- Home

- content hub

- sticker sizes chart: Find Your Perfect Sticker Dimensions

sticker sizes chart: Find Your Perfect Sticker Dimensions

Emma Davis

Content Writer

Nov 28, 2025932 views

Nov 28, 2025932 views

Ready to pick the perfect sticker size? A good sticker sizes chart is your best friend here. These charts usually break things down into simple categories: small (1-2 inches), medium (3-4 inches), and large (5+ inches). This makes it super easy to match a size, like a 2" x 2" square, to its best use, say, for branding a laptop. It's all about making a quick, smart choice without the guesswork.

Your Quick Reference Sticker Sizes Chart

Choosing the right sticker size can feel like a shot in the dark, but it really doesn't have to be. A well-organized sticker sizes chart is the most practical tool you can have for picturing how your design will look out in the wild. Forget guessing—you can just reference common dimensions and see what they're typically used for. It’s the best way to get your project started on the right foot.

To make things even simpler, let's break sticker sizes into three general buckets:

- Small Sizes (1" to 2"): These are perfect for those subtle branding moments or adding a little finishing touch. Think sealing an envelope, labeling small products like lip balm tubes, or sticking a discreet logo on the back of a phone. They pack a surprising punch without taking over the whole surface.

- Medium Sizes (3" to 4"): This range is the sweet spot for a great mix of versatility and visibility. A 3" x 3" sticker is a classic choice for laptop decals, water bottle branding, and making your packaging pop. It's big enough for detailed artwork and text to be clear and readable from a close distance.

- Large Sizes (5" and up): When you absolutely need to make a statement, you go big. These sizes are made for car bumpers, storefront windows, or slapping on large shipping boxes. They’re designed to grab attention from far away and are almost always printed on tough, weatherproof materials to last.

This visual guide gives you a quick idea of how these size categories translate to real-world uses, from personalizing your gear to branding a whole vehicle.

Ultimately, the sticker's job dictates its size. Are you going for a subtle product accent or a high-impact promo piece? This quick-reference approach is designed to help you zero in on the best option in no time.

If you want to dive deeper into the huge variety of options out there, you can explore our full range of custom stickers and labels. Think of this chart as your starting point, pointing you toward more detailed info when you need it.

