- Home

- content hub

- Screen Printing vs Vinyl Printing: Which Is Best for Your Needs?

Screen Printing vs Vinyl Printing: Which Is Best for Your Needs?

Emma Davis

Content Writer

Dec 11, 2025268 views

Dec 11, 2025268 views

When you're looking to get custom apparel made, two of the most popular options you'll come across are screen printing and heat transfer vinyl (HTV). On the surface, they might seem similar—both put a design on a shirt, right? But the reality is they are fundamentally different processes, each with its own strengths and ideal use cases.

Think of screen printing as the workhorse for large batches. It's an age-old craft perfected for mass production, where efficiency and low per-item costs are king. In contrast, heat transfer vinyl (HTV) is the go-to for small orders, highly detailed graphics, and one-of-a-kind personalizations like team jerseys.

Choosing Your Print Method: A Quick Comparison

So, how do you know which one is right for your project? Let's break down how each method actually works.

Screen printing is a hands-on process. A mesh stencil (the "screen") is created for every single color in your design. Ink is then pushed through these screens directly into the fabric of the garment. This process takes a fair bit of setup, which is why it's not very practical for a single shirt but becomes incredibly cost-effective for large runs. Because the ink becomes part of the fabric, the final print feels soft and is extremely durable.

Heat transfer vinyl, on the other hand, is a digital process. Your design is precision-cut from a sheet of colored vinyl, and then a heat press is used to apply it to the surface of the garment. The setup is minimal, making it perfect for producing one-off items or small batches with vibrant, multi-color, and even textured designs. The vinyl sits on top of the fabric, giving it a distinct feel that stands out.

Screen Printing Vs Vinyl Printing At a Glance

To make the decision a little easier, we've put together a simple table that lays out the key differences. This is your cheat sheet for figuring out which method aligns best with your needs, whether you're ordering custom t-shirts printing for a big event or just creating a single prototype for a new design idea.

| Attribute | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|

| Ideal Order Size | Large batches (typically 25+ items) | Small batches, single items, and prototypes |

| Cost Per Item | Very low for bulk orders, high for small runs | Consistent per-item cost, great for small quantities |

| Design Complexity | Best for simple designs with limited solid colors | Excellent for complex, multi-color, and detailed graphics |

| Durability | Extremely high; ink fuses with fabric and lasts for years | Good to excellent, but may crack or peel over time with heavy wear |

| Feel on Fabric | Soft and breathable, as ink soaks into the fibers | Slightly thicker layer that sits on top of the fabric |

| Color Options | Colors are mixed to match, but each adds setup cost | Wide variety of colors and special effects (glitter, metallic) |

| Setup Time | High; requires screen creation for each color | Low; a digital process with minimal preparation |

| Turnaround Time | Slower for initial orders, faster for reprints | Fast, ideal for quick-turnaround and on-demand projects |

Ultimately, the right choice comes down to your project's specific needs: quantity, complexity, and budget. For a large event with a simple logo, screen printing is almost always the winner. For a handful of custom jerseys with individual names, HTV is the only way to go.

How Each Printing Process Actually Works

To really get to the heart of the screen printing vs. vinyl debate, you have to look at how each design actually makes its way onto the fabric. The "how" is what explains why one method is perfect for big bulk orders and the other is a rockstar for one-off custom pieces. These aren't just two different paths to the same destination—they are fundamentally different techniques from the ground up.

Knowing the basics here gives you the context for all the practical differences you'll see later in cost, durability, and what you can (and can't) do with your design.

