- Home

- content hub

- Top 8 Different Types of Printing You Should Know in 2025

Top 8 Different Types of Printing You Should Know in 2025

Emma Davis

Content Writer

Jul 16, 20252106 views

Jul 16, 20252106 views

The world of printing is vast and varied, extending far beyond the simple click of a 'print' button. Understanding the different types of printing is crucial for businesses, designers, and creators who want to make a lasting impression. The method you choose directly impacts your final product's quality, cost, and turnaround time, whether you're producing thousands of glossy brochures, a batch of custom t-shirts, or a high-end architectural model.

This guide is designed to demystify the complex landscape of printing technologies. We provide a comprehensive roundup of the most significant methods used today, from traditional workhorses to modern innovators. By breaking down the specific mechanics, pros, cons, and ideal applications for each technique, this article empowers you to make strategic decisions for your next project.

You will gain actionable insights into a wide range of processes, including:

- Offset and Flexographic Printing for high-volume runs.

- Digital, Inkjet, and Laser Printing for speed and customization.

- Screen and Letterpress Printing for specialty and tactile finishes.

- Gravure and 3D Printing for unique, high-fidelity applications.

By the end, you will have a clear framework for selecting the printing process that best aligns with your specific needs, budget, and creative vision. This knowledge ensures your designs are brought to life with maximum impact and professional precision, moving your concept from pixels to a polished, tangible product.

1. Offset Printing

Offset printing, also known as offset lithography, is the undisputed workhorse of the commercial printing world. This technique doesn't apply ink directly to paper. Instead, it transfers or "offsets" an image from a metal plate to a rubber blanket, which then rolls the ink onto the final printing surface. The process relies on the fundamental principle that oil and water do not mix; the image area on the plate holds oil-based ink, while the non-image area attracts a water-based film, repelling the ink.

This method is one of the most common types of printing for high-volume jobs because of its exceptional image quality and consistency across large runs. Once the initial setup is complete, the press can produce thousands of identical impressions quickly and efficiently.

When to Use Offset Printing

Offset printing is the ideal choice for projects where quality and quantity are paramount. Businesses producing large runs of marketing materials, like brochures, catalogs, and magazines, benefit significantly from its cost-effectiveness at scale. The initial setup cost is higher than digital printing, but the per-unit cost drops dramatically as the quantity increases, making it the go-to for bulk orders.

It's also favored for projects demanding precise color reproduction and a professional finish, such as annual reports, hardcover books, and high-end packaging. The ability to use custom Pantone inks ensures perfect brand color matching, a critical requirement for many corporate clients.