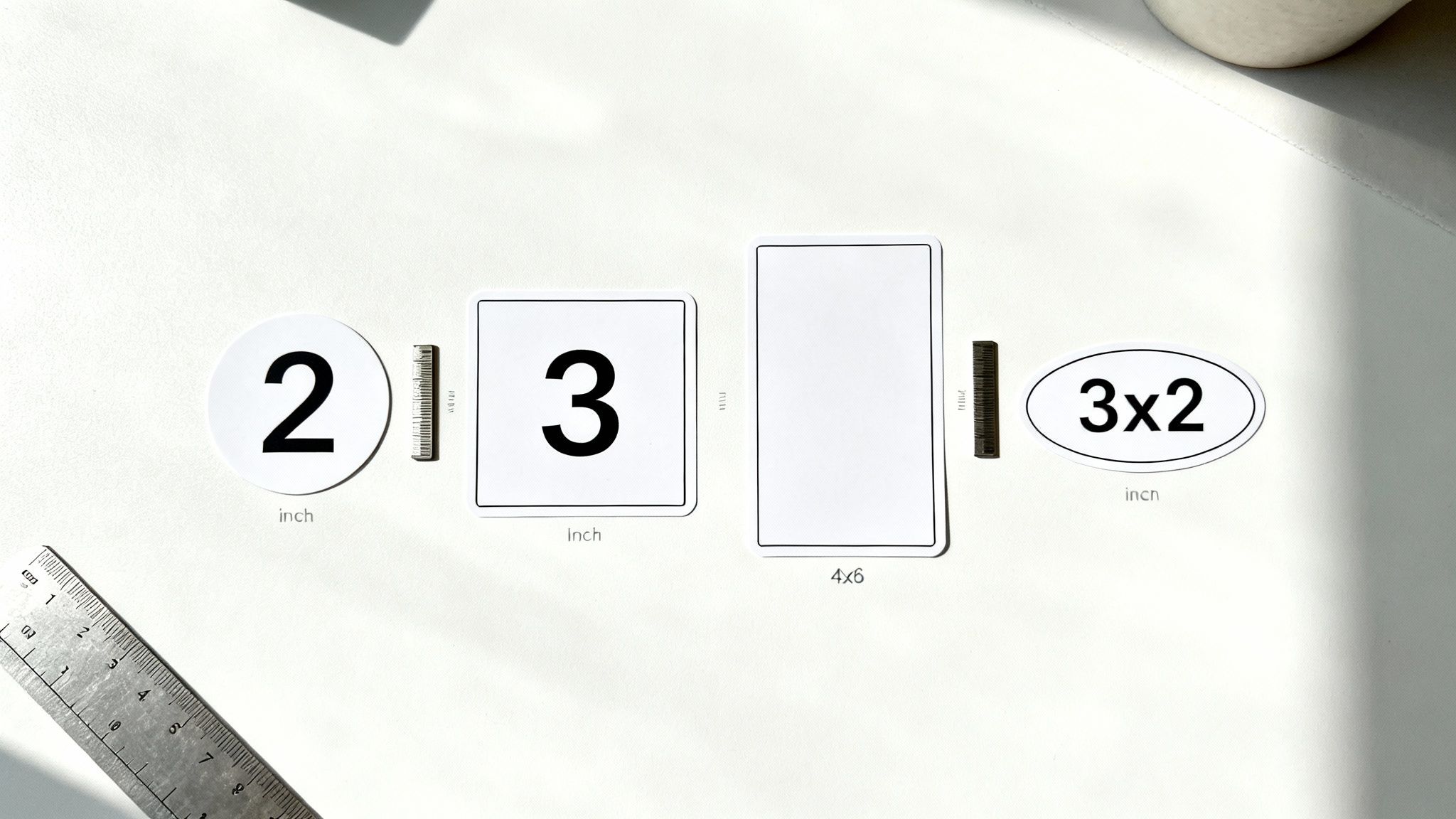

Standard Sticker Dimensions by Shape

While a quick reference chart is handy, diving into a detailed sticker sizes chart organized by shape is the best way to guarantee precision. The shape you choose dramatically influences where and how your sticker will be used, and knowing the standard dimensions helps you perfectly visualize the final product. Let's break down the most popular shapes and their go-to sizes.

In this section, you'll find the exact dimensions in both inches and millimeters for total clarity, along with some practical examples to steer your decision-making.

Round Sticker Sizes

Round stickers are a classic for a good reason. Their symmetrical shape is perfect for logos, seals, and minimalist designs, making them incredibly versatile for just about any surface. If you're looking to get specific, take a look at our options for printing custom round labels.

Here are the most common round sticker dimensions we see:

- 1" x 1" (25.4mm x 25.4mm): These are excellent for tiny branding touches. Think envelope seals, small product labels on cosmetic jars, or a subtle accent on a thank-you card.

- 2" x 2" (50.8mm x 50.8mm): A super popular and well-balanced size. It's large enough for a clear logo and is often slapped on product packaging, coffee cups, and given away as a freebie.

- 3" x 3" (76.2mm x 76.2mm): This is the go-to size for laptop decals and water bottle stickers. It gives you plenty of room for detailed artwork and text, making sure your brand gets noticed.

Square Sticker Sizes

Square stickers deliver a modern, clean look with defined edges that frame your design beautifully. They work especially well for QR codes, social media icons, and bold, graphic-heavy artwork where symmetry is key.

Consider these standard square sticker sizes:

- 2" x 2" (50.8mm x 50.8mm): A compact but effective size for product packaging, especially on small boxes or bags. It’s a favorite for adding a professional touch to handmade goods.

- 3" x 3" (76.2mm x 76.2mm): Just like its round cousin, this is a prime choice for promotional giveaways and branding personal items like notebooks and phone cases.