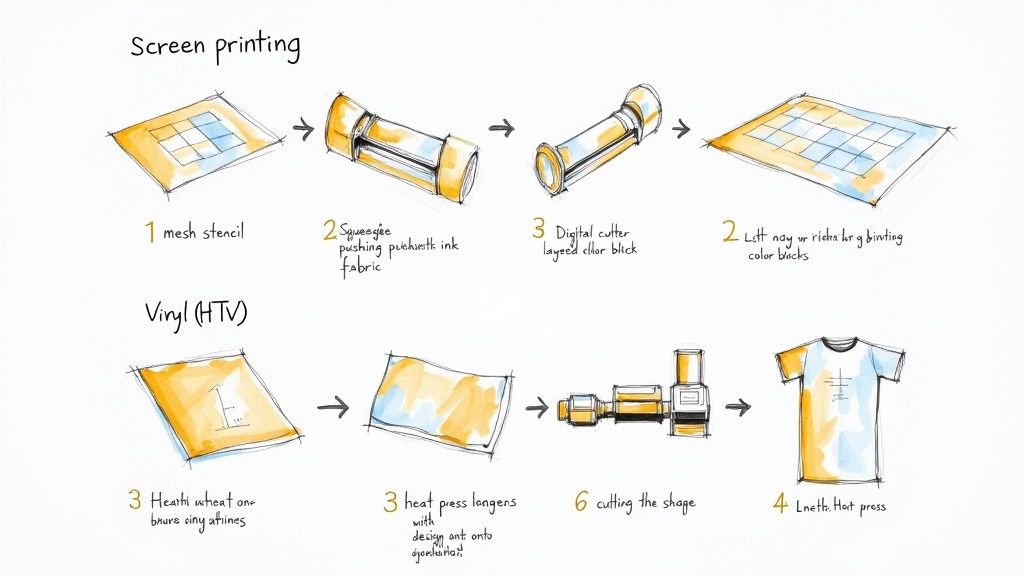

The Screen Printing Method Explained

Screen printing is a classic, hands-on technique where ink is pushed directly into the fibers of the material. The best way to think of it is as a highly refined stenciling process.

Here’s a quick look at the steps involved:

- Screen Creation: It all starts with a fine mesh screen stretched tightly over a frame. This screen gets coated with a light-sensitive emulsion.

- Burning the Stencil: Your design is printed onto a transparent film. That film is placed on the coated screen and blasted with a powerful light. The light hardens the emulsion everywhere except where your design blocks it, creating an incredibly precise stencil.

- Applying the Ink: The screen is laid on top of the garment. A thick layer of plastisol ink is spread across the screen, and a squeegee presses it through the open mesh of your stencil, directly onto the fabric.

- Layering Colors: Got more than one color in your design? The entire process has to be repeated with a brand-new screen for each individual color.

- Curing: Once all the colors are down, the garment takes a trip through a large conveyor dryer. This cures the ink, making sure it becomes a permanent, durable part of the fabric.

This meticulous, multi-step setup is exactly why screen printing has higher initial costs but becomes amazingly efficient and cheap for large batches.

How Heat Transfer Vinyl (HTV) Works

Heat transfer vinyl (or HTV) is a totally different beast. It’s a modern, digital process that applies a design to the surface of a garment instead of soaking ink into it. Think of it more like a high-tech, permanent sticker application. While some projects use adhesive vinyls for hard surfaces, HTV is specifically engineered for textiles.

Key Takeaway: The fundamental difference is application. Screen printing pushes ink into the fabric, while HTV bonds a layer of material onto the fabric. This single distinction influences the final look, feel, and longevity of the print.

The HTV process is much simpler and requires way less manual prep:

- Digital Cutting: Your design is sent from a computer straight to a vinyl cutter. This machine uses a tiny blade to precisely cut the design out of a sheet of colored vinyl.

- Weeding: All the excess vinyl around and inside your cut design is removed by hand—a process known in the biz as "weeding."

- Heat Pressing: The weeded design is placed on the garment. A heat press clamps down, applying both high temperature and intense pressure. This activates the adhesive on the back of the vinyl and bonds it securely to the fabric.

Since there are no screens to create, HTV is the go-to for knocking out single items or small orders with complex, multi-color designs quickly and affordably.