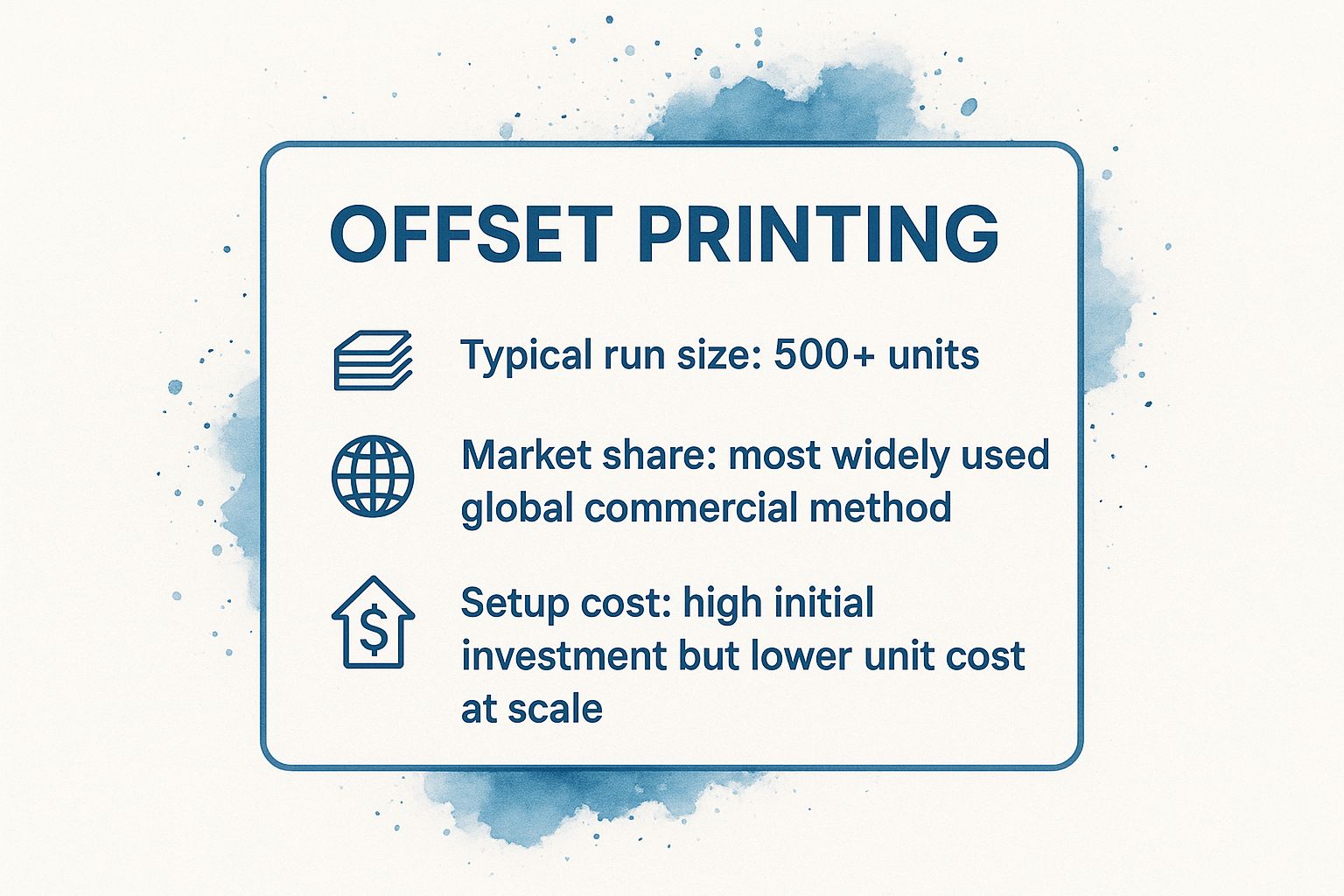

The infographic below summarizes the key considerations for choosing offset printing.

As the data shows, offset printing is not for small, one-off jobs but rather for substantial projects where its high setup cost is justified by a lower cost per piece.

Tips for Success

To maximize the benefits of offset printing, preparation is key.

- Order in Bulk: Plan ahead and consolidate your printing needs to order larger quantities, significantly reducing your per-item cost.

- Use High-Resolution Files: Provide your artwork in CMYK format with a minimum resolution of 300 DPI (dots per inch) to ensure sharp, clear images.

- Consider Gang-Run Printing: For smaller items like business cards or flyers, ask your printer about gang-run printing. This process places multiple jobs on the same large press sheet, splitting the setup costs among several clients.

2. Digital Printing

Digital printing is a modern method that prints digital-based images directly onto various media substrates. Unlike offset printing, it doesn't require printing plates. Instead, it uses technologies like inkjet or laser systems to transfer toner or liquid ink, allowing for rapid, on-demand printing directly from a digital file. This process was pioneered and popularized by companies like Xerox, HP, and Canon.

This technique is celebrated for its speed and flexibility, making it a cornerstone for modern, fast-paced printing needs. It excels at producing short runs with quick turnaround times, as there is minimal setup required compared to traditional methods.

When to Use Digital Printing

Digital printing is the best choice for small to medium-sized print runs where speed and cost-efficiency are critical. It's perfect for projects requiring personalization, such as direct mail campaigns where each piece has a unique name or address. The ability to print one or one thousand copies without significant setup costs makes it highly accessible.

This method is ideal for short-run projects like business cards, custom invitations, photo books, and promotional flyers. It is also the go-to for proofing, allowing designers to see a physical sample of their work before committing to a large, expensive offset run. If your project has a tight deadline or requires variable data, digital printing offers a powerful solution.

Tips for Success

To get the most out of your digital printing projects, keep these tips in mind.