- 4" x 4" (101.6mm x 101.6mm): A larger square sticker that really makes a statement. This size is great for event promotions, informational labels, or decorating bigger surfaces like takeout containers.

Pro Tip: For square stickers, think about adding a 0.125-inch rounded corner. This small tweak not only gives it a softer look but also helps prevent the corners from peeling up over time, which makes the sticker way more durable.

Comprehensive Dimensions for Standard Sticker Shapes

To make things even easier, we've compiled the most common sizes for all standard shapes into one comprehensive table. This chart lays out the exact dimensions in both inches and millimeters, complete with practical use cases to help you pinpoint the perfect fit for your project.

| Shape | Dimension (Inches) | Dimension (Millimeters) | Practical Use Case |

|---|---|---|---|

| Rectangle | 2" x 3.5" | 50.8mm x 88.9mm | Standard business card size; perfect for name tags. |

| Rectangle | 3" x 4" | 76.2mm x 101.6mm | Product labels for bottles, jars, and boxes. |

| Rectangle | 4" x 6" | 101.6mm x 152.4mm | A popular choice for shipping and mailing labels. |

| Oval | 1.5" x 2.5" | 38.1mm x 63.5mm | Ideal for candle labels or sealing food packaging. |

| Oval | 2" x 3" | 50.8mm x 76.2mm | Great for branding products with a logo and text. |

| Oval | 3" x 5" | 76.2mm x 127mm | Often used for vehicle decals or on larger containers. |

This table serves as your quick-glance guide, ensuring you can match the right shape and size to the job at hand without any guesswork.

Oval Sticker Sizes

Oval stickers offer a unique and elegant alternative to the traditional round and square shapes. Their elongated form is especially well-suited for logos with wide text or designs that benefit from a softer, more dynamic frame. You'll often see them on curved surfaces like bottles and jars, where they just fit better.

Common oval sticker dimensions include:

- 1.5" x 2.5" (38.1mm x 63.5mm): A small but distinctive size, ideal for candle labels, coffee cup branding, or sealing food packaging.

- 2" x 3" (50.8mm x 76.2mm): This versatile size provides enough real estate for both a logo and a line of text, making it great for branding products or as a decorative touch.

- 3" x 5" (76.2mm x 127mm): A larger oval that commands attention. This one is often used for vehicle decals, promotional event stickers, or labeling on bigger containers.

Why Your Sticker Size is a Bigger Deal Than You Think

Picking the right sticker size isn't just about making sure your design fits. It's a critical business decision. Think of stickers as tiny, portable billboards for your brand. They’re a key part of your packaging, promotions, and product labeling, and the size you choose has a direct line to your visibility, cost, and how well your message actually lands with people.

In a world crowded with brands, the little things make all the difference. A sticker that’s too big for the spot it’s meant for looks amateur and peels off easily. One that's too small? It might as well be invisible. The first step to making a real impact is thinking about where and how that sticker will be used.

The Sticker Economy is Booming

This isn't just a fad; the demand for stickers is a massive, growing industry. In 2024, the global sticker market hit a value of about USD 4.61 billion. It’s projected to climb to roughly USD 7.67 billion by 2033, which is a steady growth rate of around 5.81% each year.

What’s driving this? A huge part of it is the demand for classic paper stickers, which grabbed 41.5% of the market share in 2024. You can read the full breakdown of the growing global sticker market on marketdataforecast.com. This explosion shows just how much businesses rely on stickers for everything from marketing to logistics. As the market gets more crowded, having a smart sticker strategy is your secret weapon to get noticed.

Sizing for Business and Legal Needs

Beyond just looking good, sticker sizing often comes down to practical—and sometimes legal—needs. For things like product packaging and shipping, labels have to meet certain standards to be clear and compliant.

Think about these common commercial situations:

- Product Labeling: Food and drinks need labels with enough room for ingredients, nutrition facts, and barcodes. A tiny, cute sticker won’t cut it. You need a size that fits all the required info without looking like a cluttered mess.

- Shipping and Logistics: There's a reason shipping labels are a standard 4" x 6". They're designed to fit carrier requirements and make addresses and tracking info easy to read at a glance.