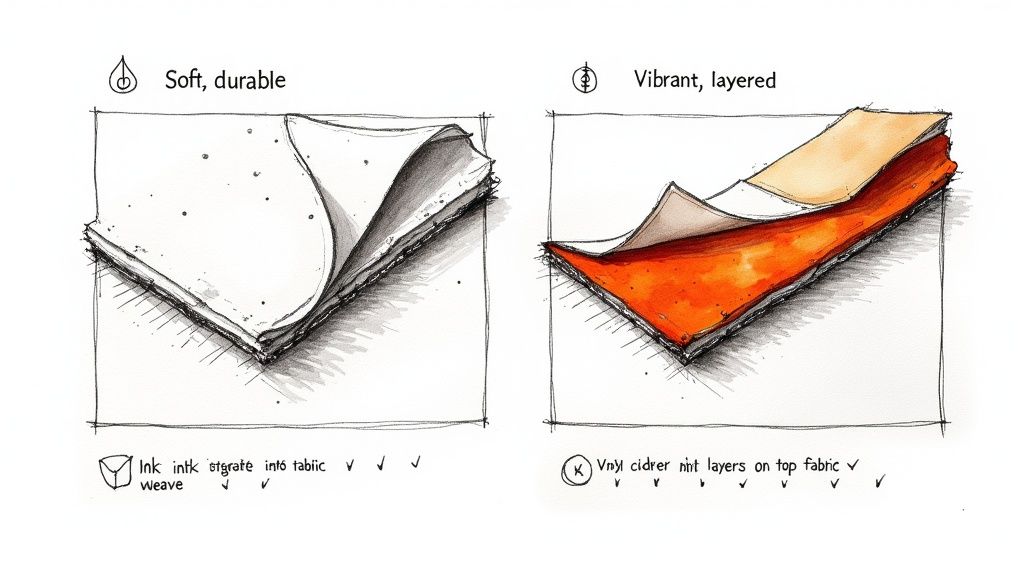

Comparing Final Print Quality and Long-Term Durability

When you're weighing screen printing against vinyl, the final look, feel, and lifespan of the design are probably at the top of your list. These two methods create wildly different results. One gives you a soft, integrated feel, while the other delivers a sharp, layered look. The choice you make here really shapes how people will experience the final garment.

Screen printing has built its reputation on creating a product that feels soft and lets the fabric breathe. The process involves pushing ink through a screen directly into the fibers, so the design literally becomes part of the shirt. This results in a finish you can barely feel, especially after that first wash.

Durability is where screen printing truly shines. Because the ink bonds so strongly with the fabric, the design can stretch and move without cracking. We’re talking about garments that can handle dozens—even hundreds—of washes without much fading. That’s why it's the industry standard for retail apparel, band merch, and company uniforms that need to go the distance.

The Tactile and Visual Appeal of Screen Printing

Visually, a screen print is all about rich, vibrant colors. Since each color is applied as its own thick layer of ink, the saturation is fantastic, even on dark fabrics. It’s a classic, professional look that stays consistent across huge orders.

The catch? The process works best for designs with a handful of solid colors. While you can do complex prints, every new color means another screen, which adds to the setup time and cost. For bold, graphic designs, though, the result is a crisp, high-quality print with longevity that's hard to beat. This reliability is a huge reason why screen printing commands a 41% share of the custom t-shirt market.

The Crisp and Dimensional Finish of Vinyl

Heat transfer vinyl (HTV) is a completely different animal. Here, the design is cut from a sheet of vinyl and then heat-pressed onto the surface of the fabric. This means the design sits on top of the garment instead of soaking in, creating a distinct, slightly raised layer you can feel.

This on-the-surface application gives vinyl prints a super sharp, crisp look with perfectly clean edges. It's fantastic for reproducing intricate details or complex, multi-color logos that would be a headache with screen printing. The colors pop—they're incredibly bright and opaque, creating a bold statement.

Key Differentiator: Screen printing is about integration—the ink becomes one with the fabric for a soft, lasting finish. Vinyl is about application—the design is a distinct layer on top of the fabric, offering sharp detail and unique textures.

The durability of vinyl really comes down to two things: the quality of the material and how well it was applied. High-quality HTV can look great for years if you take care of it, resisting fading and staying vibrant. But, if you use lower-grade vinyl or the heat press job was sloppy, you might see peeling, cracking, or lifting edges over time. That's why following the care instructions—like washing inside-out and never ironing directly on the design—is so important.

When Quality and Durability Matter Most

So, which one is right for you? It almost always boils down to how the garment will be used. Here’s a quick guide to help you decide:

- For Staff Uniforms and Workwear: Go with screen printing. It’s built to withstand constant wear and tear, including industrial laundering.