- Optimize for Short Runs: Keep quantities below 1,000 units for maximum cost-effectiveness. For larger volumes, offset printing typically becomes the more economical choice.

- Leverage Variable Data: Take full advantage of digital printing's unique strength by personalizing your materials. Customizing names, offers, or images for different segments of your audience can significantly boost engagement.

- File Preparation is Key: While some printers accept RGB files, providing artwork in CMYK format often yields more predictable color results. Always check your printer's specific file requirements for resolution and color profiles.

- Consider Paper Coatings: A UV or aqueous coating can be applied after printing to protect the ink and make colors appear richer and more saturated, giving your project a professional finish. Explore different options for business cards and stationery on 4over4.com.

3. Screen Printing

Screen printing, often called silk screening, is a versatile and durable printing technique that involves transferring ink onto a substrate through a mesh screen. A squeegee is used to push ink through the open areas of a stencil, which is created on the screen to block ink from passing through certain parts. This direct ink transfer results in vibrant, opaque colors that sit on top of the material, creating a tactile and long-lasting finish.

This method is one of the most popular types of printing for apparel and promotional products due to its ability to print on a wide variety of materials, including fabric, plastic, wood, and metal. The thick layer of ink provides excellent durability, making it resistant to fading from sunlight and repeated washing.

When to Use Screen Printing

Screen printing is the superior choice for projects that require bold, vibrant graphics on non-paper surfaces, especially textiles. It is the industry standard for custom t-shirts, hoodies, and tote bags, making it perfect for company merchandise, event apparel, and fashion brands. Its durability also makes it ideal for industrial applications like signage, decals, and even electronic circuit boards.

Because each color requires a separate screen and setup, screen printing is most cost-effective for medium to large-volume orders with a limited color palette. While the initial setup can be time-consuming, the cost per item decreases significantly with quantity. This makes it a great option for producing promotional items like pens, mugs, and posters in bulk.

Tips for Success

To achieve high-quality results with screen printing, careful design and preparation are crucial.

- Use Vector Graphics: Always provide your artwork in a vector format (like AI or EPS). Vector files can be scaled to any size without losing quality, ensuring crisp, clean edges in the final print.

- Limit Your Color Count: Each color in your design requires its own screen, which adds to the setup time and cost. Simplifying your design to fewer colors is a highly effective way to manage your budget.

- Choose the Right Mesh Count: The mesh count of the screen determines the level of detail possible. A higher mesh count is needed for intricate designs, while a lower mesh count is suitable for bold, less detailed graphics and works better with thicker inks.

4. Flexographic Printing

Flexographic printing, often shortened to flexo, is a modern version of letterpress printing that excels at high-speed production on a wide range of materials. This rotary printing method uses flexible photopolymer relief plates wrapped around rotating cylinders. The raised image areas on the plate pick up a fast-drying ink and transfer it directly onto the substrate, making it one of the most versatile and efficient different types of printing for packaging.

Its ability to print on non-porous materials like plastic, foil, and cellophane, as well as traditional paper and corrugated cardboard, makes it indispensable in the consumer goods industry. Flexo presses can run at extremely high speeds, producing thousands of impressions per hour with consistent quality.

When to Use Flexographic Printing

Flexography is the dominant printing method for the packaging industry due to its speed, versatility, and cost-effectiveness at very high volumes. It is the ideal choice for printing food packaging, flexible pouches, shopping bags, and self-adhesive labels. Because it uses fast-drying inks, it’s also perfect for printing on corrugated boxes and multi-wall sacks without smudging.

Beyond packaging, flexo is also used for printing newspapers and some magazines where speed is a critical factor. While the plate creation involves a higher initial cost, the low cost of consumables and high press speeds make it incredibly economical for long, continuous print runs. This method is not suitable for short runs but is unparalleled for large-scale, repetitive jobs requiring good, but not necessarily photorealistic, quality.

Tips for Success

To achieve the best results with flexographic printing, careful planning and technical consideration are essential.

- Optimize Designs for Flexo: Simplify graphics and use vector-based artwork. Avoid extremely fine details, small reverse text, and smooth gradients that can be challenging for the flexo process.

