads to disappointing print quality, weak adhesion, and a frustrating, sticky mess during application. For a clean, durable result, purpose-built label paper is always the way to go.

What Is the Difference Between Die Cut and Kiss Cut Labels?

The main distinction here is all about how deep the blade goes when cutting the label sheet. Getting this right is key to ordering the perfect format for whatever you have in mind.

Kiss Cut Labels: A kiss cut is a light touch. The blade slices through the label material itself but leaves the backing paper completely intact. This is how you get multiple, uniquely shaped labels on a single sheet, making them super easy to peel and organize. Think of a sheet of planner stickers—that's a classic kiss cut.

Die Cut Labels: A die cut goes all the way. The blade slices through both the label material and the backing paper. This creates a custom-shaped label where the backing is perfectly trimmed to match the sticker's exact outline. These are perfect for standalone handouts, like promotional stickers you’d give away at an event.

How Do I Choose Between a Matte, Semi-Gloss, or High-Gloss Finish?

Your choice of finish really comes down to two things: the look you want and the job the label needs to do.

A matte finish gives you a non-reflective, modern look that’s super easy to write on. It’s perfect for organic products, minimalist branding, or anything with an earthy vibe. High-gloss, on the other hand, is all about a shiny, vibrant appearance that makes colors leap off the label, grabbing attention on a crowded retail shelf.

Semi-gloss hits that sweet spot right in the middle, and it's popular for a reason. It has a subtle sheen that boosts color vibrancy without the intense glare of a high-gloss finish. That versatility makes it a fantastic all-around choice for a huge range of product labeling and branding projects.

Ready to create labels that look professional and perform flawlessly? 4OVER4 offers a vast selection of high-quality, customizable label printing options to meet any need. Explore our collection and find the perfect paper, adhesive, and finish for your project today at https://4over4.com.

More from

729

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

![]() Emma Davis

Emma Davis

Feb 3, 2026

336

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

![]() Emma Davis

Emma Davis

Feb 2, 2026

1307

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

![]() Emma Davis

Emma Davis

Feb 1, 2026

397

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

![]() Emma Davis

Emma Davis

Jan 31, 2026

387

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

![]() Emma Davis

Emma Davis

Jan 30, 2026

198

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

![]() Emma Davis

Emma Davis

Jan 29, 2026

352

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

![]() Emma Davis

Emma Davis

Jan 28, 2026

320

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

![]() Emma Davis

Emma Davis

Jan 27, 2026