- For Custom Sports Jerseys: Vinyl is the champ here. It’s perfect for adding individual names and numbers, and it sticks beautifully to the polyester fabrics used in athletic wear. This is also where specialized vinyl labels printing comes in handy for other branding elements.

- For Retail Fashion Lines: Screen printing is generally the way to go. Its soft feel and professional finish are what customers expect from high-quality clothing.

- For Promotional Event T-Shirts: For big batches that need to look good and last, screen printing is the most durable and cost-effective choice.

- For One-Off Gifts or Specialty Items: Vinyl is perfect. You can tackle complex, one-of-a-kind designs and even use specialty finishes like glitter or metallic foils.

Breaking Down Costs and Speed

When you’re weighing screen printing against vinyl, your budget and deadline are probably the two biggest things on your mind. The way each method is priced is fundamentally different, and that difference trickles down to everything from setup fees to what you pay per shirt. Getting a handle on these financial and time dynamics is the key to making a smart call for your project.

Screen printing is all about economies of scale. Think of it as a high initial investment that pays off big on large orders. The main upfront cost comes from creating the screens—you need a separate, carefully prepped stencil for every single color in your design. This process takes time and skill, which is why ordering just a handful of shirts can feel surprisingly expensive.

But once those screens are ready? The printing itself is incredibly fast. The cost of ink and the time it takes to print each shirt drops to almost nothing, so the price per piece plummets as your order size goes up. This makes screen printing the undisputed champ for big batches.

The Upfront Investment of Screen Printing

The setup costs for screen printing are tied directly to how complex your design is. A simple one-color logo needs just one screen. A vibrant, four-color graphic? That means four different screens, and your setup fee just quadrupled. This is why we usually recommend keeping designs to four colors or fewer for screen printing projects.

Let's look at a real-world example:

- Order A (10 Shirts, 2-Color Design): The setup for two screens might be around $50, with printing at $8 per shirt. Your total is $130, which breaks down to $13 per shirt.

- Order B (200 Shirts, 2-Color Design): You have the same $50 setup fee, but the cost to print each shirt could drop to just $4. Now your total is $850, making each shirt only $4.25.

That's the magic of screen printing in a nutshell. The more you print, the more that initial setup cost gets spread out, making each individual item much, much cheaper.

The Consistent Costs of Vinyl Printing

Heat transfer vinyl (HTV) operates on a totally different financial model. With vinyl, there are basically zero setup costs. The machine digitally cuts your design from a sheet of vinyl, which is then heat-pressed onto the garment. It's the perfect system for one-offs, samples, or very small runs.

The cost per shirt stays pretty much the same whether you order one or one hundred. Pricing is based on the amount and type of vinyl used, plus the hands-on time it takes to cut, "weed" (remove the excess vinyl), and press the design. This makes it a fantastic, budget-friendly choice for a single custom jersey, but that consistency means it's not the most economical path for large-scale production.

The Bottom Line on Cost: Go with screen printing when your number one goal is the absolute lowest cost-per-item on a big order. Choose vinyl when you need the flexibility of small quantities, personalization, or prototypes without a big upfront investment.

Production Speed and Turnaround Times

Because of all that prep work, screen printing has a longer initial turnaround. Getting screens prepped and aligned can take hours, sometimes even a full day. Once the press is rolling, though, the shirts come flying off. Reprints are even quicker because the screens are already good to go.

Vinyl printing is the sprinter here. A design can go from a file on a computer to a finished shirt in less than an hour, which is perfect for on-demand jobs and those last-minute emergencies. That speed is a huge plus for businesses needing to be nimble. This same advantage of speed and versatility holds true for other vinyl products, like when businesses need to get the word out fast with printing vinyl banners.

It's also helpful to look at the bigger picture. Understanding the costs and operations of other apparel customization methods, like starting an embroidery business, gives you a broader perspective. Every technique has its own economic quirks that fit different business goals and production sizes.

Design Possibilities and What Fabrics Work Best

Beyond the numbers, the real creative choice between screen printing and vinyl comes down to your design and the fabric you want to print on. Honestly, these two factors will often make the decision for you, pushing you toward one method simply because it’s a better technical fit. It's all about matching the process to the product you envision.