- Account for Dot Gain: Flexo printing is known for dot gain, where ink dots spread on the substrate. Work with your printer to apply proper dot gain compensation in your design files to prevent images from appearing darker or muddy.

- Consider Substrate Characteristics: The material being printed on significantly impacts ink absorption and final appearance. Discuss your chosen substrate with the printer to select the right inks and plate type for optimal results. For instance, printing on materials like vinyl requires specific considerations. For more information, you can explore options for printing on different materials on 4over4.com.

5. Gravure Printing

Gravure printing, also known as rotogravure, is a high-speed intaglio printing process renowned for its ability to produce premium-quality, continuous-tone images. The technique involves engraving the image onto a metal cylinder. During printing, the cylinder rotates through an ink fountain, filling the recessed, engraved cells with ink while a doctor blade scrapes excess ink from the non-engraved surface. The substrate, typically paper or film, is then pressed against the cylinder, transferring the ink to create a rich, detailed final image.

This method is one of the most sophisticated types of printing, prized for its exceptional color density and consistency over extremely long production runs. The durability of the engraved cylinders allows for millions of impressions without any degradation in quality, making it a cornerstone for high-volume industries like publishing and packaging.

When to Use Gravure Printing

Gravure printing is the undisputed champion for massive print runs where flawless image quality is non-negotiable. It is the go-to method for high-circulation magazines, mail-order catalogs, and large-scale flexible packaging for food and consumer goods. Its ability to print on thin films and foils makes it essential for products like snack bags and yogurt lids.

The process is also ideal for security printing, such as postage stamps and currency, due to the fine detail and difficult-to-replicate nature of the engraved cylinders. While the initial setup cost for cylinder engraving is substantial, the per-unit cost becomes incredibly low when producing millions of copies, offering unmatched economic efficiency at a massive scale.

Tips for Success

To leverage the power of gravure printing effectively, meticulous planning and optimization are crucial.

- Commit to Very Long Runs: The high cost of cylinder preparation is only justified by extremely large quantities. Reserve this method for jobs numbering in the hundreds of thousands or millions to see a return on the initial investment.

- Plan Color Sequence Carefully: The order in which colors are printed (typically darker colors first) can impact the final appearance. Work with your printer to determine the optimal sequence for your specific design and substrate.

- Optimize Cylinder Usage: To maximize cost-effectiveness, design projects that utilize the full width of the printing cylinder. Printers like Bobst and Comexi offer various cylinder sizes, so designing with web width efficiency in mind can reduce material waste and cost.

6. 3D Printing

3D printing, also known as additive manufacturing, represents a revolutionary shift from traditional printing on flat surfaces to creating tangible, three-dimensional objects. Instead of applying ink, this process builds an object layer by layer from a digital 3D model. Materials like plastic, resin, metal, or even biomaterials are deposited, fused, or solidified under computer control, allowing for the creation of intricate and complex geometries that are impossible to produce with conventional methods.

This technology has rapidly moved from a niche prototyping tool to a mainstream manufacturing process. It is one of the most transformative types of printing because it enables on-demand production, mass customization, and rapid innovation across countless industries.

When to Use 3D Printing

3D printing is the ideal solution for projects that require rapid prototyping, custom parts, or complex designs. It excels in scenarios where creating a mold or tooling would be prohibitively expensive or time-consuming, especially for low-volume production. Businesses use it extensively for creating and testing product prototypes before committing to mass manufacturing.

It is also indispensable in specialized fields like medicine for creating custom surgical guides, prosthetics, and patient-specific implants. Furthermore, aerospace and automotive industries rely on it for lightweight yet strong components. For designers and creators, it offers unparalleled freedom to produce everything from architectural models to bespoke jewelry and accessories with a level of detail that other methods cannot match.

Tips for Success

To get the most out of your 3D printing projects, careful planning and optimization are essential.

- Optimize Your Design: Not all 3D models print well. Design with additive manufacturing in mind, considering factors like overhangs, wall thickness, and internal structures to minimize failures and material usage.

- Choose the Right Layer Height: The layer height determines the trade-off between print speed and surface quality. A smaller layer height (e.g., 0.1mm) creates a smoother finish but takes longer, while a larger height (e.g., 0.3mm) is faster but more visibly layered.