- Warning and Safety Labels: For industrial equipment or chemical products, safety warnings have to be legible from a certain distance. This directly dictates the minimum size of the sticker and the font.

When you line up your design choices with both market trends and real-world uses, your sticker stops being just a piece of sticky paper and becomes a powerful tool. It’s about more than looks; it’s about function, compliance, and making a real impact in a booming market. That’s how a simple sticker becomes a true business asset.

Sizing and Designing Custom Die-Cut Stickers

Sometimes, a standard circle or square just doesn't cut it. When you need a sticker that truly captures your brand’s personality, custom die-cut stickers are the way to go. Unlike traditional shapes, these stickers are trimmed to the exact outline of your design, giving your artwork a unique and professional look that really makes it the star of the show. This is the perfect method for intricate logos, brand mascots, or any design that needs to break the mold.

This level of customization is a huge driver in the market. In fact, the custom printing segment for stickers hit a value of around USD 1.6 billion in 2024 and is projected to climb to nearly USD 2.9 billion by 2030. That growth shows just how much businesses are relying on unique shapes and sizes to meet all kinds of commercial needs. You can see more data on the rise of the custom sticker printing market on grandviewresearch.com.

Preparing Your Custom Shape

Creating a die-cut sticker all starts with a special vector path in your design file known as a die-line. This line is mission-critical—it tells our cutting machine precisely where to trim the sticker, acting as the blueprint for its final shape.

Here are the key steps to get your artwork ready:

- Define the Outline: First, create a solid line around your design in a vector program like Adobe Illustrator. This line becomes the cut path.

- Set a Margin: For a clean, professional finish, your die-line should be slightly offset from your artwork. We recommend about 1/8th of an inch (3mm). This creates a small, uniform border that looks great.

- Simplify Your Paths: Try to avoid overly complex die-lines with tons of sharp points or tiny, intricate details. Smoother curves and simpler shapes always produce a cleaner cut and a more durable sticker.

Important Note: Always place your die-line on a separate layer in your design file and label it clearly (e.g., "Die-Line" or "Cut Path"). This is a huge help for our prepress team, allowing them to identify and process your custom shape accurately for a perfect result.

From Concept to Cut

Once your artwork is good to go, the die-cutting process begins. We use digital cutting technology that follows the die-line you provided to guide a super-precise blade, flawlessly trimming each sticker into its unique shape. This advanced process allows us to produce even the most intricate designs without needing expensive traditional dies, which makes custom shapes accessible for any order size.

This flexibility lets brands create promotional items that are truly memorable. Think about it—a sticker shaped like your company mascot or one that perfectly mimics your product's silhouette. The possibilities are pretty much endless. If you're ready to see how this technology can bring your own unique ideas to life, you can learn more about our custom die-cutting services and see just how easy it is to get started.

Preparing Your Artwork for Flawless Printing

A killer sticker starts long before it hits the press. Getting your design file prepped correctly is the single most important thing you can do to make sure your final product looks sharp, vibrant, and professional. Think of it as the bridge between your digital vision and a flawless physical sticker.

If you're designing custom stickers, making sure your artwork is print-ready is non-negotiable. The core principles are pretty universal for most print projects, as this detailed guide to making your own custom graphics explains. Let's walk through the key technical specs you need to get right.

Understanding Bleed, Trim, and Safe Zone

These three concepts are the bedrock of professional print design. Getting them wrong is the fastest way to end up with stickers that have awkward white borders or, even worse, chopped-off text.

- Trim Line: This is the finish line—the exact edge where your sticker will be physically cut. It represents the final dimensions you chose, like a 3" x 3" square.

- Bleed Area: Think of this as a safety net. It's a small buffer, usually 0.125 inches (or 1/8"), that extends beyond the trim line. Any background color or image needs to fill this entire area to prevent ugly white slivers if the cutting machine shifts even a tiny bit.

- Safe Zone: This is your VIP section, located just inside the trim line. All your critical elements—your logo, text, and key parts of the graphic—must stay within this zone. Keeping them 0.125 inches away from the trim line guarantees they won't get clipped during cutting.