Screen printing is, and always has been, the king of bold, solid-color graphics. Because it lays down a thick, vibrant layer of ink, it’s unbeatable for designs that need to pop, especially on dark fabrics. Just think of your favorite band t-shirt or a classic company logo—those rich, opaque colors are the hallmark of a great screen print.

But that strength is also its biggest limitation. Every single color in your design needs its own screen. That means more setup time and more cost. A simple one or two-color job is a breeze and super cost-effective. But start adding five or six colors, and the project can get expensive fast.

The Creative Edge of Vinyl Printing

This is exactly where heat transfer vinyl (HTV) shines. Since vinyl designs are cut digitally from a sheet, the complexity of the art has almost zero impact on the cost. This opens up a whole world of creative options that would be way too pricey for most screen printing projects.

Vinyl is your go-to for:

- Intricate, Multi-Color Designs: Got a detailed logo with a bunch of colors or super fine lines? Vinyl handles it without breaking a sweat.

- Gradients and Photos: Screen printing really struggles with smooth color fades, but certain printable vinyls can reproduce them beautifully.

- Specialty Finishes: This is vinyl’s superpower. You can get wild with eye-catching effects like glitter, holographic, metallic, flock (which has a fuzzy texture), or even puff vinyl for a cool 3D look.

Heat transfer vinyl (HTV) has seriously changed the game for custom apparel. It now accounts for a massive 47% of all textile-related applications. The market is booming, expected to jump from USD 1.6 billion to over USD 2.27 billion, which just shows how popular it's become for everyone from small creators to big brands.

Matching the Method to the Material

Fabric compatibility is the last piece of the puzzle. Screen printing ink is formulated to chemically bond with natural fibers, making it the perfect match for 100% cotton, canvas, and high-cotton blends. While you can find specialty inks for synthetics, you'll always get the softest feel and best durability on cotton. That’s why it's such a great choice for classic t-shirts and promotional gear like quality custom cotton tote bags.

On the other hand, vinyl's adhesive-based application makes it far more versatile. It sticks incredibly well to a bunch of different fabrics that are often a nightmare for screen printers.

Vinyl works great on:

- Cotton and Cotton Blends

- Polyester (the standard for most athletic wear)

- Nylon (think jackets and tracksuits)

- Spandex/Lycra Blends (for stretchy performance gear)

This flexibility makes vinyl the undisputed champ for modern sportswear, performance apparel, and specialty items like waterproof jackets or nylon bags where screen printing ink just wouldn’t hold up. If your project involves a mix of natural and synthetic materials, vinyl has the clear advantage.