- Plan for Post-Processing: Most 3D prints require some form of post-processing to achieve a finished look. This can include removing support structures, sanding, polishing, painting, or vapor smoothing to improve the surface finish.

7. Letterpress Printing

Letterpress printing is a historic technique that involves pressing an inked, raised surface directly onto paper. This method, a form of relief printing, creates a distinct and tangible debossed impression in the paper, a tactile quality that sets it apart from modern, flat printing methods. Originally popularized by Johannes Gutenberg with movable type, letterpress has enjoyed a modern revival, beloved for its artisanal charm and handcrafted feel.

The process is methodical and hands-on. A custom plate with a raised design is created, inked, and then pressed into a sheet of paper, typically using a vintage press like a Heidelberg platen or a Vandercook proof press. This direct contact between plate and paper not only transfers the ink but also imparts a physical texture, making each piece unique.

When to Use Letterpress Printing

Letterpress is the perfect choice for projects where you want to convey a sense of luxury, tradition, and craftsmanship. It’s not meant for high-volume, low-cost jobs but for premium items where the print quality itself is a key part of the message. The deep impression and rich ink saturation create a memorable experience for the recipient.

This technique is highly sought after for high-end wedding invitations, boutique business cards, and elegant stationery. It is also a favorite among artists for creating limited edition prints and posters. The process lends itself beautifully to simple, bold designs that emphasize typography and linework, giving them a classic and sophisticated finish. For businesses looking to make a strong impression with items like custom letterheads, letterpress offers an unparalleled level of quality. You can explore a variety of high-quality options and learn more about letterhead printing on 4over4.com.

Tips for Success

To get the most out of the letterpress process, consider these key tips.

- Choose Thick, Soft Paper: The signature impression of letterpress shows up best on thick, soft paper stocks, like 100% cotton paper. These papers have the give needed to capture a deep, crisp deboss.

- Keep Designs Simple and Bold: Fine, delicate lines or complex patterns can get lost or appear muddy. Letterpress shines with bold typography, strong lines, and clear, uncluttered layouts.

- Consider Blind Embossing: For a subtle, purely textural effect, ask for a "blind" pass. This is when the plate is pressed into the paper without ink, creating a beautiful and elegant debossed design.

- Plan Color Sequences Carefully: Since each color requires a separate plate and a separate run through the press, plan your color usage strategically to manage costs and production time.

8. Inkjet Printing

Inkjet printing is a highly versatile digital printing method that recreates a digital image by propelling droplets of ink directly onto paper, plastic, or other substrates. Unlike techniques that use plates, inkjet printers use microscopic nozzles to spray liquid ink precisely, building the image line by line. This process allows for incredible detail and color vibrancy, making it a popular choice for both home users and commercial enterprises.

This method is one of the most accessible different types of printing available, offering a low barrier to entry for producing high-quality, full-color prints without the extensive setup of traditional methods. From compact desktop models by Canon and HP to massive industrial machines for banners and textiles, inkjet technology is scalable and adaptable to a wide range of applications.

When to Use Inkjet Printing

Inkjet printing is the ideal solution for projects that require high-resolution detail, rich color saturation, and on-demand production. It excels at photo printing, where its ability to blend colors smoothly produces photorealistic images. It's also the go-to for large format graphics like posters, banners, and trade show displays, as it can handle a variety of materials, including vinyl and canvas.

Small businesses and marketing professionals often use inkjet for short runs of promotional materials, such as custom labels, direct mail pieces, and personalized items. The technology's flexibility makes it perfect for proofing designs before committing to a larger run with another method or for creating one-of-a-kind pieces. For personalized office supplies, you can explore more about custom notepad printing on 4over4.com.

Tips for Success

To achieve professional-grade results with inkjet printing, attention to detail is crucial.

- Use Appropriate Paper: Match your paper to your ink type. Use glossy or luster photo paper for vibrant images and matte paper for text-heavy documents. The paper's coating significantly impacts how the ink is absorbed and how the final colors appear.

- Prevent Nozzle Clogging: Run a test print at least once a week, even if you don't have a specific job. This keeps the ink flowing through the print heads and prevents the microscopic nozzles from drying out and clogging.