It’s like painting a room. You use painter's tape (the safe zone) to protect the woodwork, you might slop a little paint on the drop cloth (the bleed), but the wall itself (your core design) ends up looking perfect.

Setting Up Your File Correctly

A brilliant design can be totally undone by the wrong file settings. To get maximum clarity and spot-on color, you'll want to stick to these industry standards. For a deeper dive, you can always check out our full list of expert printing tips.

Resolution and Color Mode

Your file's resolution dictates how sharp it will be, while the color mode ensures what you see on screen is what you get on paper.

- Resolution Must Be 300 DPI: Dots Per Inch (DPI) is the key to print quality. Images on the web are often just 72 DPI, which looks great on a screen but will come out blurry and pixelated in print. For crisp, high-quality stickers, your artwork must be created and saved at 300 DPI.

- Use CMYK Color Mode: Your monitor displays colors in RGB (Red, Green, Blue), but professional printers use CMYK (Cyan, Magenta, Yellow, Black). Designing in CMYK from the get-go prevents nasty surprises and color shifts during printing, so your brand colors stay true.

Key Takeaway: Always, always start your design project with a 300 DPI resolution and CMYK color mode. Trying to "upscale" a low-res RGB file later just doesn't work and usually leads to disappointment.

The Best File Formats

The format you save your file in matters, too. Some preserve quality and editability way better than others.

- PDF (Preferred): A high-quality PDF is the gold standard for a reason. It locks in your fonts, images, and vector paths, making sure nothing moves or changes when we open it on our end.

- AI (Adobe Illustrator): If you built your design in Illustrator, sending the native AI file is a fantastic option. This is especially true for custom die-cut stickers because it keeps all the vector paths perfectly intact.

- EPS: This is another solid vector format that maintains scalability and quality without any loss.

Try to avoid sending formats like JPG or PNG unless they are saved at a very high resolution. Nailing these setup steps guarantees that the sticker size you carefully picked from the chart will be matched by a perfectly printed, professional-grade product. Every single time.

Choosing the Right Sticker Material and Finish

Getting the dimensions right on a sticker size chart is a huge first step, but the material and finish you pick are what really bring your sticker to life. It’s what determines the final look, feel, and how long it'll last.

The right combo can turn a simple design into a serious branding tool. The wrong one? You’re looking at peeling, fading, and a totally missed opportunity. This decision is a big deal—it impacts everything from visual pop to where the sticker can actually be used.

Core Sticker Materials Explained

Think of the material as the sticker's foundation. It dictates durability, weather resistance, and where you can stick it. A sticker destined for a car bumper needs a much tougher base than one sealing a paper gift bag.

The most important question to ask is: where will this sticker live? Indoor use gives you more flexibility, but anything going outside or in a high-contact spot needs a tougher, more specialized option.

Here’s a rundown of the most common materials and what they’re best for:

- Weatherproof Vinyl: This is the undisputed champ for durability. Vinyl is waterproof, scratch-resistant, and won't fade in the sun. It's the go-to for anything outdoorsy like car decals, window graphics, and equipment labels.

- Classic Paper: A budget-friendly and super popular choice for anything staying indoors. Paper stickers are perfect for product packaging, shipping labels, and promotional giveaways where you don't need to worry about the weather. They have that classic, tactile feel.

- Transparent Polyester: When you want your design to stand out without a distracting background, clear polyester is your answer. It creates that slick, "no-label" look that’s awesome for branding on glass, water bottles, or product containers where you want the surface to show through.

For projects that need to withstand some serious abuse, exploring a full range of durable adhesive vinyls will open up even more possibilities for those heavy-duty applications. Each material has its own unique personality that affects how the sticker performs.

Selecting the Perfect Finish

If the material is the foundation, the finish is the final coat of paint. It protects and enhances your design, adding a specific texture and visual punch that can completely change the sticker's vibe.

Pro Tip: Your finish choice can actually change how your colors look. A gloss finish makes colors appear more vibrant and saturated, while a matte finish gives off a softer, more subdued, and modern feel.