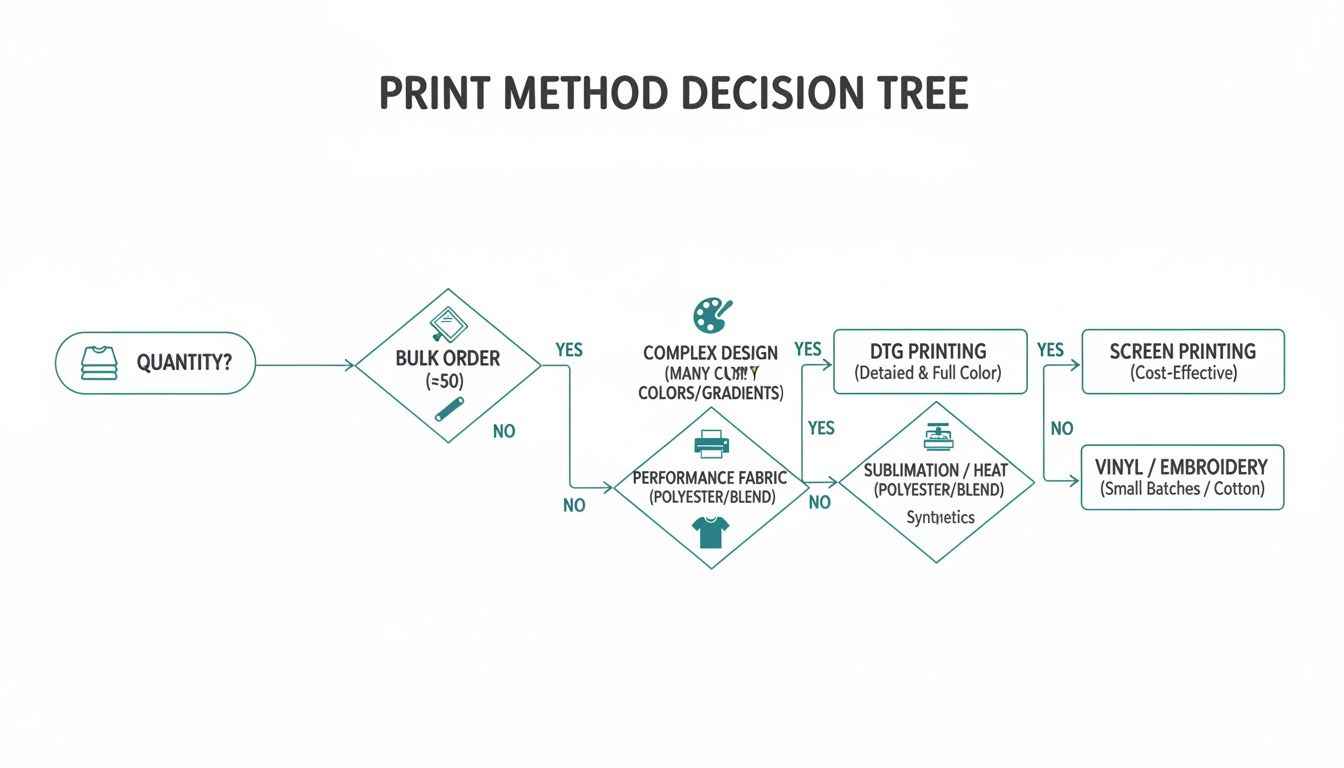

Alright, let's get down to brass tacks. You know the technical differences, but when the rubber meets the road, which printing method do you actually choose? It really boils down to your specific project, and a little expert guidance can help you skip the guesswork.

Making the right call means balancing four key things: your order size, how complex your design is, your budget, and what you’re printing on. Each method has its own sweet spot, and picking the right one is the difference between a good result and a great one.

When Screen Printing Is the Clear Winner

Screen printing is built for big jobs. The whole process is fine-tuned for cranking out large batches of the same design with perfect consistency and a crazy-low cost per shirt. If your project sounds like any of these, screen printing is almost always the answer.

You'll want to go with screen printing for projects like:

- Large Corporate Events: Need 200+ t-shirts with a two-color company logo for a trade show or company picnic? The per-unit price at this scale is just too good to pass up.

- School Uniforms or Spirit Wear: When you’re outfitting an entire school or sports team, you need every single shirt to look identical and last. Screen printing delivers that consistency and will easily hold up through a full year of wear and tear.

- Band Merchandise: Selling merch on tour means you need professional, retail-quality shirts that fans will actually want to wear again and again. Screen printing gives you that durable, classic finish that feels legit.

- Promotional Giveaways: If you're a business ordering a ton of branded tees or tote bags for a marketing campaign, screen printing is the most cost-effective way to get it done right.

Key Insight: Screen printing is all about simplicity and scale. For any order over 25-50 pieces with a fairly straightforward design, it’s an unbeatable mix of quality, durability, and low cost.

When Vinyl Printing Is the Perfect Fit

Heat transfer vinyl (HTV) shines exactly where screen printing can’t: small orders, tons of detail, and total personalization. Because it's a digital process, there are no screen setup costs, making it perfect for one-of-a-kind creations or small test runs where you need flexibility.

The versatility of vinyl is a big reason why its market is booming. The global printed vinyl market was valued at USD 9.53 billion and is only expected to grow, driven by the demand for high-quality promotional gear. You can read more about the growth of the printed vinyl market to see just how popular it's become.

Opt for vinyl printing when you need:

- Personalized Team Jerseys: Putting a unique name and number on every single jersey is a nightmare for screen printing but a piece of cake for HTV.

- Small Business Startups: Got a cool new t-shirt idea? Vinyl lets you make a small batch of 5-10 shirts to see if people like it, all without a huge upfront investment.