- Consider Pigment Inks for Longevity: For prints that need to be archival or withstand environmental exposure, such as fine art prints or outdoor signage, choose pigment-based inks. They are more resistant to fading from UV light and water damage compared to standard dye-based inks.

9. Laser Printing

Laser printing is a fast and efficient digital printing process known for producing high-quality text and graphics with exceptional speed. The technology operates by projecting a laser beam onto a photosensitive drum to create a charged, electrostatic image. This charged area attracts fine powder, known as toner, which is then transferred onto paper and permanently fused to it using heat.

This method, originally pioneered by Gary Starkweather at Xerox, has become a cornerstone of office environments and short-run production due to its reliability and precision. Unlike inkjet printers that spray liquid ink, laser printers use dry toner, which prevents smudging and produces crisp, sharp lines, making it one of the most dependable types of printing for document-heavy tasks.

When to Use Laser Printing

Laser printing is the optimal solution for environments that require speed, clarity, and cost-effective text-based document production. It excels in office settings for creating internal reports, forms, invoices, and everyday correspondence. The speed of laser printers makes them ideal for high-volume, transactional printing where documents need to be produced quickly and consistently.

It's also a strong contender for producing short runs of marketing materials, manuals, and booklets where sharp text and clean graphics are more important than photographic color depth. While it may not match the color vibrancy of offset or high-end inkjet for photo-realistic images, its efficiency and low cost-per-page for monochrome and color documents make it a practical choice for many business applications. To explore specific options, you can learn more about Laser Printing on 4over4.com.

Tips for Success

To get the most out of your laser printing projects, focus on proper maintenance and material selection.

- Use Laser-Compatible Paper: For the best results, use paper specifically designed for laser printers. Its smoothness and heat resistance prevent curling and ensure proper toner fusion.

- Monitor Toner Quality: Replace toner cartridges as soon as you notice a decline in print quality, such as fading or streaking. Using high-yield cartridges can also lower your long-term cost per page.

- Perform Regular Cleaning: Keep the printer's interior free of dust and stray toner particles. A clean machine will prevent blemishes on your prints and extend the life of the components.

Comparison Matrix of 9 Printing Methods

| Printing Method | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Offset Printing | High setup complexity; requires skilled operators | High initial setup cost; printing plates needed | Consistent high-quality, sharp images over large runs | Large volume prints like books, magazines, packaging | Cost-effective at scale, excellent color accuracy |

| Digital Printing | Low complexity; quick setup | Low setup cost; no plates required | Good quality; variable data, fast turnaround | Short runs, personalized items, on-demand printing | Flexible, fast, cost-effective for short runs |

| Screen Printing | Labor-intensive setup; requires multiple screens | Multiple mesh screens per color needed | Durable, vibrant prints; limited fine detail | Apparel, signage, promotional products requiring durability | Durable prints, great for specialty inks |

| Flexographic Printing | Moderate complexity; skilled operators needed | High setup costs; flexible plates required | Good quality, fast print speeds on various substrates | Packaging, labels, long production runs | Very high speed, suitable for continuous web printing |

| Gravure Printing | Very high complexity; expensive cylinder prep | Extremely high setup costs; engraved cylinders | Exceptional color consistency and detail for very long runs | Luxury packaging, high-volume magazines | Unmatched print quality and color saturation |

| 3D Printing | Moderate complexity; digital modeling required | No tooling; variety of materials used | Customized, complex 3D objects; slower than mass production | Prototyping, medical implants, custom products | Complex geometries, rapid prototyping |

| Letterpress Printing | Labor-intensive, requires specialized skills | Low to moderate resource needs; physical presses | Distinctive tactile impression; limited colors | High-end invitations, art prints, small runs | Unique texture, premium vintage aesthetic |

| Inkjet Printing | Low complexity; variable droplet control | Moderate; variable cartridges and media | High-quality photos; variable data printing | Photo prints, banners, textile printing, direct mail | Versatile substrates, excellent for photo reproduction |

| Laser Printing | Moderate complexity; requires maintenance | Moderate equipment cost; toner cartridges needed | Sharp text and graphics; fast print speeds | Office documents, short-run marketing, transactional prints | Fast, reliable, low running costs for text documents |

Choosing Your Perfect Print Partner

Navigating the vast landscape of different types of printing can feel overwhelming, but understanding the core strengths of each method is the key to unlocking exceptional results. As we've explored, the journey from a digital concept to a tangible, high-quality printed piece is not a one-size-fits-all process. The optimal choice hinges on a careful evaluation of your project's unique variables: quantity, substrate, quality requirements, budget, and desired turnaround time.