Take a look at how these popular finishes can complement your artwork:

- Gloss Finish: This high-shine coating makes colors pop and gives your sticker a vibrant, reflective look. It’s great for grabbing attention and has the added bonus of being easy to wipe clean, offering a bit of extra protection from moisture and scuffs.

- Matte Finish: For a more modern and understated look, you can't go wrong with matte. It has a non-glare, satin-like surface that feels smooth to the touch. This finish is perfect for sophisticated branding and designs with a softer color palette.

- UV Coating: Think of a UV coating as sunscreen for your sticker. It's a clear, glossy liquid applied over the ink and then zapped with ultraviolet light to cure it. This process gives it superior protection against fading from sun exposure, making it a must-have for any sticker that’s going to live outdoors for a long time.

Frequently Asked Questions About Sticker Sizes

Getting into the world of sticker printing can feel a bit overwhelming, especially when you're aiming for that perfect final product. From figuring out the best dimensions on a sticker sizes chart to making sense of industry lingo, getting clear answers is key to a smooth project.

Think of this section as your cheat sheet. We've gathered the most common questions we get and laid out the answers in a straightforward way, so you can move forward with total confidence.

What Is the Most Popular Sticker Size?

While there's a sticker size for just about everything, the sweet spot for versatility and popularity is definitely in the 2 to 4-inch range. If we had to pick one, a 3" x 3" square or a 3" circle is the undisputed champion.

This size is big enough to show off a detailed logo or cool piece of art, but it's still compact enough to fit on everyday items without looking awkward. It's become the go-to for branding laptops, water bottles, notebooks, and even product packaging. If you’re not sure where to start, you really can’t go wrong with this one.

How Do I Choose the Right Sticker Size for My Product?

Choosing the right size always comes down to context. The very first thing you should do is measure the surface where the sticker is going to live. You want your sticker to complement the item, not overpower it or get lost in the shuffle.

Here’s what to think about:

- Viewing Distance: Where will people see this sticker? A design for a big storefront window needs to be much, much larger than one for a tiny lip balm tube.

- Design Complexity: If your art has a lot of fine detail or small text, you’ll need a bigger sticker to keep it legible. A simple, bold icon can get away with being much smaller.

- Surface Shape: For curved surfaces like bottles or candles, an oval sticker or one made from flexible vinyl will hug the shape much better. A rigid square might have corners that peel up over time.

For example, a 1" x 2" rectangle is perfect for small items like essential oil bottles, whereas a larger 4" x 6" sticker is a great fit for branding shipping boxes. A good rule of thumb is to always leave a little bit of a clean margin around the sticker—it just looks more professional.

What Is the Difference Between Kiss Cut and Die Cut Stickers?

They might look the same once they’re stuck on something, but the real difference is all about how they’re cut from the backing paper.

A die-cut sticker is cut straight through both the vinyl and the paper backing, following the exact outline of your design. This gives you a really striking, custom-shaped sticker with no extra white space around the edges.

A kiss-cut sticker, on the other hand, is only cut through the vinyl layer. The paper backing stays intact, usually as a square or rectangle, creating a border around your sticker. This makes peeling a breeze, especially for complex shapes, and the extra backing acts as a protective bumper for the sticker's edges before you use it.

Ready to bring your vision to life? At 4OVER4, we offer a huge selection of high-quality, fully customizable stickers in any size, shape, or finish you can imagine. Explore our custom sticker options and start creating today.

More from

576

Full bleed printing is a simple but game-changing technique. It's how you get your artwork—whether it’s a photo, a background color, o

Emma Davis

Emma Davis

Feb 3, 2026

298

Even though we live in a digital world, the humble business card is still a powerhouse networking tool. But here's something most people d

Emma Davis

Emma Davis

Feb 2, 2026

1144

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

Emma Davis

Emma Davis

Feb 1, 2026

341

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

Emma Davis

Emma Davis

Jan 31, 2026

345

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

Emma Davis

Emma Davis

Jan 30, 2026

162

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

Emma Davis

Emma Davis

Jan 29, 2026

323

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

275

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026