- Complex or Full-Color Logos: If your logo has gradients, fine lines, or a bunch of different colors, vinyl can capture that detail perfectly, even on a small order.

- One-of-a-Kind Custom Gifts: Making a single, personalized shirt for a birthday or bachelorette party is exactly what vinyl was made for.

- Specialty Finishes: Want your design to pop with glitter, metallic foil, or even a holographic effect? Vinyl is the only way to get those awesome, eye-catching textures.

Frequently Asked Questions

Even after a side-by-side comparison, you probably have a few specific questions about picking between screen printing and vinyl. Let's tackle the most common ones to clear up any confusion before you place an order.

This decision tree gives you a quick visual guide. It breaks down the choice by looking at the key factors—quantity, design, and fabric—that point you toward the best method for your job.

As you can see, the path is pretty clear: big orders with simple graphics are a job for screen printing. Small batches or one-off custom designs? Vinyl is your winner.

Which Method Is Better for Full-Color Photos?

Honestly, neither screen printing nor vinyl printing is the best tool for the job when it comes to photorealistic images. Screen printing would need a ridiculous number of screens, making it wildly impractical and expensive.

While you can use some printable vinyl for photos, the go-to method for this is Direct-to-Garment (DTG) printing. It works just like a high-end inkjet printer but for fabric, so it’s fantastic at capturing tiny details, gradients, and a huge range of colors.

Can You Iron Over Screen Printed and Vinyl Designs?

You should never put a hot iron directly on either type of print. It's a quick way to ruin the design.

- Screen Print: The plastisol ink can easily melt and smear, wrecking your shirt and your iron.

- Vinyl Print: The heat can reactivate the adhesive underneath, causing the vinyl to warp, peel off, or even melt.

For best results, always wash your custom gear inside out with cold water and either tumble dry on low or let it hang dry. If you absolutely have to iron the garment, turn it inside out first. That way, you're only heating the fabric, not the print itself.

Care Tip: Keeping your custom print looking great is simple—just avoid high heat. Gentle washing, drying, and ironing will help the design stay vibrant and intact for years.

How Does the Feel of Screen Printing Compare to Vinyl?

The way they feel to the touch is one of the biggest differences. A screen print feels soft and breathable because the ink actually soaks into the fabric fibers. After a couple of washes, you can barely feel it’s there.

Vinyl, on the other hand, sits right on top of the fabric. This creates a distinct, slightly raised layer that has a smooth, sometimes plastic-like feel. It’s much more noticeable to the touch than a screen print.

Ready to turn your ideas into wearable art? Whether you need the volume and efficiency of screen printing or the bespoke flexibility of vinyl, 4OVER4 has the high-quality solutions to make it happen. Explore our custom apparel options and get an instant quote today.

More from screen printing vs vinyl printing

12

Staring at a wall of banner dimensions can feel a little overwhelming. But while there's no single "typical banner size" that wo

Emma Davis

Emma Davis

Feb 1, 2026

24

Stretching your marketing budget doesn't mean you have to settle for flimsy, forgettable brochures. The real secret to low cost br

Emma Davis

Emma Davis

Jan 31, 2026

38

Advertising magnets are one of those marketing tools that are so simple, you might overlook their power. They’re tangible, they last for age

Emma Davis

Emma Davis

Jan 30, 2026

40

Tired of fighting with torn paper and sticky residue? We’ve all been there. The best way to get labels off bottles is often a simple soak in

Emma Davis

Emma Davis

Jan 29, 2026

111

Want to know the real secret to getting a poster to stick to a wall without it peeling off in the middle of the night? It's all about what

Emma Davis

Emma Davis

Jan 28, 2026

91

When you hear "table tent specs," what we're really talking about are the foundational details for printing them correctly: the

Emma Davis

Emma Davis

Jan 27, 2026

319

When you're ready to print a poster, one of the first questions you'll face is, "What size should it be?" The industry has a

Emma Davis

Emma Davis

Jan 26, 2026

202

Picture this: you're at a networking event, and someone hands you their business card. You do the usual glance—name, title, company—an

Emma Davis

Emma Davis

Jan 25, 2026