Your decision transforms an idea into an impactful reality. The industrial might of offset and flexography delivers unparalleled cost-efficiency and color consistency for large-scale production runs, making them the undisputed champions for magazines, packaging, and extensive marketing campaigns. Conversely, the agility and personalization prowess of digital printing offer a modern solution for short runs, variable data projects, and rapid prototyping, empowering businesses to be more responsive and targeted.

Key Takeaways for Strategic Print Selection

To make the best choice, always start with your end goal. Don't just select a printing method; build a printing strategy. Here are the most critical takeaways to guide your decision-making process:

- Quantity is King: The single biggest factor influencing cost-per-unit is volume. For runs in the thousands or tens of thousands, offset printing will almost always be more economical. For anything from one to a few hundred, digital printing is your most cost-effective and efficient option.

- Material Matters: The surface you are printing on (your substrate) can immediately narrow your options. Screen printing excels on unconventional materials like textiles and glass, while flexography is designed for flexible packaging. Always confirm your chosen method is compatible with your desired paper, plastic, or fabric.

- Time is a Resource: If you need your materials tomorrow, digital printing is your only viable path. Methods like offset, gravure, and letterpress involve significant setup time for creating plates or screens, making them unsuitable for tight deadlines.

- Quality is Not Universal: "High quality" means different things. For photorealistic images, gravure printing offers unmatched detail and tonal range. For a luxurious, tactile feel that conveys heritage and craftsmanship, the debossed effect of letterpress printing is second to none. Define what quality means for your specific project.

From Theory to Action: Finding Your Print Partner

Understanding these different types of printing is the first step. The next, more crucial step is finding a partner who can execute your vision flawlessly. A reliable printing partner acts as a consultant, guiding you toward the best method rather than the one most convenient for them. They should have a deep understanding of how to translate your design files into a format optimized for the press, ensuring color accuracy and preventing costly mistakes.

When vetting potential printers, look for transparency in their process and proof of their capabilities. Ask to see samples of their work that are similar to your project's scope. Examining a provider's past work, like a detailed portfolio, is an excellent way to gauge their expertise across various techniques and substrates. For instance, reviewing a comprehensive collection like Piexels' project portfolio can reveal a studio's versatility and commitment to quality, helping you make a more informed decision.

Ultimately, the power of print lies in its ability to create a lasting physical connection with an audience in an increasingly digital world. Choosing the right printing method is not just a technical decision; it's a strategic brand choice that impacts how your message is perceived. By aligning your project's needs with the powerful capabilities of these diverse printing technologies, you ensure your final product is not only produced efficiently but also resonates deeply with your intended audience, leaving a memorable and professional impression.

Ready to bring your projects to life with the perfect printing method? The team at 4OVER4 has over two decades of experience leveraging state-of-the-art technology across a massive range of printing services. Explore their solutions at 4OVER4 and let their experts help you select and execute the ideal printing technique to elevate your brand.

More from different types of printing

12

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

25

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

102

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

103

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026

129

Believe it or not, figuring out how to make a card in Word is surprisingly easy. You can knock out everything from slick, professional busines

Emma Davis

Emma Davis

Jan 24, 2026

112

Printing on packaging takes a simple container and turns it into one of your most powerful marketing tools. It’s the very first physical int

Emma Davis

Emma Davis

Jan 23, 2026

399

When you're getting ready to print a flyer, one of the first questions you'll face is, "What size should it be?" The most co

Emma Davis

Emma Davis

Jan 22, 2026

362

How Our Free Business Cards Program Works (Quick Overview) Free business cards are available through two different

Emma Davis

Emma Davis

Jan 22, 2026